Color Laser Printers at Bargain Prices

One-Pass Or Four-Pass, Laser Or LED

Color laser printers use one of two methods to print: one-pass and multi-pass. In the first case, the sheet of paper is fed in a single pass over all four toner cartridges, representing the four primary colors (cyan, magenta, yellow and black), which results in faster printing. In multi-pass, the same sheet travels a longer path since it goes through four successive passes (one per color). Multi-pass reduces the cost of the printer since there's only one drum for all the toner cartridges, whereas with one-pass, there has to be one drum per toner. But of course printing times for color are at least four times as long. That's why for multi-pass color laser printers, manufacturers show two distinct printing times - one for monochrome and one for color, with a ratio of one to five between them.

Since one-pass models are more expensive by nature, until now there haven't really been entry-level models. With the exception of Oki, that is. The Japanese maker has offered one-pass models for years, even at entry level, and the C3200 we tested for this article is no exception. It's true that it's faster in monochrome (20 ppm compared to 12 ppm), but it's also the fastest of all for color. However, Oki is different in that it uses not laser but LED technology for printing.

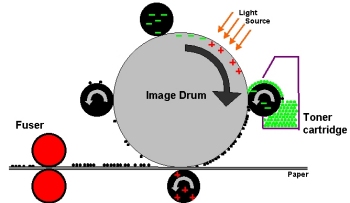

To understand how this technology operates, we first have to recall the operating principle of printers that use electro-photography used by LED and laser printers. In both cases, the first stage consists in illuminating the surface of a photosensitive drum in order to create an electrical field corresponding to the image to be printed. The drum, whose perimeter corresponds to the length of an 8 ½ x 11 page or A4 page, rotates under the beam from the laser or the LED arrays.

In the second phase, the drum is positioned under the toner cartridge corresponding to the color to be printed. It makes a second rotation, attracting the capsules of toner to the areas that were charged by the light source. On the third rotation of the drum, the particles of toner are placed on the page to be printed, and the page passes through the fuser roller to fix the particles. This operation is repeated four times, once per color (but almost simultaneously in the case of one-pass printers).

The difference between LED and laser is in the first stage of the printing process. In the case of laser printers, the beam must sweep the page for each line using a complex process of reflection on a faceted mirror.

The LED technology performs the electro-photography operation one entire line at a time using an array containing several thousand diodes - resulting in a higher potential speed, noticeable above all on top-of-the-line models.

Yet, despite Oki's claims, LED doesn't really offer better image definition, as our tests show. On the other hand, by limiting the number of mechanical parts (and in particular the pivoting mirror), the Oki models are more reliable over time.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

To wrap up this technological chapter, note that the very latest HP printer, the Color LaserJet 2600n, is a one-pass laser model that uses a new type of drum that's smaller and limits the number of passes necessary. So it's halfway between the two categories.

Current page: One-Pass Or Four-Pass, Laser Or LED

Prev Page Introduction Next Page Aberrant Pricing Policies-

chrisbak Your image (laser2.gif) is an excellent animation of an LED printhead in action. Can I use it in some material I am putting together for Xerox, or is there a copyright on it.Reply

Christine Baker

christine.baker@xerox.com