Intel Begins Construction of $100 Billion Ohio Campus

First fabs coming online in 2025.

Intel is set to hold a ground-breaking ceremony for its first two fabs in a campus located in Licking County near Columbus, Ohio. The all-new manufacturing site will be able to house up to eight chip fabrication facilities and will require investments of around $100 billion over time. President Joe Biden and Ohio governor Mike DeWine will join Intel's Pat Gelsinger at the ceremony.

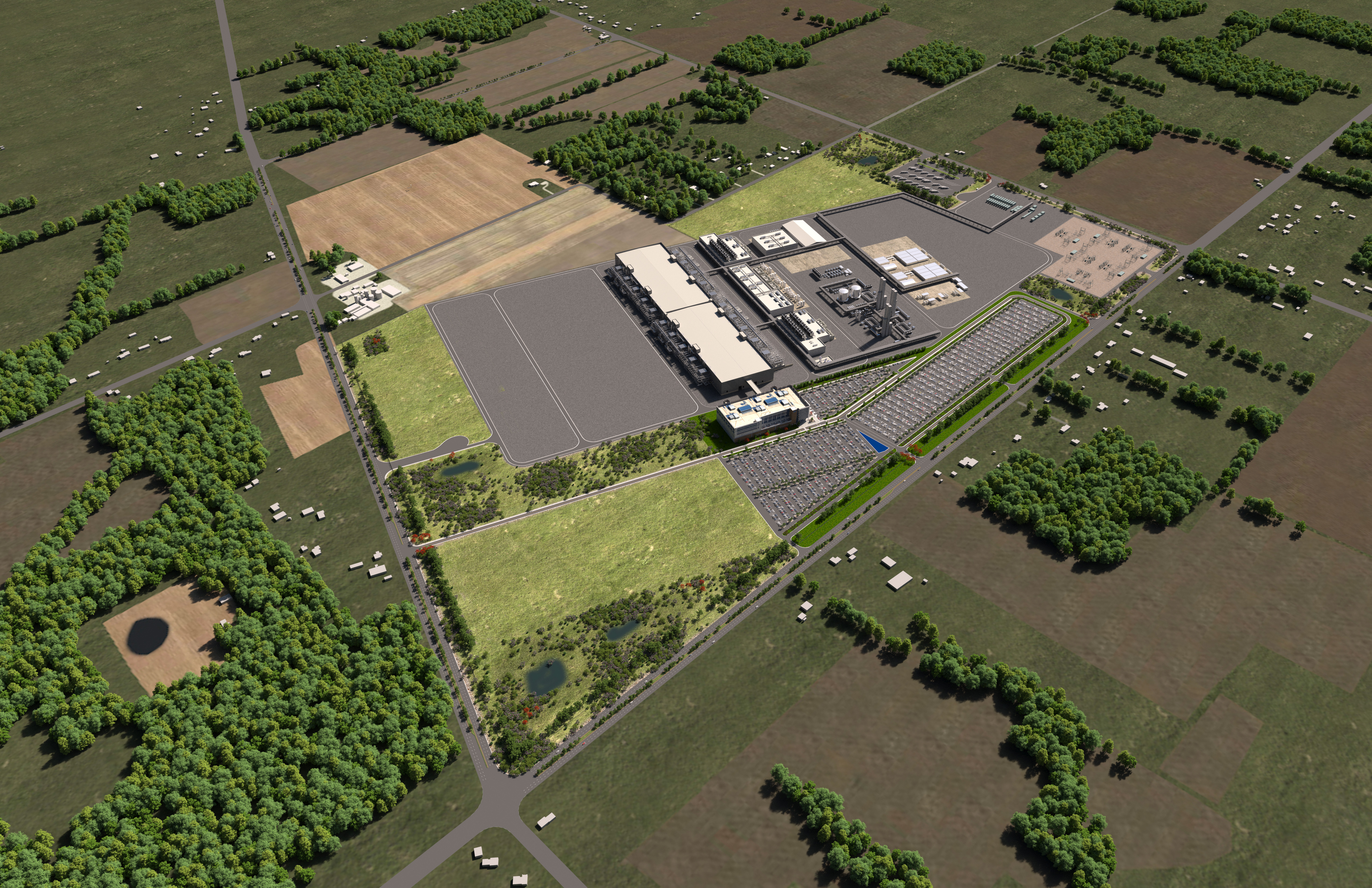

The first two fabs in Intel's Ohio, Silicon Heartland manufacturing site will cost Intel around $20 billion, and will be built simultaneously. These fabs are expected to come online in 2025. The new campus will span around 1,000 acres (4 square kilometres) and will be able to house up to eight semiconductor fabs as well as support operations and ecosystem partners. To buildout the site, Intel will need to invest some $100 billion, the company once said.

