Ultrathin Silicon-28 Nanowires in CPUs Could Be a Game Changer

Heat conductance is the key advantage

Scientists have discovered and demonstrated a new material, for use in advanced processors, that can conduct heat 150% more efficiently, claims an article published by Lawrence Berkeley National Laboratory. Heat build-up in processors is a big problem for performance, and silicon acts as a natural heat insulator, inhibiting cooling. With new ultrathin silicon nanowire technology applied, it is hoped that chips will be able to get smaller, faster and cooler from a relatively simple change. The key change that has been tested is the use of isotopically purified Silicon-28 (Si-28).

Silicon is cheap and abundant but a poor heat conductor, and this is a problem in tiny microchips with tens of billions of transistors clocked at GHz speeds. Natural silicon is made up of three isotopes: silicon-28, silicon-29, and silicon-30. Silicon-28 is the most naturally abundant, making up about 92% of natural silicon. Moreover, it has long been known that Si-28 is the best conductor of heat. If purified, Si-28 can conduct heat about 10% better than natural silicon. However, the advantage has been judged as not really being worthwhile, until now.

Sometimes technologies are worth re-examining and re-evaluating as complementary technologies emerge, and this seems to be the case here. In brief, the scientists decided to use purified Si-28 to create ultrathin nanowires.

Initially, the scientists confirmed that Si-28 was just 10% better at heat conductance than natural silicon. Moving down to wires of 1mm in diameter, this remained the case. However, when they created 90nm Si-28 nanowires (about a thousand times thinner than a human hair) the heat conductance was 150% better, which was a great surprise to them. They had only expected 10–20% better performance.

Investigations brought to light two main reasons for the excellent thermal conductivity of Si-28 nanowires. Electron microscopy revealed that the Si-28 nanowires had a more perfect glassy finish, so they didn't suffer from the drawbacks of phonon confusion / escape in natural silicon nanowire thermal transmission. Secondly, a natural layer of SiO2 formed on these nanowires, keeping the phonons transporting heat on-track. In summary, two previously observed phonon blocking mechanisms were vastly reduced due to the new material.

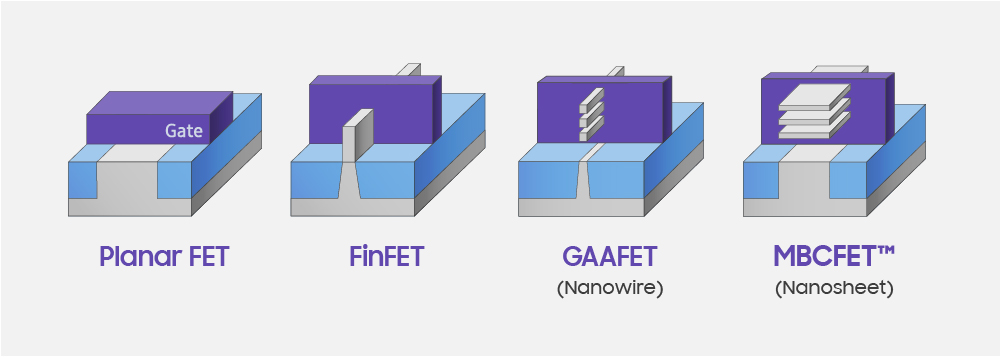

So, what is the use of a 150% better heat conducting silicon nanowire? Some state-of-the-art transistor designs already incorporate silicon nanowires. The Gate-All-Around Field Effect Transistor (GAA-FET) uses silicon nanowires stacked together to conduct electricity, but they still suffer from heat build-up. If this new material can be substituted then processor designers can grab a relatively quick and easy win.

Moving forward, the research team involved in Si-28 nanowires want to do more to control, rather than measure, heat conduction in the nanowires. Reading through the source article, there currently seems to be a severe lack of purified Si-28 available for further testing. The samples used in the above experiments came from a former Soviet-era isotope manufacturing plant.

If the benefits are really as good as claimed, then it would be necessary for one or more manufacturers to begin refining Si-28 again. Given the difficulty of further scaling of process technology, even a 50% boost in heat conductance might be reason enough to do so, never mind the claimed 150% improvement.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

TJ Hooker "Photon" is used several times throughout this article, the correct word in this context is "phonon".Reply -

Geef They probably just took a closeup picture of my blue jeans and greyed it out to get that photo.Reply -

warezme Reply

A red thread from your shirt seems to have unraveled on your jeans.Geef said:They probably just took a closeup picture of my blue jeans and greyed it out to get that photo. -

derekullo Why not just use silver nano-wiring?Reply

Silver is already highly conductive and extremely malleable, unlike silicon.

Find a way run silver threads in a processor and have that in contact with a heatsink. -

hotaru.hino Reply

My guesses:derekullo said:Why not just use silver nano-wiring?

Silver is already highly conductive and extremely malleable, unlike silicon.

Find a way run silver threads in a processor and have that in contact with a heatsink.

The wires are etched into the die, so it's only a slight modification to the process. Silver would have to be deposited.

Silver is electrically conductive, which I'd wager is something you don't want touching transistors. At least not without wrapping the silver around something electrically insulating, which would decrease the thermal benefit, if not take up more die space.

It's also one more material to keep around. -

InvalidError Using Si28 nano-wires as GAA channels sounds problematic since you need to dope the junction (knock out some Si28 atoms to put in the N/P dopant appropriate for the desired junction type) to make it work.Reply -

edzieba Sourcing isotopically pure silicon in bulk quantities is no easy task. Unless there is a convenient chemical separation process discovered you're looking at banks of centrifuges for physical isotope separation for silicon enrichment similar to those used for Uranium enrichment, except you will need to do so in many orders of magnitude larger quantities due to the demand for silicon vs. HEU (under 3 tonnes per year vs over 15,000 tonnes). Even if a chemical separation process is available, its still not an easy task to scale that up from a small lab to mass production, as if growing monocrystalline silicon boules was not hard enough already!Reply -

I agree I don’t see this happening anytime soon if ever at all. Most of this junk is just pie in the skyReply

More important to me is the electric grid. Not enough attention is paid to this. Governments what all cars to be electric and our electric grids cannot even handle the current load that is placed upon it. They need to solve more problems than this. -

InvalidError Reply

Work smarter, not harder: grid load has peaks and lows, just put grid-aware L2 EVSEs in every parking lot and give people the option of slow-charging at a variable speed based on grid conditions at a preferential billing rate to smooth out grid load. This would be good enough for most people to charge their EVs overnight every 2-3 days.Mandark said:More important to me is the electric grid. Not enough attention is paid to this. Governments what all cars to be electric and our electric grids cannot even handle the current load that is placed upon it. They need to solve more problems than this. -

mamasan2000 Reply

https://www.pluglesspower.com/learn/tesla-model-s-charging-home-public-autonomously/ Whateverway you charge, it uses a lot of watts, kilowatts. Now add a million cars. 1 000 Watts x 1 000 000 = 1 000 000 000 watts. How many power plants is that? That is just for 1 million cars. This is like the smallest country in the world, 1 mil cars. Now you add the trucks, the taxis, vehicles that are roilling on the roads at all times. Emergency sevices. Suddenly the load wont be the smooth, small or even feasible unless you build like 5-100 new nuclear plants in every country. In a political climate where even building one is questionnable and would take 10 years.InvalidError said:Work smarter, not harder: grid load has peaks and lows, just put grid-aware L2 EVSEs in every parking lot and give people the option of slow-charging at a variable speed based on grid conditions at a preferential billing rate to smooth out grid load. This would be good enough for most people to charge their EVs overnight every 2-3 days.