How to Cut Hard Tubing for Your Custom Loop

Want to get into custom watercooling and hard tubing? Here are a few tips!

Custom watercooling has always been a popular topic in the enthusiast community, and hard tubing has made it a lot more appealing for people who want cool temps as well as cool looks. It goes without saying that using hard tubing is a real challenge compared to the easier soft tubing approach.

So, in this article, I’m going to show you some of the basics needed to work with hard tubing and the steps I go through when planning an entire hardline custom loop. Let’s get started!

Choosing the Right Tubing

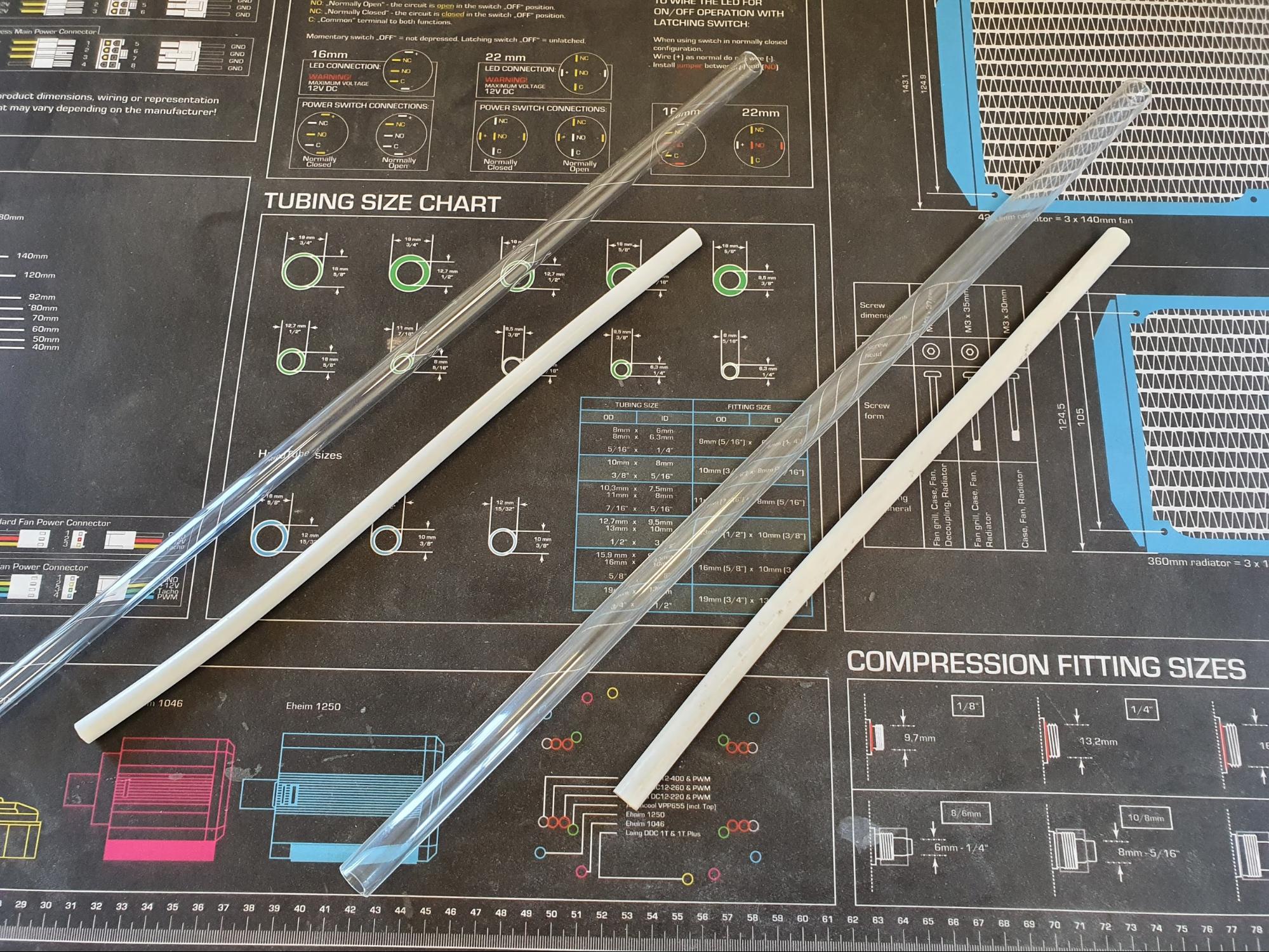

There are a few options available when choosing the type of hard tubing, both for materials and size. The available sizes are 12mm, 13mm, 14mm and 16mm. You should choose based on your tastes in looks, as well as the size of the case, since bigger tubing looks better in bigger cases and vice versa. I have never detected a difference in terms of performance and water flow.

The most common materials are acrylic and PETG, followed by brass, copper, glass and carbon fiber. We will be looking at the first two options here.

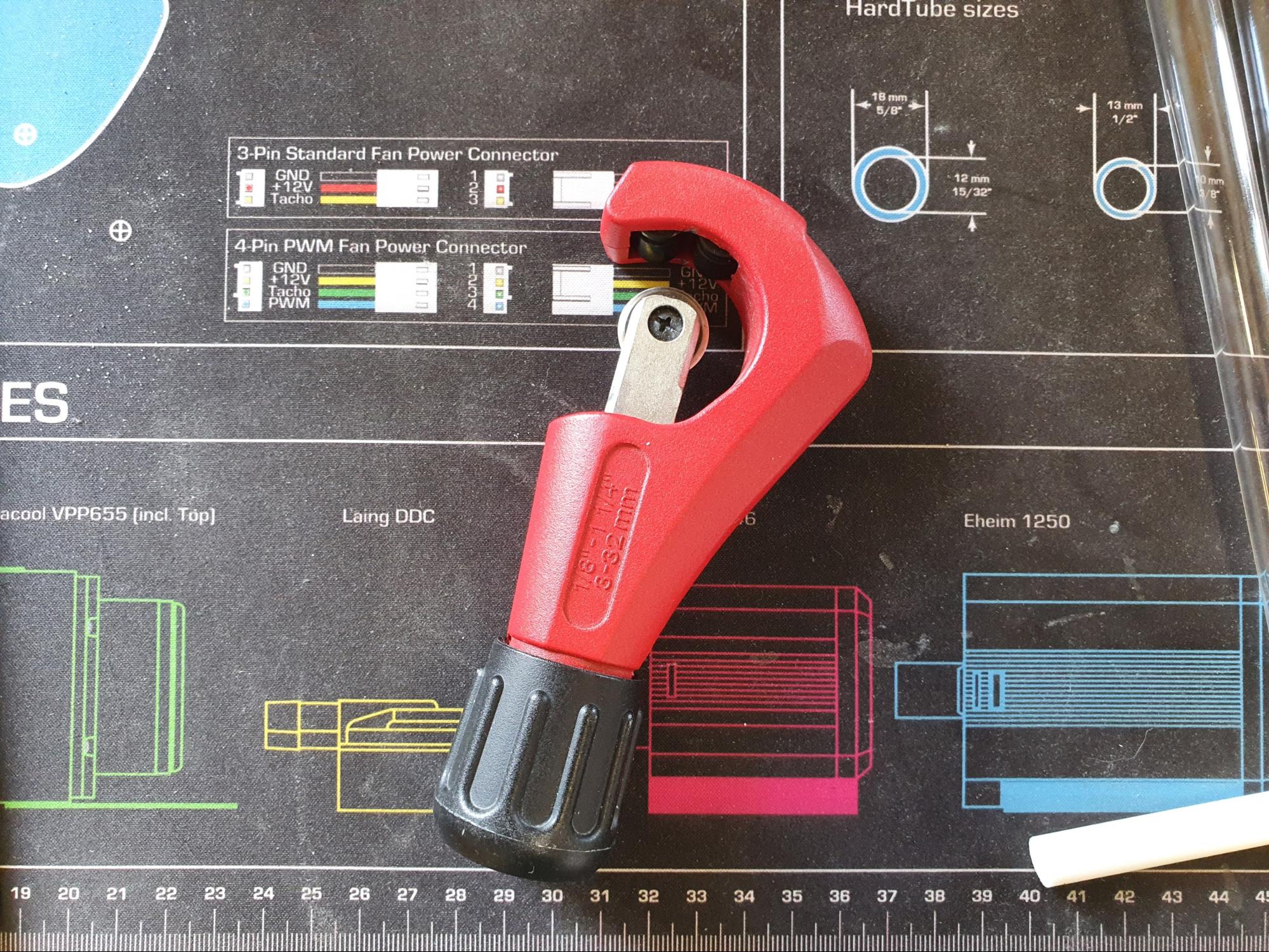

So, how do you choose between acrylic and PETG? The main difference is the ease of use: acrylic is more heat-resistant, so it’s a little harder to bend than PETG; acrylic is also harder to cut because you will need some sort of toothed saw, while almost any type of pipe cutter will work on PETG.

That said, I will always recommend choosing acrylic, because a custom loop that runs hot can be enough to warp PETG, causing the tube to pop out of the fitting and casue a disaster. This happened to me in the past with one of my builds. This is what PETG tubing looks like when it deforms under the pressure of the fittings:

It’s not super-warped because I replaced it before coolant flooded the case, but the potential for disaster is definitely there. On the other hand, acrylic won’t ever get hot enough to deform, even in the hottest build.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The difference when bending it isn’t even very noticeable. It will just take a little longer to heat the acrylic compared to the PETG. The fact that PETG is softer than acrylic also makes it more prone to give lower-quality bends.

