SilverStone Strider Titanium ST60F-TI PSU Review

SilverStone released its first Titanium PSU series, which is made by Enhance Electronics. The smallest Strider Titanium unit will be under our scope today. Besides high efficiency it also offers compact dimensions and a fully modular cable design.

Why you can trust Tom's Hardware

A Look Inside And Component Analysis

Parts Description

Before proceeding with this page, we strongly encourage you to a look at our PSUs 101 article, which provides valuable information about PSUs and their operation, allowing you to better understand the components we're about to discuss. Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station, and a Hakko 808 desoldering gun.

| Primary Side | |

|---|---|

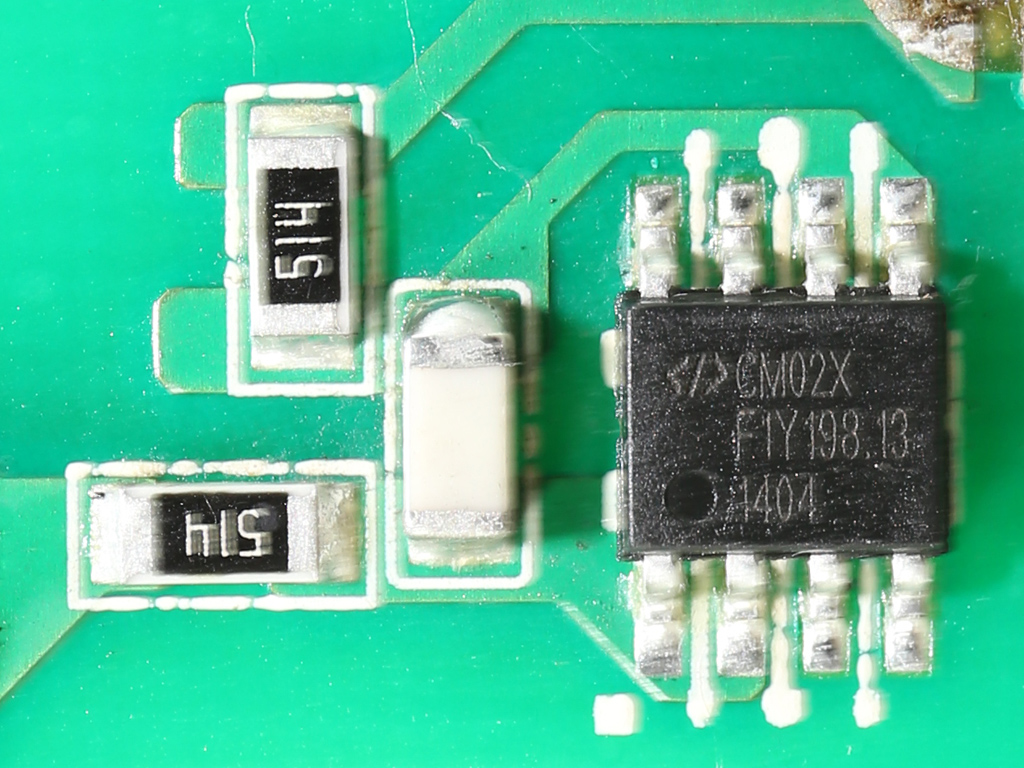

| Transient Filter | 4x Y caps, 4x X caps, 2x CM chokes, 1x MOV, 1x CM02X |

| Inrush Protection | NTC Thermistor |

| Bridge Rectifier(s) | 2x Vishay BU1506 (600V, 15A @ 150 °C) |

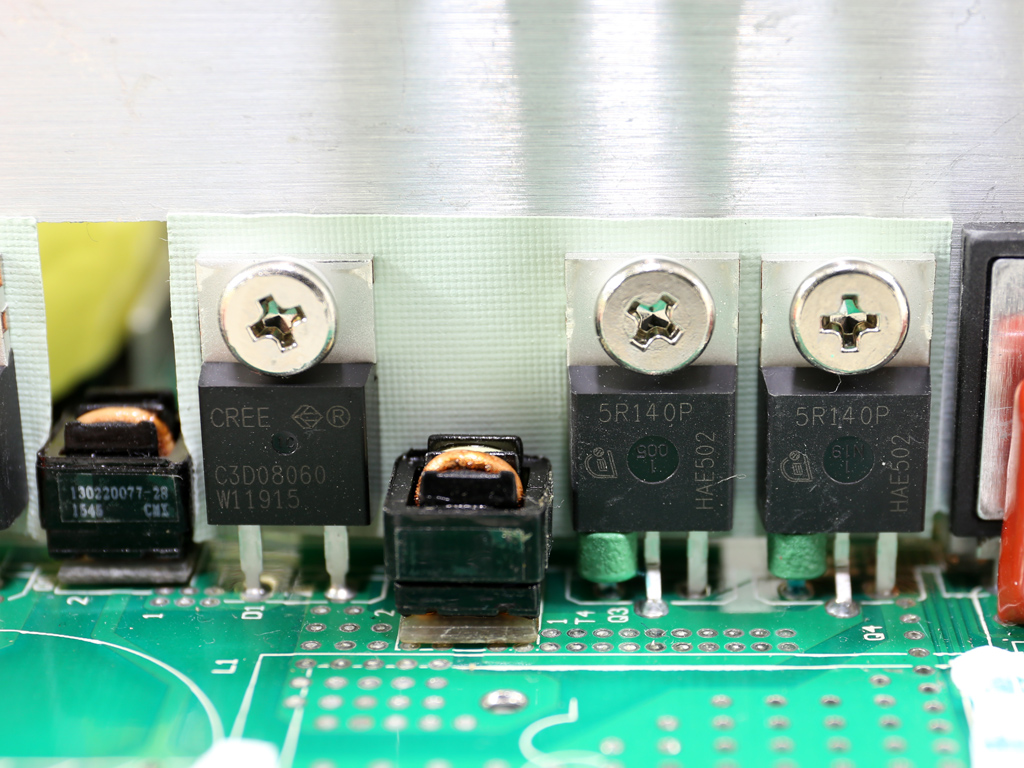

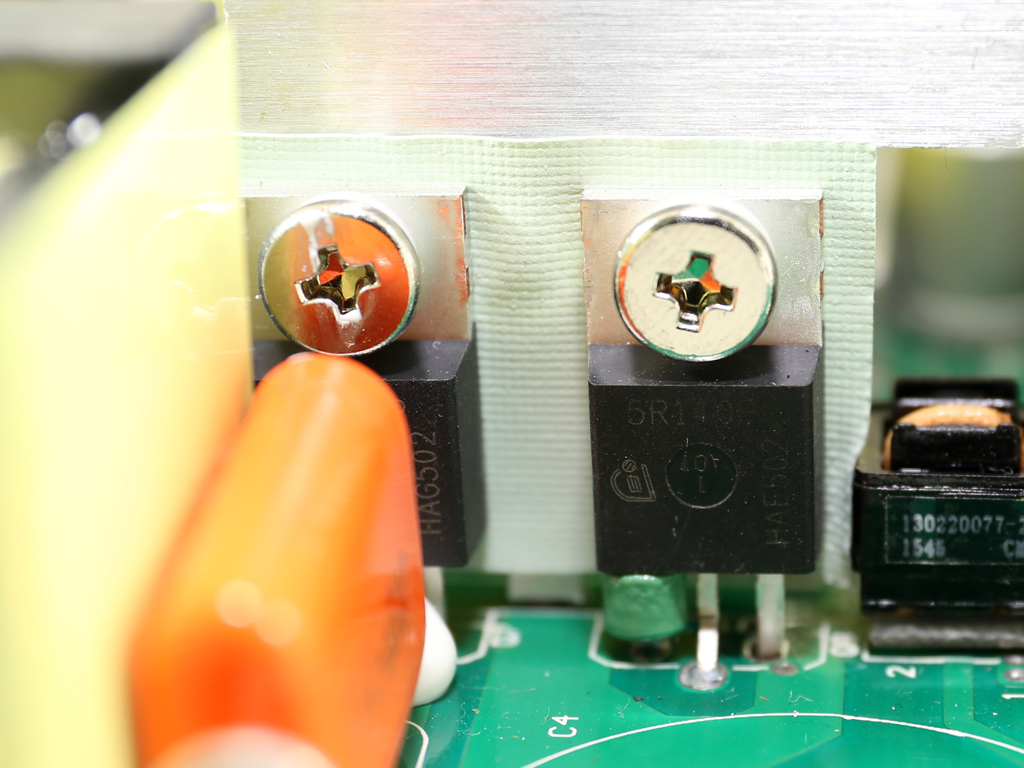

| APFC MOSFETs | 2x Infineon IPP50R140CP (550V, 15A @ 100 °C, 0.14 ohm) |

| APFC Boost Diode | 1x CREE C3D08060A (600V, 8A @ 152 °C) |

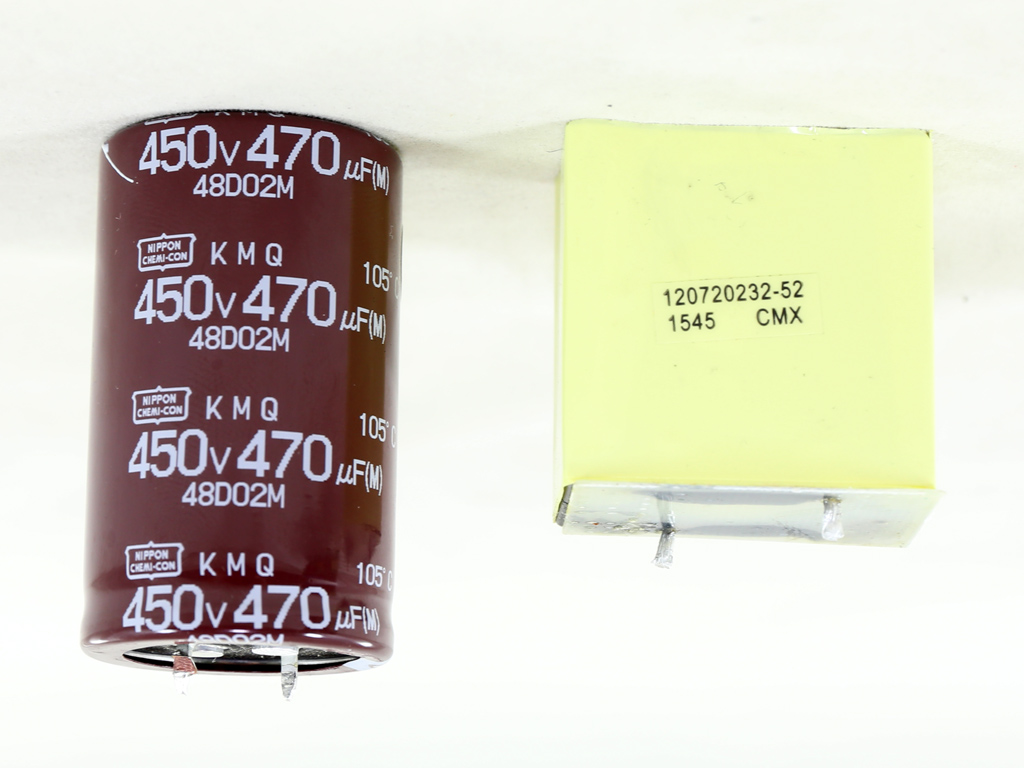

| Hold-up Cap(s) | 1x Nippon Chemi-Con (450V, 470uF, 2000h @ 105 °C, KMQ) |

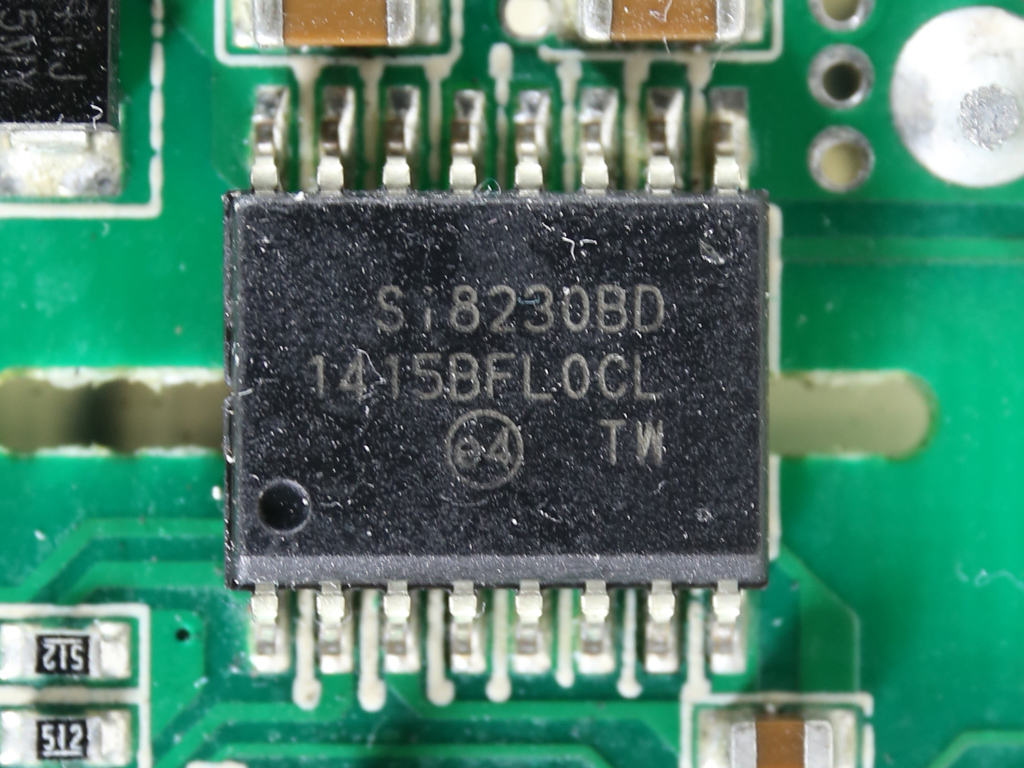

| Main Switchers | 2x Infineon IPP50R140CP (550V, 15A @ 100 °C, 0.14 ohm) Driver IC: 1x Silicon Labs Si8230BD |

| APFC Controller | Champion CM6502S & CM03X Green PFC controller |

| Switching Controller | Champion CM6901 |

| Topology | Primary side: Half-Bridge & LLC Resonant Converter Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

