EVGA 450 B3 PSU Review

Why you can trust Tom's Hardware

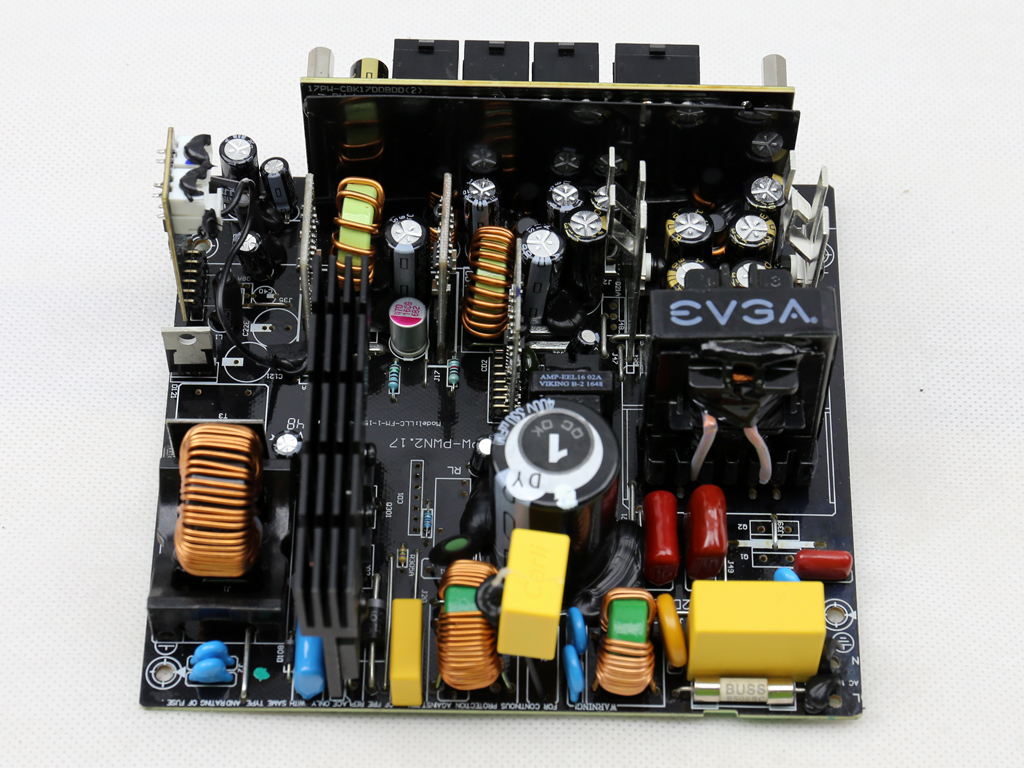

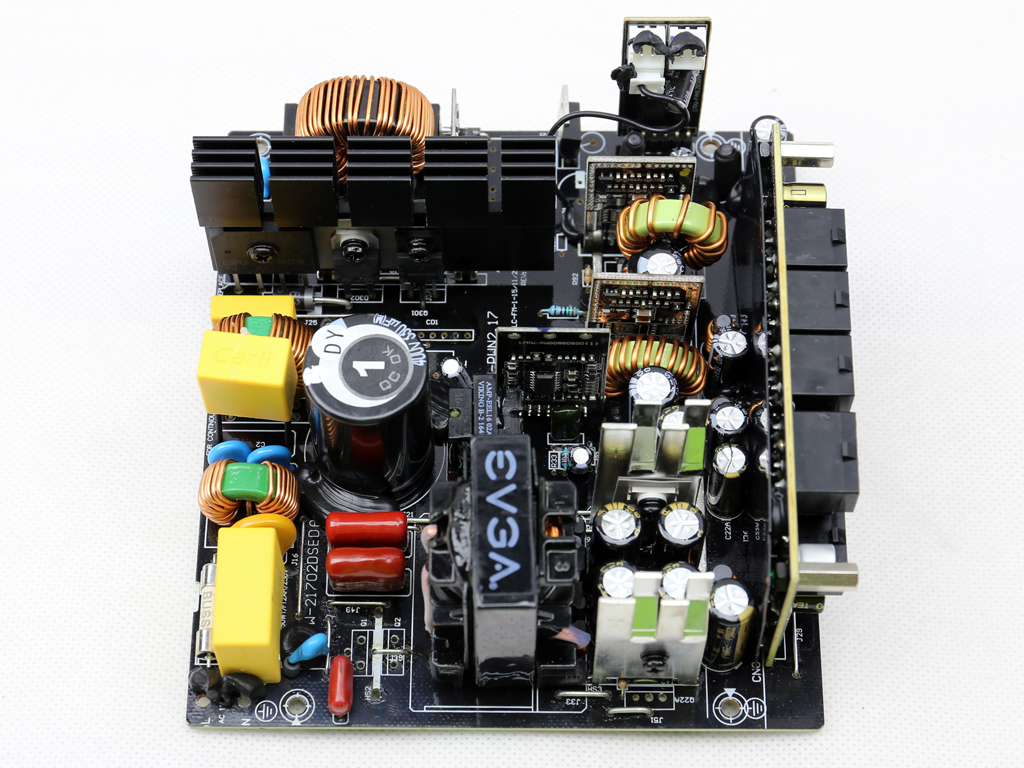

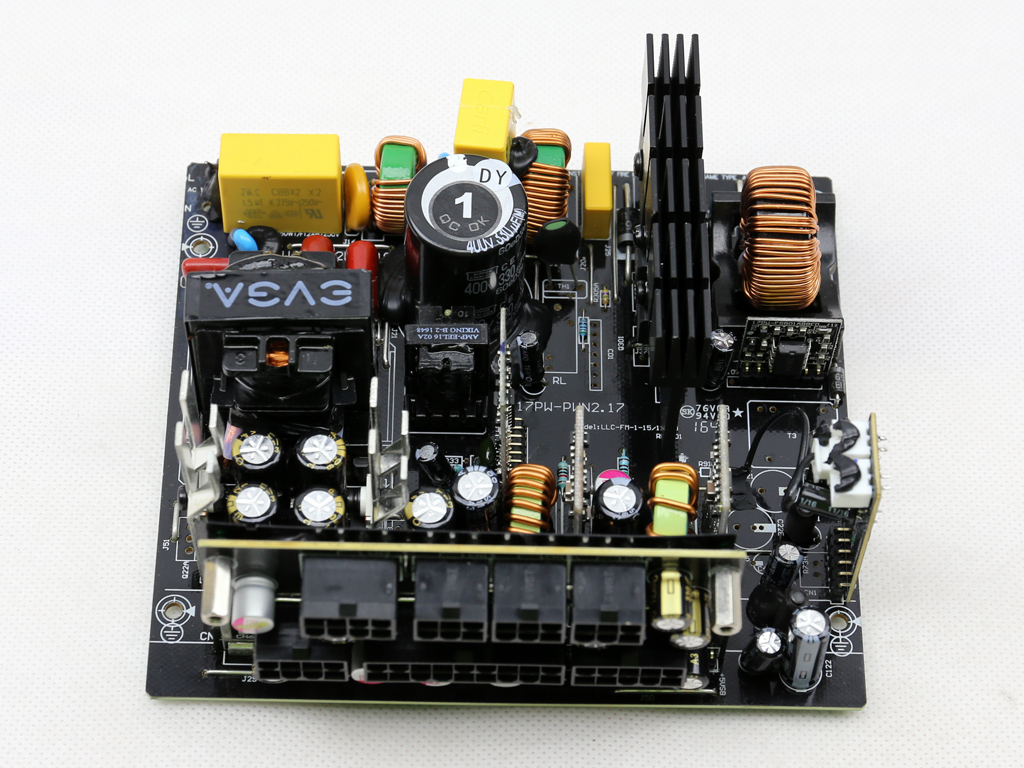

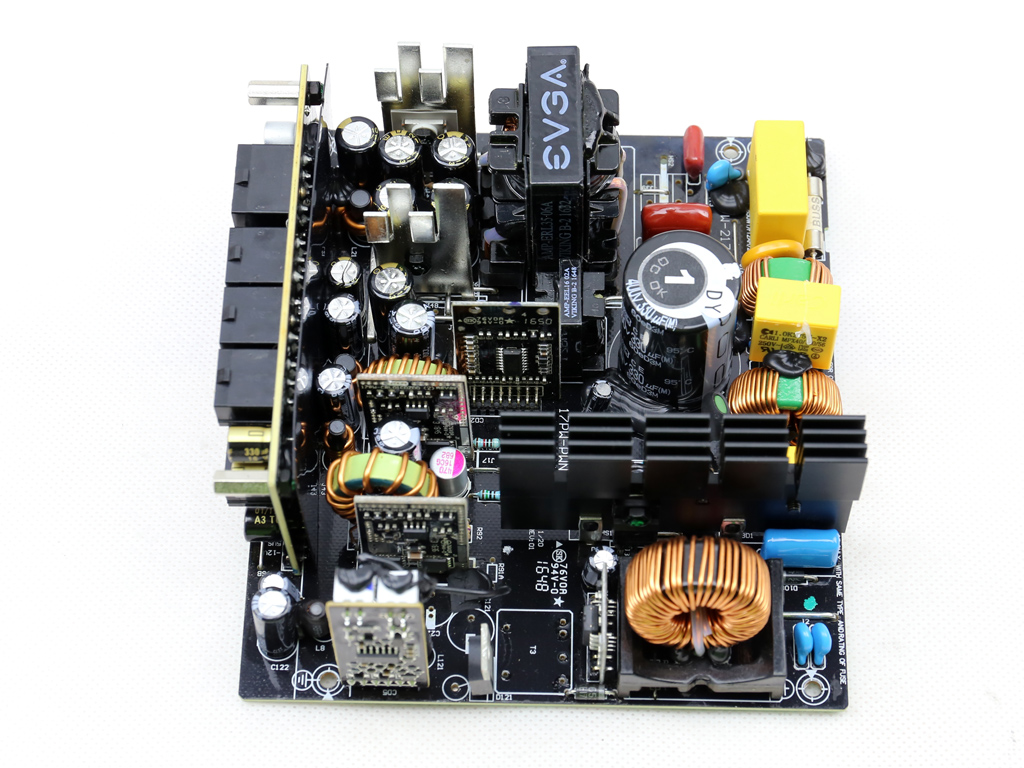

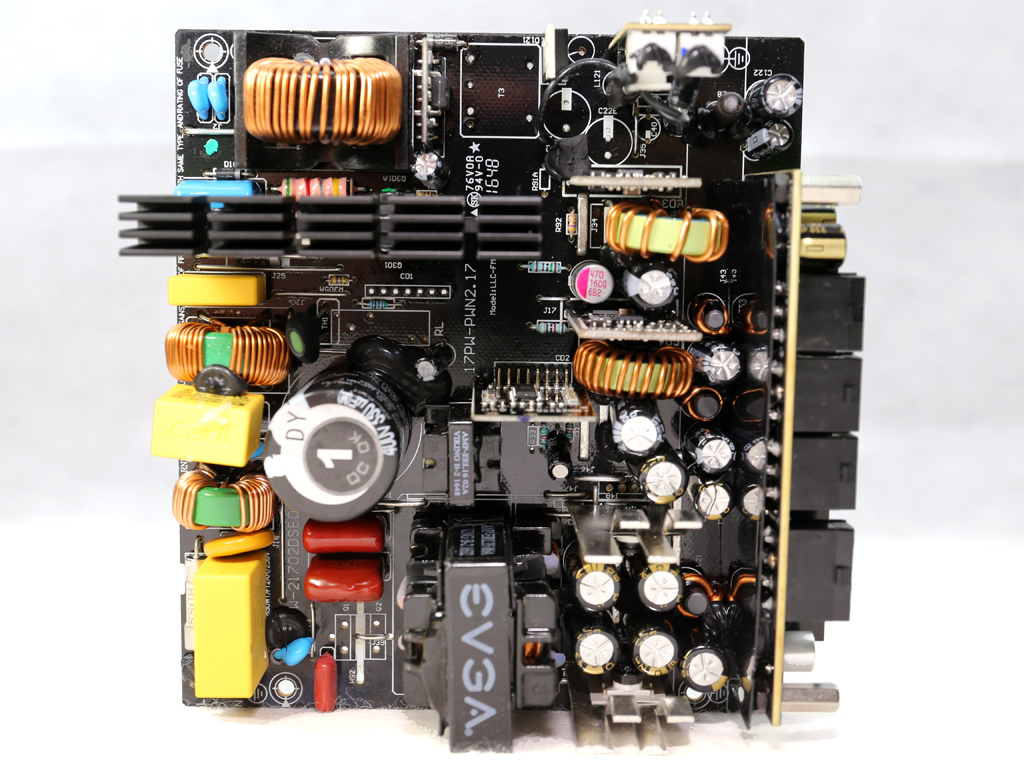

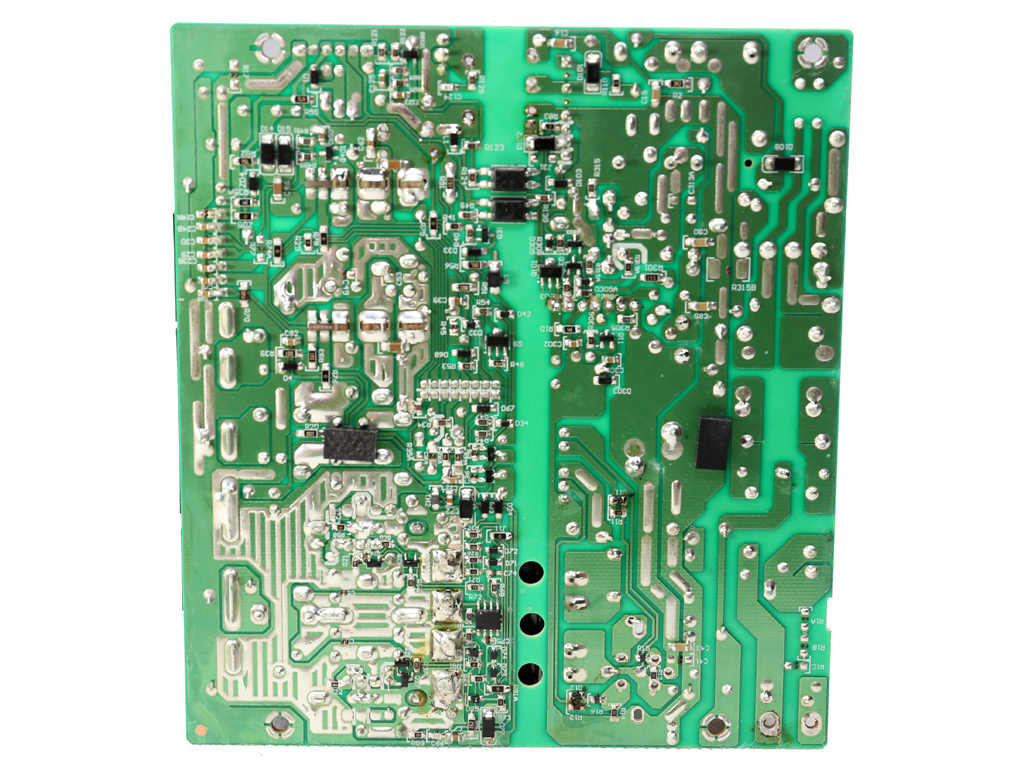

Teardown & Component Analysis

Parts Description

Before proceeding with this page we strongly encourage you to a look at our PSUs 101 article, which provides valuable information about PSUs and their operation, allowing you to better understand the components we're about to discuss. Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station and a Hakko FR-300 desoldering gun. Finally, for the identification of tiny parts we use an Andonstar HDMI digital microscope.

