Bambu Lab issues A1 Printer heat bed recall: Here’s how to get a free replacement part

One unit reportedly caught fire, while others have reported unstable temperature readings.

Bambu Lab released a statement early Sunday morning that’s concerning for anyone who purchased an A1, the company’s super-fast bed slinger we reviewed in December. A flaw has been discovered in the cable that provides power to the heated bed, which could cause damage if put under stress. The cable is preinstalled at the factory and connects the heated bed to the base of the machine. Note the smaller A1 Mini is not part of this recall.

A user on the Bambu Lab community forum reported on January 24th that his A1 had caught fire, destroying the printer and knocking out the power to his home after only six days of use. The user posted a photo of a scorched cable on the back of the printer.

It is unknown if this problem is related to the cable damage that Bambu Lab has been investigating. A company representative said in a blog post that the issue is not immediately dangerous, as fuses on both the power supply and heat bed provide protection from overheating. However, a damaged cable could cause temperature reading errors, leading to a short circuit and power loss.

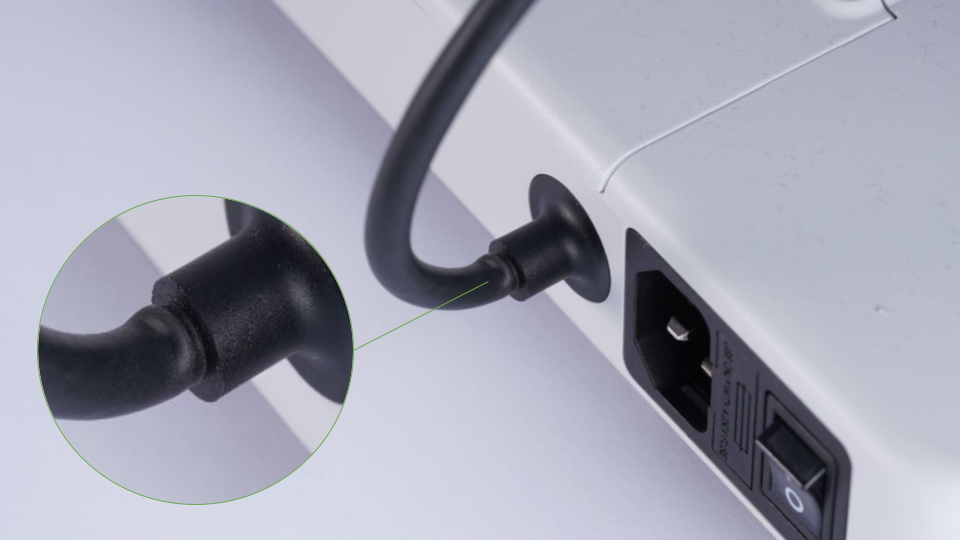

Bambu Lab recommends A1 owners stop using the printer and inspect the cable, located on the back of the case near the power switch, and check for signs of wear. A damaged cable will have a wrinkled appearance, as seen below. If your cable is damaged, you can reach out to customer support immediately via this link and provide a picture of the cable at the root.

If your A1 3D printer is confirmed to be damaged, you can request a replacement heat bed assembly. Bambu Lab will also provide compensation for making the repair yourself, though that figure was not listed in the blog post. If you are unable to make the repair on your own, you can request a replacement printer.

The company is also providing a file for a 3D printed cable protector for anyone with an undamaged cable.

Bambu Lab states that few printers have been affected, and blames rough handling during shipping for the damage. But it claims there is one culprit that the user could have brought on during assembly.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

“During installation, if the base is vertically placed on the table with the cable side at the bottom, all the weight of the printer will be concentrated on the root of the cables and cause damage.”