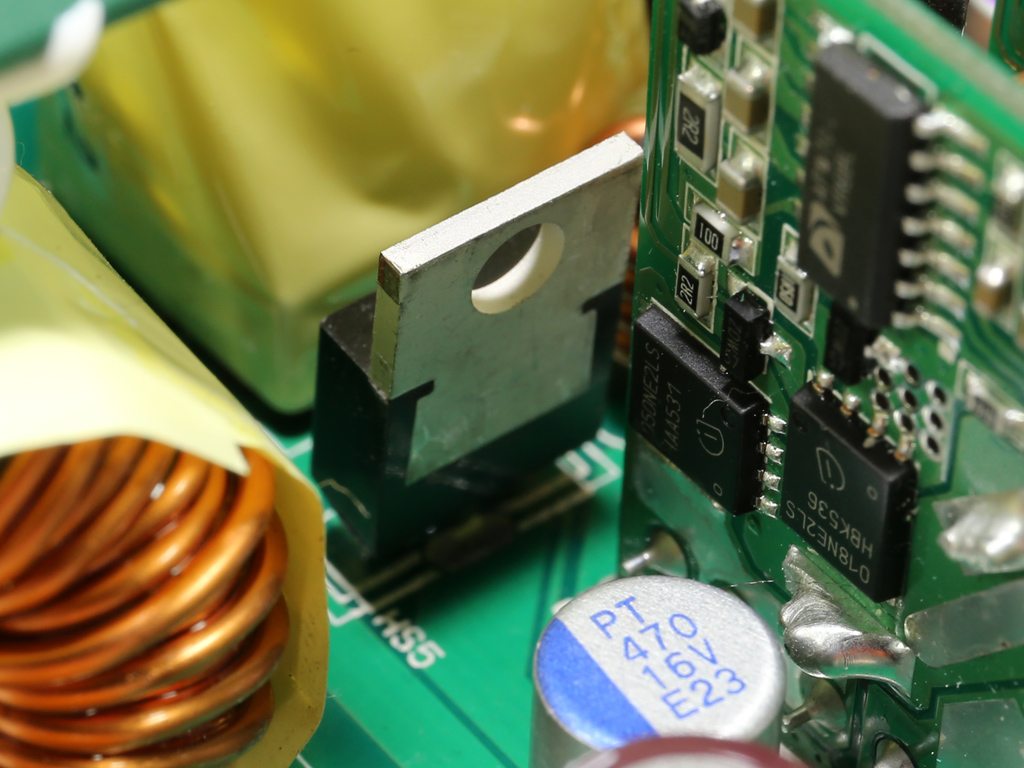

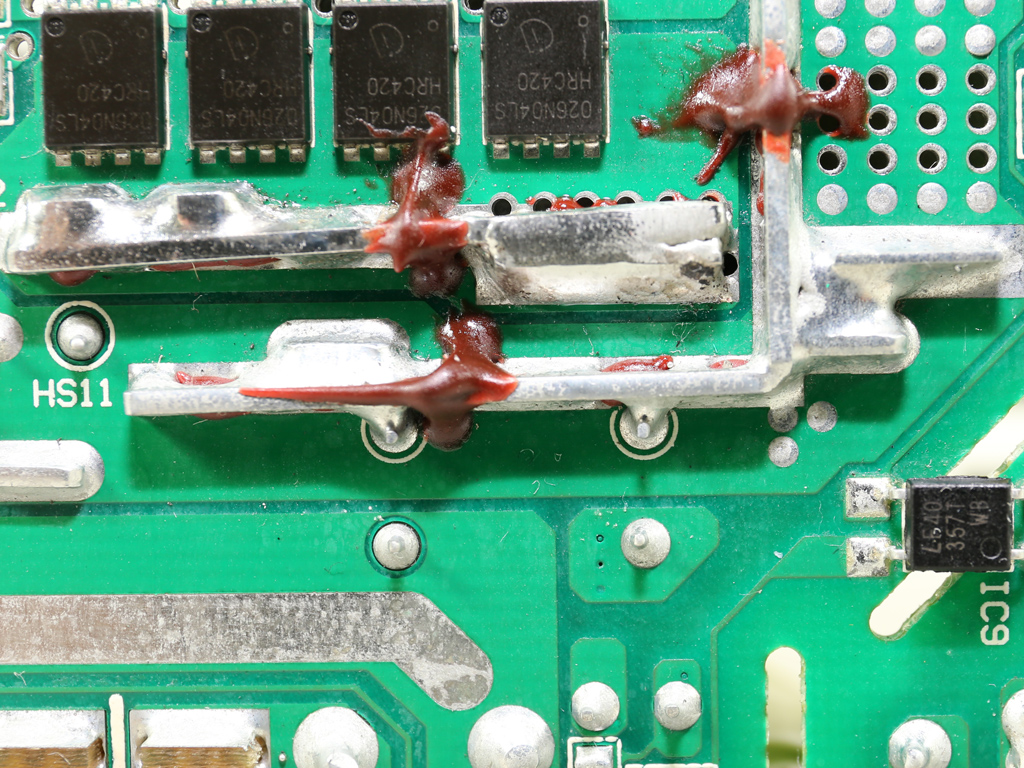

| +12V MOSFETs | 8x Infineon BSC014N04LS (40V, 100A @ 100 °C, 1.4 mohm) |

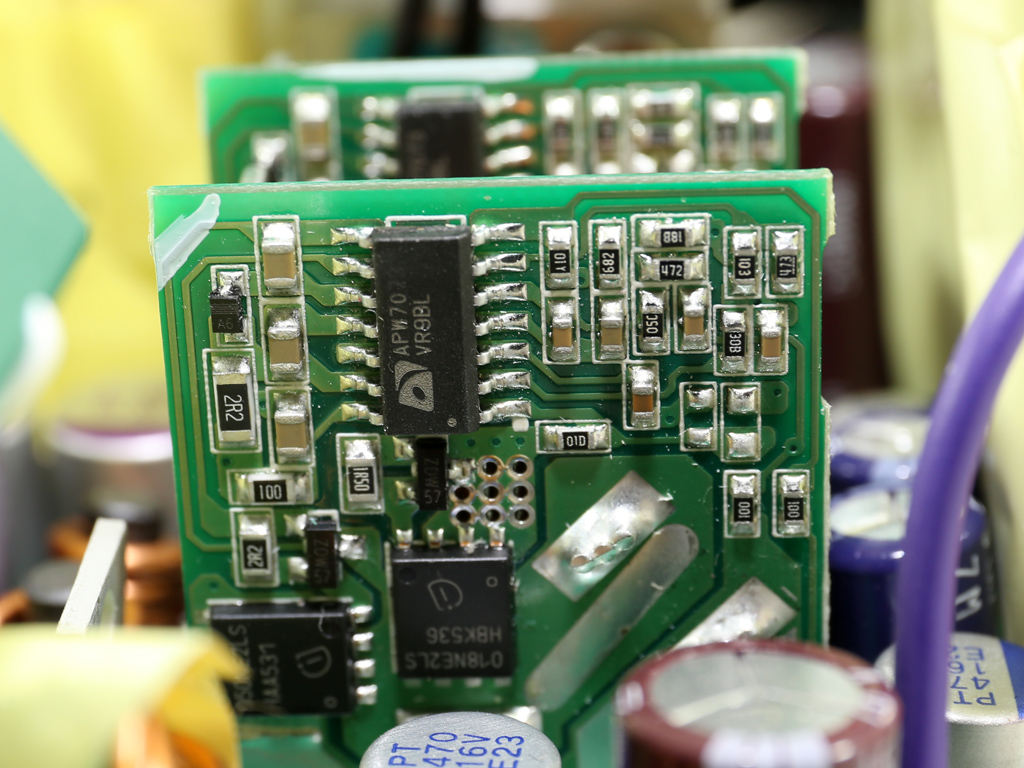

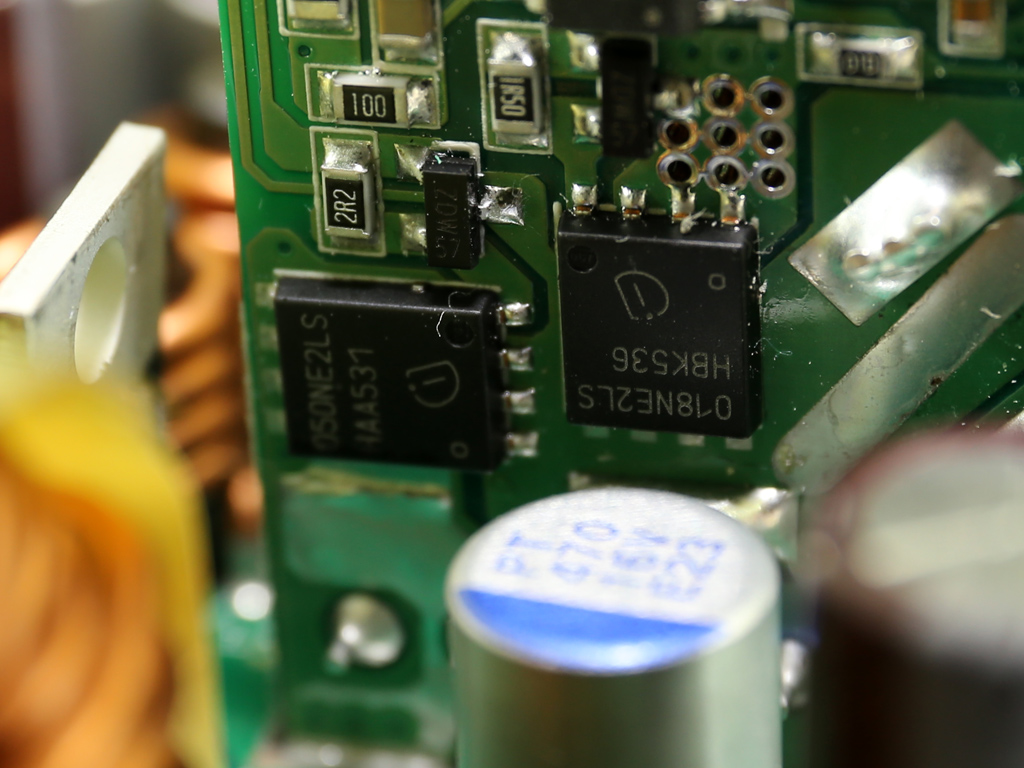

| 5V & 3.3V | DC-DC Converters: 2x Infineon BSC050NE2LS FETs (25V, 37A @ 100 °C, 5.0 mohm) 2x Infineon BSC018NE2LS FETs (25V, 97A @ 100 °C, 1.8 mohm) PWM Controller: 2x APW7073 |

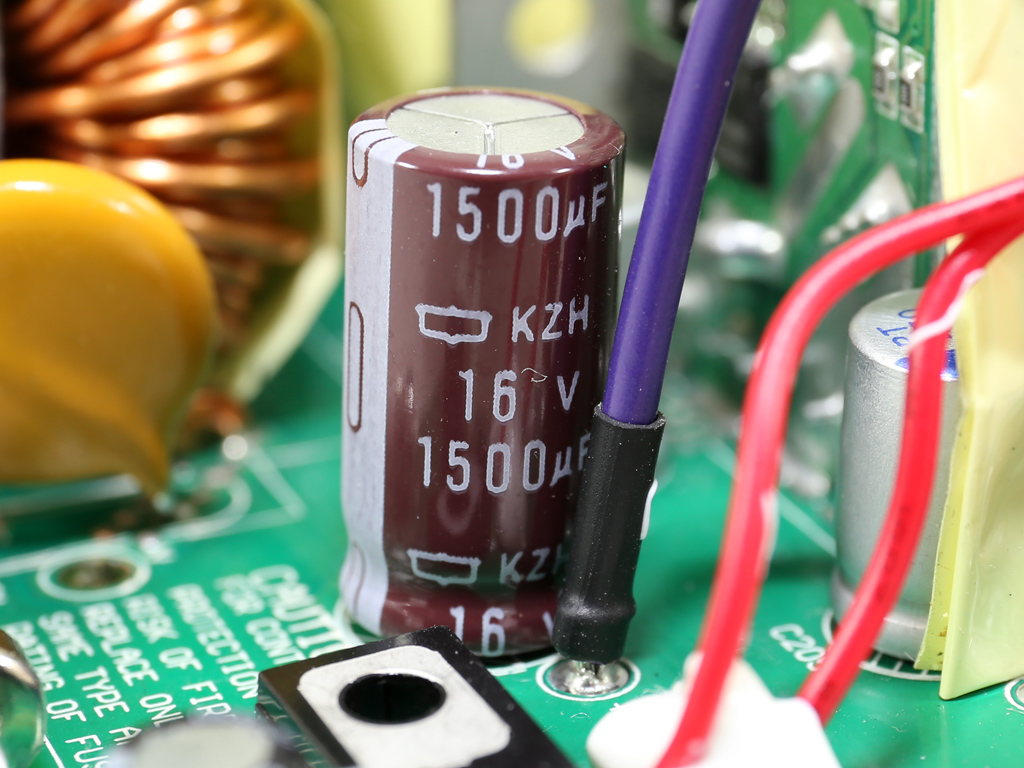

| Filtering Capacitors | Electrolytics: Nippon Chemi-Con (105 °C, KY 4000-10,000h, KZH 5000-6000h), Rubycon (105 °C, ZLH 6000-10,000h, YXG 3000-6000h) Polymers: Unicon (TW) |

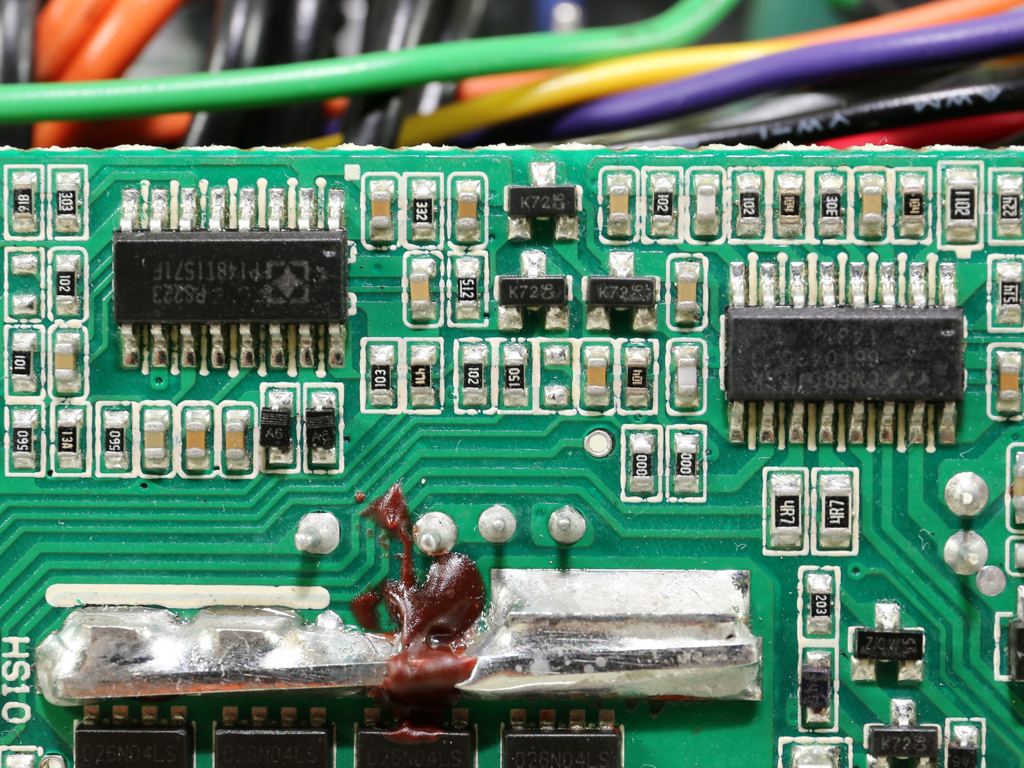

| Supervisor IC | SITI PS223 (OVP, UVP, OCP, SCP, OTP ) |

| Fan Model | Hong Hua HA1225H12F-Z (120mm, 12V, 0.58A, 2200 RPM, Fluid Dynamic Bearing) |

