Prusa Announces Next-Gen, MK4 3D Printer

The Rolls Royce of 3D printers has a new model.

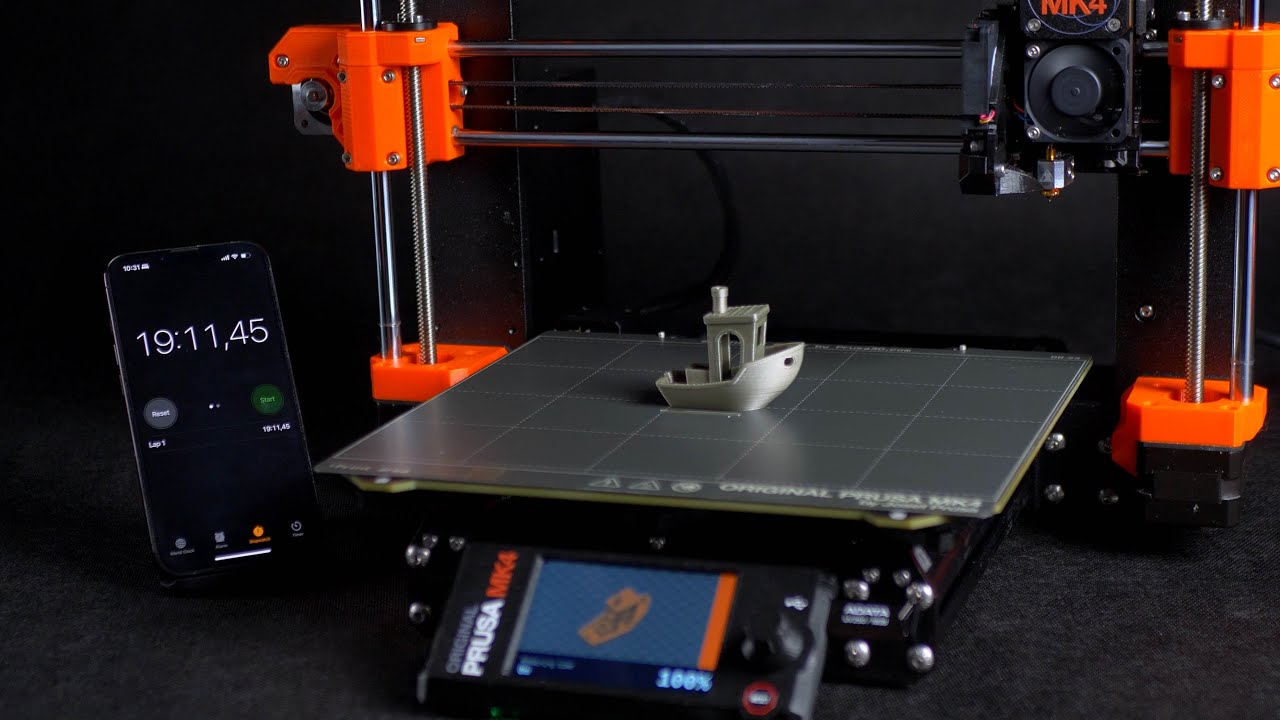

Prusa Research today announced the long awaited release of the Prusa MK4 3D printer, and on paper it looks like you get a lot of printer for your money, perhaps enough to make it on to our list of best 3D printers. The $1,099 MK4 is described by Josef Průša "as an open-source 3D printing workhorse with long-term support." and the team have been running hundreds of units for more than a year.

