Acoustically Manage Your Hard Drive

Acoustic Management: How It Works

While all hard drives have supported some form of configurable power management since the early days of ATA-4 (UltraDMA/33), automatic acoustic management (AAM) has been supported since the introduction of ATA-6 (UltraATA/100). In the case of power management, a value between 1 and 254 determines the level of power savings. To take a simple example, if you stay below 128, the hard drive will automatically stop the spindle motor after a defined idle time. Note that this has nothing to do with operating system power management, which makes more sense for day-to-day operation, as it is aware of applications and workloads.

AAM is programmed with values that define drive parameters in a very granular way, allowing for the adjustment of noise,performance, temperature, power requirements, and life expectancy. The range of possible values is 128-254. The actual effect of each of the settings remains hidden within the hard drive firmware, though, and most of the simple utilities on the Web will only let you choose between maximum performance and minimum noise.

Why Noise is Such an Issue

Although it may differ from one person to the next, overall human hearing is limited to the frequency range between approximately 20 Hz and 20 kHz, with increased sensitivity to particular frequencies. Most people are able to hear frequencies between 1 kHz and 3 kHz very well, which means that a reduction of noise just in this frequency range makes more of a difference than trying to insulate or reduce other frequencies. This is where acoustic management kicks in.

Most of the sonic waves between 1 and 3 kHz consist of noise from two different sources. The first is hard drive noise caused by the spindle motor and friction within the drive. This noise can usually only be reduced by modifying hard drive components. The second, though, constituting most of the noise we perceive, is caused by vibration between the hard drive and the computer case. This in turn consists of rotational vibration that is caused by the spindle motor, as well as vibration noise from the read/write heads, which accelerate and brake many times per second.

The fastest way of relocating heads is by accelerating them in the direction of the new track until half of the distance has been covered and then slow down the head movement until they’ve reached their destination. There are multiple options available for changing this operation, starting with modifying acceleration and braking, as well as the impulse power that is required. Adding Native Command Queuing to the equation—which analyzes and reorders all incoming commands in an effort to find the most efficient processing order—helps to decrease head movement, which can improve both access time and access noise.

AAM Tools

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

There are several utilities available on the Internet to modify the AAM settings. Hitachi, whose Deskstar 7K1000.B we used for this article, provides its own Feature Tool 2.11. The software is powerful, as you can modify cache settings, transfer modes, power consumption, and interface settings, but it is DOS-based and requires command line execution and starting your system from a bootable 3.5” floppy disc or CD image. The image and the Feature Tool 2.11 are available on Hitachi’s download page. This isn’t only the case for Hitachi. We found similar command line apps from hard drive vendors Samsung and Seagate. Other tools, such as the HDD Acoustic Manager by Abacus, the AAM Tool, the Hard Disk Sentinel, and others are written to be more convenient to use.

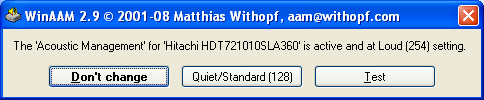

WinAAM

We decided to use one of the simplest tools that we found: WinAAM. Version 2.9 is the most recent release and worked well with our Hitachi drive. It does nothing other than setting the AAM parameters either to quiet (value 128) or to loud (254), which equals maximum performance. This is exactly what we want, as it allowed us to check performance, acoustics and power consumptions using the two extreme settings.

Current page: Acoustic Management: How It Works

Prev Page AAM--Automatic Acoustic Management Analyzed Next Page Hitachi Deskstar 7K1000.B