Acrylic is admittedly harder to cut than PETG, but it’s still worth it to have a safer end result. More on the cutting process later.

Some people argue about acrylic being brittle, while PETG is basically indestructible, but that’s only a difference when hammering both. In real scenarios, acrylic tubing will never crack unless you put way too much force on it, which would likely damage other parts of the loop as well, like the threaded ports on acrylic waterblocks.

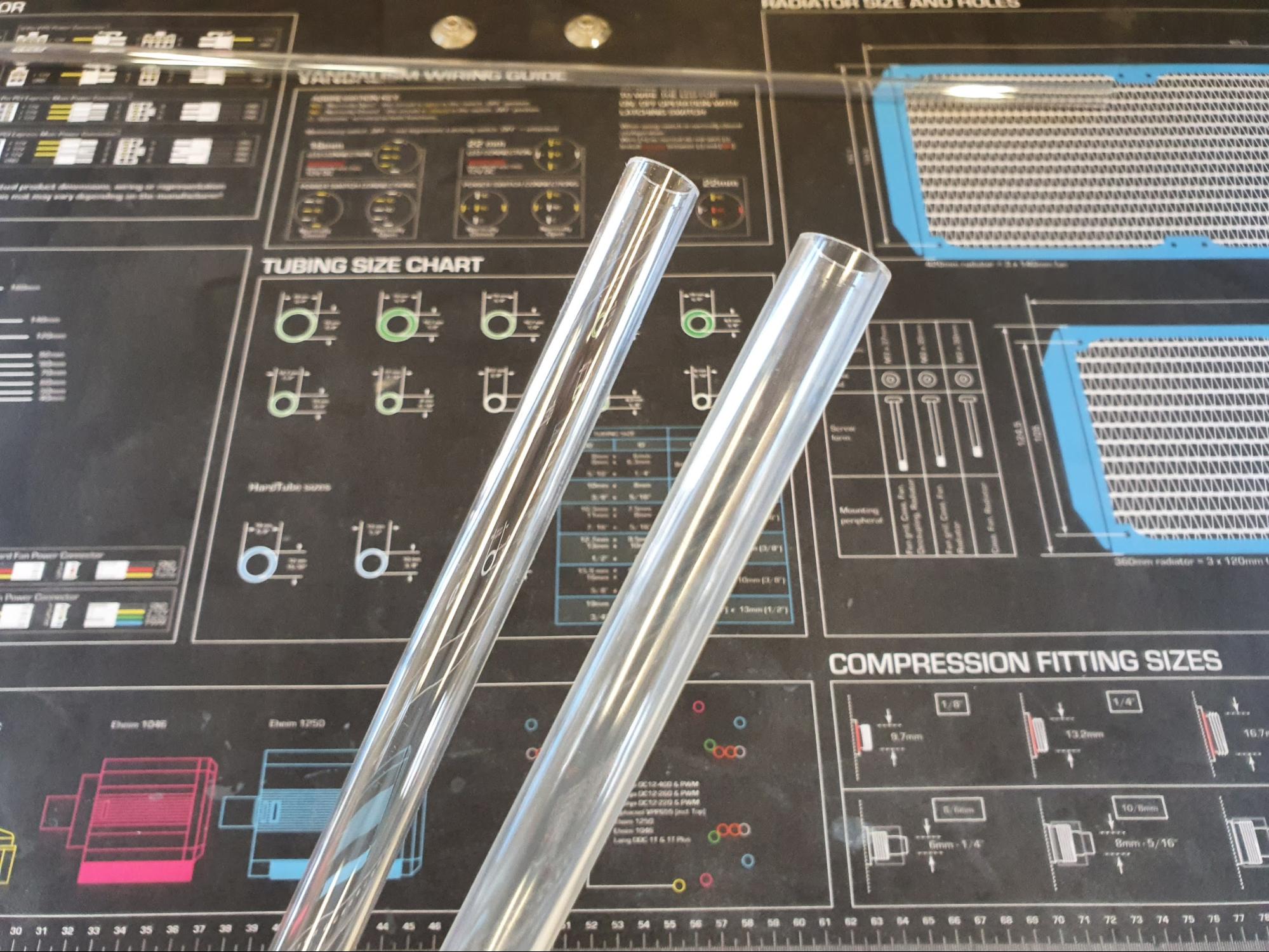

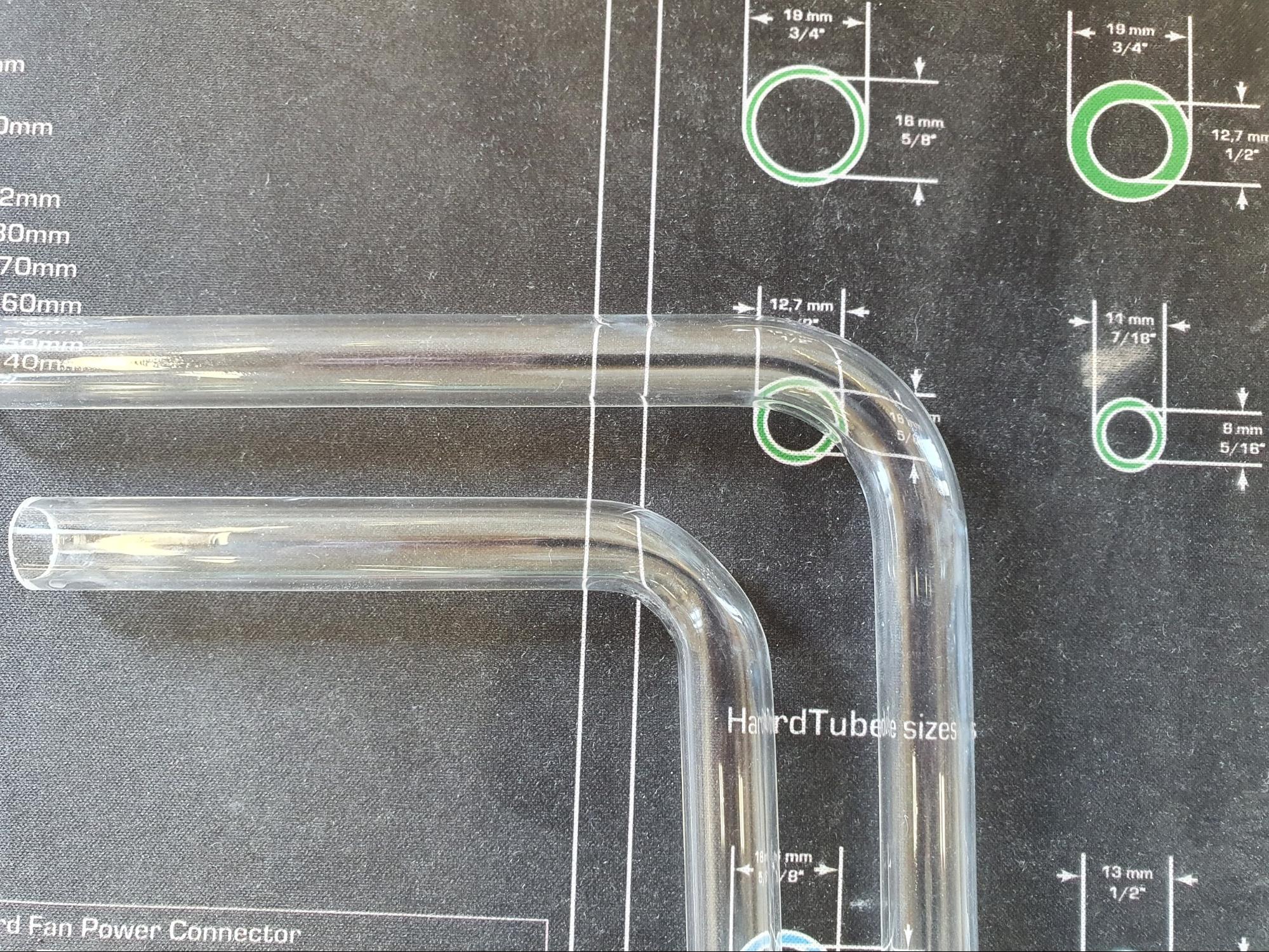

Acrylic is clearer than PETG, so it also looks slightly better. It actually depends on the various brands and production lines, but this is generally the case. The following photo has 13mm acrylic tubing on the left and 16mm PETG tubing on the right.

Tools of the Trade

While soft tubing will only require you to have a pair of scissors at hand, hard tubing is more demanding in terms of needed tools.

The first important tool to have is a silicone insert, which will need to be the same diameter as the inner diameter of the tube. I suggest getting it in the same brand as the tube, since size tolerances often change slightly between brands.

A heat gun is needed to bend the tubing, preferably one with different levels of temperature, and some kind of saw together with a deburring tool will serve you well when cutting it to length and cleaning the edges.