| General Data | |

|---|---|

| Manufacturer (OEM) | Super Flower |

| Platform Model | Leadex Bronze |

| Primary Side | |

| Transient Filter | 5x Y caps, 3x X caps, 2x CM chokes, 1x MOV, 1x TVS Diode |

| Inrush Protection | NTC Thermistor |

| Bridge Rectifier(s) | 1x GBU806 (600V, 8A @ 100°C) |

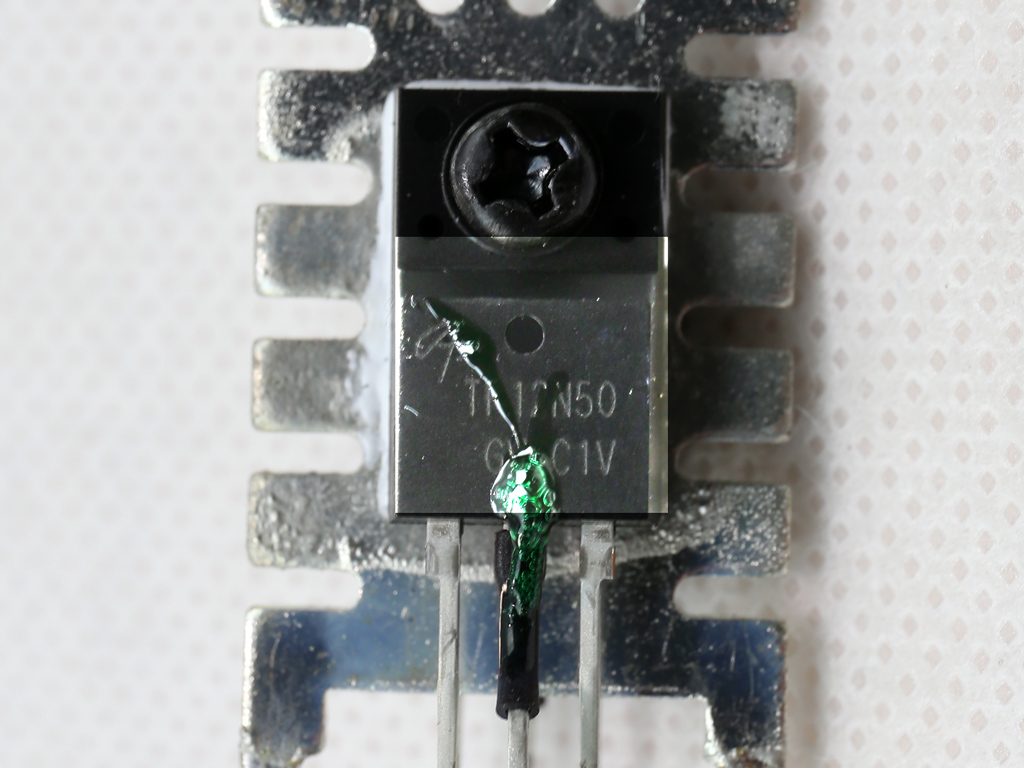

| APFC MOSFETs | 1x A&O AOTF14N50 (500V, 11A @ 100°C, 0.38Ω) |

| APFC Boost Diode | 1x STMicroelectronics STTH8R06D (600V, 8A @ 130°C) |

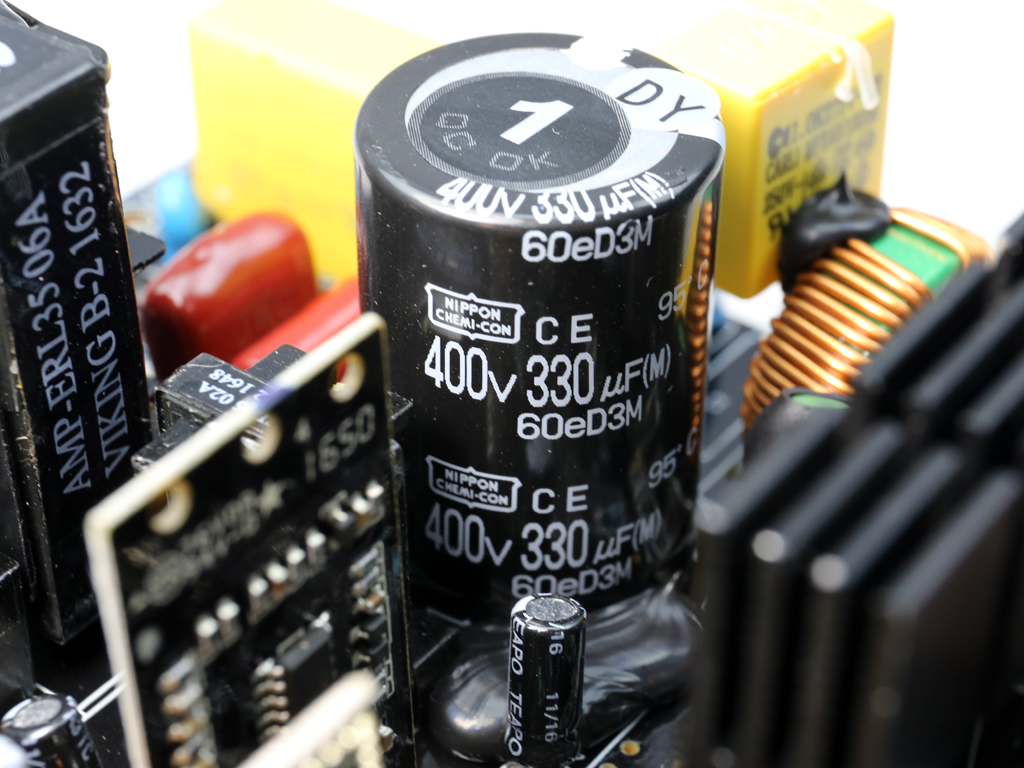