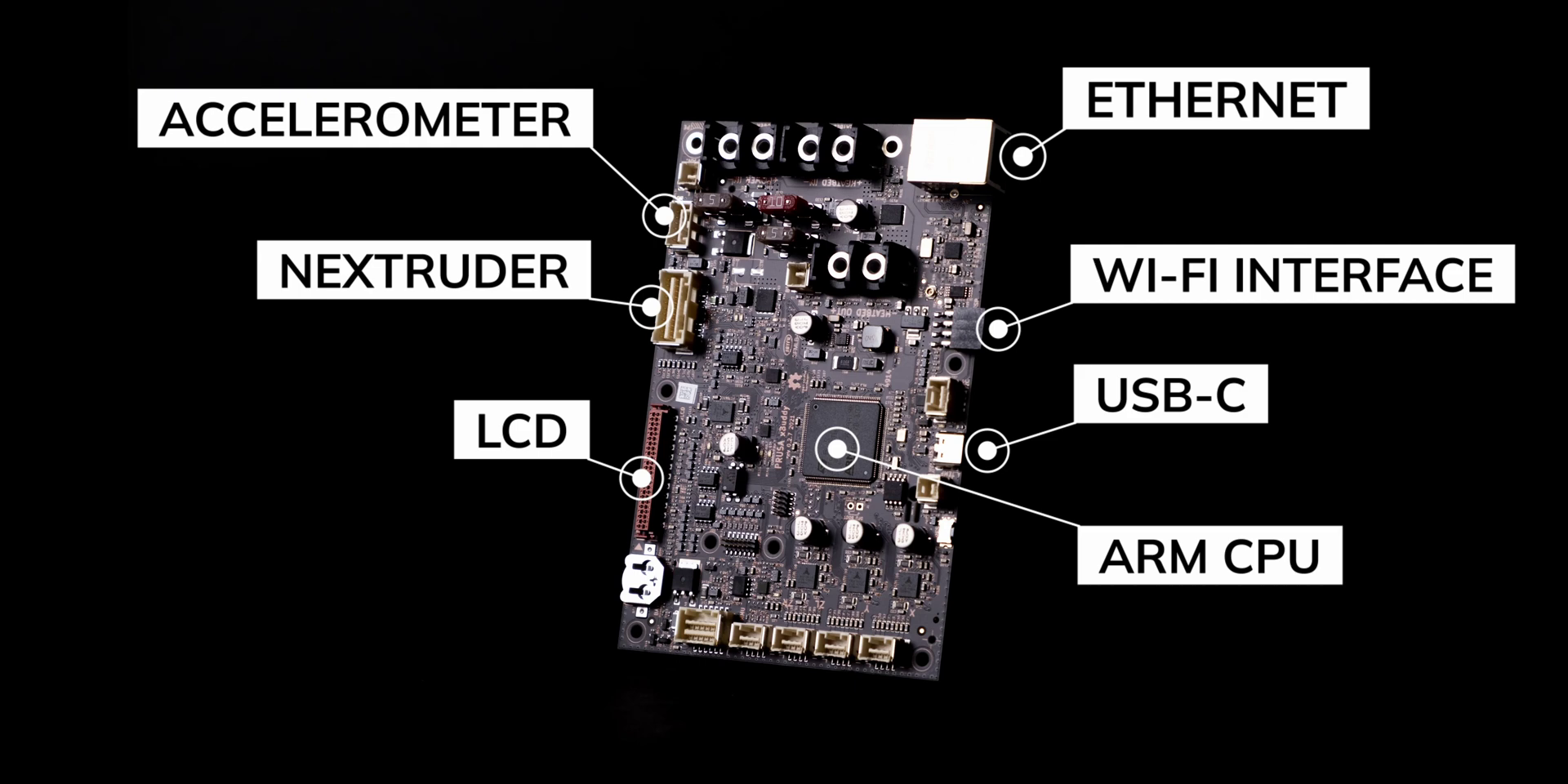

The MK4 is built around a 32-bit STM32-powered mainboard, "xBuddy board" which also provides Ethernet access and more importantly new features such as Input Shaper (fine speed control of the motion system) and Pressure Advance (increasing the filament as the nozzle accelerates, retracting as it slows).