| 5VSB Circuit | |

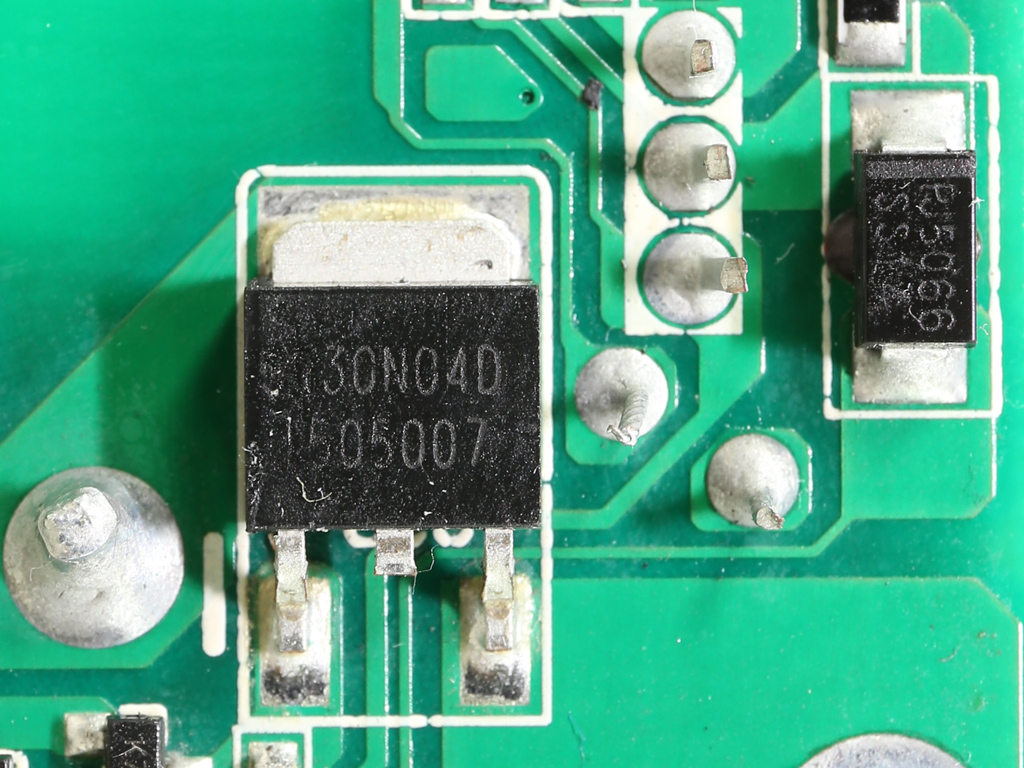

| Rectifier | 1x PFR10V45CT & 1x SG30N04D |

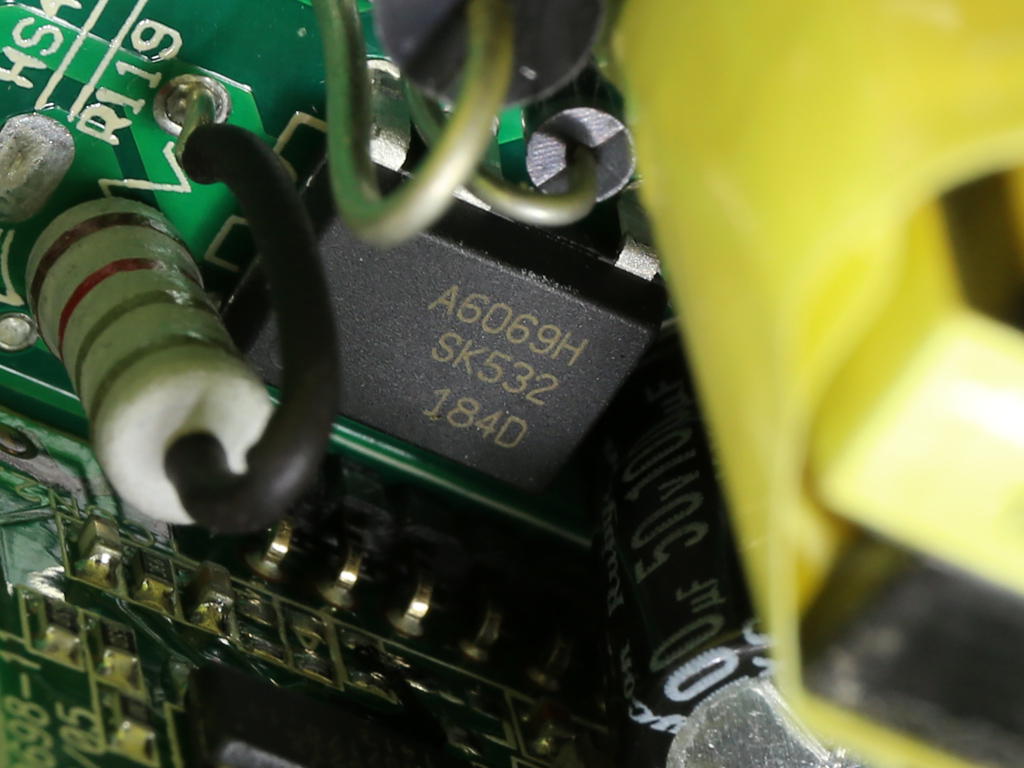

| Standby PWM Controller | Sanken STR-A6069H |

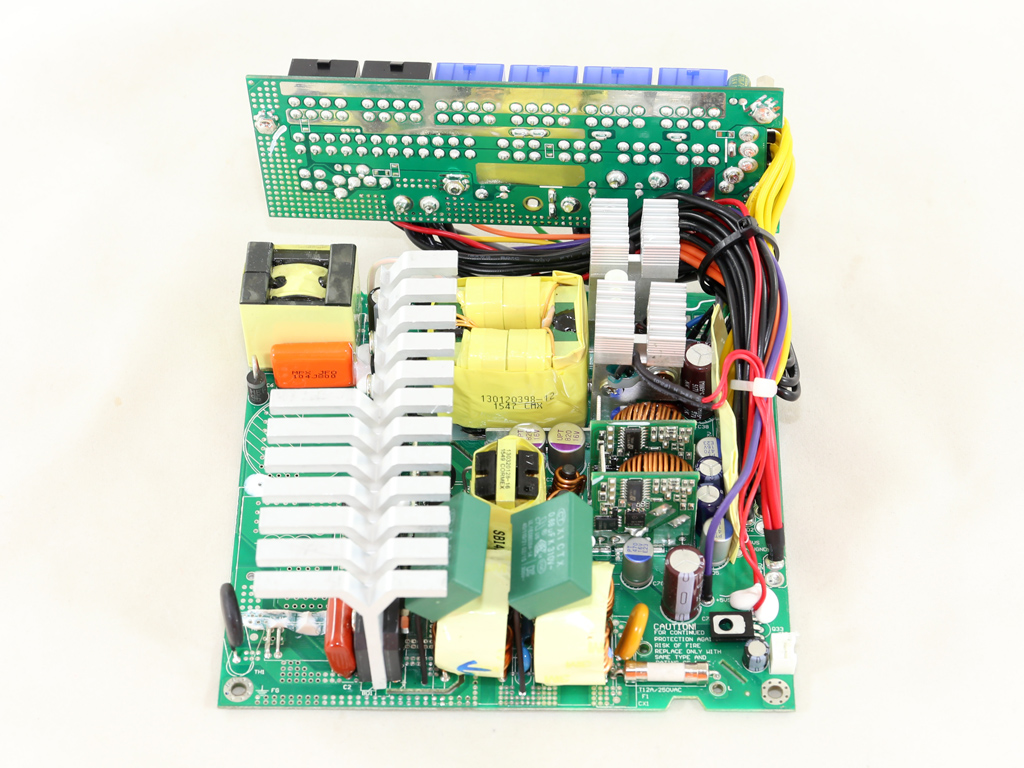

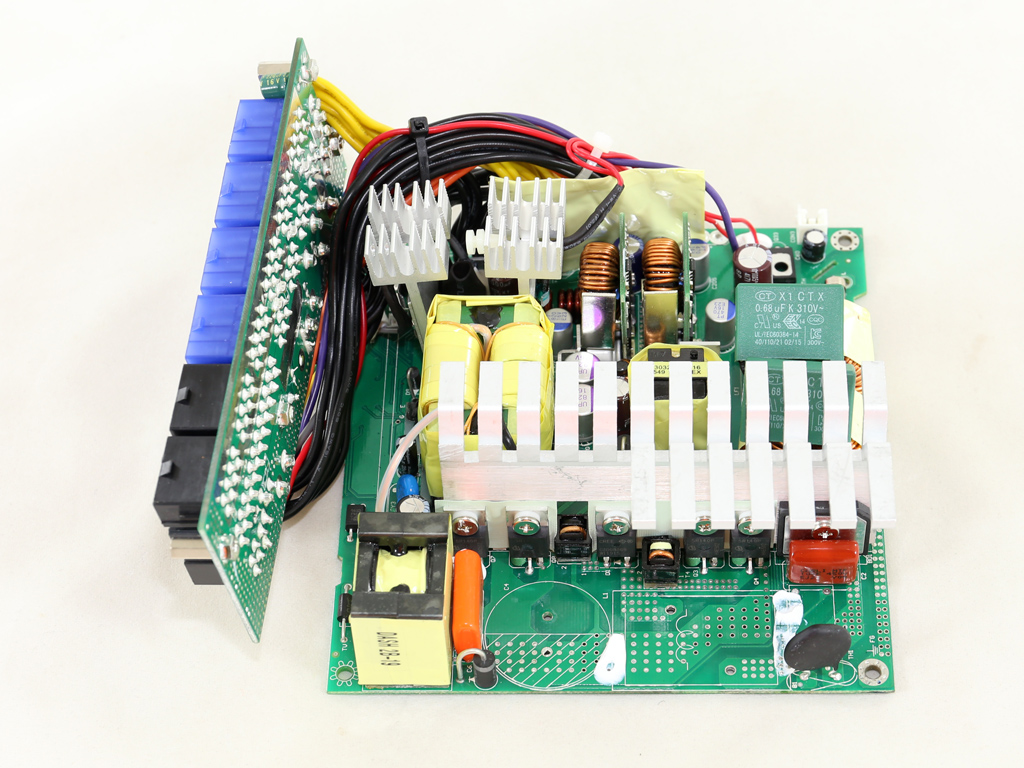

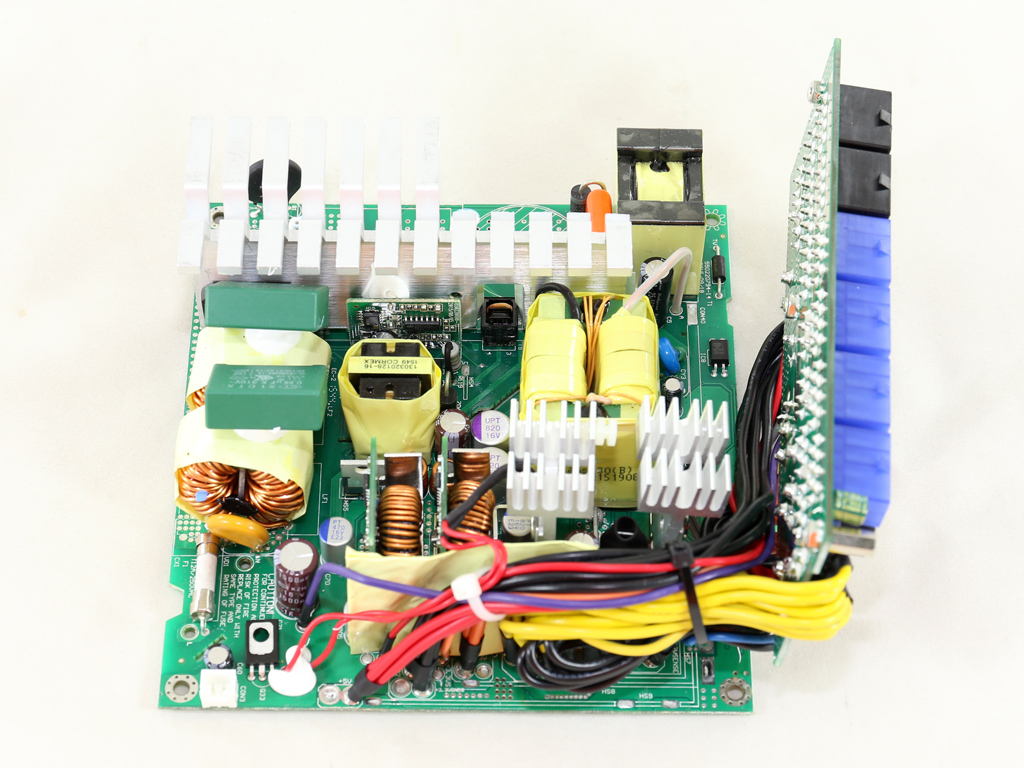

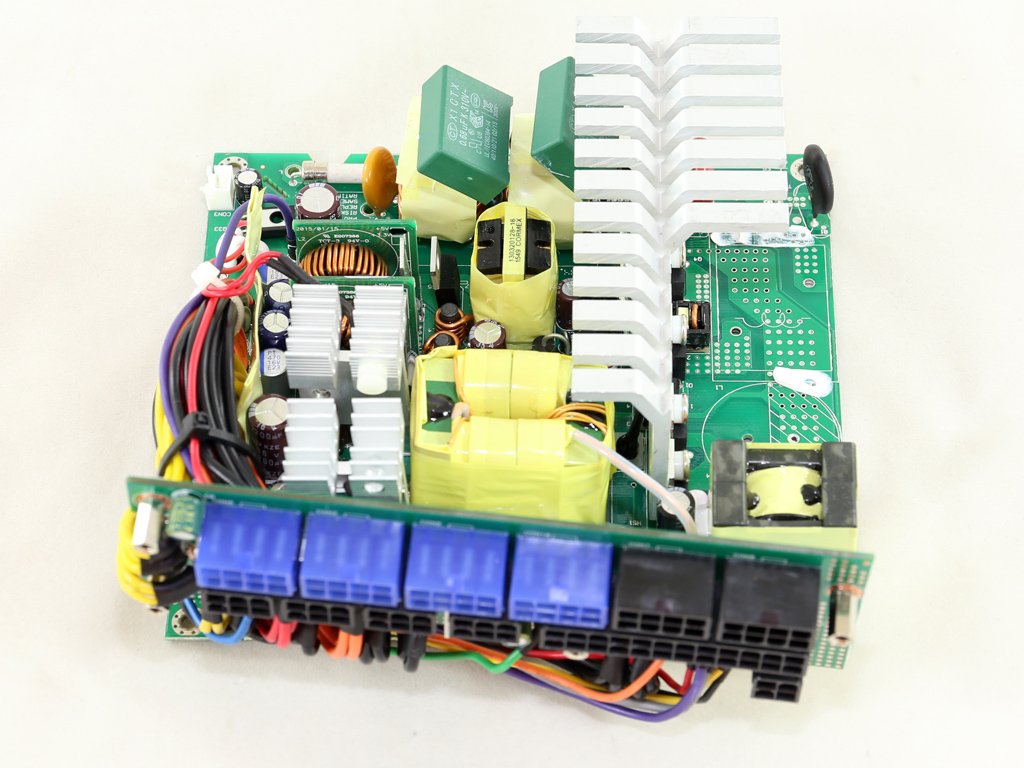

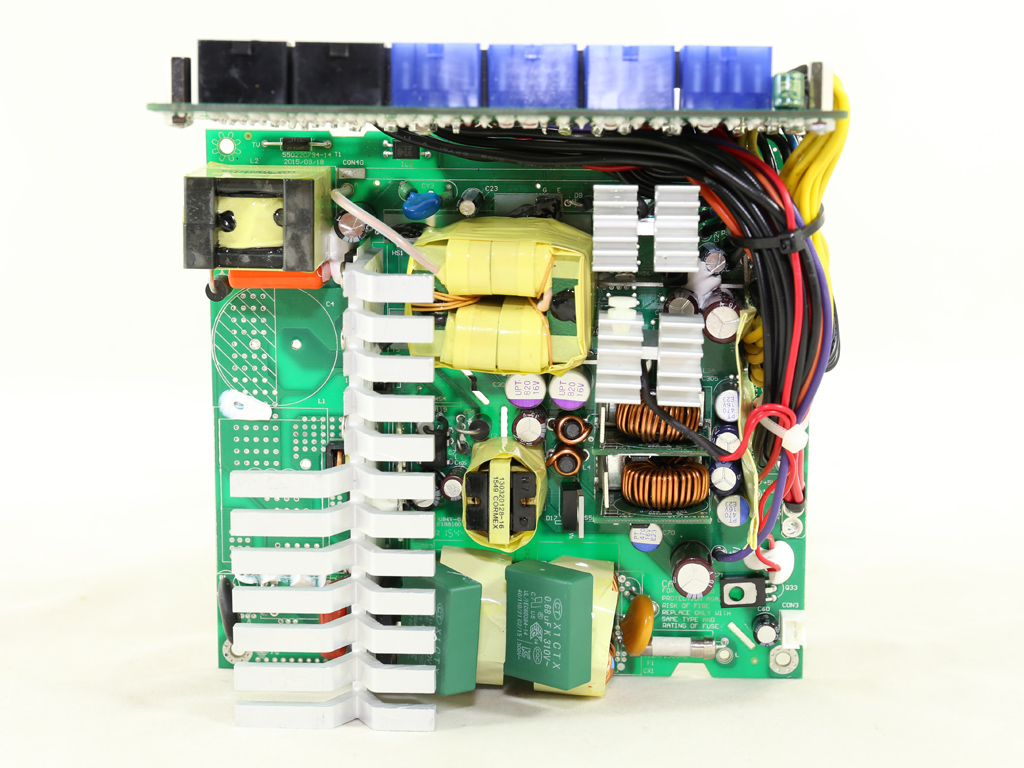

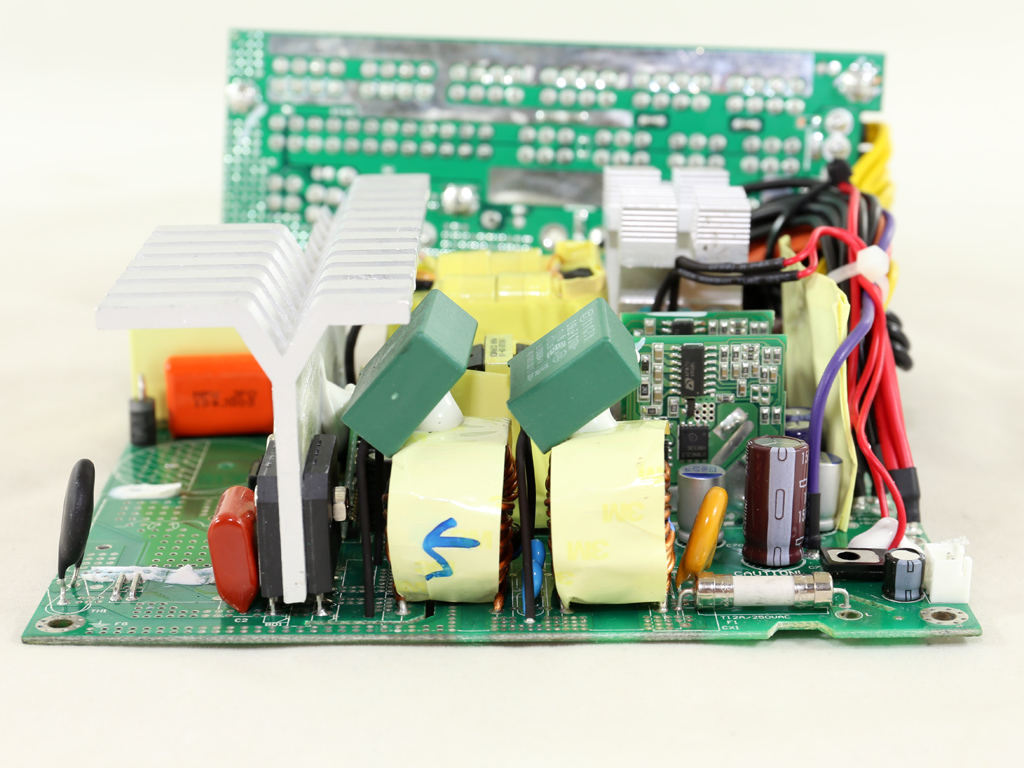

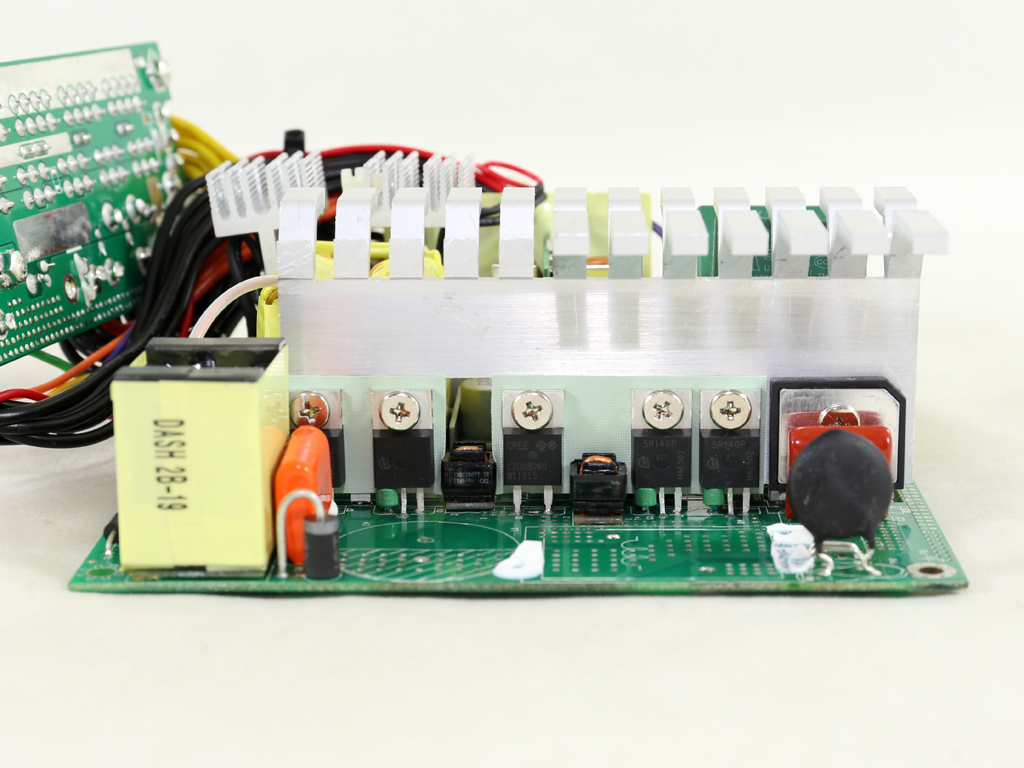

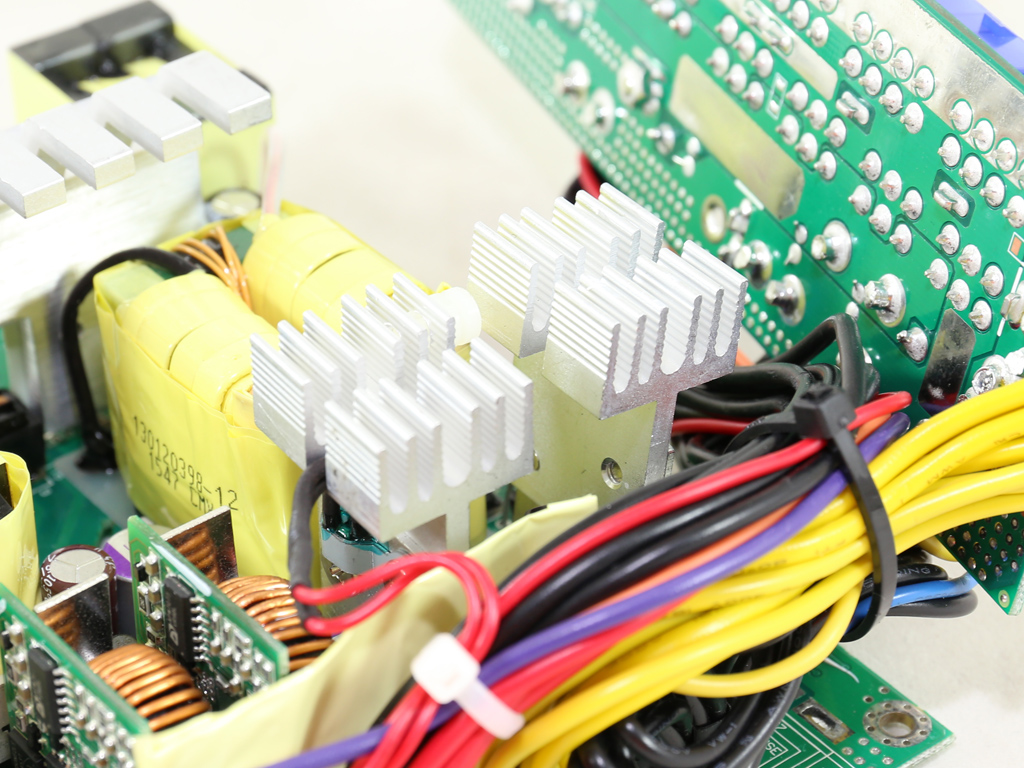

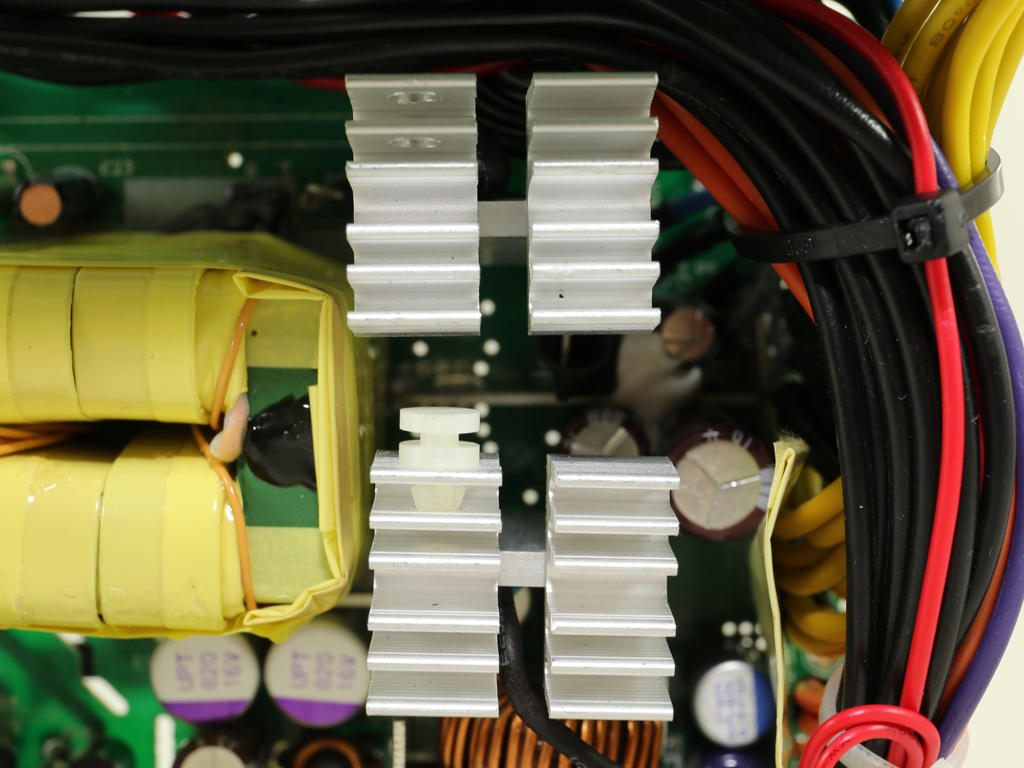

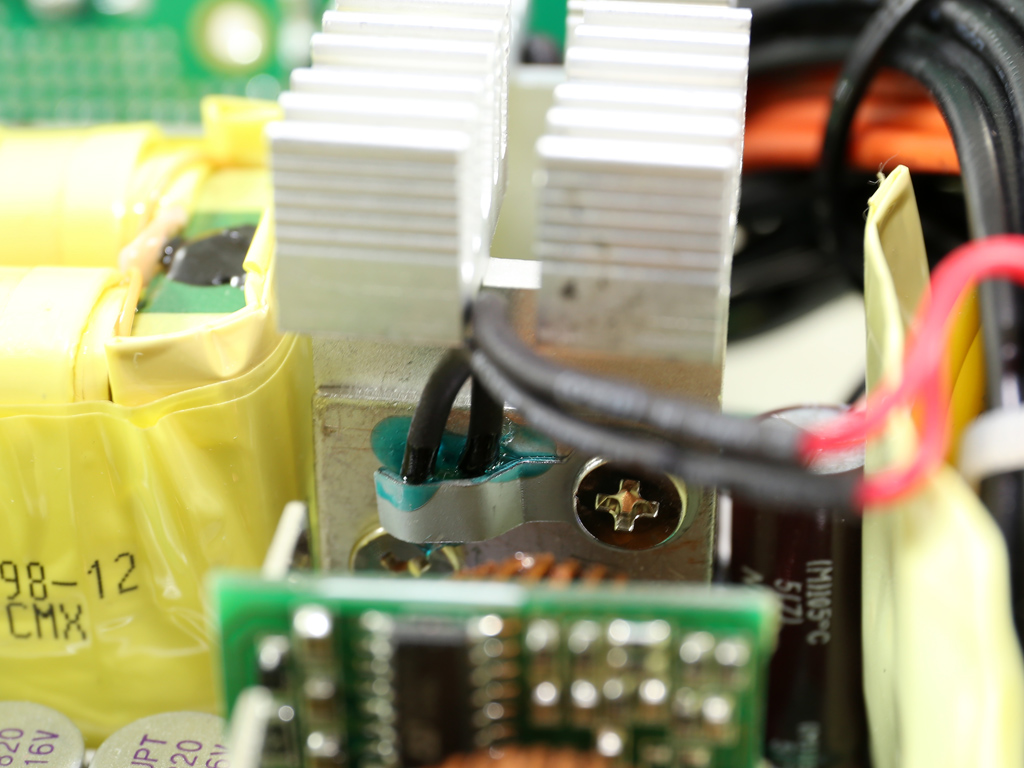

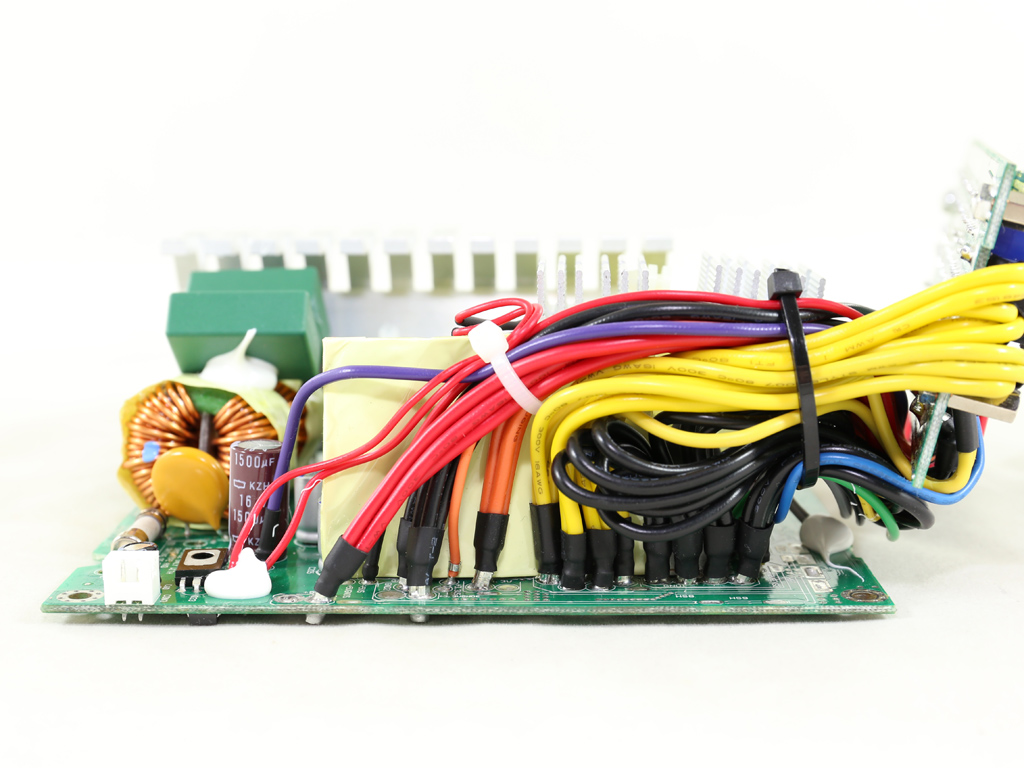