| Hold-up Cap(s) | 1x Nippon Chemi-Con (400V, 330uF, 95°C) |

| Main Switchers | 2x A&O AOTF12N50 (500V, 8.4A @ 100°C, 0.52Ω) |

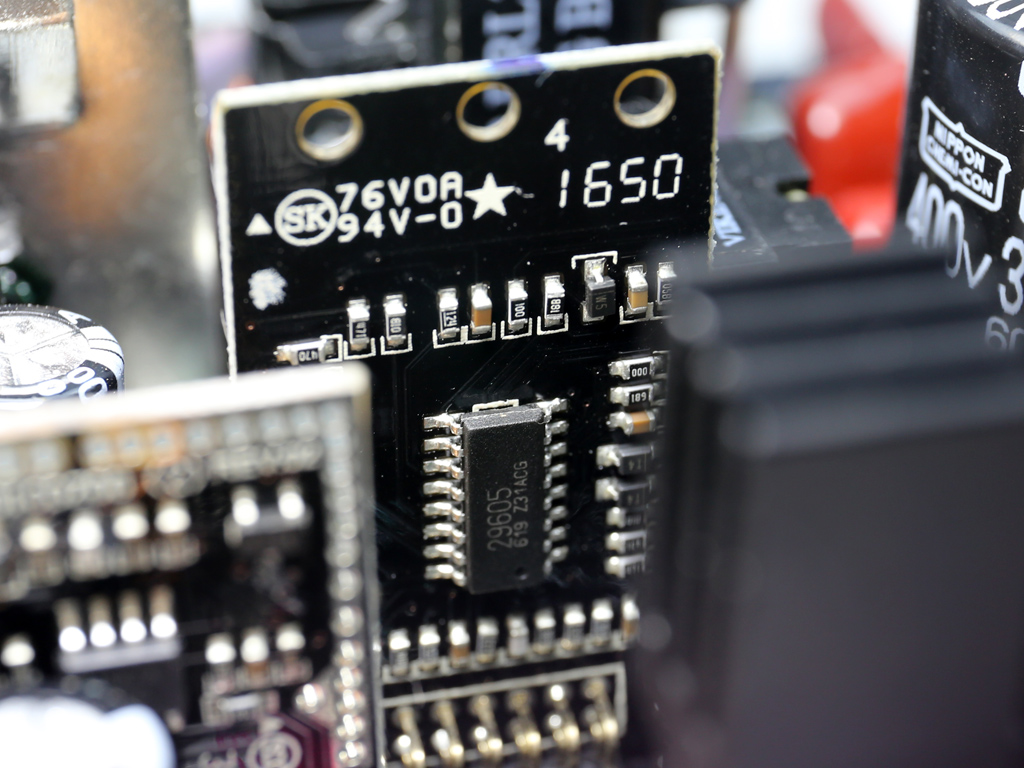

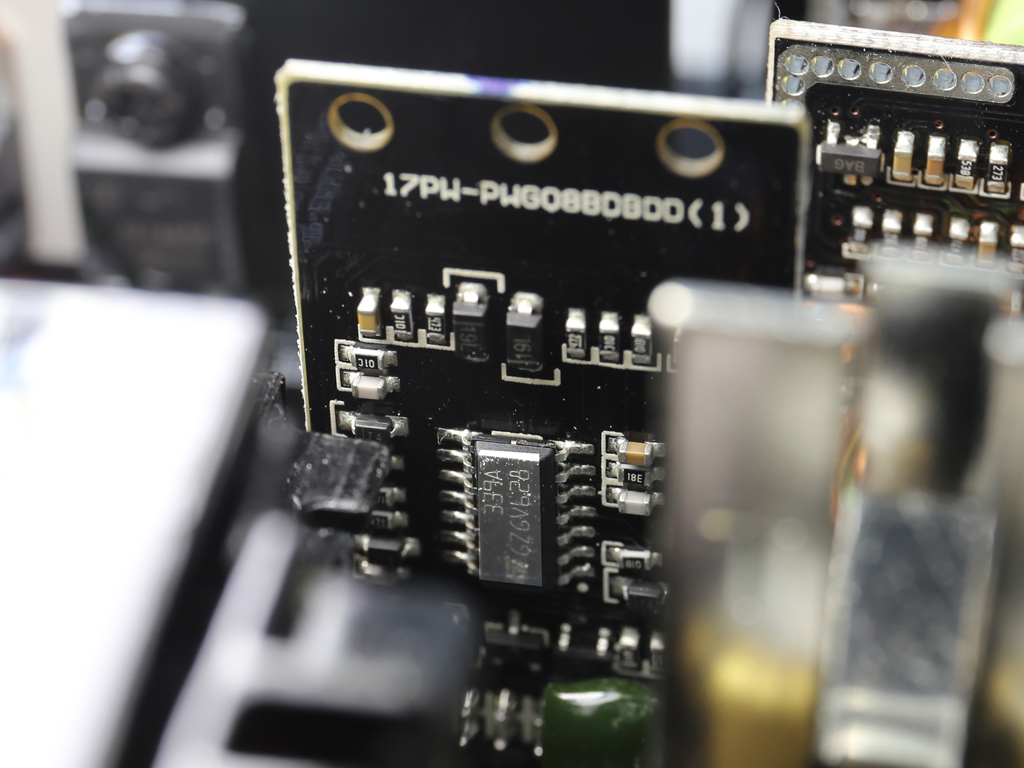

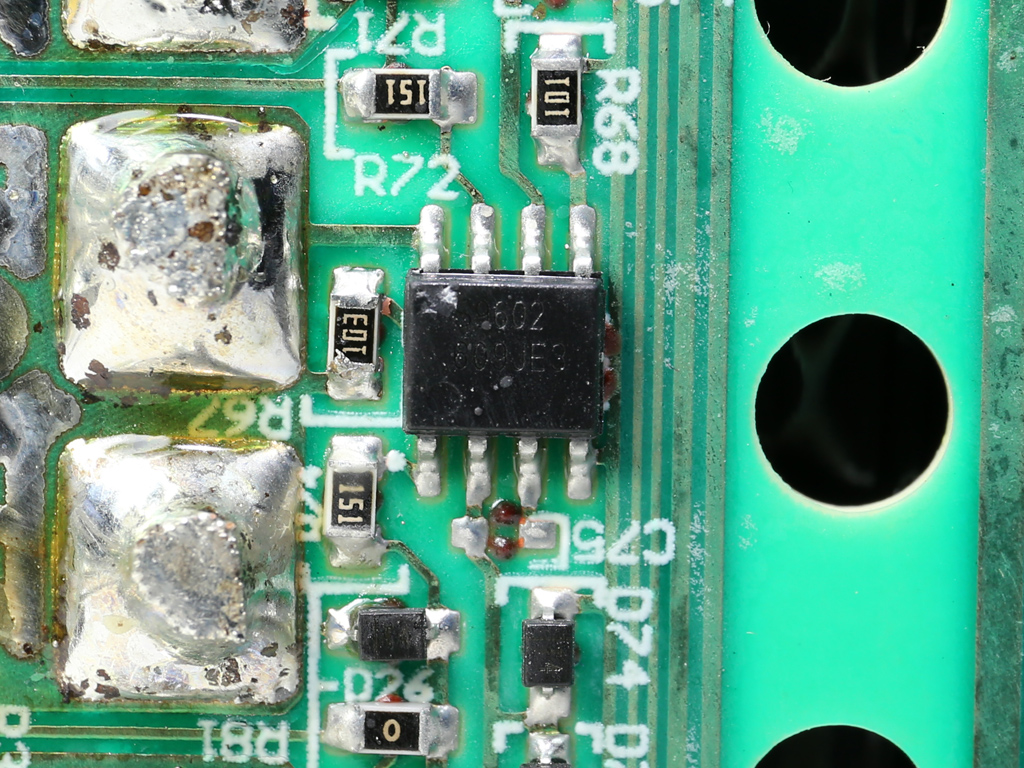

| APFC Controller | SF29603 & S9602 |

| Resonant Controller | SF29605 |

| Topology | Primary side: Half-Bridge & LLC Resonant Controller Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 2x A&O AOT240L (40V, 82A @ 100°C, 4.7mΩ @ 125°C) |