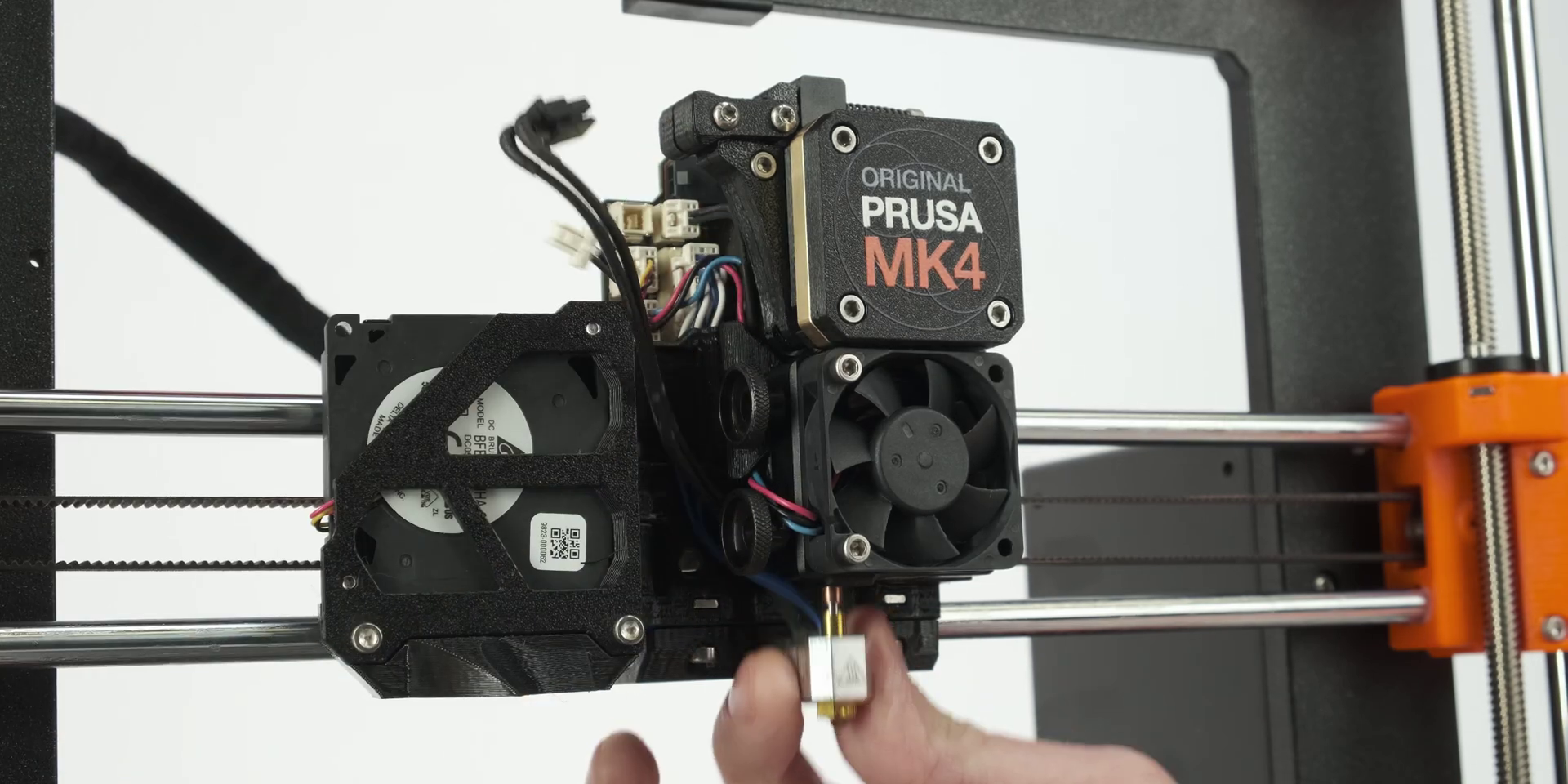

The Nextruder uses quick-swap nozzles to alter the diameter of the aperture. Bigger nozzles means faster prints, and by default it ships with a 0.4mm nozzle. Swapping the nozzles is now a simple task of releasing two thumbscrews and disconnecting two cables. The entire hotend is then released.