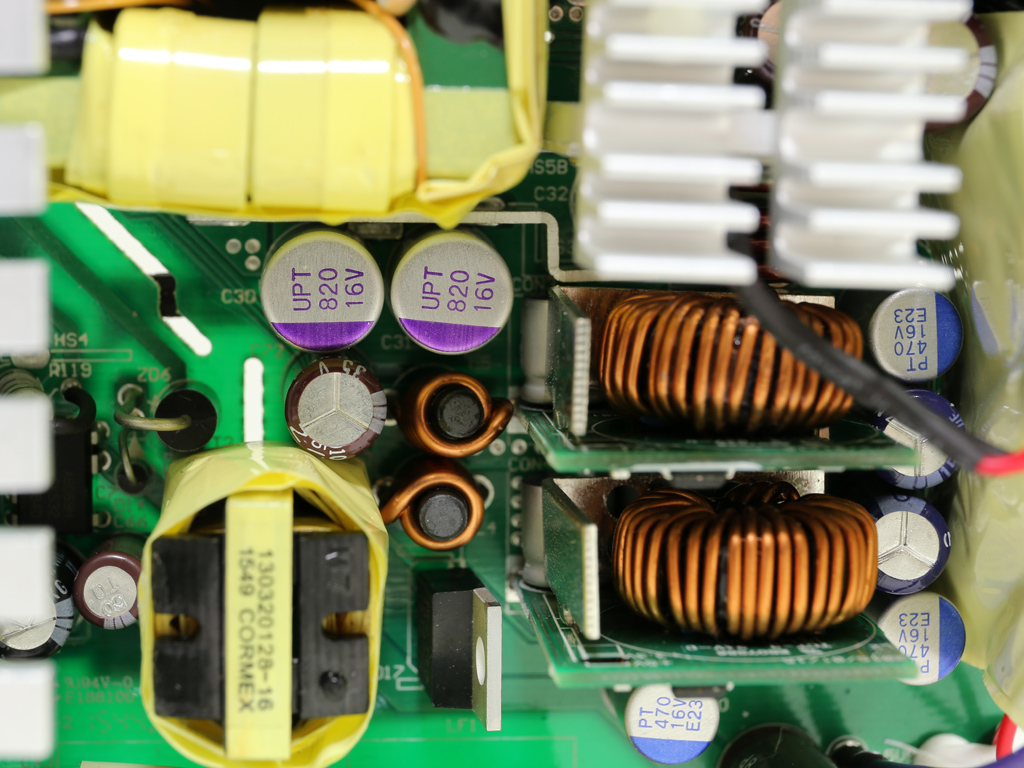

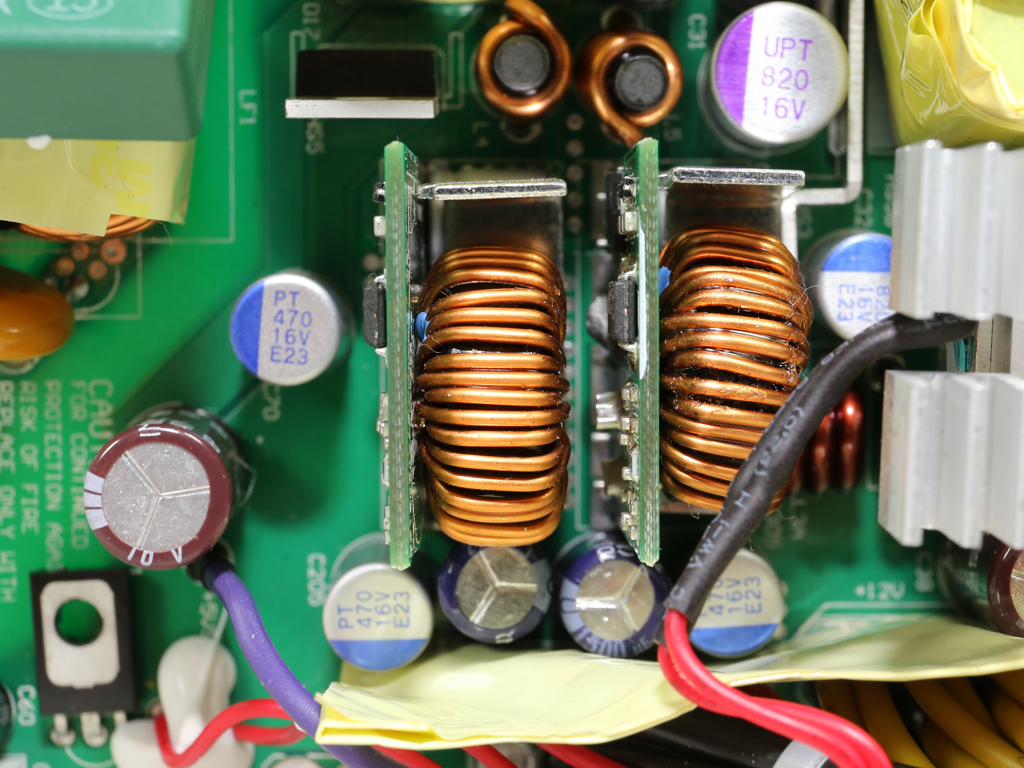

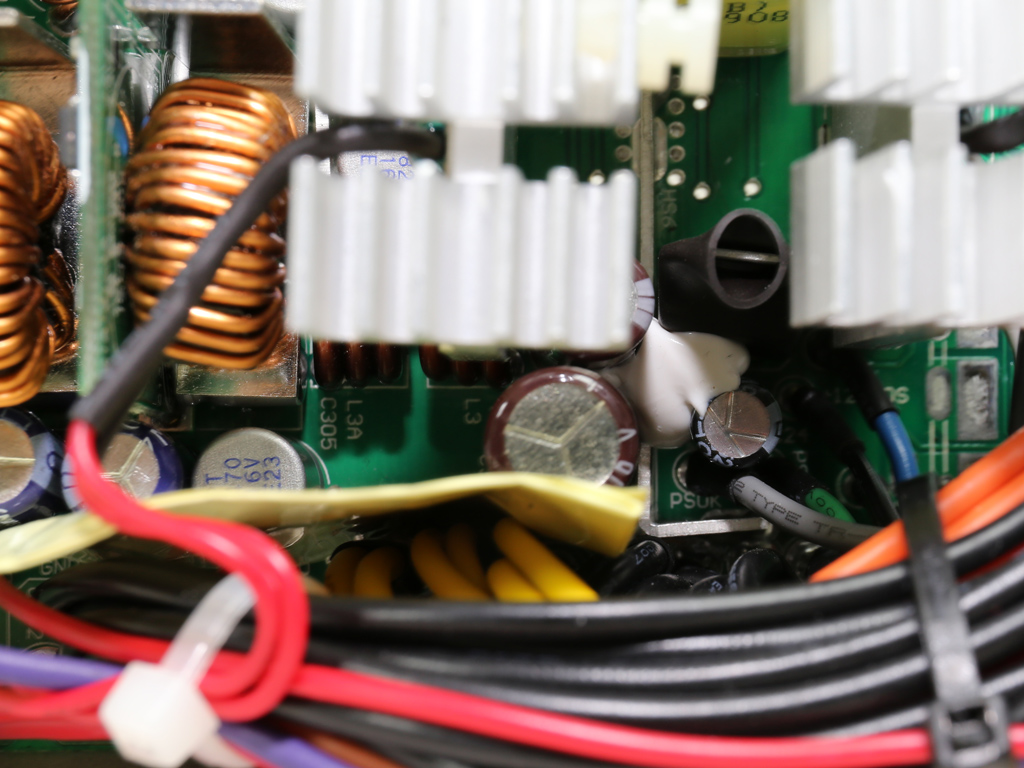

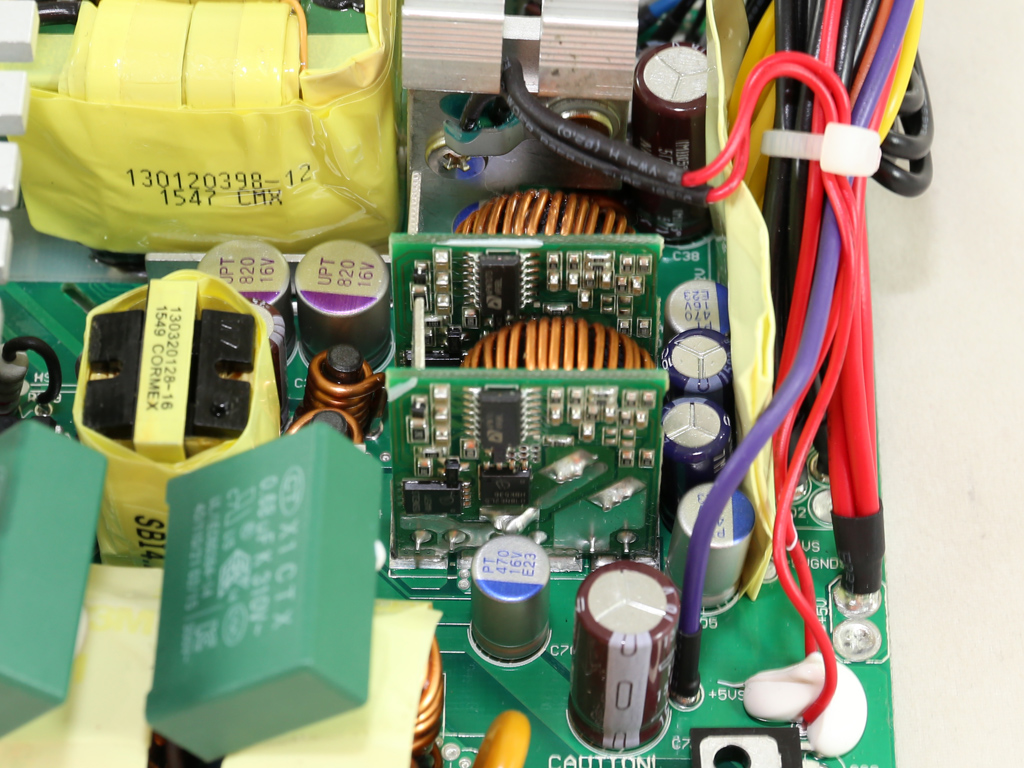

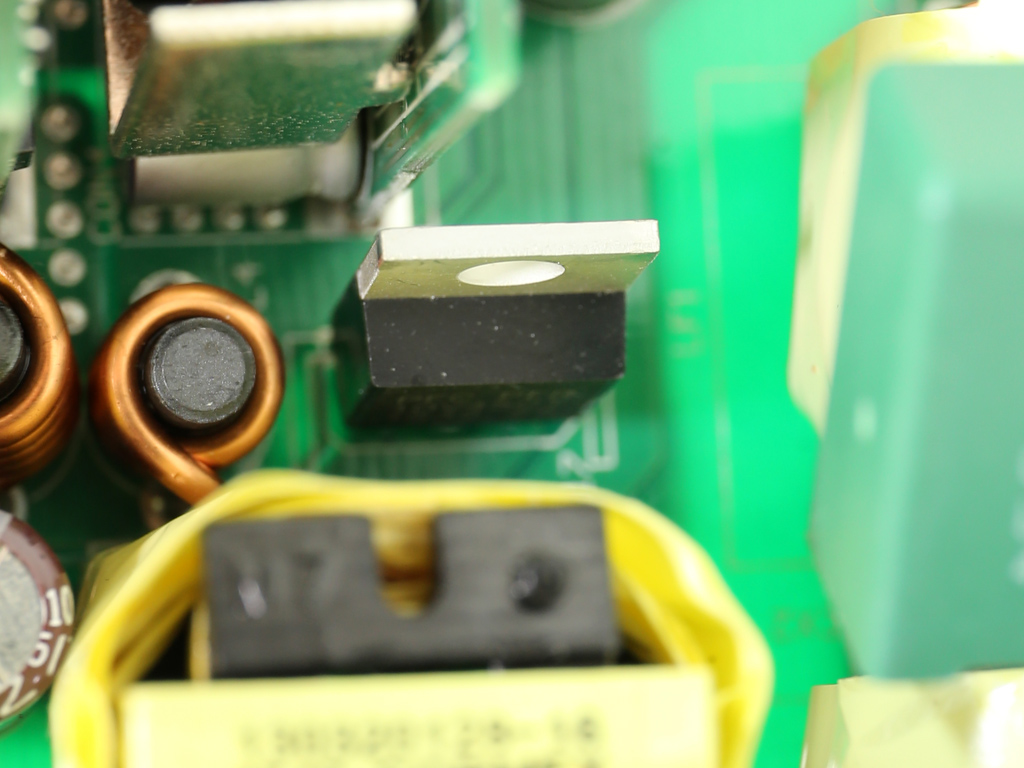

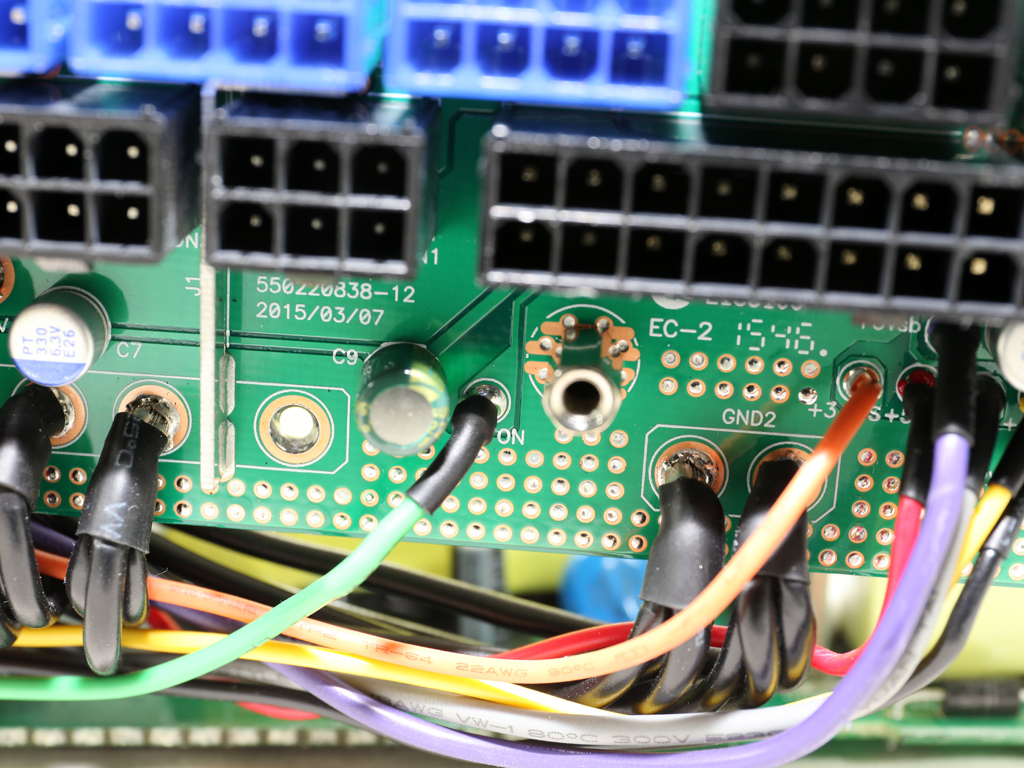

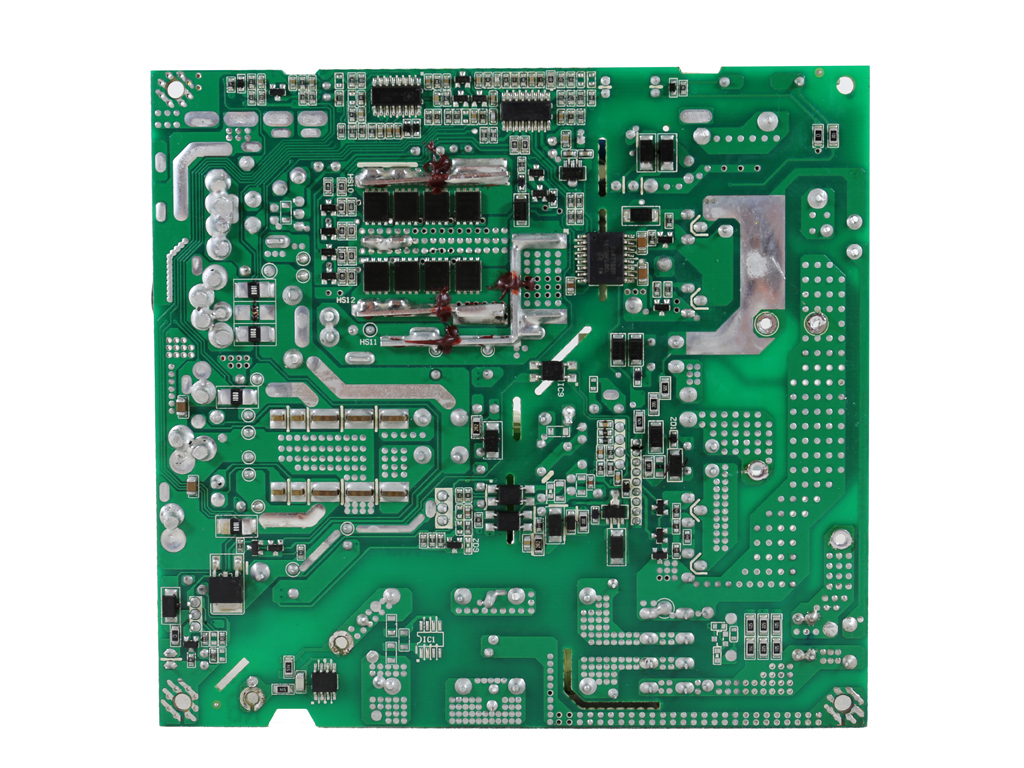

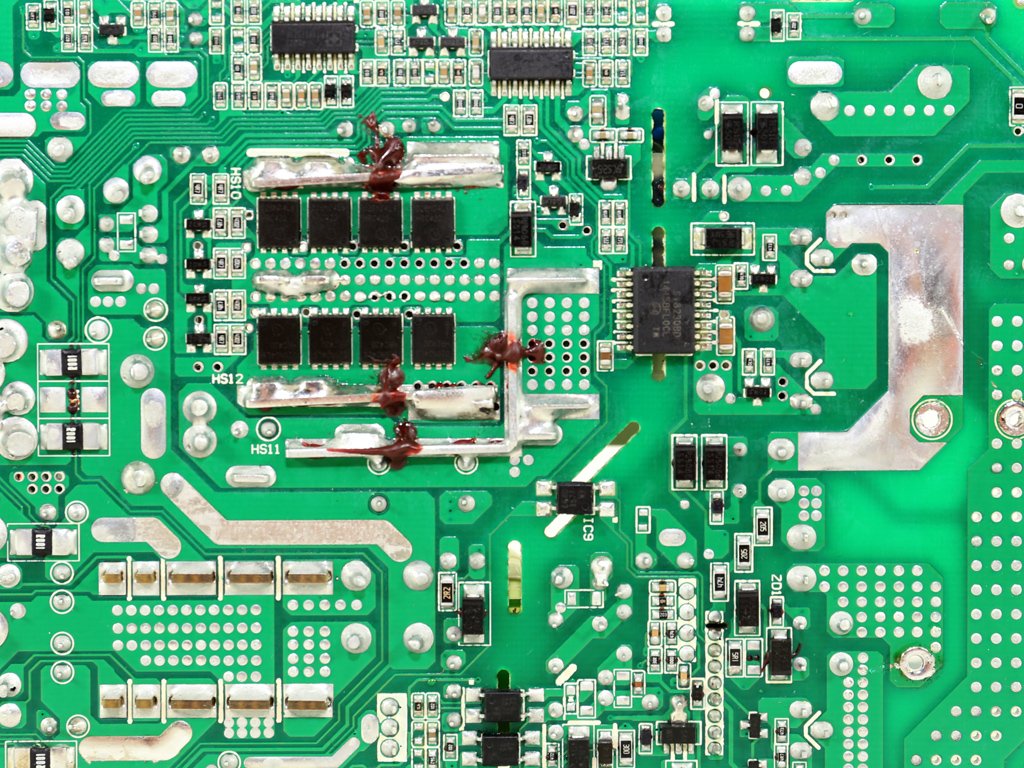

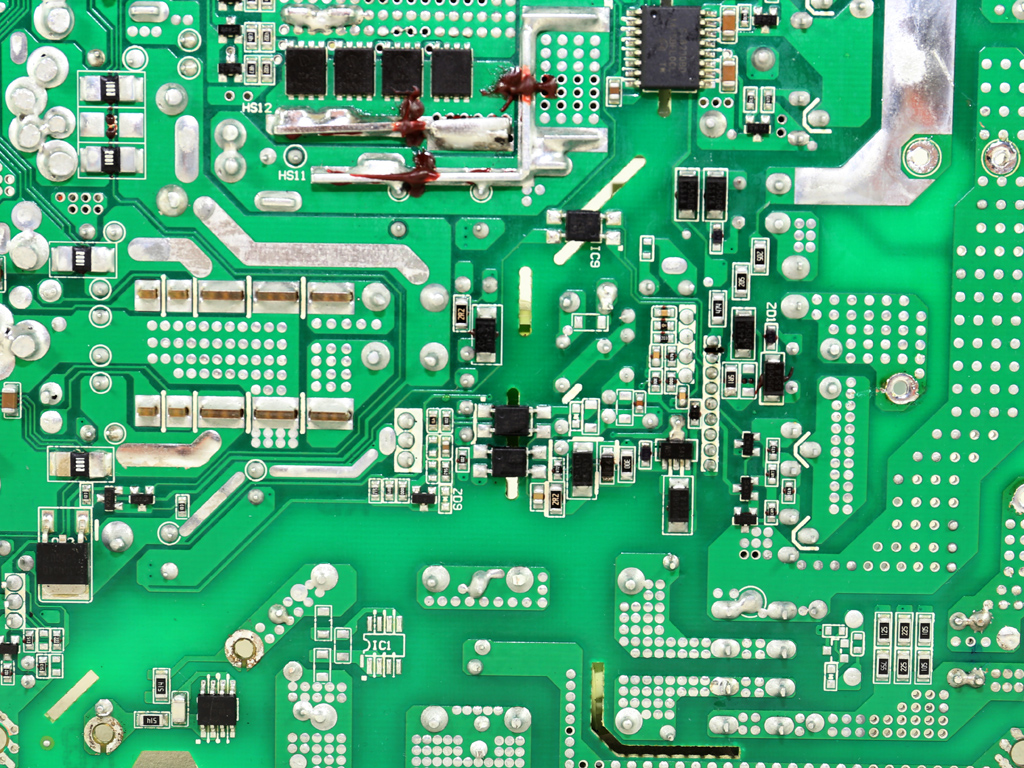

The ST60F-TI is based on an upgraded Platinum platform that manages to clear the Titanium requirements. It doesn't use a bridge-less design like Super Flower's Titanium platforms, so we don't expect to see ultra high efficiency levels out of it. The PCB features a clean design though, and there is plenty of room between components to allow for optimal airflow. The primary heat sink is huge, something common to almost all Enhance platforms. Meanwhile on the secondary side, two small heat sinks don't accommodate any components since the +12V FETs are installed on the PCB's solder side. All electrolytic capacitors are provided by Japanese manufacturers, while the polymer ones are made in Taiwan. An LLC resonant converter is utilized on the primary side, while on the secondary side a synchronous design is used along with a couple of DC-DC converters for generating the minor rails.