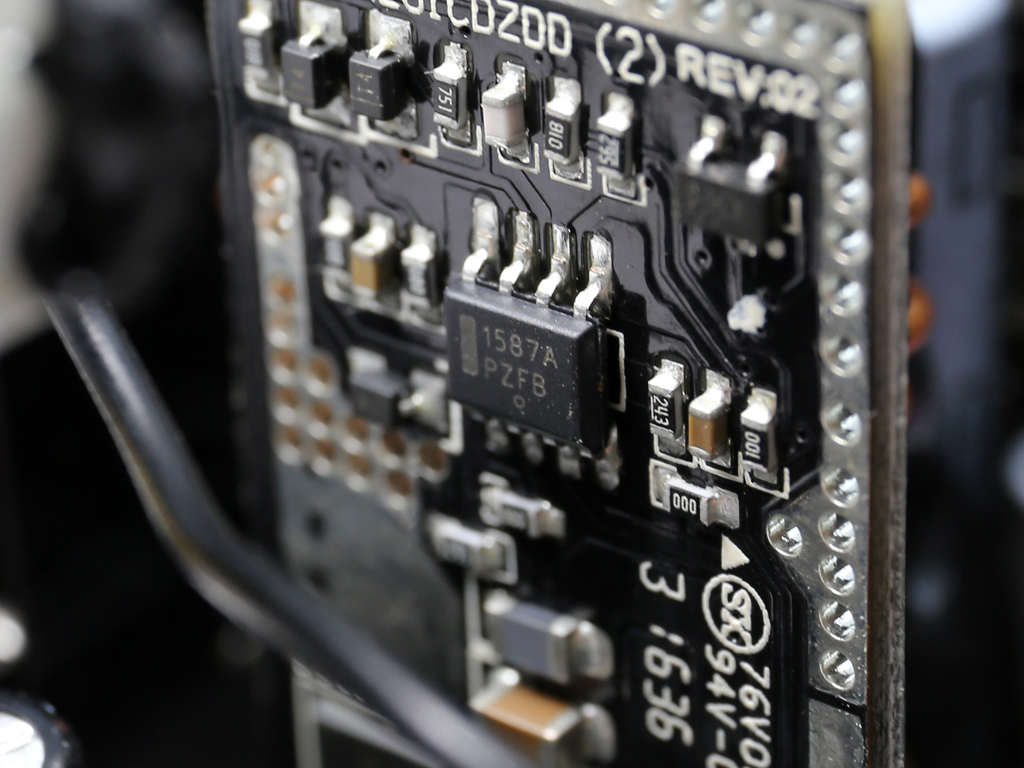

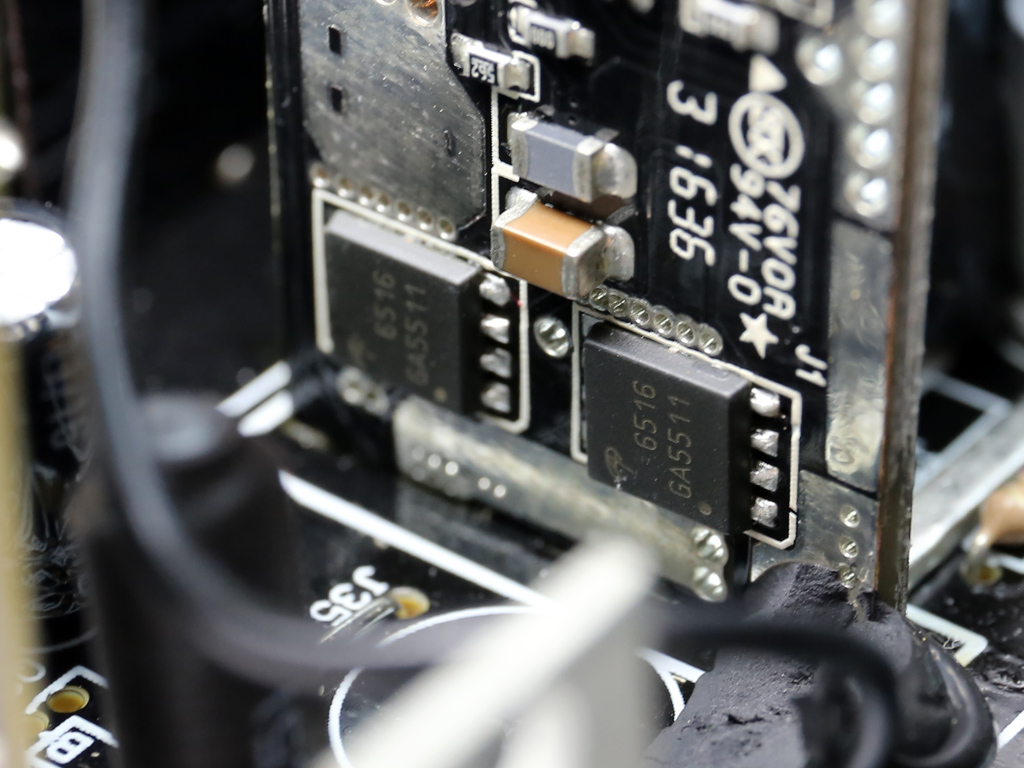

| 5V & 3.3V | DC-DC Converters: 4x A&O AON6516 (30V, 25A @ 100°C, 8mΩ) PWM Controller: 2x On Semiconductor NCP1587A |