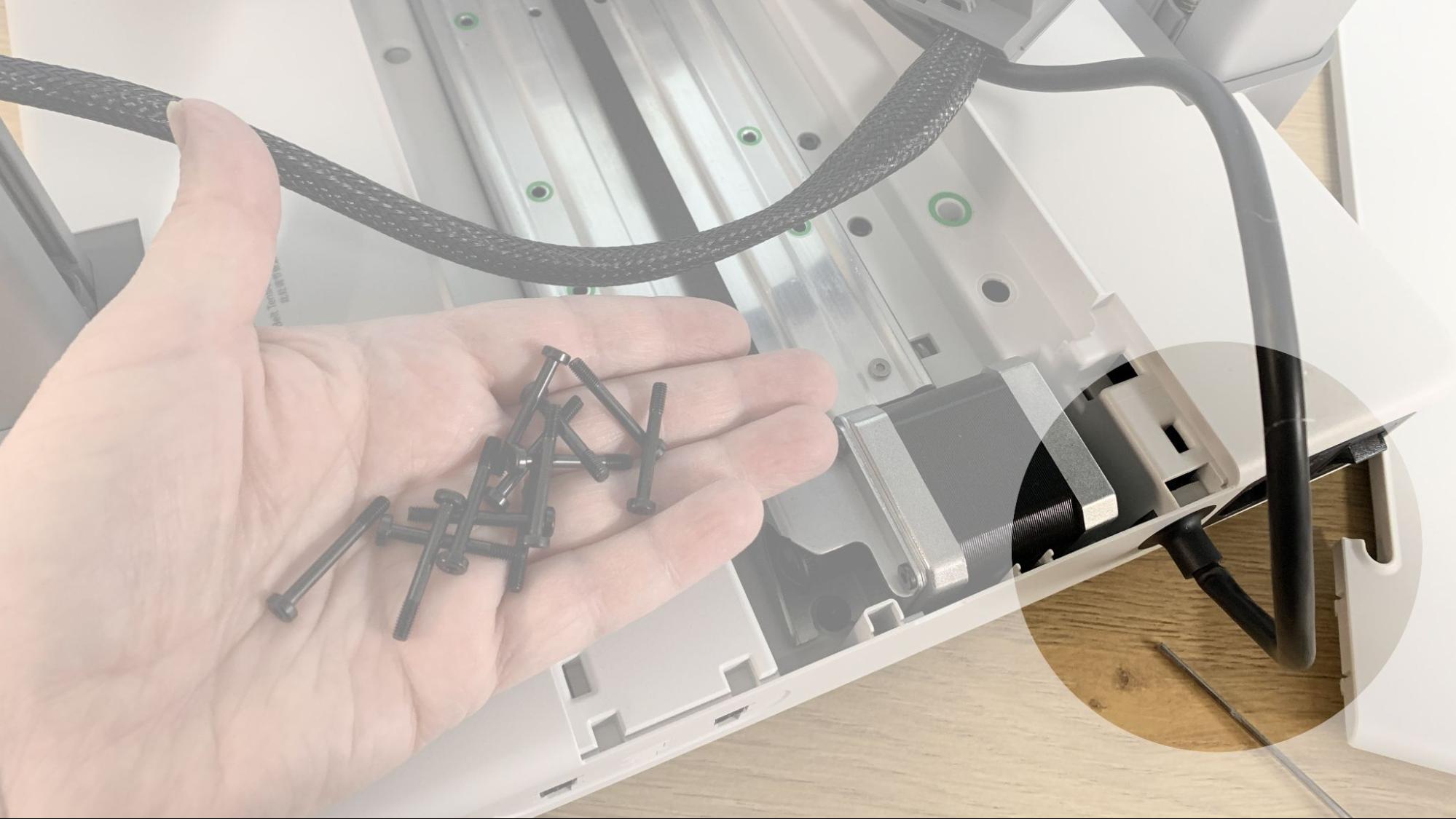

Bambu Lab’s assembly instructions clearly show placing the printer on the edge of a table to complete the wiring under the printer’s base. If you found that placement unhandy – as I did – and didn’t want to risk the printer falling on your foot, you may have simply tipped it backward and accidentally damaged the cable.

I inspected the A1 that Tom’s Hardware reviewed, and have continued to use in my workshop, and found that it also shows signs of stress. In fact, a photo I took while assembling the A1 for its review shows the tell-tale signs of a bent cable before it was ever plugged in.

A quick look at the Bambu Lab website shows that the A1 3D printer is temporarily out of stock. Hopefully, the company is already working on a built-in fix for future A1 buyers.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

NeatOman I've always been weary of AC mains to directly heat the bed. It faster and will warp the bed, although that's not as big an issue with bed mesh leveling. But the imagine immediately reminded me of iPhone chargers that always have to hard transition from thick to thin where the cable always frays. They definitely should have used individual thicker wire in silicone, but hindsight is always 20/20Reply

I previously "downgraded" from a 2.5mm thick 290x280mm 320watt heated bed to a 3mm thick 310x310mm 240 watt bed (both glass). Takes about 20% longer to heat but I run the bed at 110c for amazing ABS adhesion (about 11 minutes to heat). The original Glass bed started warping after a few weeks and the new bed has yet to show any signs of warp while also having more even heat spread out.

Side note; my printer uses thick gauge wire that syphons heat from the bed, would be nice if the wires ran to the middle of the bed. Although spread out, as to not effect the thermistor as much -

knox1138 The guy claims it knocked out power to his house, and I'm curious if he means a single breaker tripped or it somehow tripped the 100-200a mains. Depending on what exactly happened he might have bigger problems.Reply -

edzieba Reply

The main benefit of mains-heated beds is not speed, but size and cost. DC bed heaters need the DC PSU of the printer to handle that increased peak and steady-state load, as well as adding a new power stage for temperature control. a 240W DC bed heater could easily bump the PSU requirements to triple what they would be with an AC bed. AC beds eliminate that BoM cost and board space.NeatOman said:I've always been weary of AC mains to directly heat the bed. It faster and will warp the bed, although that's not as big an issue with bed mesh leveling. But the imagine immediately reminded me of iPhone chargers that always have to hard transition from thick to thin where the cable always frays. They definitely should have used individual thicker wire in silicone, but hindsight is always 20/20

I previously "downgraded" from a 2.5mm thick 290x280mm 320watt heated bed to a 3mm thick 310x310mm 240 watt bed (both glass). Takes about 20% longer to heat but I run the bed at 110c for amazing ABS adhesion (about 11 minutes to heat). The original Glass bed started warping after a few weeks and the new bed has yet to show any signs of warp while also having more even heat spread out.

Side note; my printer uses thick gauge wire that syphons heat from the bed, would be nice if the wires ran to the middle of the bed. Although spread out, as to not effect the thermistor as much -

dmitche3 I've been looking to upgrade from my Ender 3 V2 printer but I've been holding off until these new printers have some history behind them. This article re-affirms this idea, but I have to say I didn't expect anything this serious. I expected wires breaking in the hotend and tunning and glitches dealing with acceleration and such. This, as well as by the summer Creality will release yet another Ender to replace the three, four or five that they have released in the past year. I'm not happy with any of the models of late as I want the faster printing but with a larger bed, auto-leveling with manual override. Something that just isn't there yet.Reply -

dmitche3 Reply

If it actually knocked out his entire house he should be thankful. He now knows that he needs to hire an electrician to look into his situation before he loses his house and more.knox1138 said:The guy claims it knocked out power to his house, and I'm curious if he means a single breaker tripped or it somehow tripped the 100-200a mains. Depending on what exactly happened he might have bigger problems.