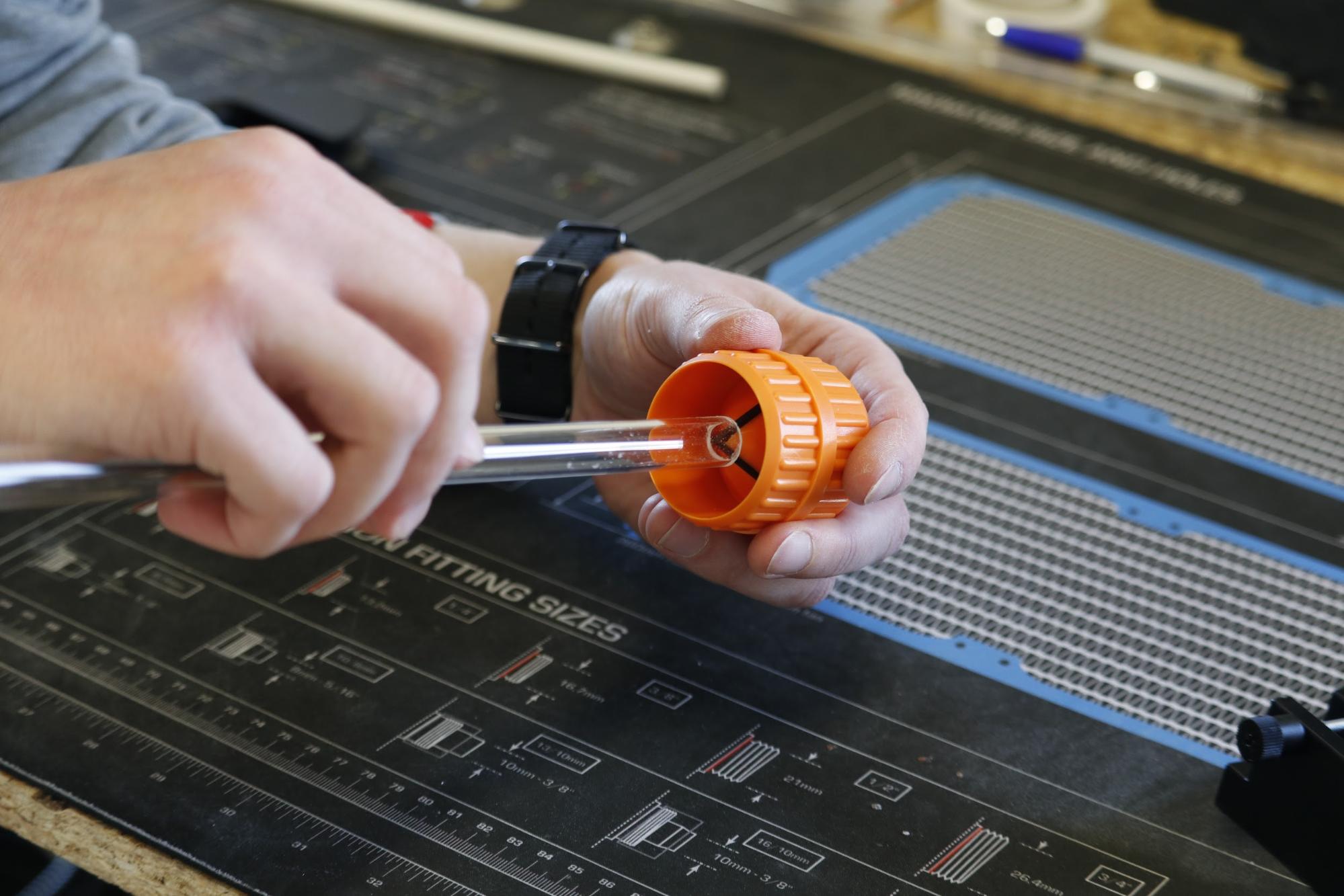

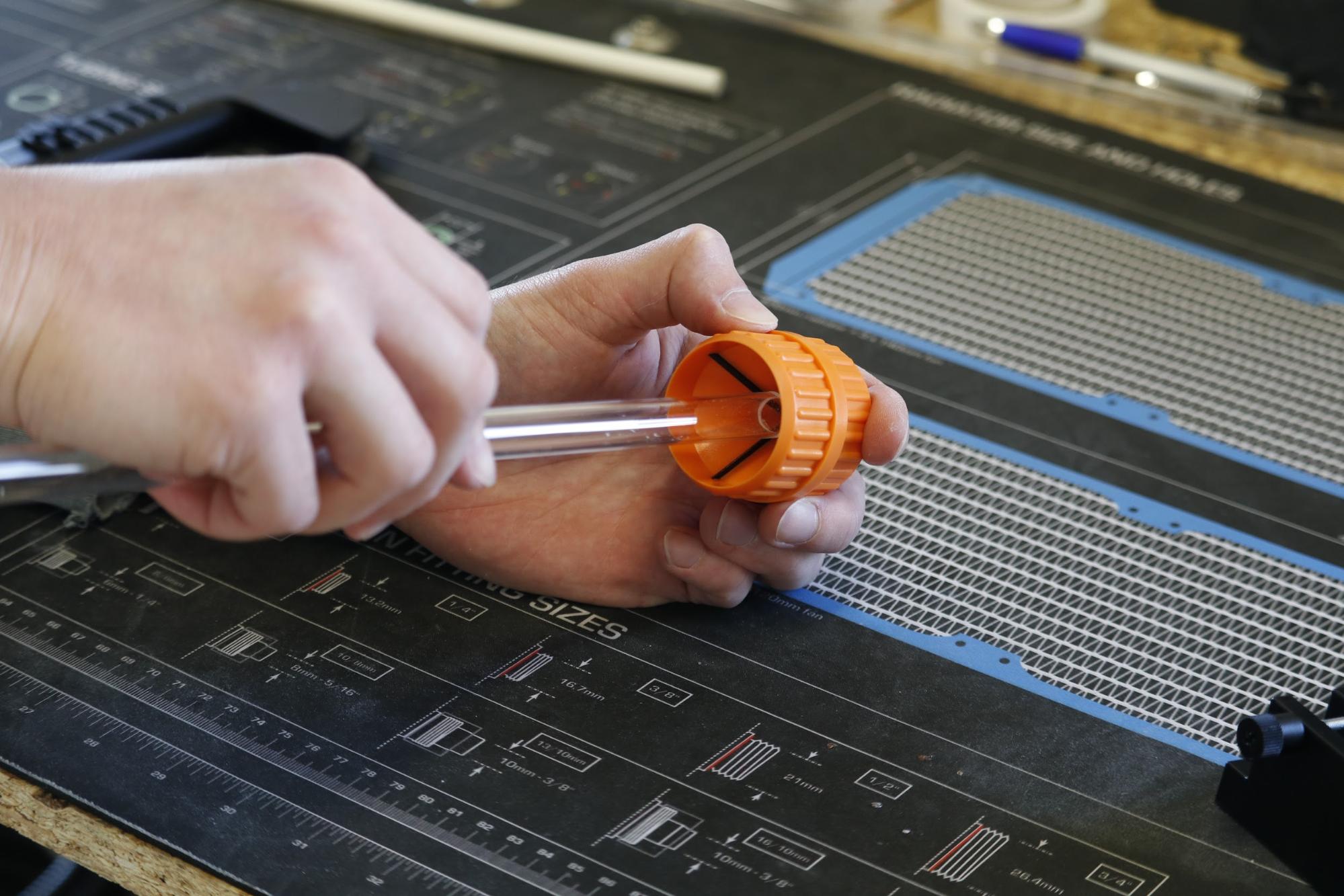

If you decide to go with PETG, a pipe cutter like the one in the photo will suffice to cut it.