| Build Volume | 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in |

| Layer height | 0.05-0.30 mm |

| Mainboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper Drivers | Trinamic 2130 |

| Stepper motors | Precise 0.9° X,Y stepper motors (prevents VFA) |

| Extruder | Nextruder, Direct Drive, E3D V6 compatible (with adapter) |

| Filament path | Aluminum heatsink, all-metal hotend, no PTFE tube |

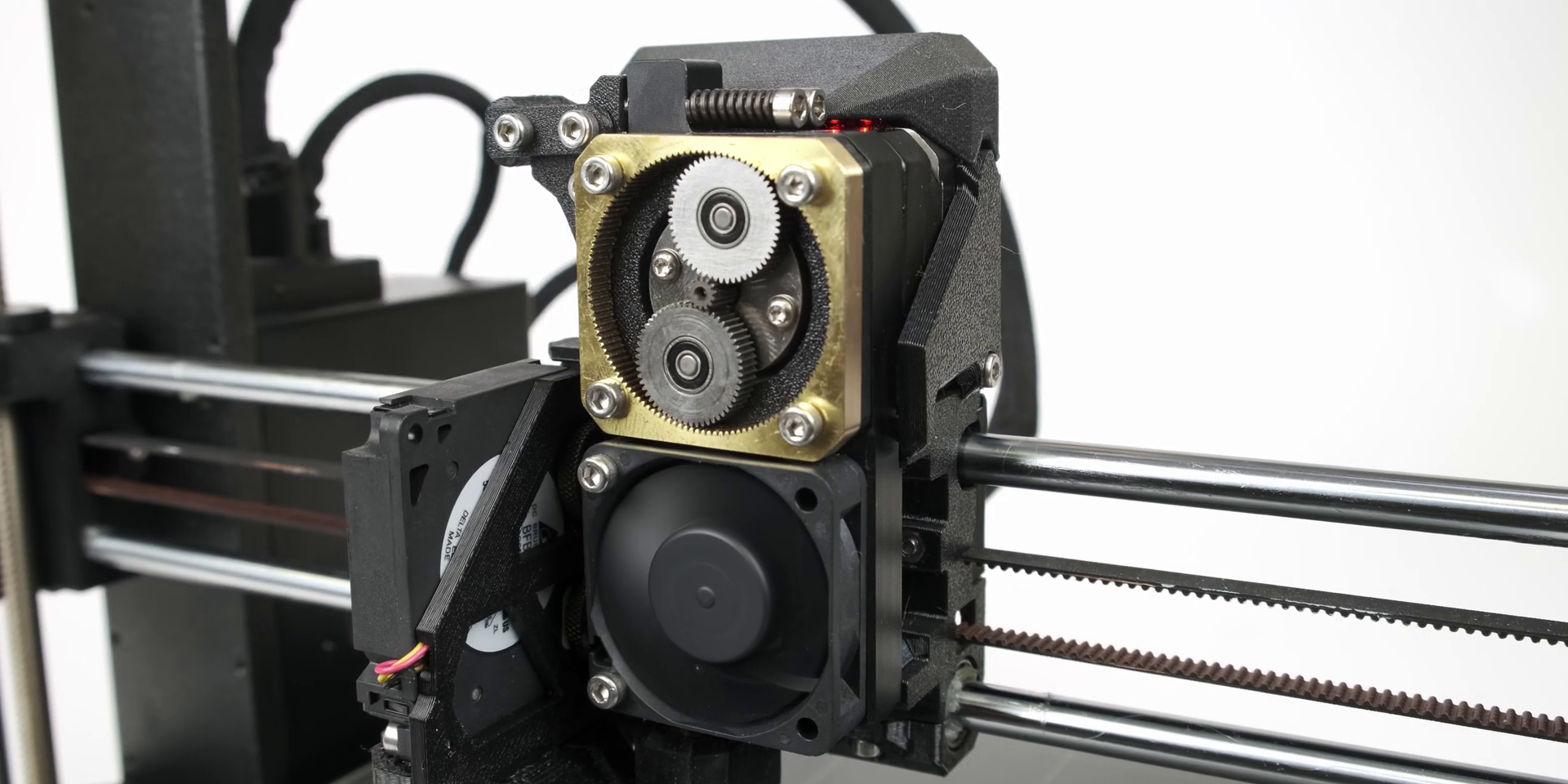

| Drive system | Nextruder Planetary Gear System, 10:1 gearbox ratio |

| Nozzle diameter | 0.4mm (default) / other nozzle diameters supported |

| Max nozzle temperature | 300 °C / 572 °F |

| Max heatbed temperature | 120 °C / 248 °F |

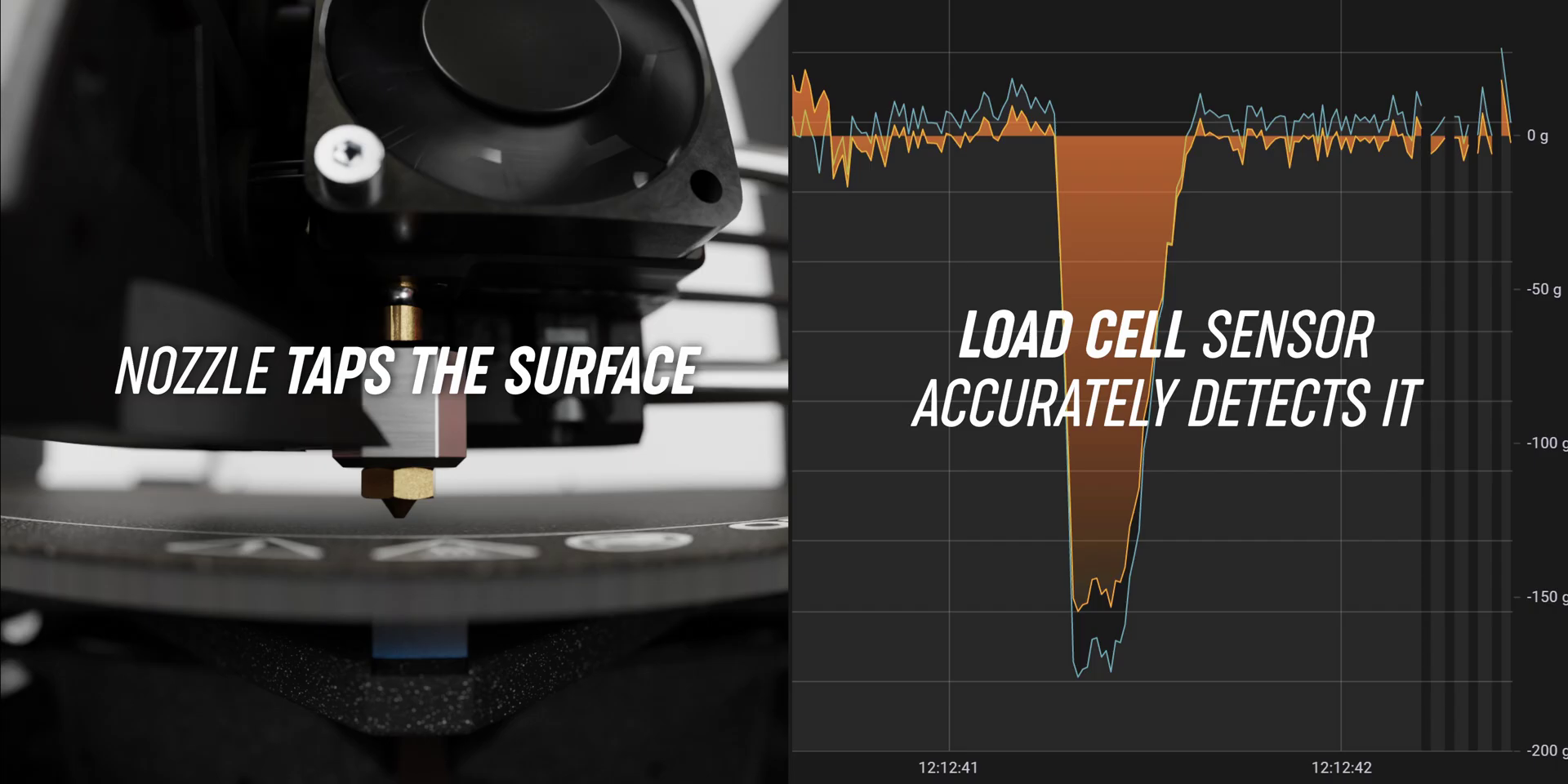

| Advanced sensors | Filament sensor, Loadcell sensor, Power panic, 4 high-precision thermistors (genuine Semitec) + fan motors RPM monitoring |

| Print surface | Magnetic heatbed with removable PEI spring steel sheets |

| Bed calibration | Automatic, Mesh Bed Leveling (only on print area) |

| Supported materials | PLA, PETG, ABS, ASA, Flex, HIPS, PA, PVA, PC, PP, CPE, PVB, NGEN, composites and more |

| Printer dimensions (without spool) | 500×550×400 mm; 19.6×21.6×15.7 in (X×Y×Z) |

