Exclusive: Gigabyte RX Vega56, Vega64 Gaming OC teardown

Gigabyte has started (something of) a mass production of its own AMD Vega-based graphics cards. We got our mitts on the Gigabyte RX Vega56 and the Vega64 Gaming OC, in the form of final retail cards. Let's take a look.

Due to limited availability of Vega GPU/HBM2 packages and modest overclocking headroom, Gigabyte isn’t using the Aorus brand for its flagship this time around. Instead, the company is playing it safe with a Gaming OC model. But that’s not a bad thing (particularly when AMD leaves so much room for improvement with its reference design).

Unlike Sapphire, Gigabyte didn’t attempt the impossible with these cards, and instead focused on a rational solution to the overclocking problem. Detailed analysis of both Gigabyte cards is still to come, but we can already spoilt the fact that both cards do their jobs exactly like you’d expect. That is to say they work well, as long as you focus on stable usability, not extreme benchmarks.

Unboxing, Optics, And Haptics

Both of Gigabyte’s cards are like floating elves compared to the Sapphire RX Vega 64 Nitro Plus. Weighing in at just over 1kg, they’re an astonishing 600g lighter than Sapphire’s monstrous offering. That’s less than 63%! As for a workhorse vs. feasibility study, well, we’ll see about that.

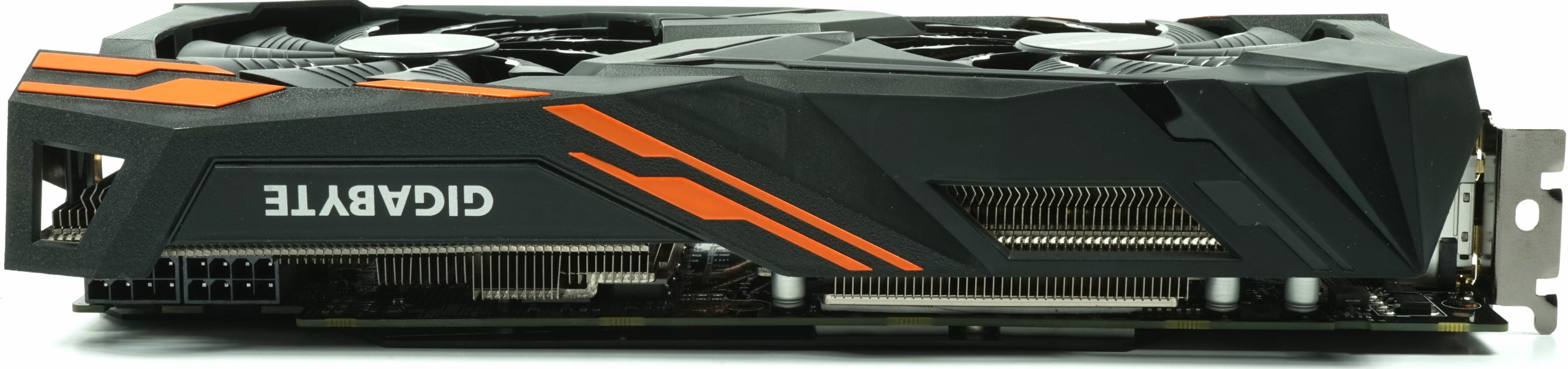

Gigabyte’s cards are also much more svelte than Sapphire’s. These are relatively short cards with installation lengths of just 27.8cm from the external surface of the slot bracket to the end of the radiator cover. With a height of 13cm from the top edge of the mainboard slot to the top of the radiator cover, as well as a thickness of 4.7cm from the board to the front of the radiator cover, the result is a rather compact card.

The two counter-rotating fans, each with a rotor blade diameter of 9.5cm, sit in a 10cm-diameter opening. With their special shape, a total of 11 rotor blades per fan helps manage airflow, turbulence, and static pressure. This should prove useful when it comes to cooling the card.