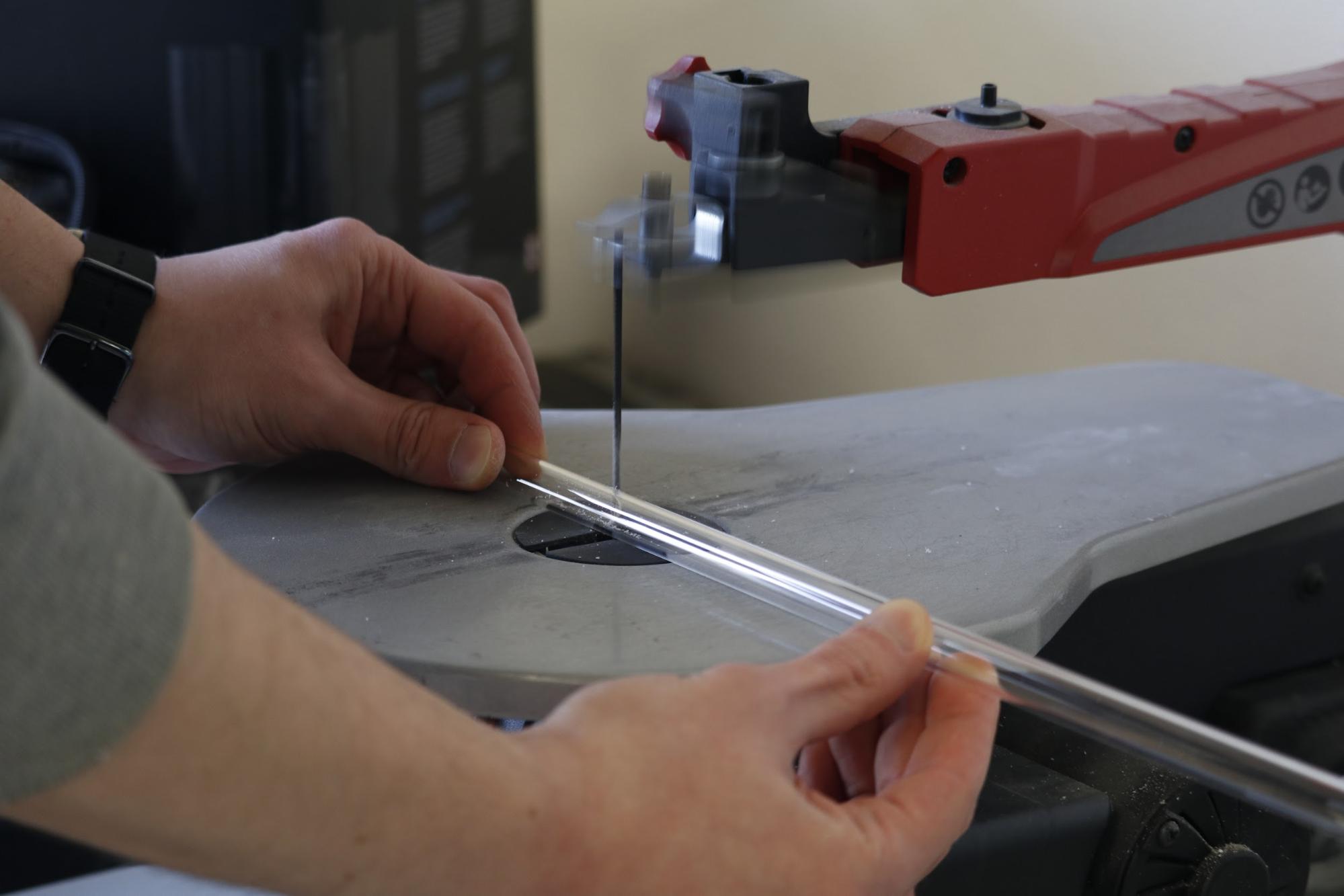

If you have access to fancier tools, a scroll saw works great to cut the tubing, and a belt/disc sander to clean up the cut. That’s what I use most of the time.

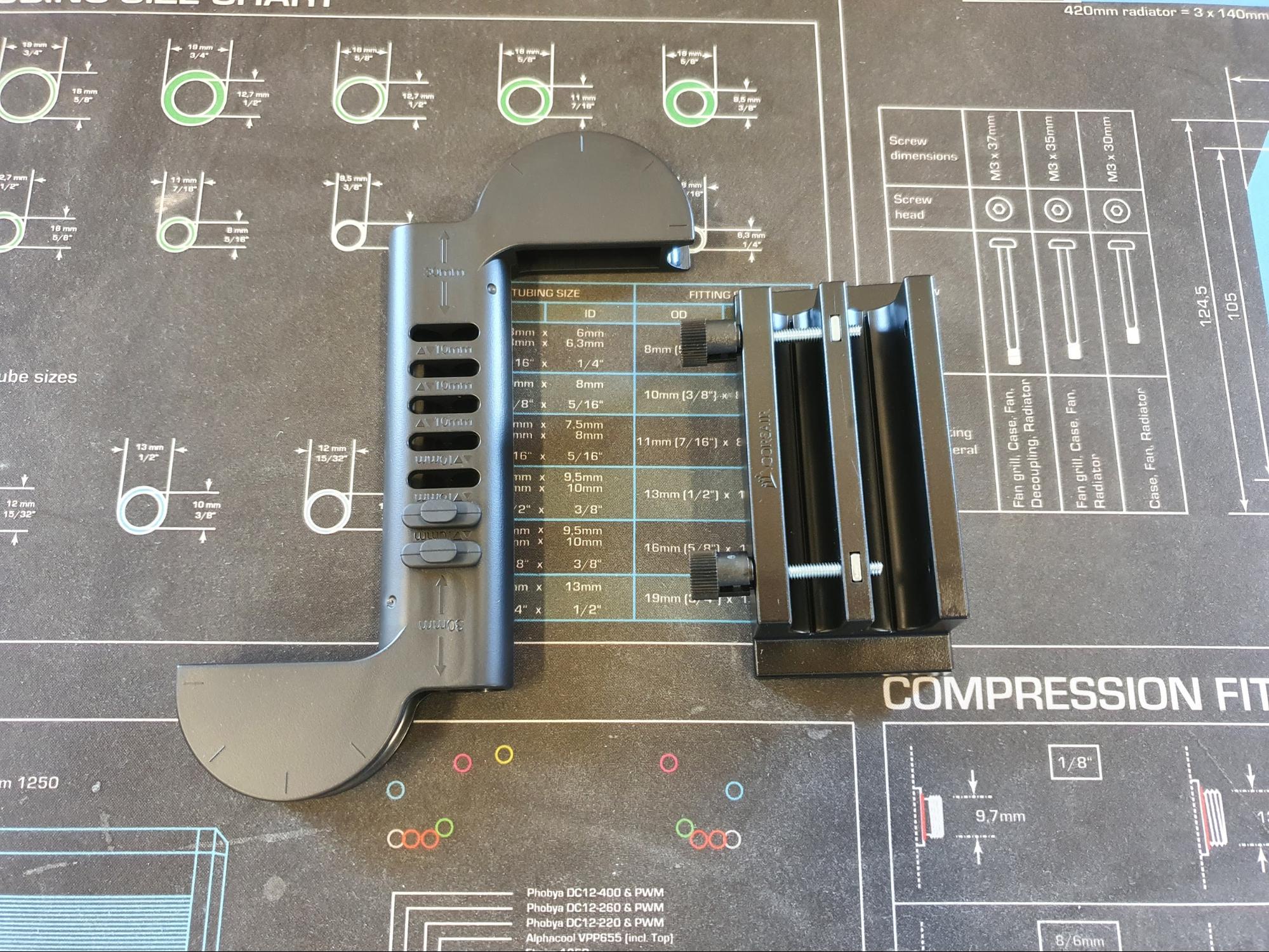

There are a few additions you can make to your tool library if you want, like bending and cutting guides such as these ones:

They make the job easier for starters, even though I personally don’t use any of these because I find them useless and too fiddly, especially the bending guides.

Bending the Tubes

Wet the silicone insert with soapy water before putting it in the tube; this will make it easier to pull it out after the bend is done.

To mark the spot where the bend needs to be, I draw two marks and set the distance between the two based on the length of tubing I want to bend. So for a standard 90-degree bend I will do about double the diameter of the tube, for example 26mm spacing for 13mm tubing.

When doing more exotic bends that are closer to 180 degrees, you will need to heat up a larger area, but it really depends on the specific case or bend, and some trial and error might be needed to get the right result.

Having done that, it’s time to take out the heat gun. Put it on the table facing upwards, and hold the tube above it, constantly turning it and moving it left and right, always staying within the two marks you did.

If you did it right, the two marks will be at both ends of the corner radius, or just about there. This will also help you get a wider or tighter radius on the same 90-degreebend, once you get more confident with the process.

When do you know the tube is ready to be bent? There are a few signs that can prevent you from wasting a perfectly good piece of tubing. When you bend a tube that’s not hot enough, you will potentially stress the area and cause stretching, which will leave a kink in the inner corner and slightly deform the outer corner, as in the photo:

On the other hand, if too much heat is added, the tube will develop bubbles that could potentially be harmful to the integrity of the tube, which is worse than just looking ugly.

You know it’s time to go ahead and bend it when it will tend to bend under its own weight, so no force should be needed to shape it. Here’s how a proper bend looks:

Compared with the previous one:

Cutting the Tubes

Go through the bending process before the cutting one, because it will give you more room for error. A longer tube will be usable when trimmed down to the right length, while a tube that's too short will be useless.

When I make the bends, I always leave extra length on both ends of the tube, so that I can then go ahead and trim them down.