The MK4 has a maximum build volume of 250 x 210 x 220 mm and uses 1.75mm diameter filament which is fed directly into the 10:1 planetary extruder, a drive gear which has a large contact area to reduce slippage.

The Nextruder also has a hall sensor to detect filament run outs. On other printers, such as the Elegoo Neptune 3 Pro, Plus and Max, this sensor is at the top of the gantry and rattles as the print moves around the bed. The electronics for the Nextruder are all easily accessible via a breakoout board on the rear of the unit.

The MK4 claims to be faster than the MK3, in one test a print on the MK3 took 10 hours, but on the MK4 just 3.5 hours. The reason for this is input shaper and pressure advance, which offers a faster print time, akin to Klipper.

Prusa elected to write its own version, tailored to its printers, rather than port Klipper to the MK4. The speed boost means that rapid prototyping, something that 3D printers have excelled at, is even quicker with the MK4. To prove how fast it can go, Prusa has released a YouTube video of a sub 20 minute benchy.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Seasoned 3D printer users will know how important a first layer is. We often babysit the first layer to ensure that we have perfection. Getting your printer perfectly leveled is an art form, and the MK4 is automating the process to provide a perfect first layer every time.

So now changing the nozzle and print sheet will not require a laborious and tedious 30 minutes as your slide a piece of paper around the bed. The print head will perform an auto-bed leveling process where the nozzle itself touches the bed, and a load cell sensor accurately detects the contact.

The frame of the MK4 is made from injection molded aluminum. Injected into a two part mold, cleaned, sandblasted and then powder coated to protect the metal while looking great. At the base of the frame is a 3.5 inch color LCD touchscreen, along with physical control knob and inputs.

The MK3 line of 3D printers was exceptionally popular, selling around 350,000 units worldwide. It seems that the MK4 has been designed to succeed the MK3 range in almost every way. The MK4 improves upon the MK3S+ by changing and upgrading around 90% of the parts. Only a few parts were saved from the upgrade.

The Prusa MK4 is available in limited quantities direct from Prusa Research for $1099 as an assembled unit. Upgrade kits will be available for $799 in the near future.

Les Pounder is an associate editor at Tom's Hardware. He is a creative technologist and for seven years has created projects to educate and inspire minds both young and old. He has worked with the Raspberry Pi Foundation to write and deliver their teacher training program "Picademy".