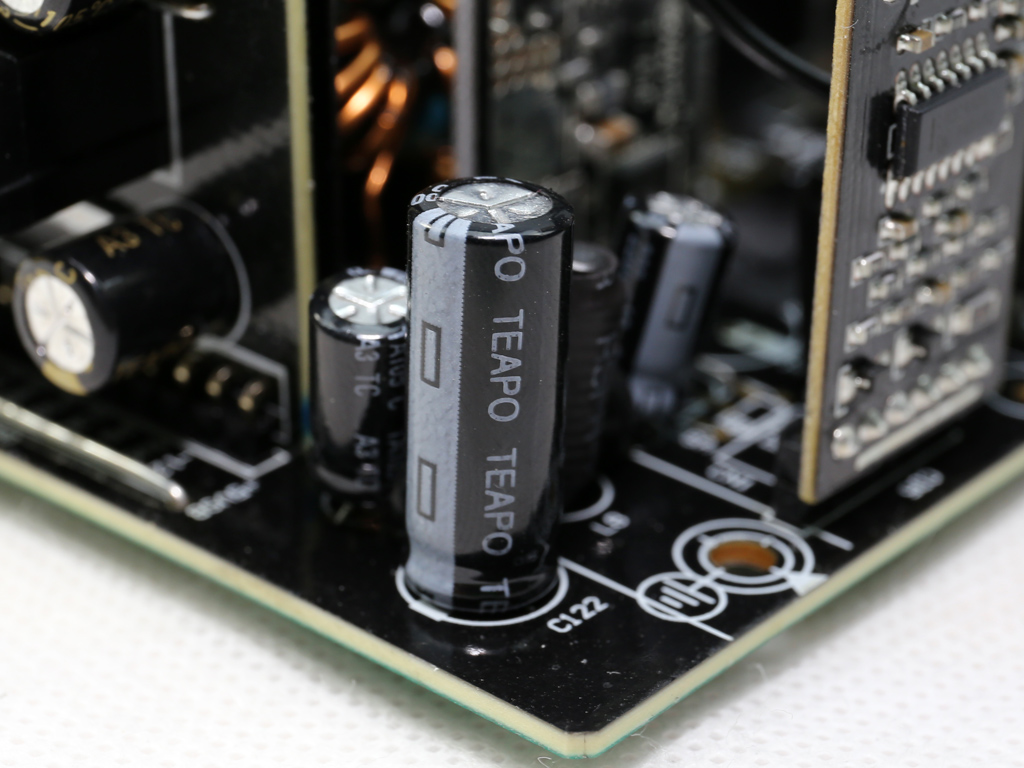

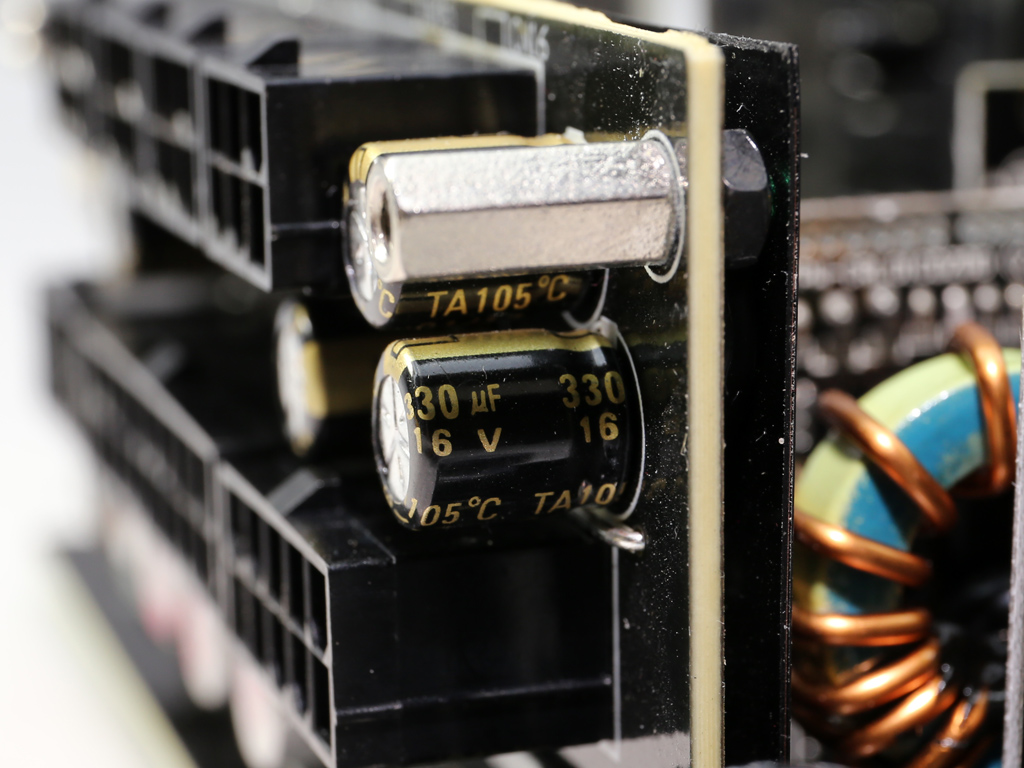

| Filtering Capacitors | Electrolytics: Teapo (3000-6000h @ 105°C, SY) Polymers: Teapo |