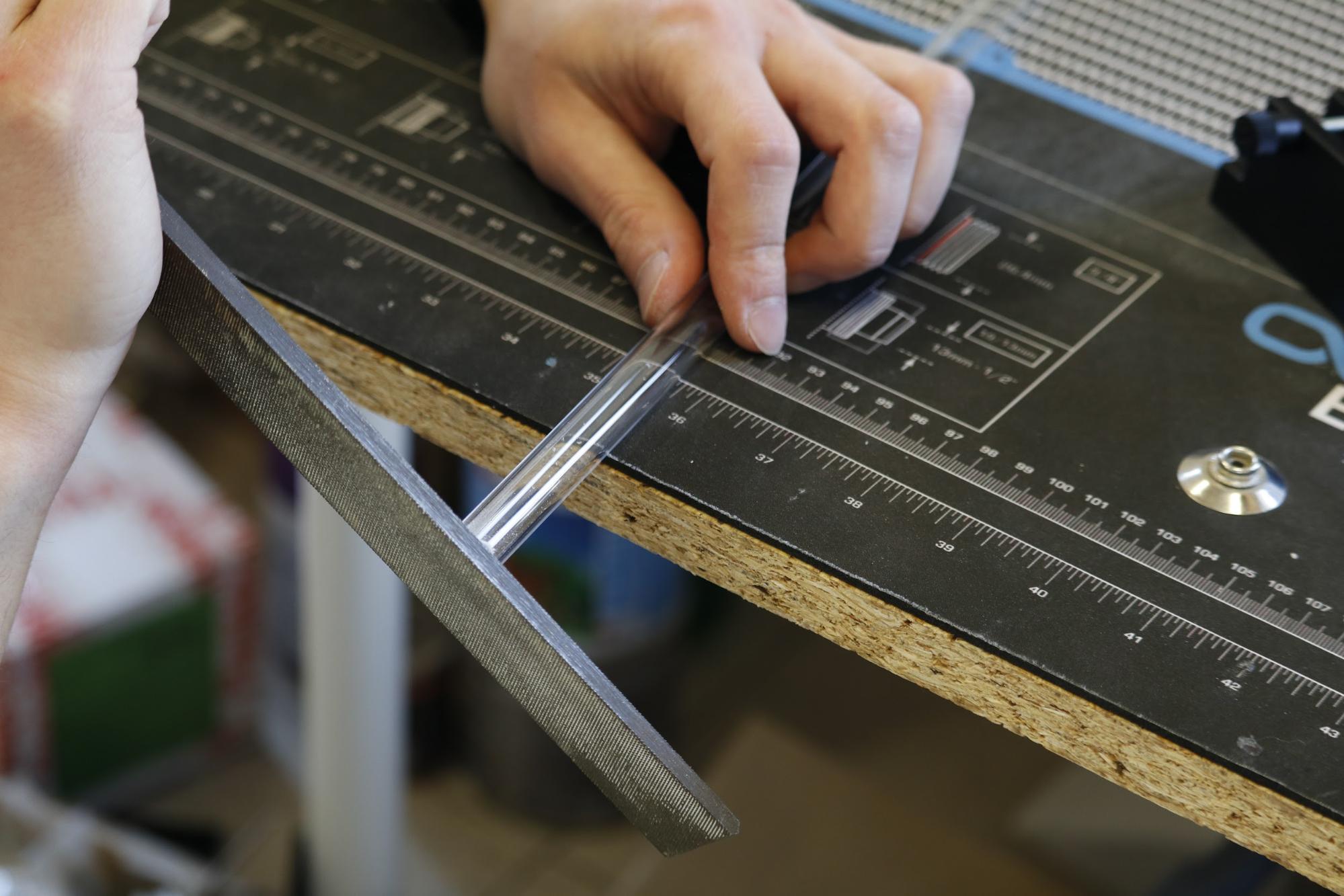

After having marked the cut, proceed with your preferred method.

If adjustment is needed, you can use a rasp or a file.

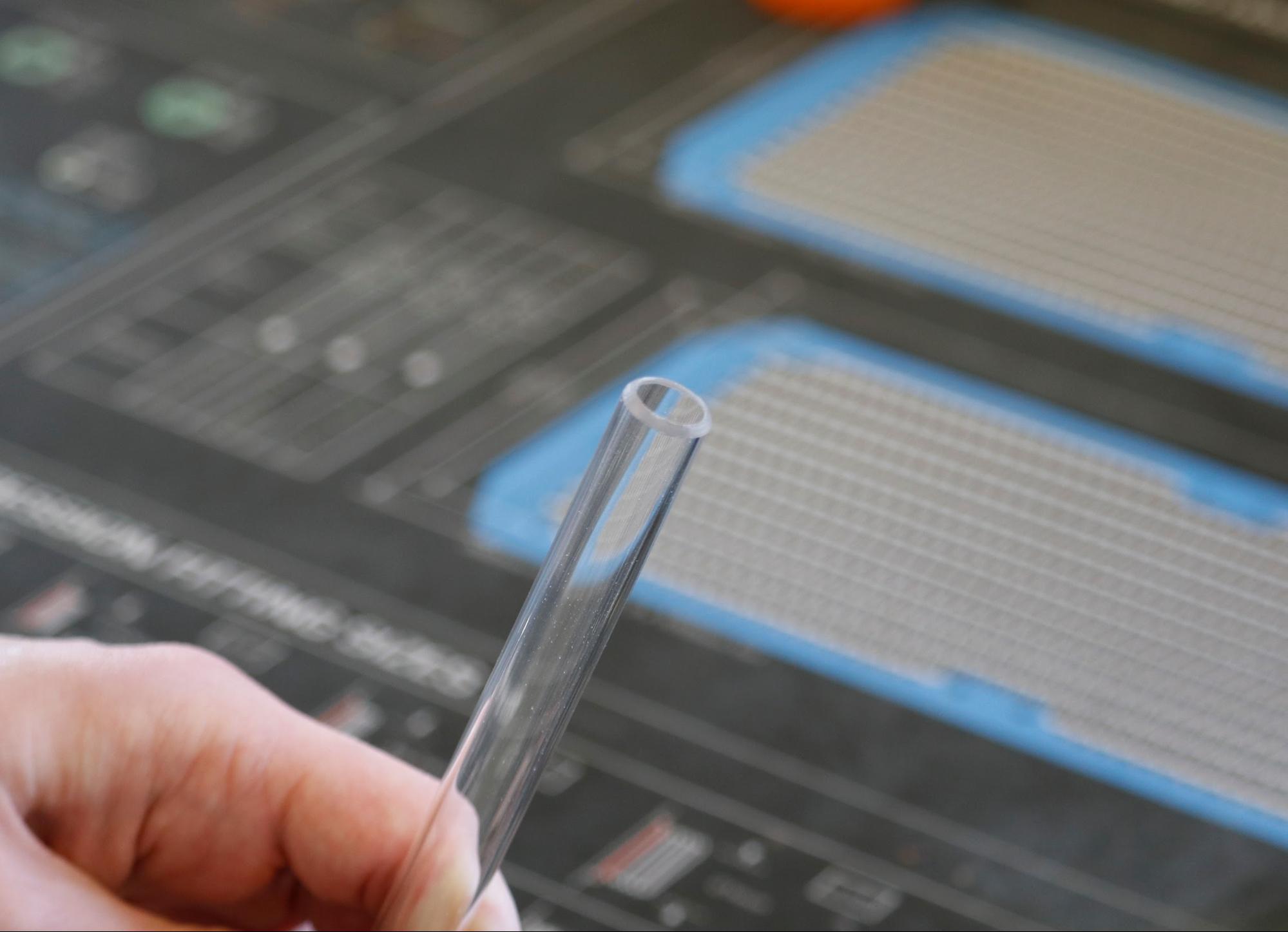

The deburring tool is very useful to clean up the edges and add a small chamfer to the outer edge, which will prevent the o-ring on the fittings from getting damaged. I don’t suggest you use this tool with PETG tubing as it leaves a very rough finish. Instead, just use a file or sandpaper to remove the sharp edges (which kind of defeats the ease of cut with the pipe cutter, but still, just don’t use PETG).