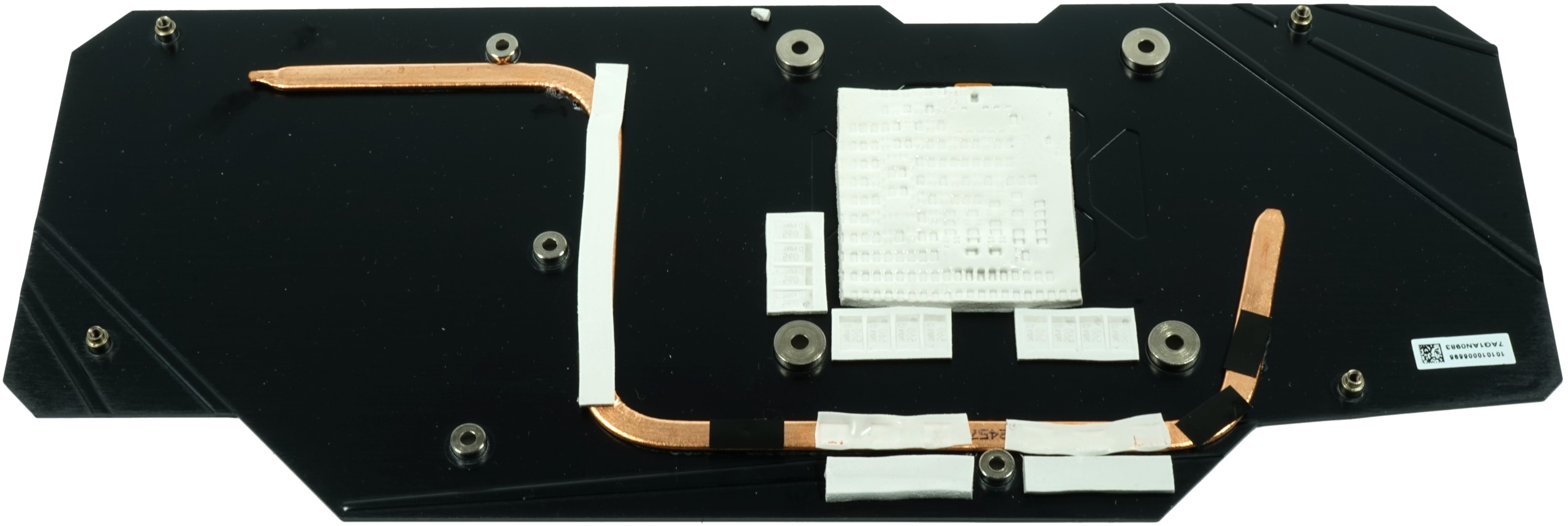

The backplate dispenses with the Aorus logo, which was still present on the pre-production model. The copper insert, which is located above the back of the package, separates the active backplate used for cooling from this area and also cools, at least a little bit. In the subsequent product tests we will go into more detail about the idea behind this very special solution.

After all, at least 5 mm should still be planned for the rear back plate, which can cause problems with some motherboards if the heat sink is too tight at the slot or the CPU cooler turns out to be extremely large.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You can already clearly see on the underside of the card that Gigabyte has sharpened the shape of the vertical slats a little bit. The oblique position and the waveform are designed to use the airflow for more efficient cooling. We’ll look into this very carefully at a later stage.

The top side of the page also clearly shows that Gigabyte's financial planner has deliberately set the red pencil. No RGB effects and no other LED gimmicks, but a somewhat jagged plastic desert of injection moulding and printed orange colour accents. The white Gigabyte logo is also only printed. In addition, two 8-pin sockets for external power supply are sufficient for both models.

The closed end of the card does not show much other than the end of the two 8mm and three 6mm heatpipes and the connection cable of the fans. On the printed circuit board, other possible jacks were provided (e. g. RGB output) which were omitted during the development process.

The slot bracket is of great interest in that it has six display outputs, rather than the reference card’s five. Three HDMI 2.0 connectors and three DisplayPort 1.4 interfaces are available to the user. This means that the card is also suitable for connecting up to six monitors in AMD's Eyefinity mode.

