Supersize Your TV for $300: Build Your Own XGA Projector!

Assembly: The Projector's LCD Panel

After carefully removing the LCD panel, you can now start putting the actual projector together.

Even during the initial test phases, the display must be firmly positioned where it can't slip. Furthermore, the panel may not be laid directly on the projector pane, as it will quickly get damaged by heat from the lamp. A thin strip of wood or plastic is good as a spacer; a height of 8 to 10 mm (about 3/8") is more than enough. We used polystyrene of the sort frequently found in packaging; these strips can also be adjusted with adhesive tape. The following pictures illustrate what you have to do.

Polystyrene foam makes sure the panel is firmly secured.

Adhesive tape...

... and the first test installation of the LCD panel

The necessary gap between the pane and the LCD panel can be clearly seen here.

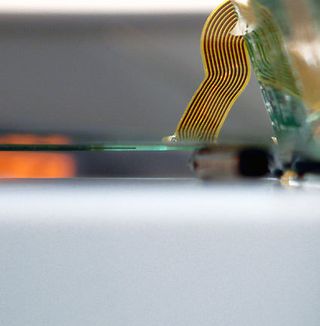

Connecting the leads to the controller: mount with adhesive tape.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Once the panel and spacers have been successfully mounted, cables can be connected to the controller and inverter. This step requires the utmost care: the contacts on the flat cable are separated by tenths of millimeters, and the slightest tilt will cause a short circuit.

A view of the mounted LCD panel and flat cable.

Current page: Assembly: The Projector's LCD Panel

Prev Page Step By Step: Removing The TFT Panel, Continued Next Page Very Important: Permanent Cooling For The LCD Panel-

Hi,Reply

I'm a 12 year old and I just got this projector working. If you live in the bay area then I recommend you go to Weirdstuff that is where I got all my parts for all under $46 -

just looking into this idea and was just wondering what the implications would be to have the lcd screen supported away from the glass of the projector thus aiding the cooling of the screen ?? Say a 2 to 3cm gap? would this affect the picture quality or would the screen still need the same amount of cooling as it does on the screen. As you can tell by the questions i havn't made one but seriously thinking about it. also ... !! woulld there be an option of other video inputs to the screen ie .. Phono jack rather than laptop / pc?Reply

Cheers for the info if you respond. -

chinmayj007 hiiiiiiii im CJ can you tell me please which in this projector plz.......................Reply

Most Popular