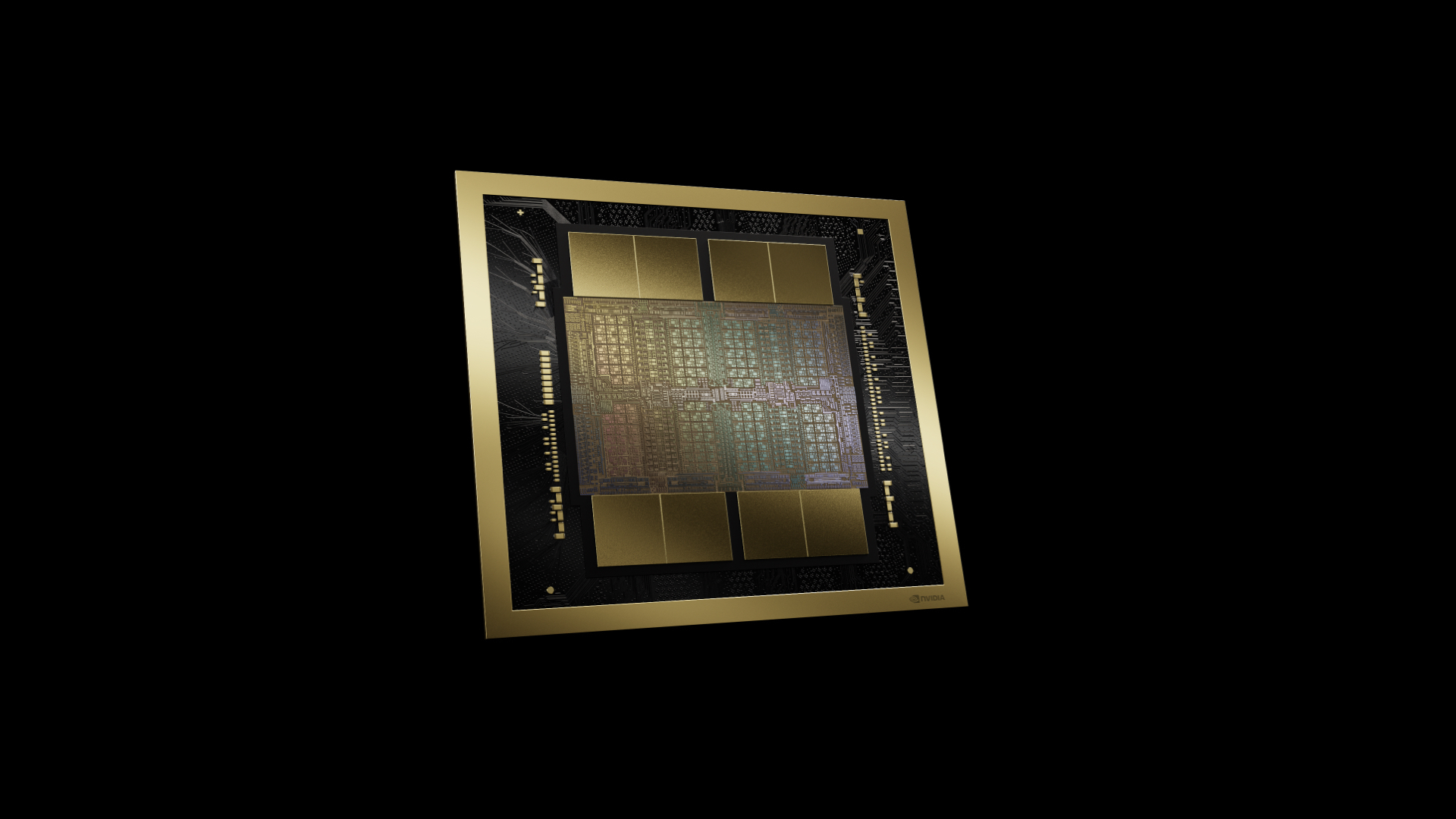

TSMC is reportedly in talks with Nvidia to make Blackwell GPUs in Arizona — Blackwell silicon needs to be shipped back to Taiwan for assembly

TSMC could move production of some of Nvidia's Blackwell GPUs to America.

TSMC is negotiating with Nvidia to produce its Blackwell GPUs for AI at its Fab 21 near Phoenix, Arizona, reports Reuters. If the companies ink an appropriate agreement, Nvidia might get additional Blackwell GPUs produced in the U.S., undoubtedly pleasing its customers and politicians. There are a couple of catches, though.

Nvidia's Blackwell GPUs are made using TSMC's custom 4NP (4nm-class) process technology that can be relatively easily ported from the foundry's fabs in Taiwan to its Fab 21 in Arizona, which is designed to make chips on 4nm and 5nm-class production nodes.