Teardown And First Impressions

Of course, we have also completely dismantled the cards and analyzed everything up to the circuit layout and the components used. First of all, we show the cooling system, in which the backplate was actively integrated into the concept. The flat heatpipe connects some of the voltage transformers on the back of the board to the cooler parts of the backplate and also leads over the areas behind a part of the coils. In addition, thermal conduction pads connect the copper plate and other areas of the board to the backplate.

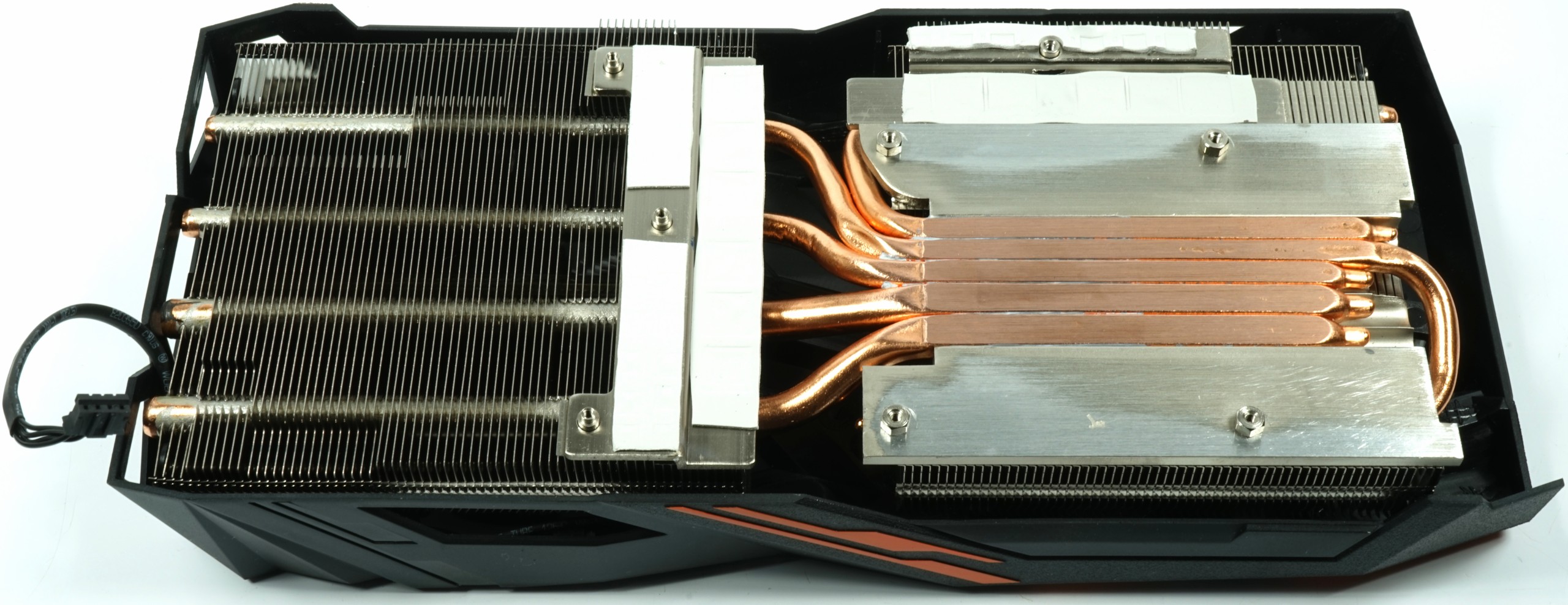

The Direct Heat Touch (DHT) cooler is interesting in that the heatpipes lie directly on the GPU; there’s no extra heat sink. That could lead to some problems, but it doesn’t have to. We’ll see in our tests whether or not this works. At least now we know how they managed to keep the card’s weight at 1kg and save on its costs.