Inserting the Tube in the Fitting

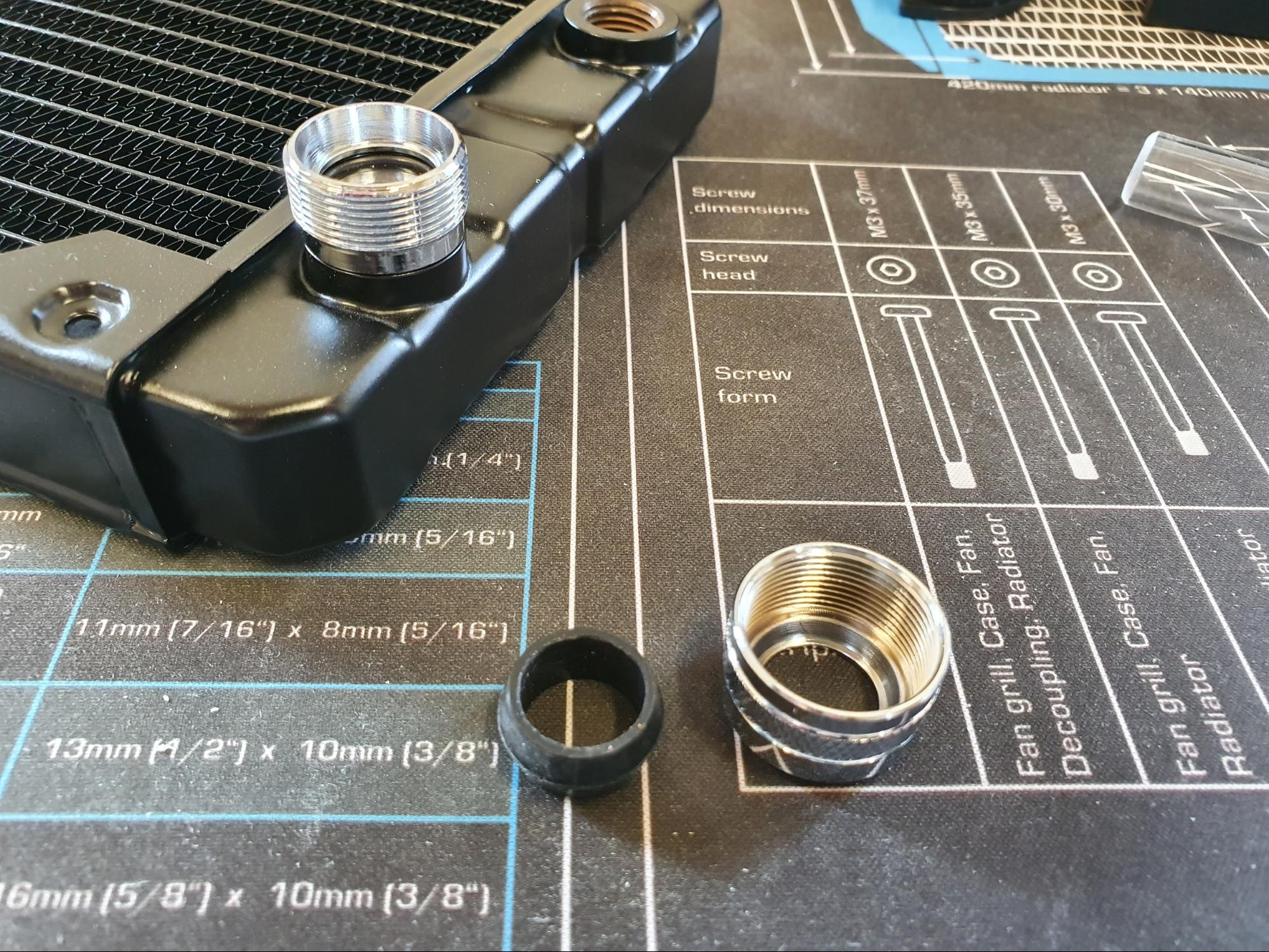

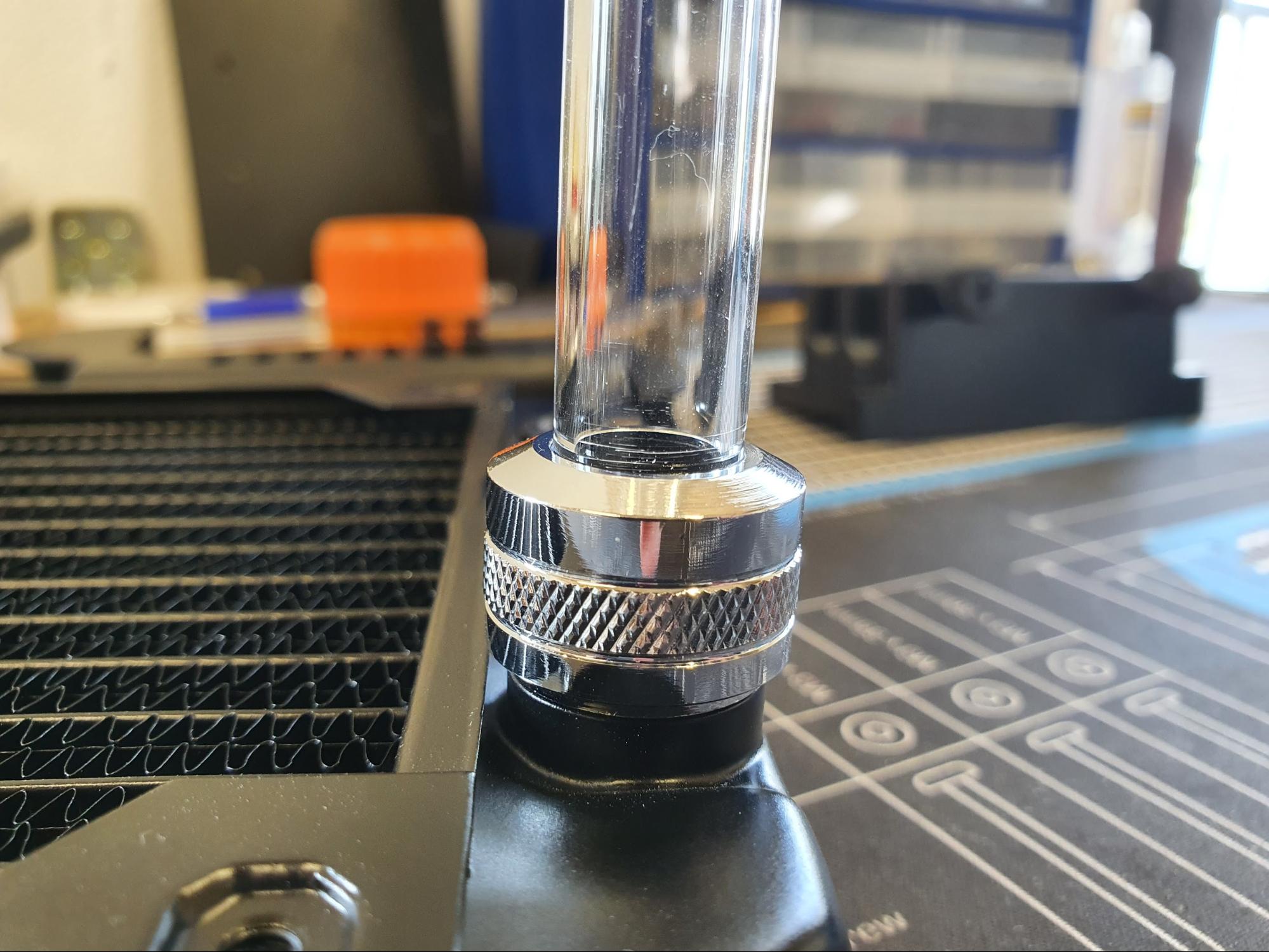

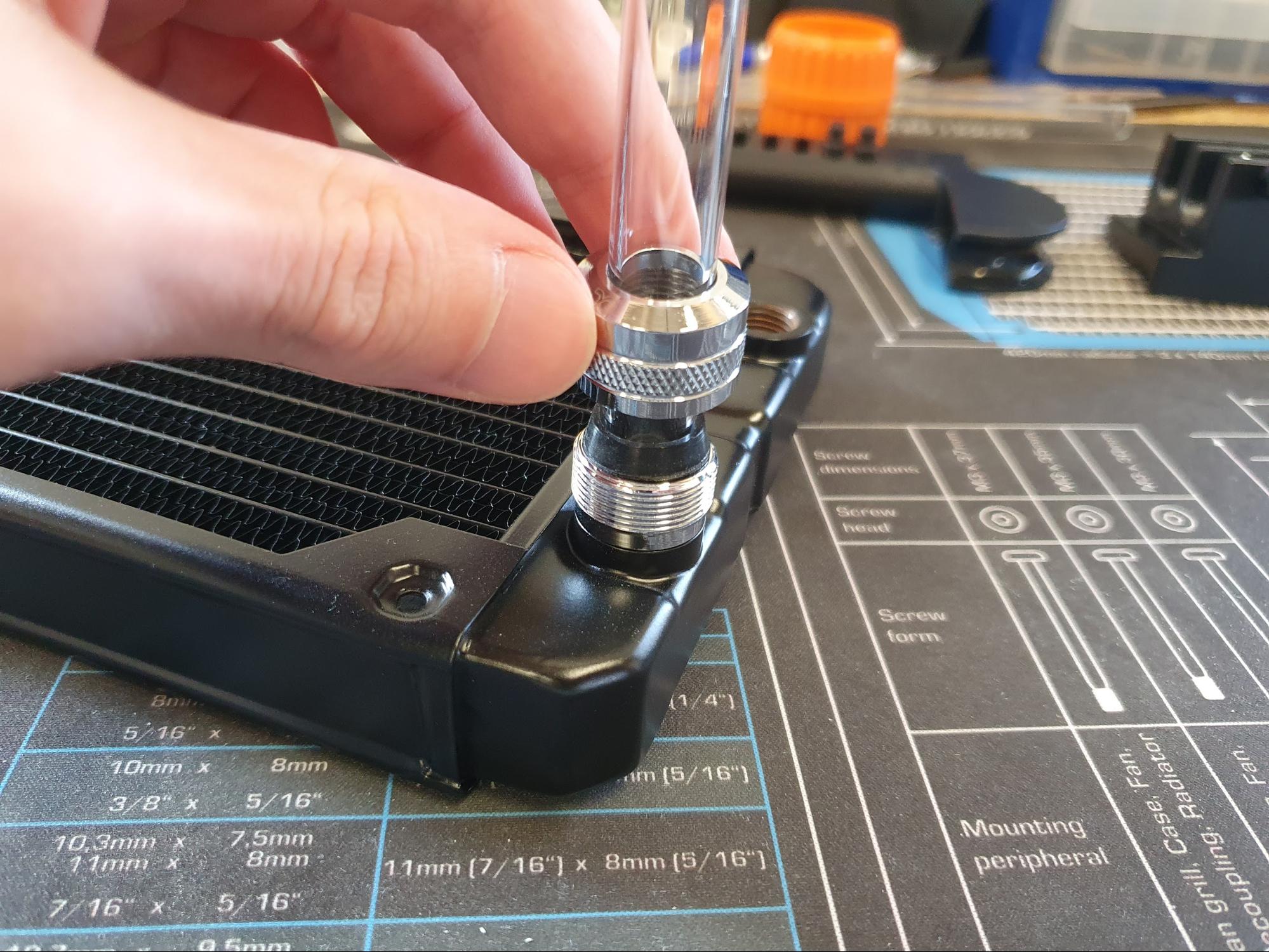

Every fitting has its unique way of holding the tube and securing it. For this guide, I’m using Alphacool Eiszapfen Pro fittings, which have a really strong and secure system, thanks to the big rubber ring.