Nvidia's highest-end Blackwell GPUs for AI and HPC rely on TSMC's CoWoS-L (B100, B200, B300, etc.) and CoWoS-S (B200A, B300A) packaging. TSMC does not have an advanced packaging facility in the U.S., and its partner Amkor will only start packaging chips in Arizona in 2027. As a result, Blackwell AI silicon produced in Arizona will need to be shipped back to Taiwan for final assembly, as all of TSMC's CoWoS packaging capacity remains in Taiwan. Shipping to Taiwan would add costs, but since most AI servers are assembled in Taiwan anyway, this should not create a significant logistics problem.

Theoretically, Nvidia could redesign Blackwell silicon for production in the U.S. and use Intel's EMIB and Foveros 3D packaging instead of TSMC's advanced packaging methods. However, that would increase costs, too. Still, if Nvidia wants all-American Blackwell GPUs for AI, this could be a way to achieve this.

Hypothetically, Nvidia could also produce Blackwell gaming GPUs at Fab 21 and, therefore, free up capacity for Blackwell AI GPUs in Taiwan. These chips do not require sophisticated packaging, so they could be assembled in the U.S. However, since nobody produces graphics cards in America these days and TSMC is set to charge extra for chips made outside of Taiwan, it hardly makes a lot of sense to make gaming GPUs in Arizona.

Apple and AMD are confirmed as customers of TSMC's Fab 21 in Arizona. Still, neither company has officially disclosed products set to be made in the U.S., even though a rumor is that Apple makes its A16 Bionic at the facility. Nvidia and TSMC also declined to comment on the ongoing negotiations to Reuters as they are confidential.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

YSCCC From what it looks there seems to have no reason to manufacture the chips in US fab, when all parts are made in TaiwanReply -

Notton This is just one example of the US not having the capability of manufacturing an item because the factory hasn't been built yet.Reply

At least the silicon, silicon ingot, and wafers can be produced in USA, I think?

IDK where TSMC AZ source their wafers from, but I know USA has the mining, refinery, and factory for wafer production. -

93QSD5 unlikely but I applaud the effort to bring semiprodictuction back to the west (for supply chain safety reasons)Reply

- Materials / supply chains. If you can't even secure the materials needed to produce chips, you're just left with a fancy expensive fab.

- Expertise (specifically production and all around it, not design).

- Costs. It's not surprising that wages, materials, transport, regulations, electricity including env. concerns and so on cost more here.

- Working conditions/morale. We already had reports of workers refusibg to adapt to the taiwan working conditions of grueling prolonged working shifts of up to 12 hours a day etc. -

gamerk316 Reply

Which is why I'm pessimistic of any long-term success under market conditions. Heck, the big discussion right now is "Will Intel sell its Fab division", and they're kind of the last game in town.93QSD5 said:unlikely but I applaud the effort to bring semiprodictuction back to the west (for supply chain safety reasons)

- Materials / supply chains. If you can't even secure the materials needed to produce chips, you're just left with a fancy expensive fab.

- Expertise (specifically production and all around it, not design).

- Costs. It's not surprising that wages, materials, transport, regulations, electricity including env. concerns and so on cost more here.

- Working conditions/morale. We already had reports of workers refusibg to adapt to the taiwan working conditions of grueling prolonged working shifts of up to 12 hours a day etc.

To me, if we want to maintain the ability to manufacture chips in the US, then the only mechanism to make production even remotely competitive is to either directly subsidize (or even nationalize) production. Even at 500% import tariffs its still substantially cheaper to produce elsewhere and eat the hit then it is to maintain US facilities and workforce. -

3en88 TSMC should be forced to move all fabs to the US where yields are higher, energy is cheaper and logistics are simpler by the end of Trumps term or be placed on the entity list. This will bring down the costs for American consumers, create jobs and remove a foreign competitor.Reply -

Conor Stewart Reply

So you think that the US should bully a company with strong ties to the Taiwanese government to jump ship and completely move to the US? You think that they should abuse a system like the entity list to get what they want?3en88 said:TSMC should be forced to move all fabs to the US where yields are higher, energy is cheaper and logistics are simpler by the end of Trumps term or be placed on the entity list. This will bring down the costs for American consumers, create jobs and remove a foreign competitor.

Also "yields are higher"? What a load of nonsense. Where the chips are manufactured has no impact on yields, a fab being in the US doesn't automatically increase yields. Where are you getting that electricity is cheaper? How will it make logistics simpler if you are just moving the fabs? There are other things that go into chip production.

Yes it may create jobs in the US but it will also cost jobs in Taiwan so it really wouldn't create jobs at all, it would just move them.

Typical selfish American mindset, thinking that you should bully a company into abandoning their country and likely most of their staff just so they can be in the US. Why do you think it should all be in the US anyway? Why isn't having fabs in multiple countries a good option?

Maybe if the US is so great and would be so much better then someone should found an American company to be the US equivalent of TSMC, but instead you just want to bully a company to move to the US since you can't manage it yourself.