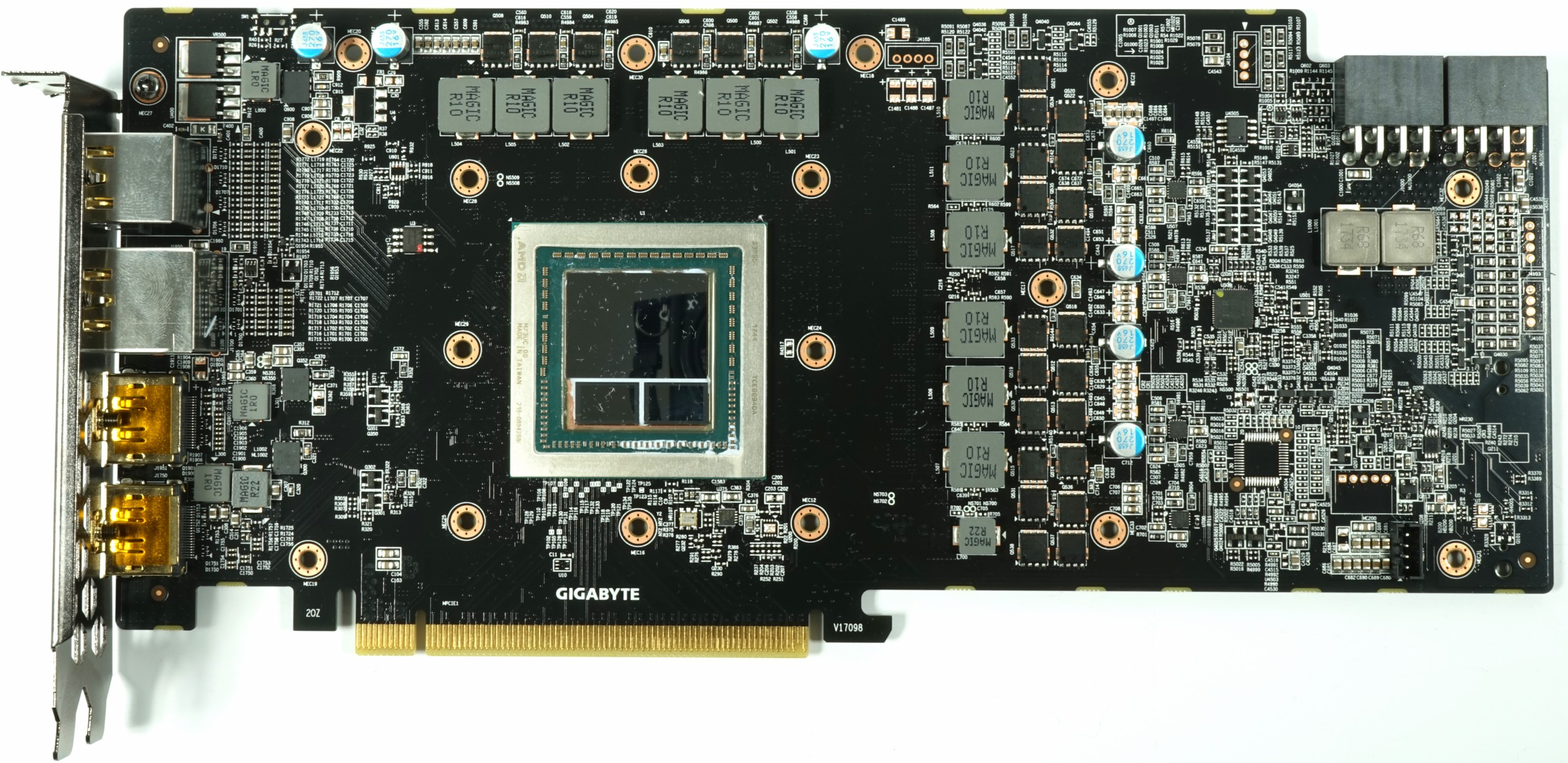

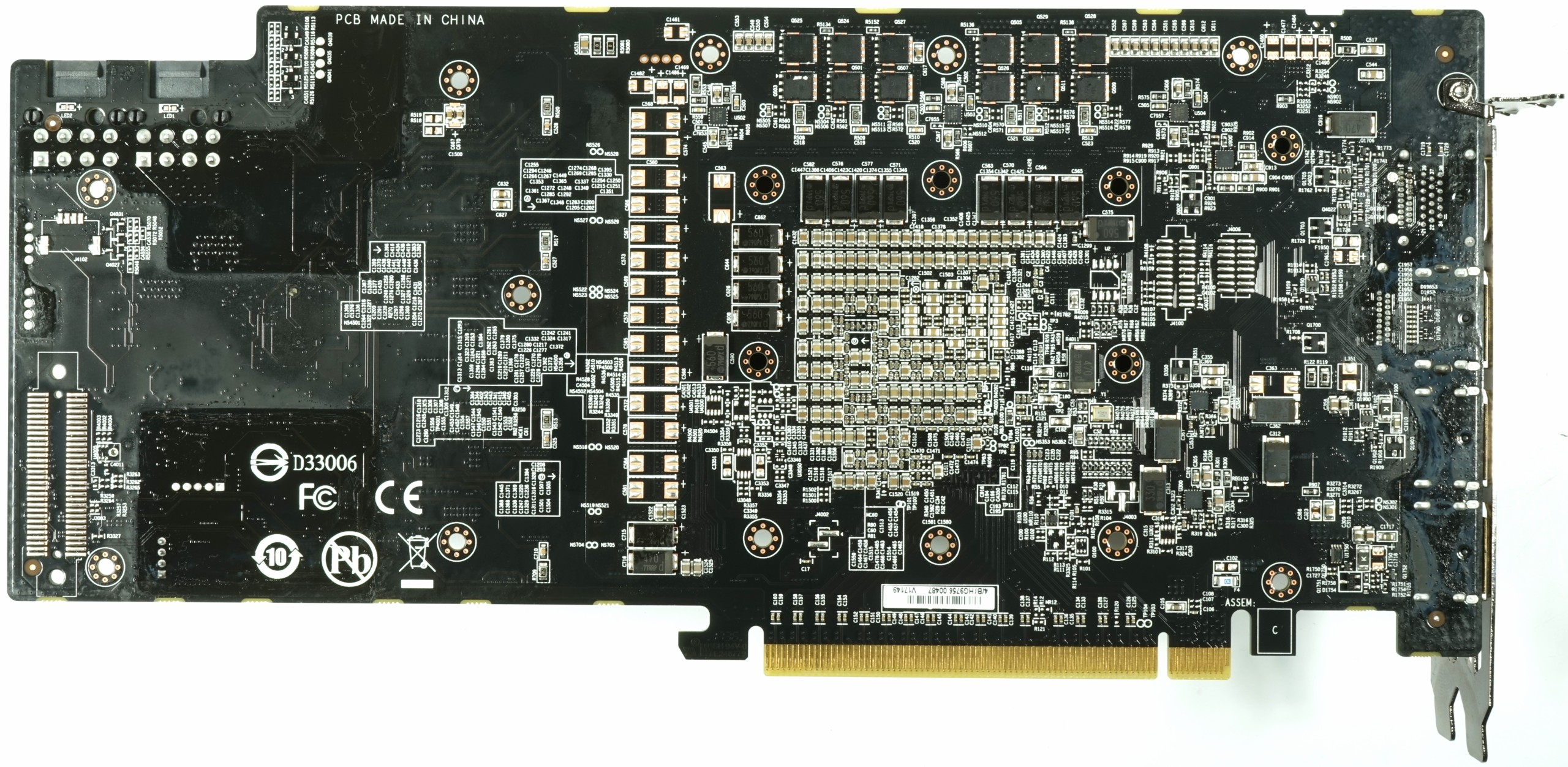

The printed circuit board is Gigabyte’s own design, not AMD’s reference, and we can see where some cost-saving decisions were made. For example, the space where Gigabyte normally uses an 8-bit Holtek microprocessor for RGB effects is free and unused, as is the spot for external LED connections. We’ll analyze the component assembly and circuit layout in our full review.