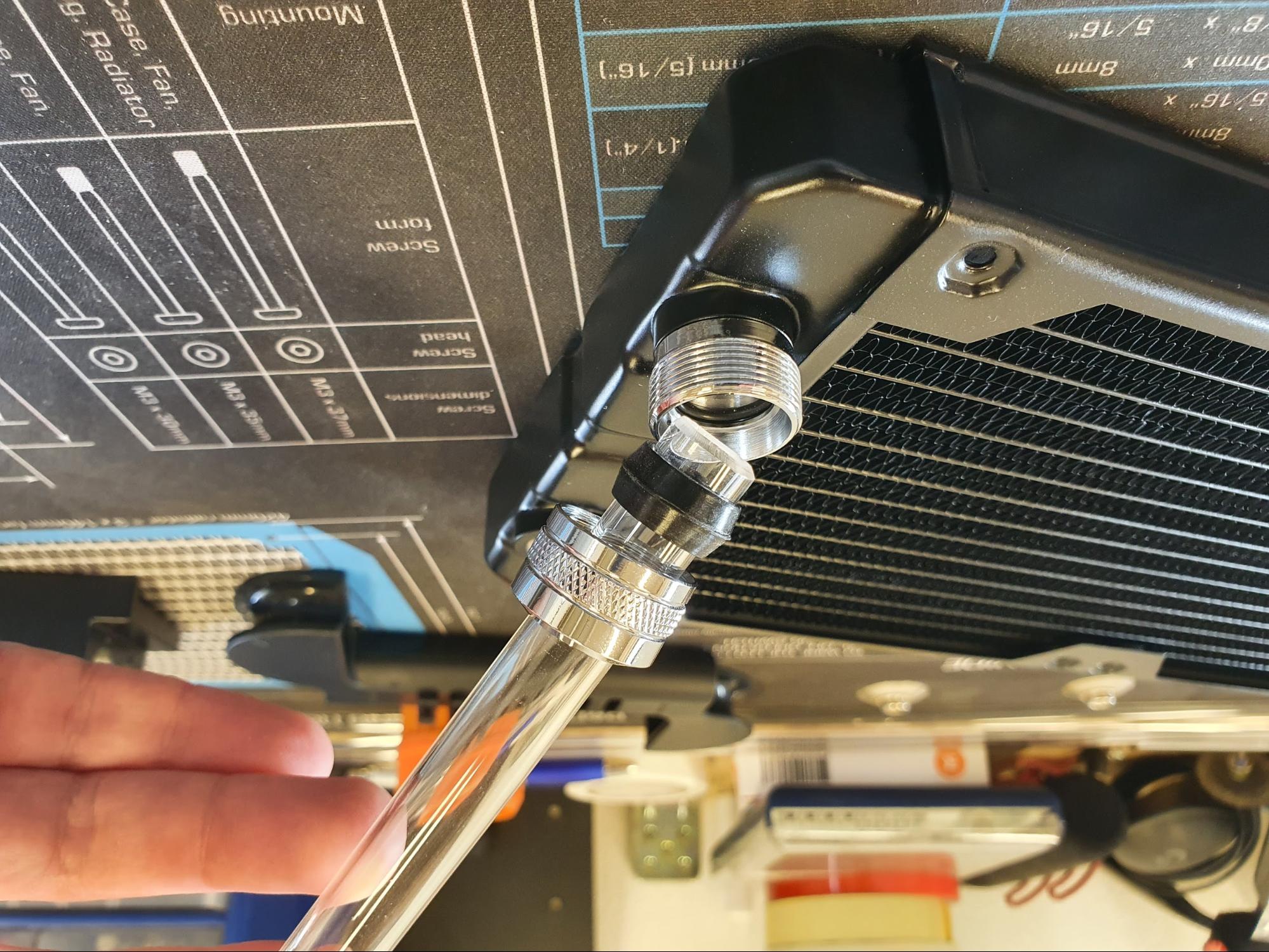

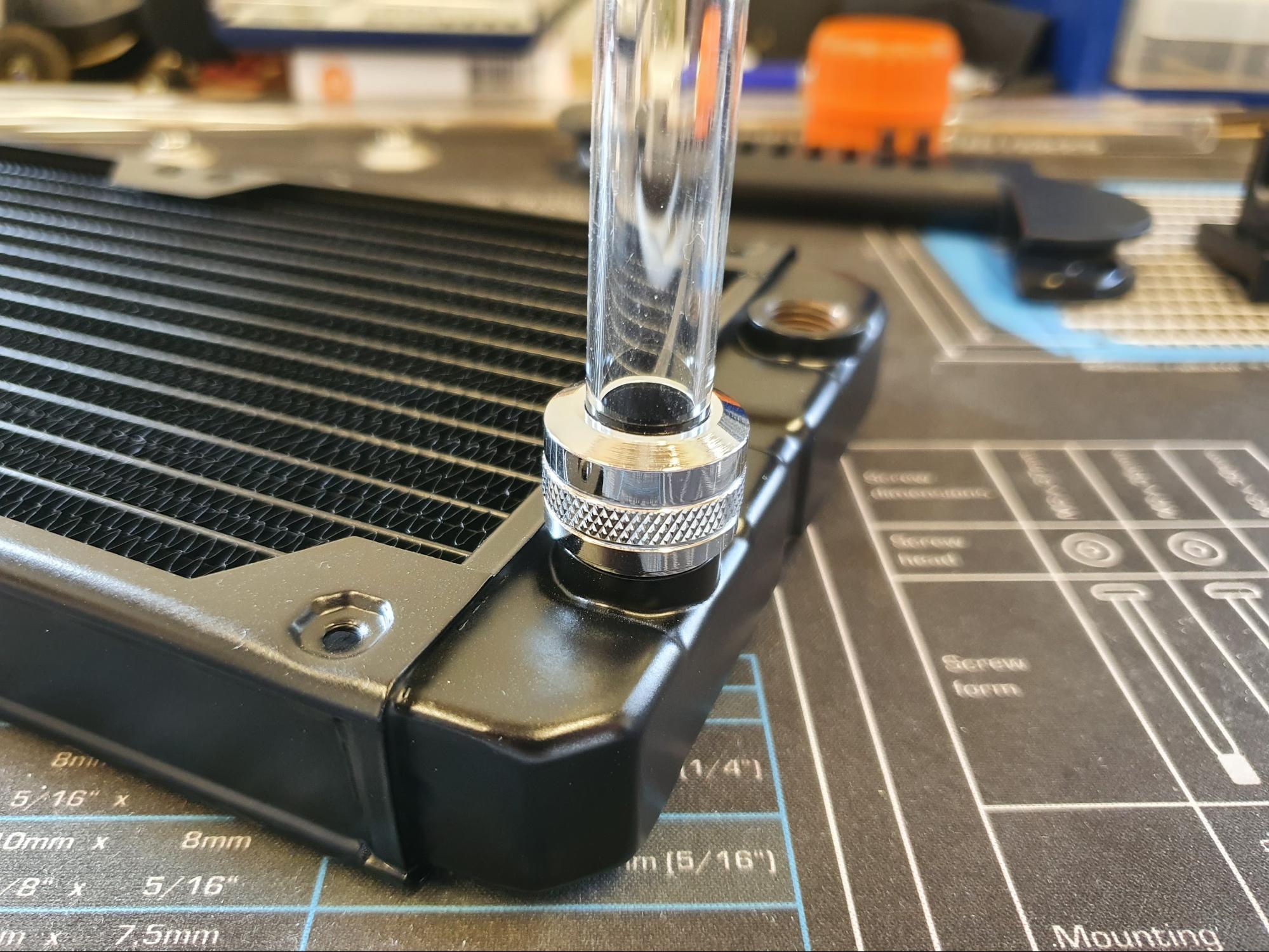

Start by sliding the compression ring together with the rubber ring or o-ring in the tube, then insert it in the fitting, making sure it goes all the way through.

Then proceed to put the o-ring/rubber ring in place and tighten the compression ring.

It’s important to note that during this process, you will need to make sure the tube is as perpendicular to the fitting as possible, because if not, you will most likely scratch the tube while tightening the compression ring. And in extreme cases, this might cause a leak because the seal provided by the o-rings is not even.

This should be a good starting point for you to start practicing on your first hardline custom loop. Now let’s see how I usually plan my loops!

Planning the Loop

After having assembled all of the main hardware in the case, I start testing out a few options for positioning the reservoir, which is often the part that needs the most fiddling with. This varies a lot, depending on the type of case and reservoir.