| Supervisor IC | SF29603 & LM339A |

| Fan Model | S1282412H (130mm, 12V, 0.35A, Sleeve Bearing) |

| 5VSB Circuit | |

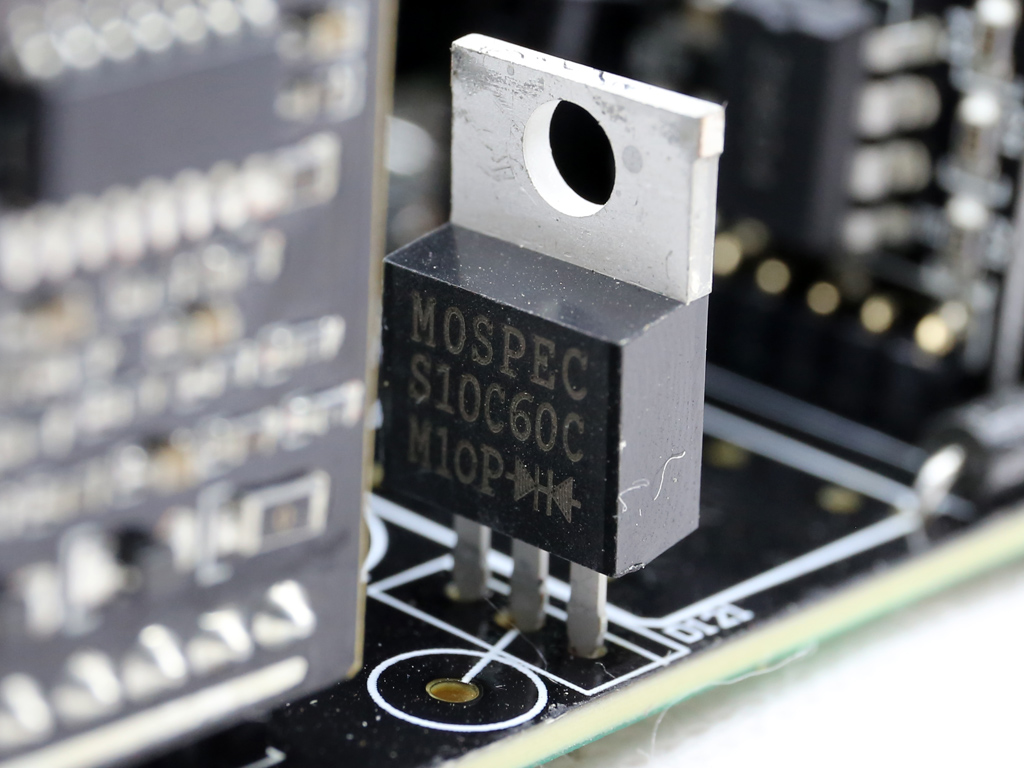

| Rectifier | Mospec S10C60C |

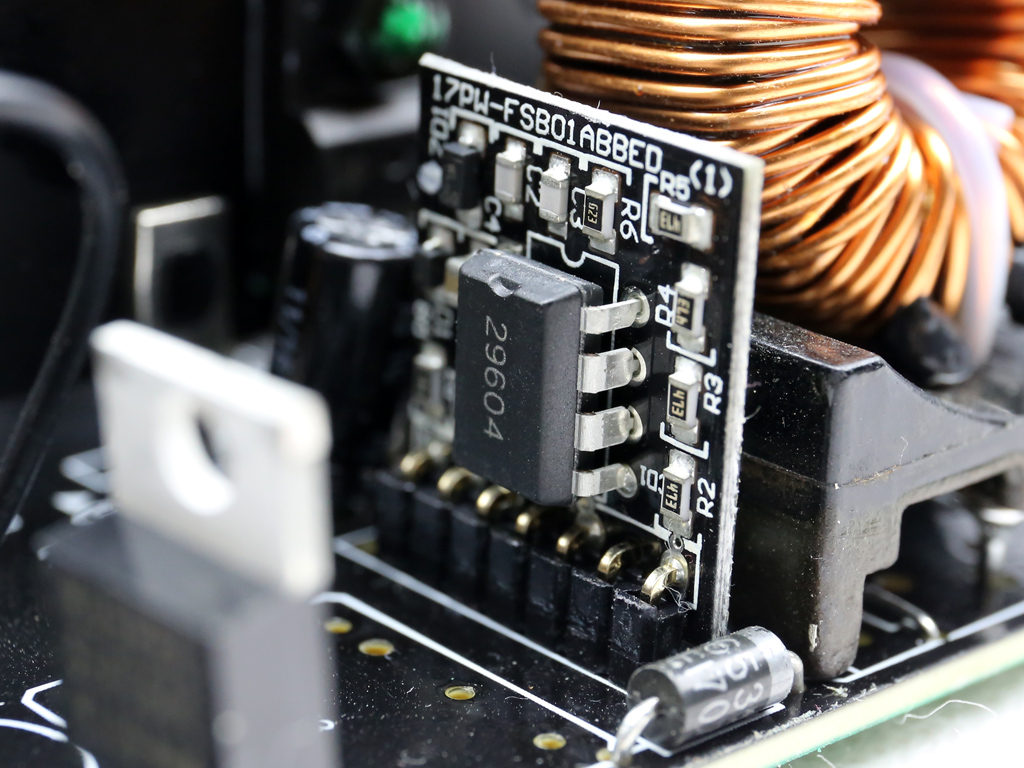

| Standby PWM Controller | 29604 |

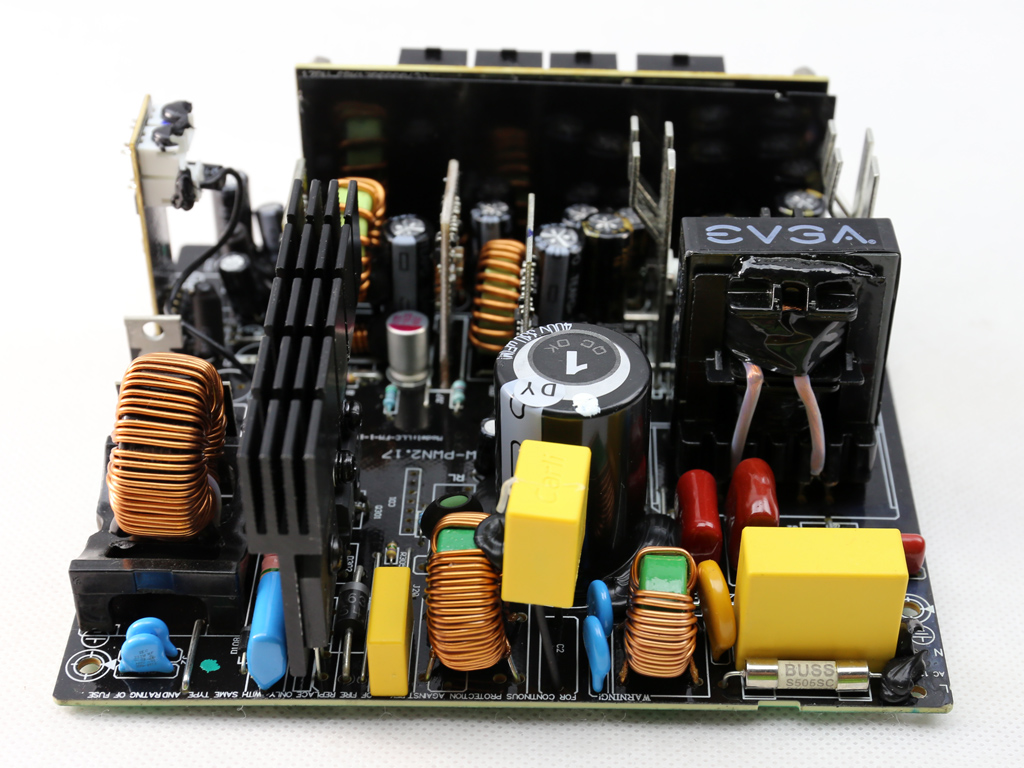

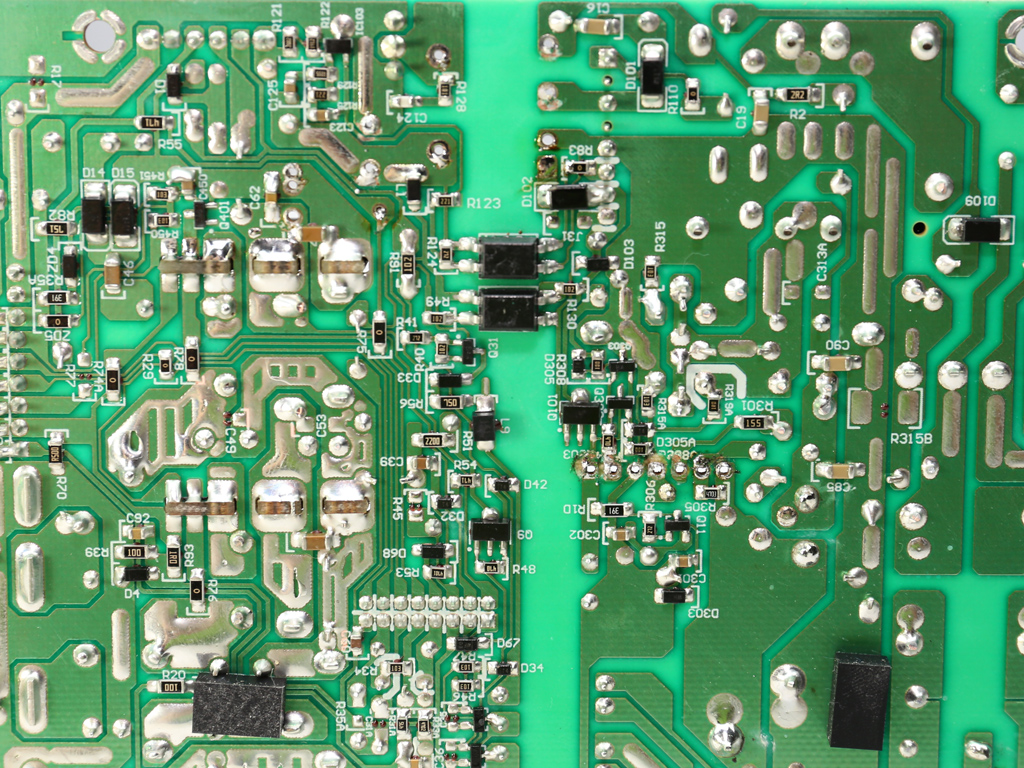

Super Flower is the reason why EVGA became so popular in the PSU market, and all of the company's B3 models are based on a low-efficiency Leadex platform (unofficially referred to as Leadex Bronze). Despite its