Another interesting solution is to banish some of the voltage transformers, in this case the low-side VRM from the row on the top, to the back of the board.

We can also see this clearly on the back. It also makes sense now that Gigabyte uses an extra heatpipe in the backplate. Naturally, we’ll use our thermal imaging technology to analyze how well this concept works out.

Market And Availability

Now for the bad news: Our sources tell us that AIB partners have received only a few chips—in the mid-four-digit range—from AMD for Vega 64 cards. This general shortage is currently preventing mass production of Gigabyte’s cards, because it’s not possible to constantly start and stop a production line, or even have it “paused” for a long period of time. Costs and the associated labor would simply be too high.

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

Sakkura ~5000 chips? Might as well not have bothered then. It's not like the reference Vega cards aren't selling, anyway.Reply

Either way no regular gamer would want to buy in at this point. We don't just need good non-reference cooled Vega cards, we need them at a reasonable price. -

FormatC This is not the job of the AIB. They can only sell, what they got from AMD. Less goods, high prices. This is the market. :(Reply -

uglyduckling81 "(particularly when AMD leaves so much room for improvement with its reference design)."Reply

Weird thing to say when Gamers Nexus raved about how well designed the PCB is and how high quality the components are.

I believe they said it's the best PCB they ever come across. I also think they mentioned how good the Titan V was built, up to Vega standard. -

Sakkura Reply20529765 said:"(particularly when AMD leaves so much room for improvement with its reference design)."

Weird thing to say when Gamers Nexus raved about how well designed the PCB is and how high quality the components are.

I believe they said it's the best PCB they ever come across. I also think they mentioned how good the Titan V was built, up to Vega standard.

I think it's referring to the reference cooler rather than the PCB. The cooling isn't great. -

mihen Gamers Nexus does some things particularly well, while toms does other things particularly well. When it comes to power draw and thermals, I would go with toms.Reply -

FormatC Reply

Read it again. It's about the cooler. The reference PCB isn't bad. It is also not perfect, but a solid layout with good component quality. AMD forgot to cool the doubler chips on the back side. This is the only improvement I would made. Thermal pads between their PCB and back plate.20529765 said:"(particularly when AMD leaves so much room for improvement with its reference design)."

-

uglyduckling81 Reply20530138 said:Gamers Nexus does some things particularly well, while toms does other things particularly well. When it comes to power draw and thermals, I would go with toms.

I'm not so sure about that. They have recently upgraded their power testing equipment. For the the Titan V testing they tested the power draw of the chip manually rather than using software to do it. They have always had a good testing methodology but being fairly new they had limitations. They are slowly acquiring more equipment and getting more and more thorough.

-

FormatC Feel you so free to read all my articles about power measurement to understand, how I measure. I spent a lot of time and money in this project and developed this methodology over 5 years together with Rohde & Schwarz. And I'm comparing /sharing my data with all big AIB, they trust me. I worked 17 years in the industry and I know what I do. For power draw I'm collecting the data over ethernet, four channels for voltage and four channels for current. Calibrated with the delay of my precision clamps. I also programmed an intelligent low-pass-filter for all and I'm sure, my resultion on the scopes is high enough ;)Reply

@all stalked out:

I'm not a newbie, benchmarks first. And I do all torture and power draw tests twice - before and after ;)

Their paste is not bad. I just tell you a secret. Most of all media samples were proofed manually from the manufacturers and are far away from retail. I know the production process in detail and can mention, if they used other thermal grease or assembled it manually. Golden samples... Not my taste. This both cards are retail. And I have also a lot of original thermal grease from the factories. Call it souvenirs :D -

TJ Hooker ReplyWeighing in at just over 1kg, they’re an astonishing 600g lighter than Sapphire’s monstrous offering. That’s 63% less!

1 kg is 63% of 1.6 kg. It's 37% less.