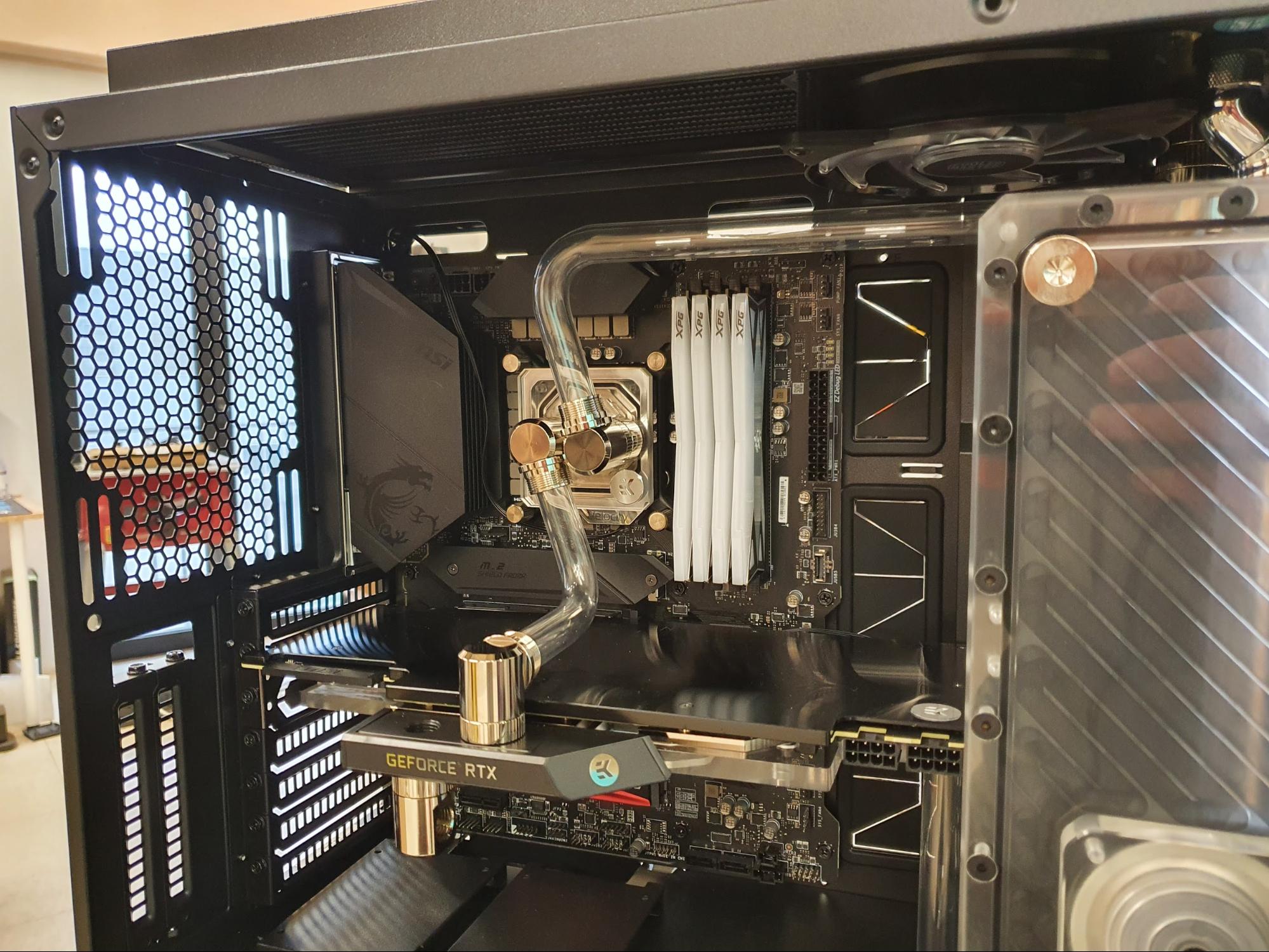

Once I’m happy with the placement of every part, I start playing with fittings to see what kind of setup works best. I always try to usea combination that will allow me to do only one bend on a tube, two at max, because it makes life easier and should look cleaner.

The secret to a good-looking tube routing is trying to use the same exact bend radius on all of the tubes in the loop. You can go classic with all 90-degree bends, or you can do something a little more unique like I did in this case, with about 25-degree bends.

Taking your time to plan the routing to optimize every tube run will help you get a really professional-looking result. Also, always take into consideration the fact that waterblocks, especially CPU ones (and pumps) have the inlet and outlet specified, so make sure you plan your loop with the right order in mind, otherwise you will get poor performance and poor water flow.

Another really fundamental thing in a custom loop with hard tubing is the drain valve, because while you can get away with not using one with soft tubing (because it’s easy to move) hard tubing can’t be moved once it’s in place and full of coolant. So being able to drain the system using a valve will make your life so much easier. Remember to put it at the lowest point in your loop, to help drain as much coolant as possible. In my case, I put it on the bottom-right fitting of the reservoir, so that I could also hide it from sight and maintain a cleaner look.

Filling the Loop

A few years ago, it was perfectly normal to fill your case with paper towels and leak-test the loop by just putting the coolant in and running it for a few hours.

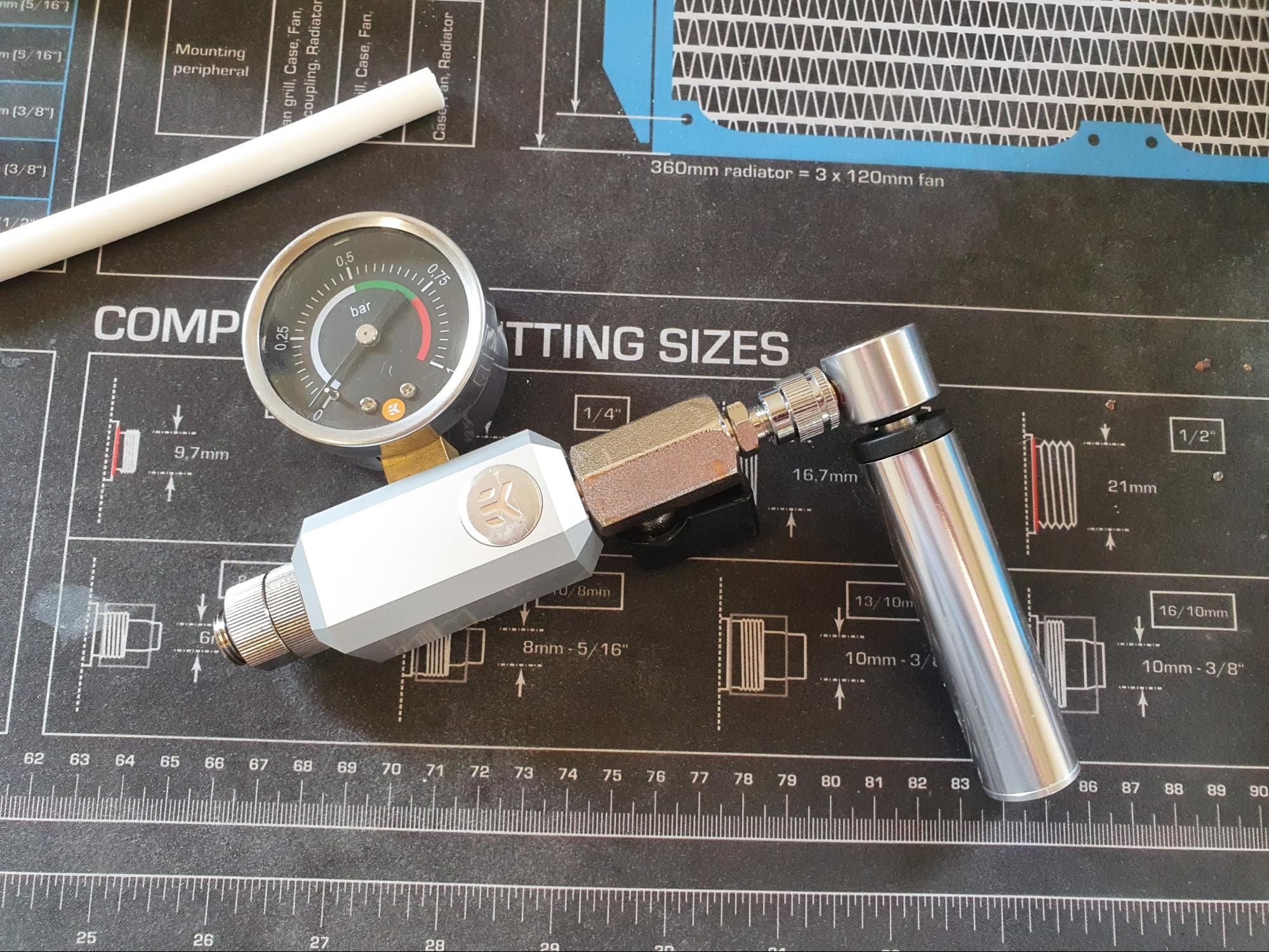

Nowadays we have air leak testers, like the EK one in the photo below. It uses compressed air to find leaks in the loops, although I still find myself just filling the system whenever I detect a leak with the tester, because it’s faster to actually find and fix it.

Remember to run the pump alone with all of the other hardware unplugged, to prevent any damage in case of major leaks.

DISCLAIMER: a lot of users are thrown off by the colours in the indicator of this specific tester model. The right pressure to leak-test a full custom loop is around 0.3 bars, so well below the green zone. EKWB is reportedly working on a fix to have clearer indications, although all the info needed is already provided in the manual.

Here’s the build once filled with coolant. Now it’s time to install the OS and RGB software and shoot a few cool photos!

Hope you enjoyed this guide, and I hope this will help you with your future endeavors in custom watercooling!

-

zodiacfml simple. cut the water cooling. a 5600x is good enough for the latest and greatest GPUs and TDP is 65watts which is easy for any coolerReply