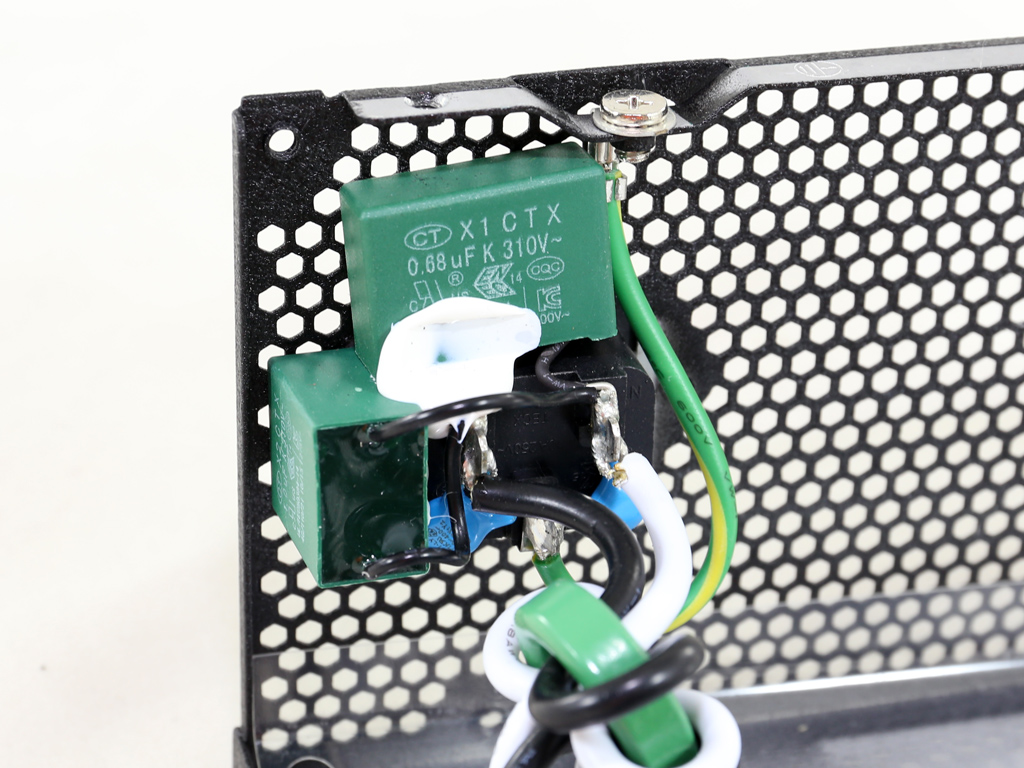

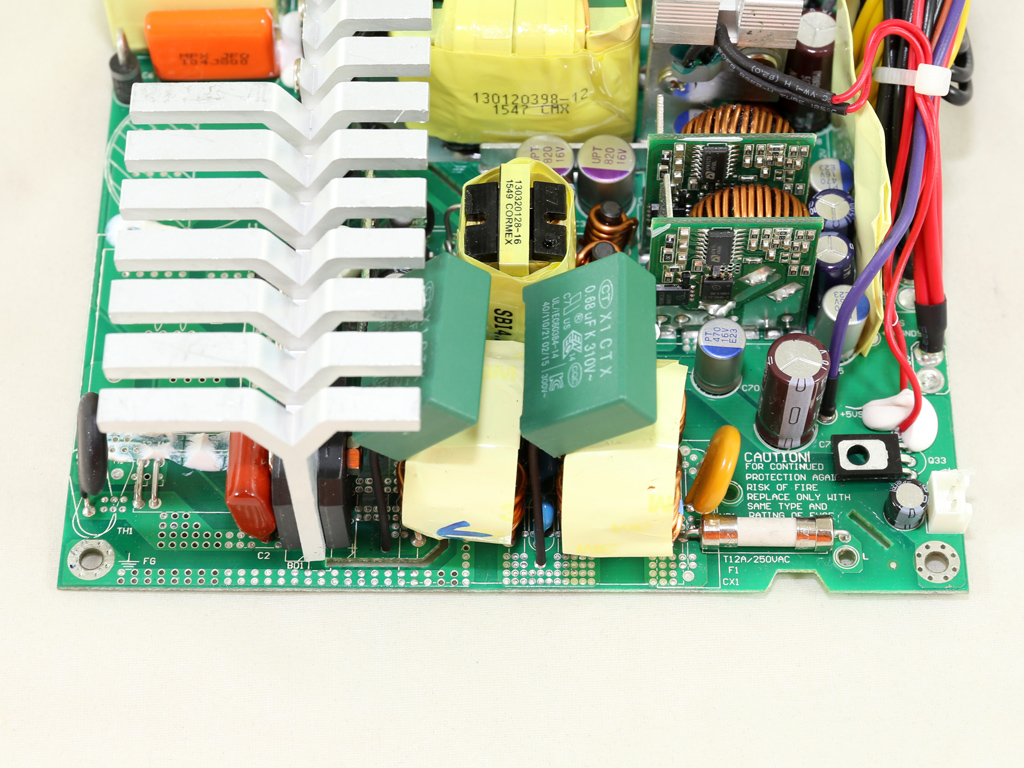

The transient filter starts at the AC receptacle with two X and two Y caps. It continues on the main PCB with two more X caps and an additional pair of Y ones. There are also two CM chokes and an MOV that absorb power surges and spikes coming from the mains network. Finally, a CM02X IC, installed on the PCB's solder side, is responsible for blocking current through an X cap's discharge (bleeding) resistor when AC voltage is connected. This leads to a small efficiency increase.

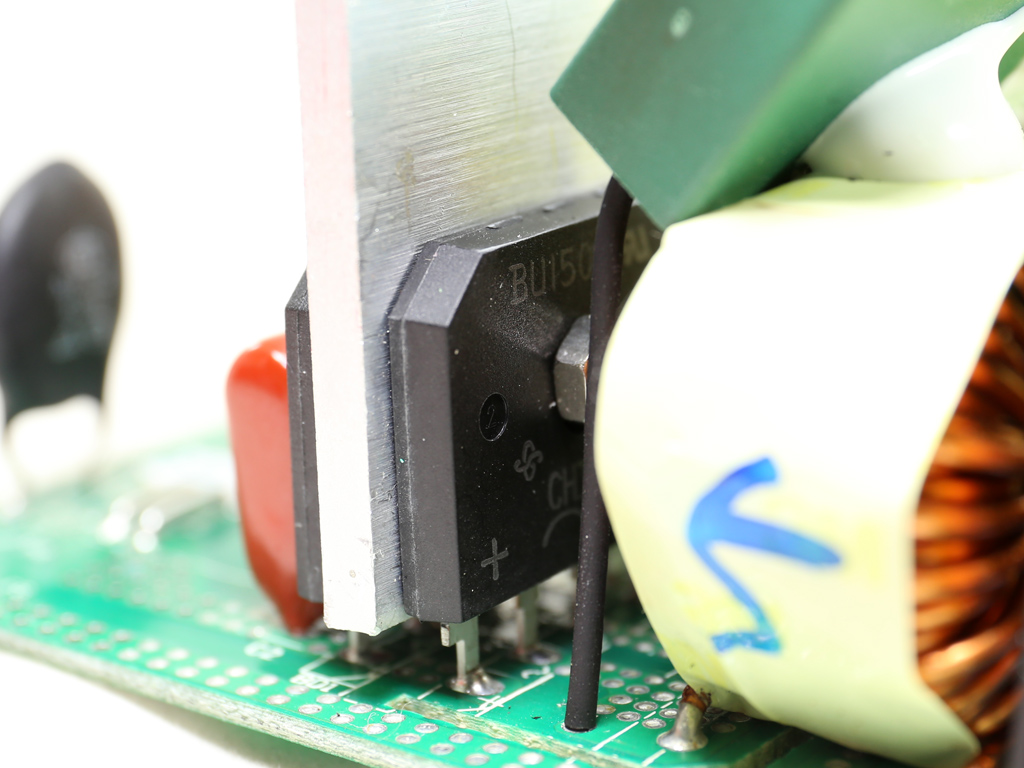

The bridge rectifiers (two Vishay BU1506) are able to handle up to 30A of current, so they'll easily meet this PSU's needs, even with 100V input voltage. Moreover, two parallel bridge rectifiers offer lower energy losses since the load current is shared between them.

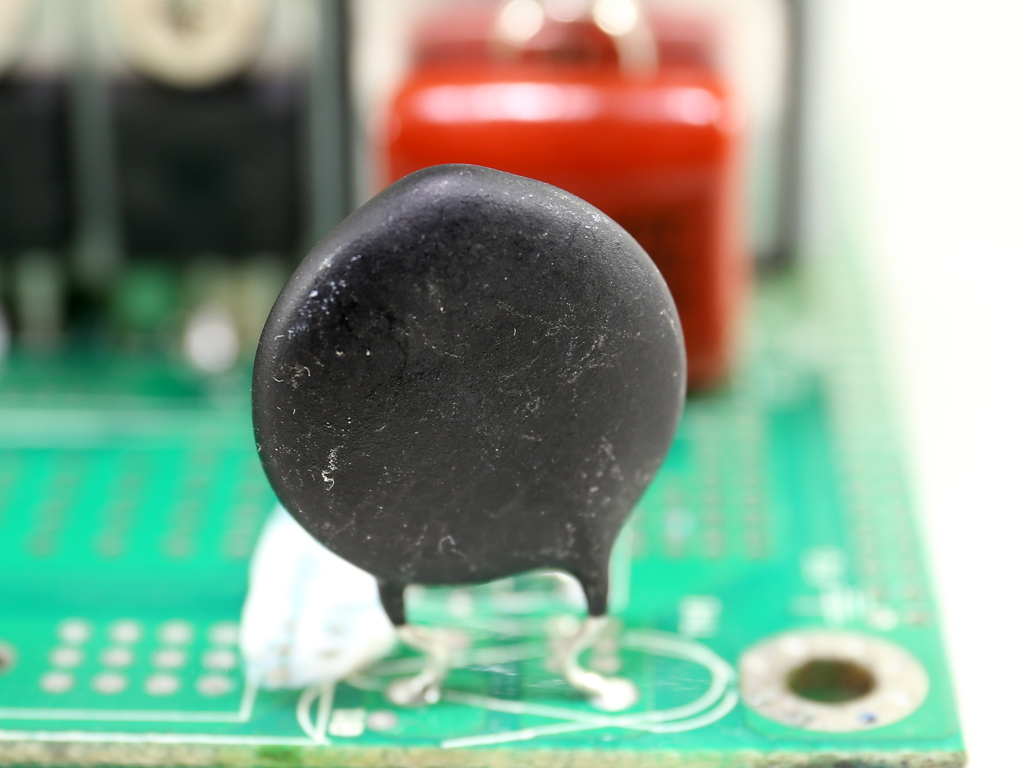

This is the NTC thermistor that lowers the inrush current during the PSU's start-up phase. Unfortunately, it isn't supported by a bypass relay, which would increase efficiency and allow it to cool down quickly.

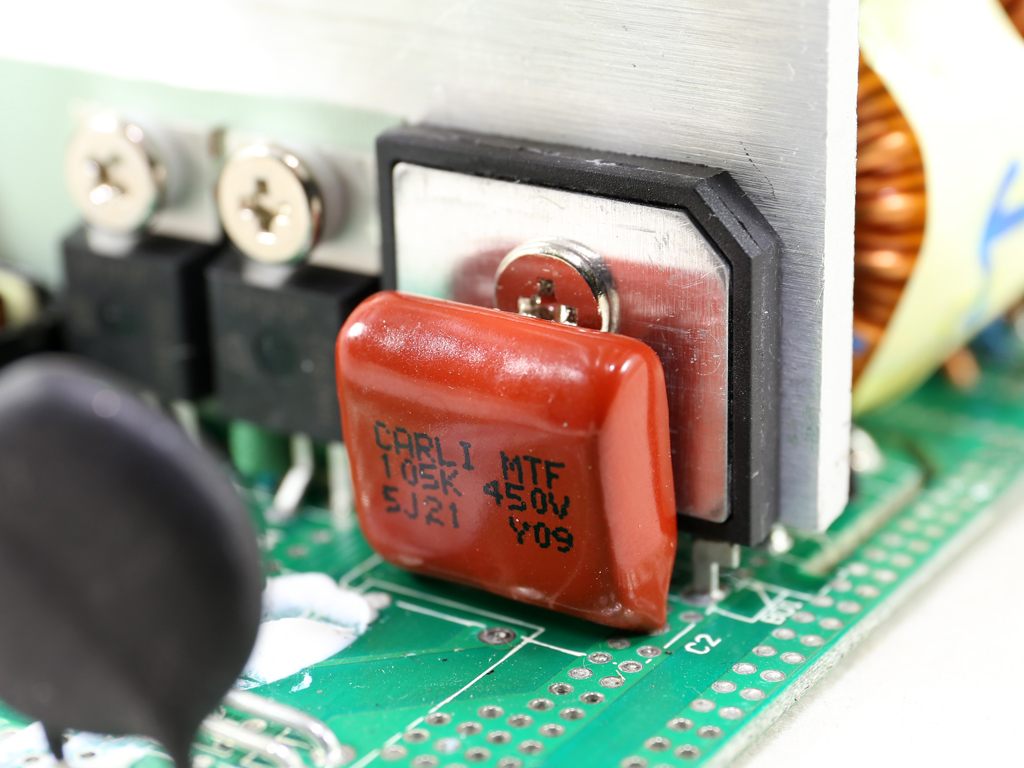

The APFC converter uses two Infineon IPP50R140CP FETs and a single CREE C3D08060A boost diode. The bulk cap is by Chemi-Con (450V, 470uF, 2000h @ 105 °C, KMQ) and its capacity isn't able to offer the ATX spec's desired 17ms hold-up time.

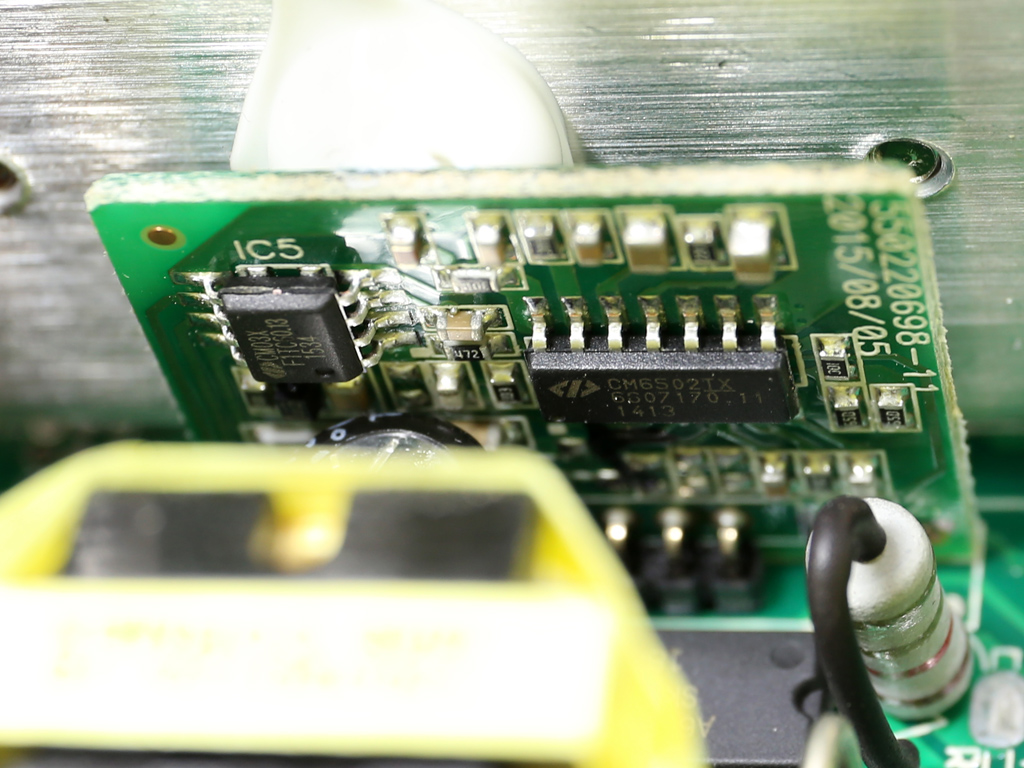

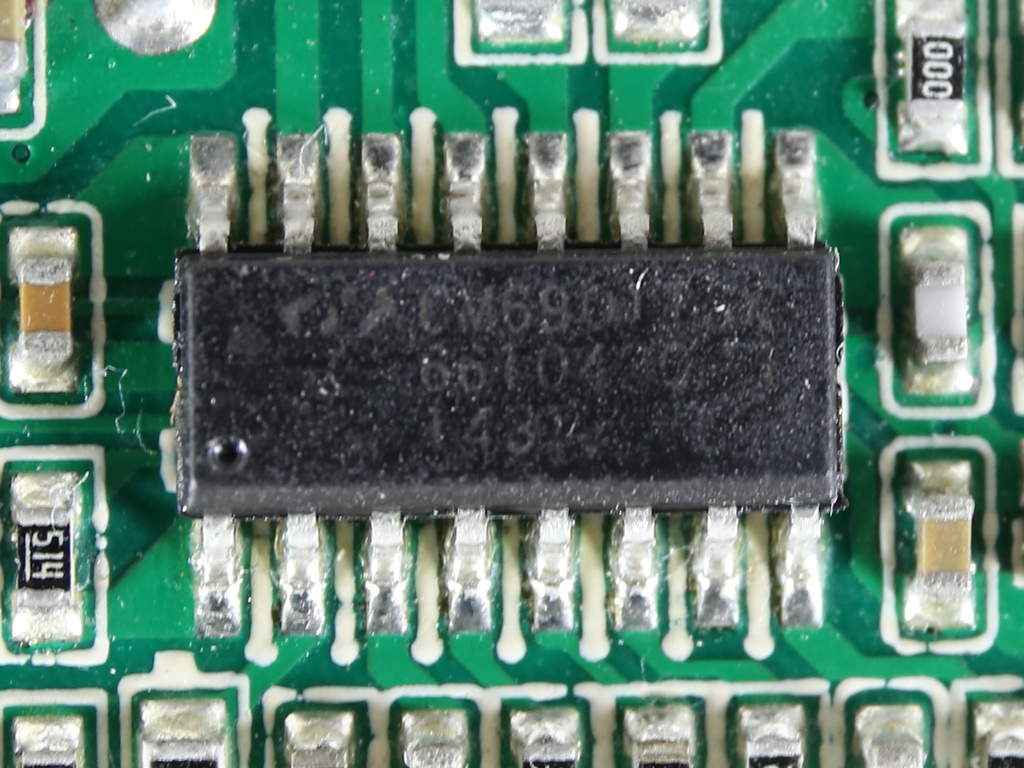

The controller responsible for the APFC circuit is a Champion CM6502S IC. It's supported by a CM03X Green PFC controller, which improves efficiency in standby mode. Both ICs are installed onto a small daughterboard.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The main switchers are two Infineon IPP50R140CP FETs, likely arranged into a half-bridge topology. The driver IC of the main FETs is a Silicon Labs Si8230BD IC. An LLC resonant converter is used for increased efficiency and the resonant controller is a Champion CM6901 IC installed on the PCB's solder side.