Intel does not disclose which production nodes will be used at its new fabs, but given that they are projected to come online in 2025, we summize that the facilities will be able to make chips on Intel's 20A and 18A fabrication technologies and will be ready for more advanced manufacturing processes. That said, expect the new fabs to extensively use current-generation extreme ultraviolet (EUV) lithography with 0.33 numerical aperture as well as utilize next-generation EUV tools with 0.55 NA.

These fabs will employ a staff of 3,000 across manufacturing and engineering, producing chips both for Intel as well as its Intel Foundry Services (IFS) clients. Furthermore, the new facilities could create about 7,000 local construction jobs.

The Ohio campus will be Intel's first all-new manufacturing site in decades. Recently Intel built new fabs at its existing sites in Arizona, Ireland, Israel, New Mexico, and Oregon. By contrast, the Silicon Heartland campus in Ohio is set to be built from scratch and is expected to add significant manufacturing capacity for Intel as well as its ISF customers, thus being instrumental to execution of Intel's IDM 2.0 strategy. Also, the site (along with Intel's fabs in Arizona and other companies' fabs) will play an important role in bringing leading-edge semiconductor manufacturing back to the U.S.

"Today marks a pivotal moment in the journey to build a more geographically balanced and resilient semiconductor supply chain," said Pat Gelsinger, Intel's chief executive. "The establishment of the Silicon Heartland is testament to the power of government incentives to unlock private investment, create thousands of high-paying jobs, and benefit U.S. economic and national security. We would not be here today without the support of leaders in the administration, Congress and the state of Ohio, who share a vision to help restore the United States to its rightful place as a leader in advanced chipmaking."

To support Intel's Silicon Heartland, a number of Intel’s partners, including Air Products, Applied Materials, LAM Research and Ultra Clean Technology have indicated plans to establish local presence to support the new operations.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

daworstplaya ReplyTom Sunday said:For some reason and from what I have been reading recently all over the tech-channels, I thought that Intel is on its way out (including stock prices) and is now saddled with cash shortages, product development problems, not being as savvy as AMD and forced in shedding existing business units to bolster their bottom-line? But a $100 billion dollar Ohio investment and cash availability for a singular fabrication facility is amazing to see! Even president Biden himself will come out to shake Pat Gelsinger’s hands and applauding him by stepping-up to the bar and especially in difficult economic times we now experience.

AMD in turn is now being heralded to be the great Intel killer and having finally won the technological lead over Intel. But to really making this happen, AMD in my simple view should open ‘Mega Fabs’ like this in the USA and become free of foreign contractors and their control, and who at one time may wind-up being our adversaries? Why is AMD in this continuing worldwide political subterfuge and blatant expansionism not reigning in their production needs? Its their ultimate lifeline! But what do I know, I can’t even afford and had to give-up drinking Mountain Dew all together. That is my horizon!

Not sure if you know this but AMD started as a fab company and would basically make Intel CPUs when Intels couldn't pump enough CPUs out of their own fabs. AMD later got into the CPU game. At one point AMD was both a fab and cpu design company. Case in point Global Foundries was owned by AMD before it was sold off due to massive losses and not being able to keep up in advancement with Intel's own fabs and TSMC. This was when AMD was at it's lowest and almost went bankrupt. AMD basically took a page out of Nvidia's playbook and outsourced the fab work to TSMC and focused on chip design to get where they are now. Basically AMD focused on their core competency and let TSMC focus on it's core competency.

The problem companies like AMD and Intel face are that other countries greatly subsize fabs in their nations which allows companies like TSMC to rapidly accelerate the rate of development. Thus undercutting fabs in the US and other nations. Until recently the US didn't subsidize fabs as much until the world got hit by COVID and the chip shortage. Now people realize having fabs in other unstable regions are not in one's national security interest. Basically the pendulum has swung the other way. -

watzupken There are pros and cons having your own fab. You can prioritise your own chip production over competitors for example. On the flip side, Intel is in this mess because their own fab failed to deliver 10nm for many years. So sticking to their 14nm for many years, they lost whatever edge they have over their competitors. Likewise AMD also got into the same problem with their own fab in the past. Plus a misstep delivering the Bulldozer architect, they almost killed themselves. The problem here is this, Intel and any other fabs are chasing after the market. Chips were selling like hotcakes because of lockdowns that trigger unnatural sales spike. Now clearly, there is any over supply and Intel is just building their fab. And with so many fab expansion, there is only limited supply of whatever raw material or equipments that required to produce chips. That will also eventually become a bottleneck. I don’t believe all these expansion will be utilised. The cost of production in the states is also not going to be cost effective.Reply