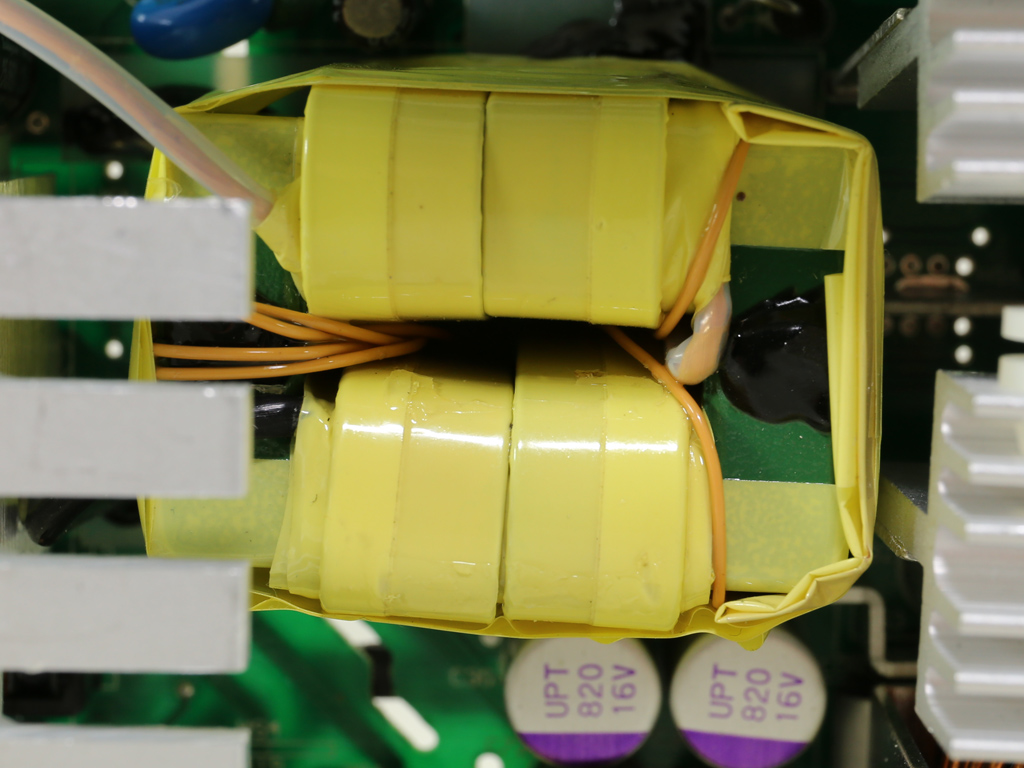

The main transformer is quite small, even for a 600W PSU.

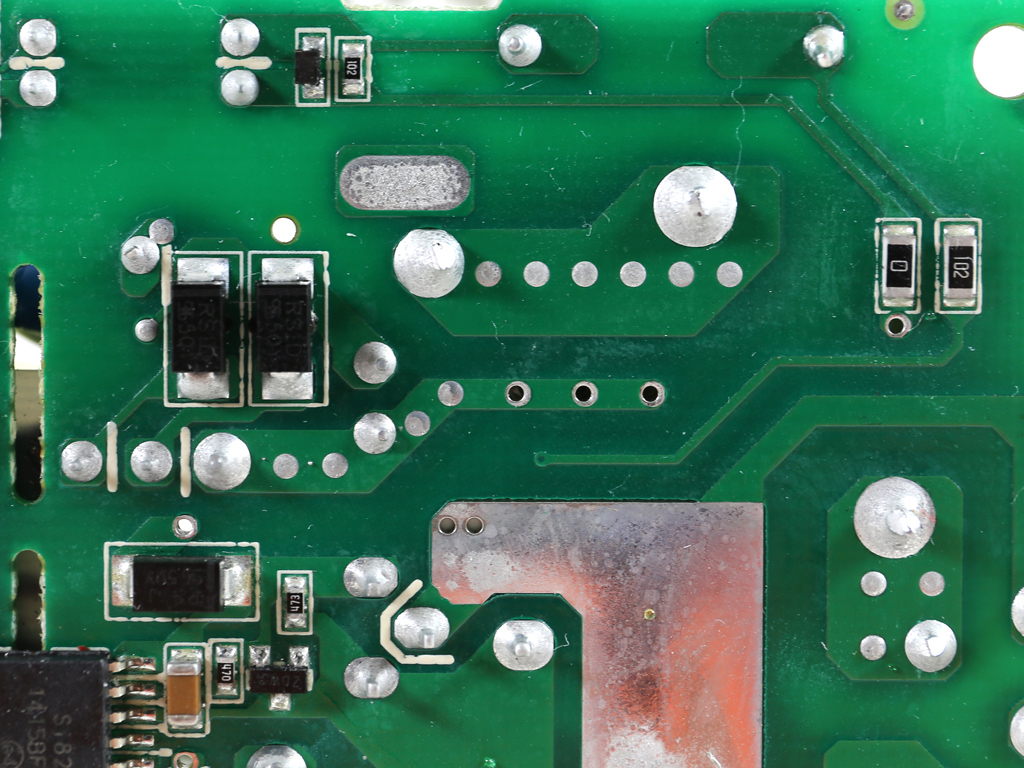

On the secondary side, two small heat sinks are empty of active components. The only parts attached to them are thermistors that provide information to the fan control circuit and supervisor IC for over-temperature protection. Speaking of the supervisor IC, this is a SITI PS223 and it is installed on the PCB's solder side.

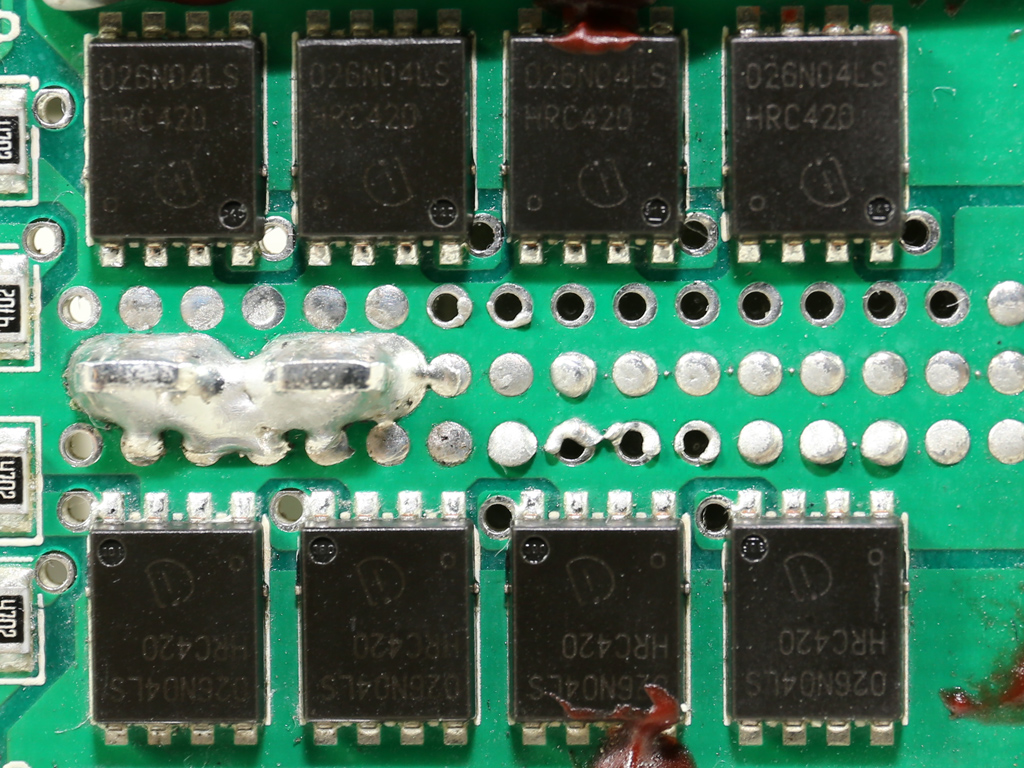

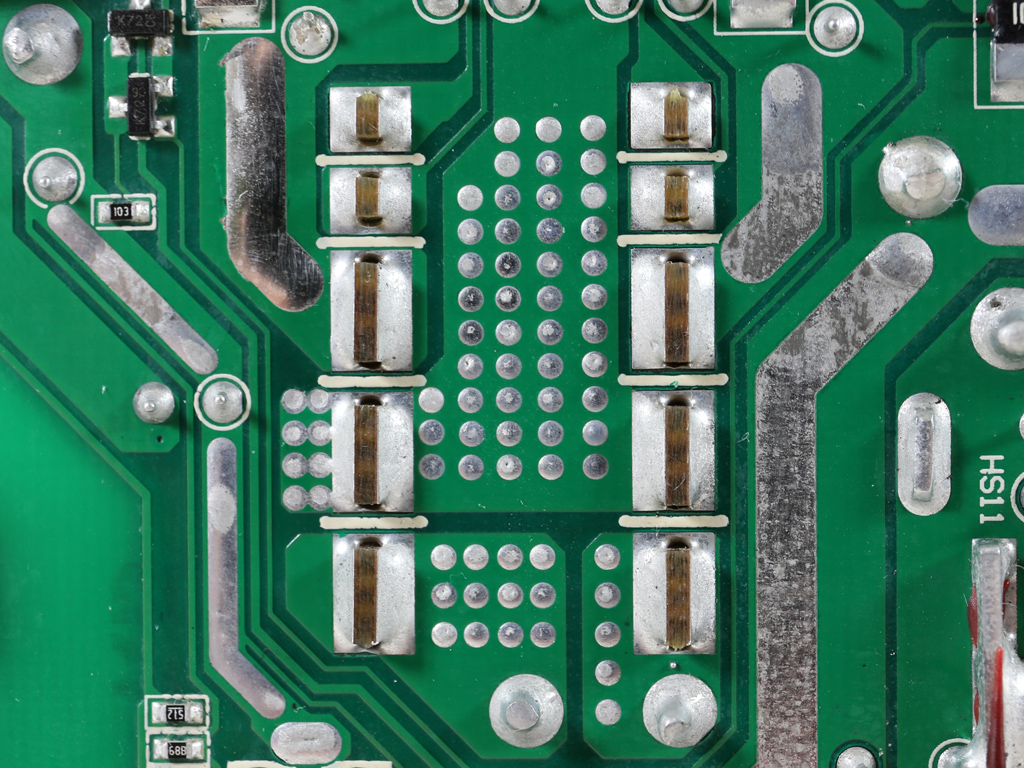

In total, eight Infineon BSC014N04LS FETs regulate the +12V rail. Enhance used so many FETs to reduce the amperage that each one handles, reducing energy losses. This is an expensive approach though, since these FETs don't come cheap.

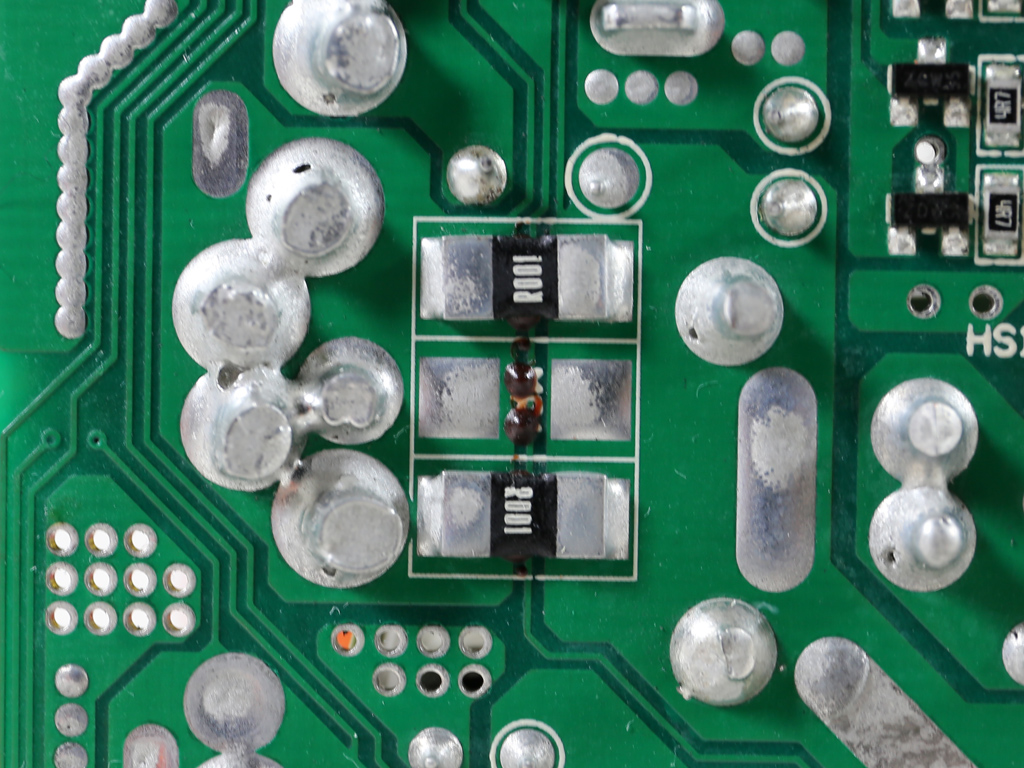

The filtering caps on the secondary side include a mix of electrolytics provided by Chemi-Con (KY, KZH, 105 °C) and Rubycon (ZLH, YXG, 105 °C), and polymers from Unicon, a company with manufacturing in Taiwan. We expect them all to be superior to Chinese-made caps.

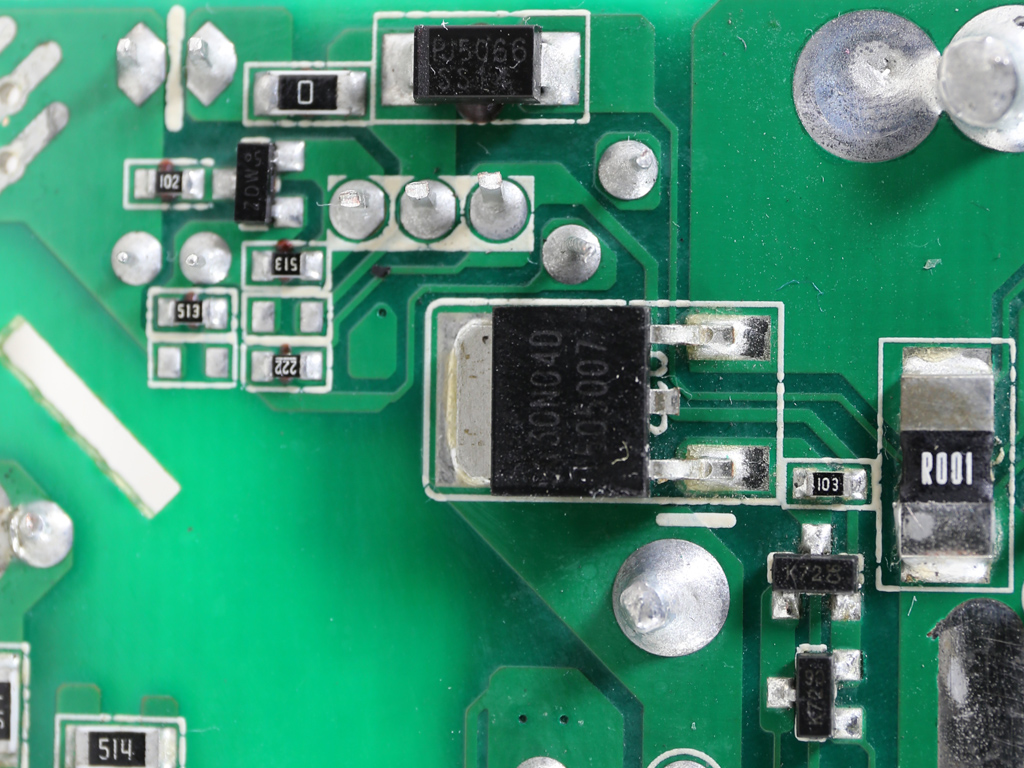

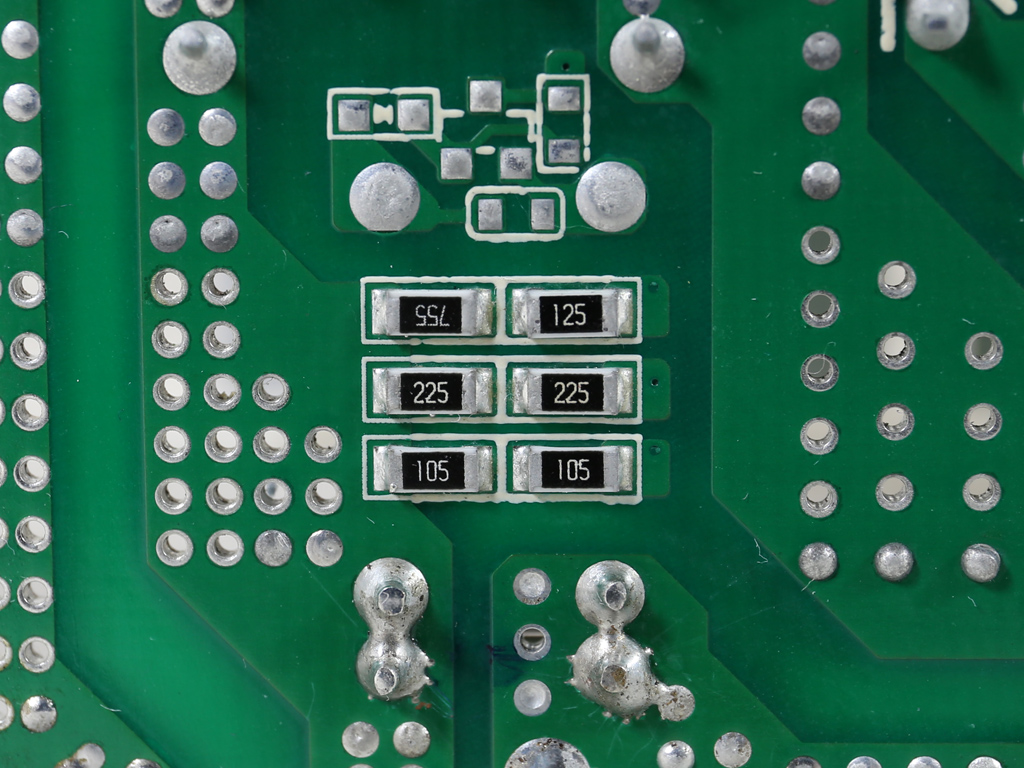

Two small DC-DC converters generate the minor rails. Each of them uses an ANPEC APW7073 PWM controller and two Infineon FETs (one BSC050NE2LS and one BSC018NE2LS).

The 5VSB rail is regulated by a PFR10V45CT SBR and the standby PWM controller is a Sanken STR-A6069H IC. On the solder side of the mainboard is a SG30N04D FET, which most likely is used to feed the 5VSB rail from the 5V one once the PSU starts.

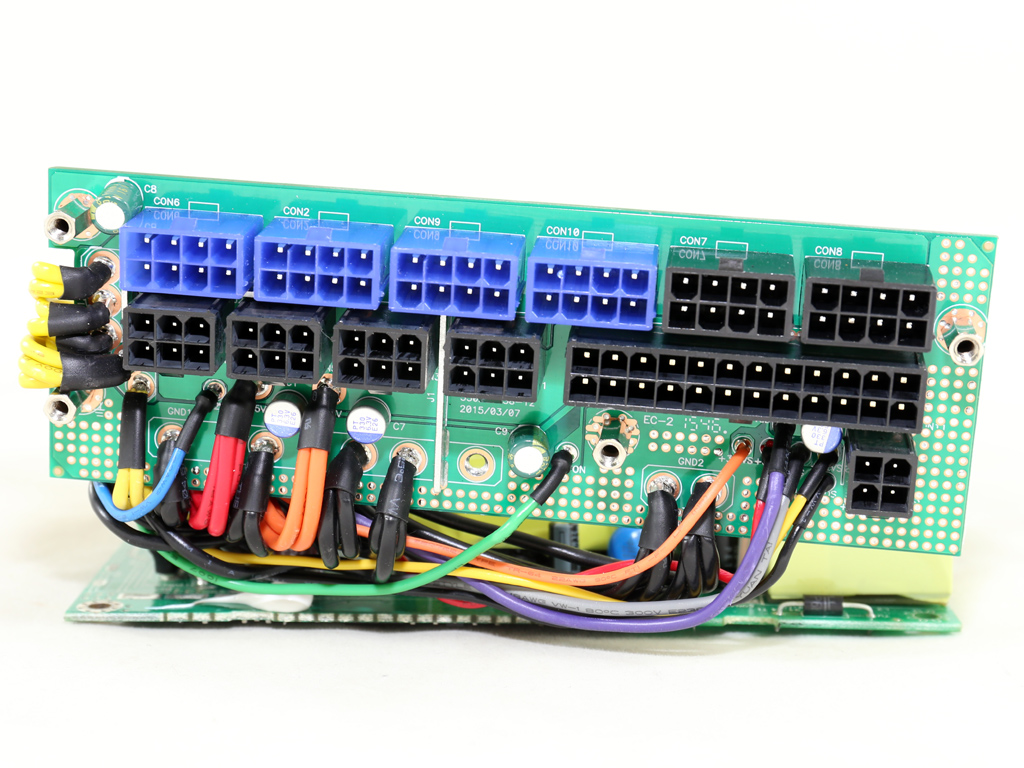

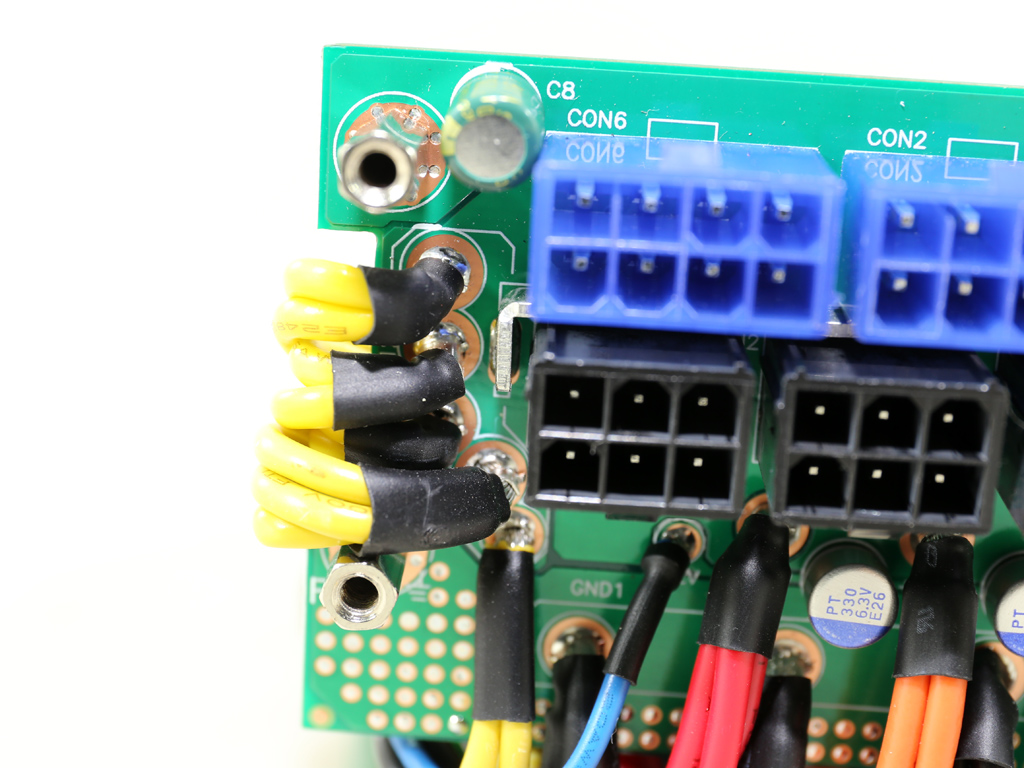

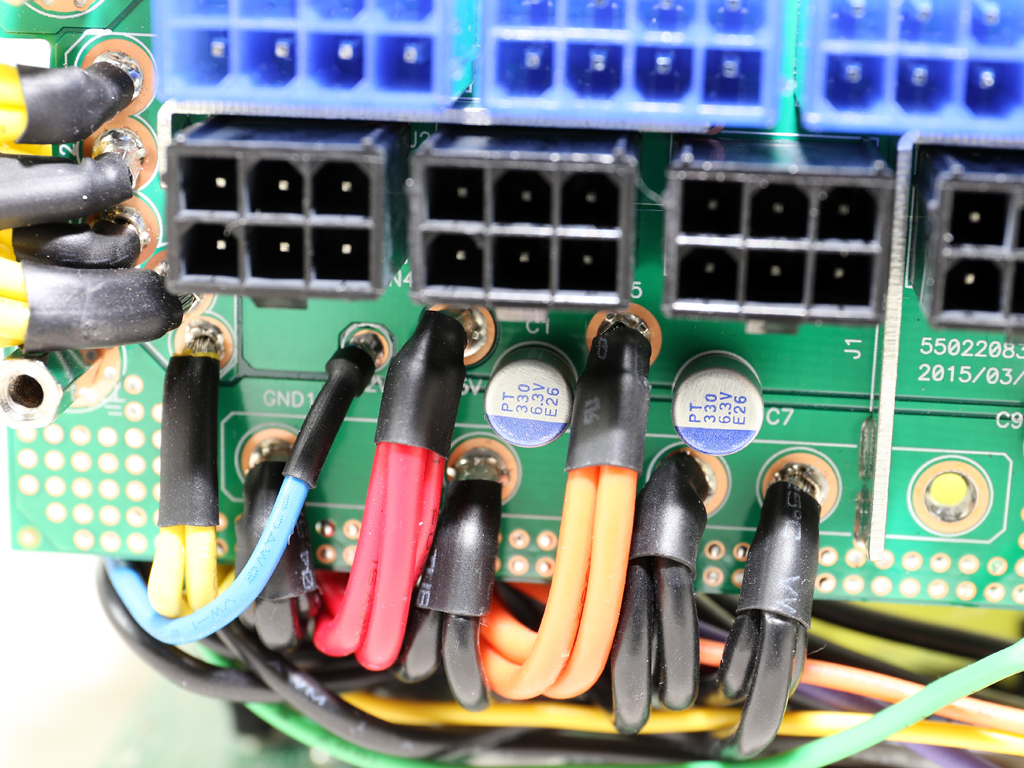

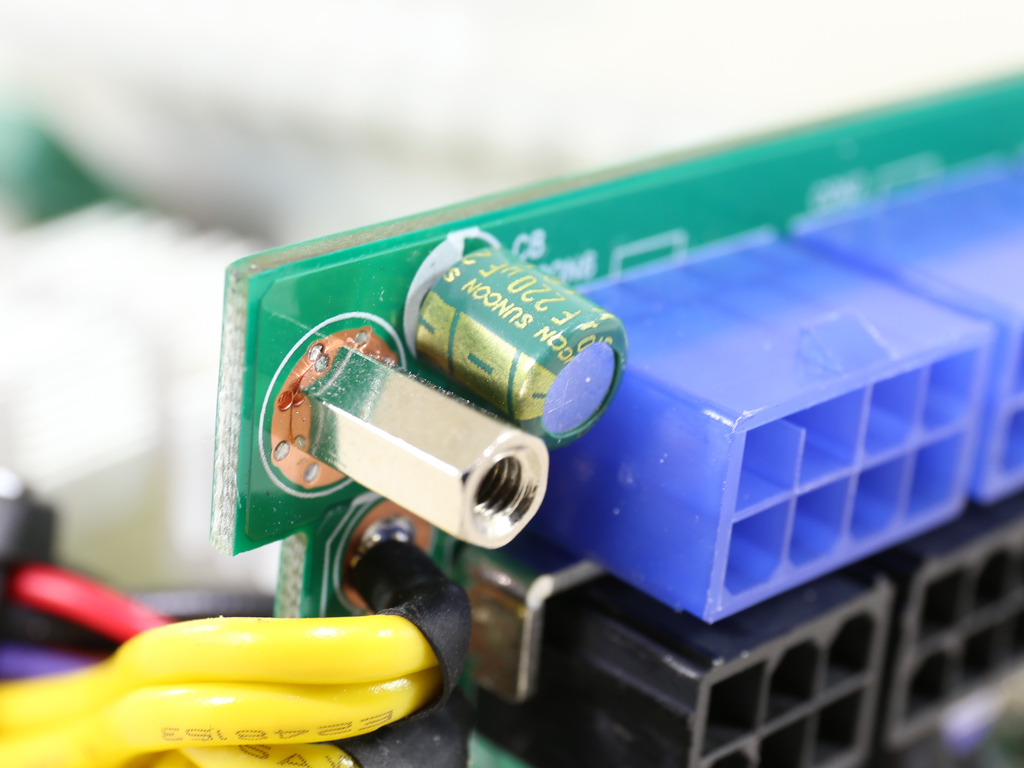

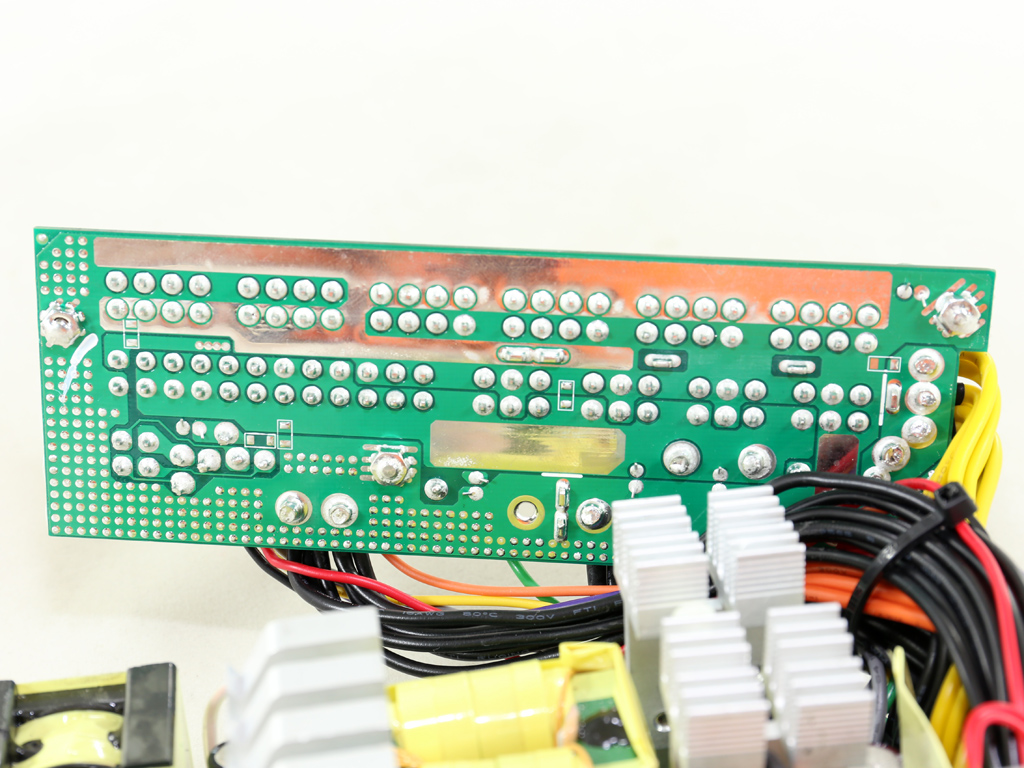

At the front side of the modular PCB, a handful of caps provide some extra ripple filtering. On the back of the same board, the soldering quality is pretty good.

The soldering quality elsewhere is spotless, as is usually the case in high-end Enhance units. There are also three PCB traces reinforced by copper wires to facilitate increased conductivity.

The cooling fan uses a Fluid Dynamic Bearing, often considered to be among the best bearing types, providing an extra long lifetime and low noise output compared to double ball-bearings. The fan is provided by Hong Hua and its model number is HA1225H12F-Z (120mm, 12V, 0.58A, 2200 RPM). Although this is a high-speed fan, we're counting on a conservative profile to help keep noise down. If you maintain decent airflow inside of your case, the PSU's output shouldn't bother you.

Current page: A Look Inside And Component Analysis

Prev Page Packaging, Contents, Exterior And Cabling Next Page Load Regulation, Hold-Up Time And Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

JamesSneed So essentially this is a overpriced PSU with to much ripple. This left me wondering why the EVGA SuperNova 850 T2 was not in the charts. You mentioned the SuperNova towards the end and it just seems like the proper competitor since its another TI rated PSU.Reply -

Jack_565 Nice to see a review on at least one of the Strider Titanium units.Reply

I recently purchased a 800w Version(these are the only Titanium PSUs in the Australian Market under 1000w) and its been everything i've wanted, running at almost 50% load it gives me its peak efficiency which is exactly why i paid the premium to get a Titanium PSU.

I can see the 600w version being a more commonly purchased unit with the way power consumption has dropped, Skylake Rigs only use around 300w(give or take variables) which would be the Striders peak efficiency. -

turkey3_scratch Jonnyguru also did a review on the same unit here, so the "high" ripple is consistent among these units. Probably due to a lack of filter capacitors, either to increase efficiency or conserve space. I'd like to see how the efficiency would be improved if they used a relay.Reply

What I don't understand is the small transformer. Aris, you mentioned that this unit, to have higher efficiency, switches to not-as-high of a frequency (which also affects transient response negatively). Since transformer size is inversely proportional to the AC frequency, wouldn't the transformer have to be larger? Is there any downside to a smaller transformer?

Yet again, more PWR_OK cheaters. It seems like at least one in two PSUs are like this. I agree that no power switch on this unit seems very silly to me. -

Aris_Mp The switching frequency probably isn't as high in order to achieve the higher possible efficiency, but this doesn't necessary means that it isn't high enough to allow for a small main transformer. In addition the design of the transformer plays a key role also in this.Reply