entry-level efficiency rating, this platform has some serious potential. It utilizes a half-bridge topology on the primary side, along with an LLC resonant converter. On the secondary side, a synchronous rectification scheme is used for the +12V rail, while the minor rails are regulated through a couple of DC-DC converters. All filtering caps are provided by Teapo and belong to a respectable line, which helps extend the 450 B3's longevity. Teapo is a safe choice when cost considerations preclude the use of quality Japanese caps.

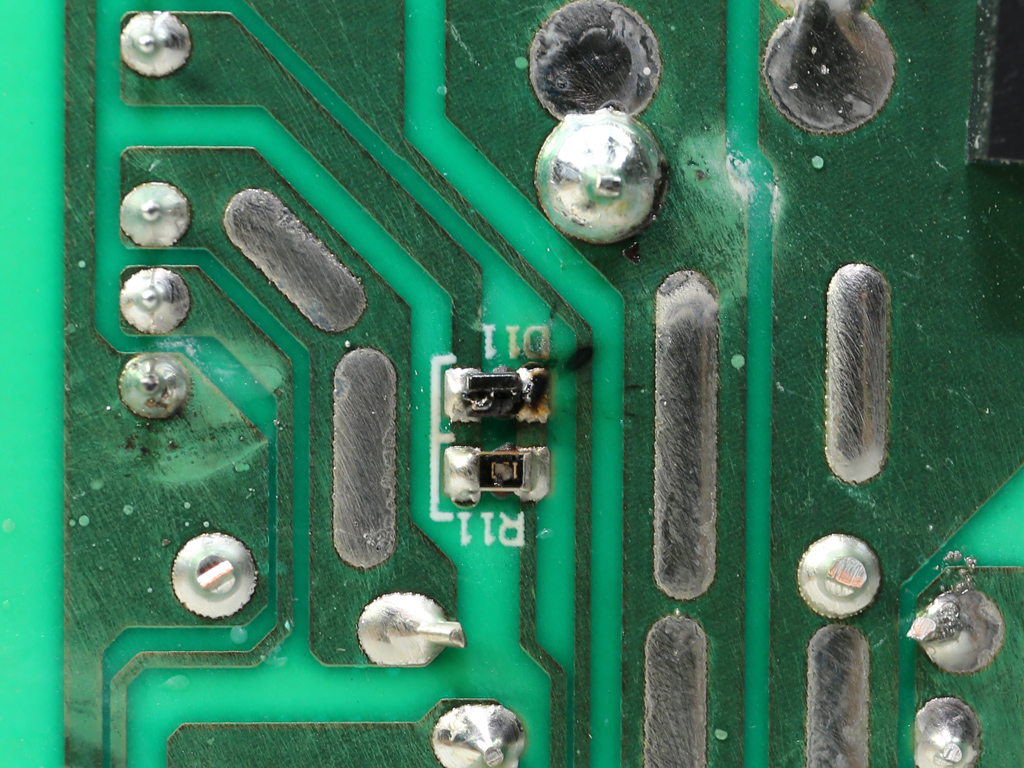

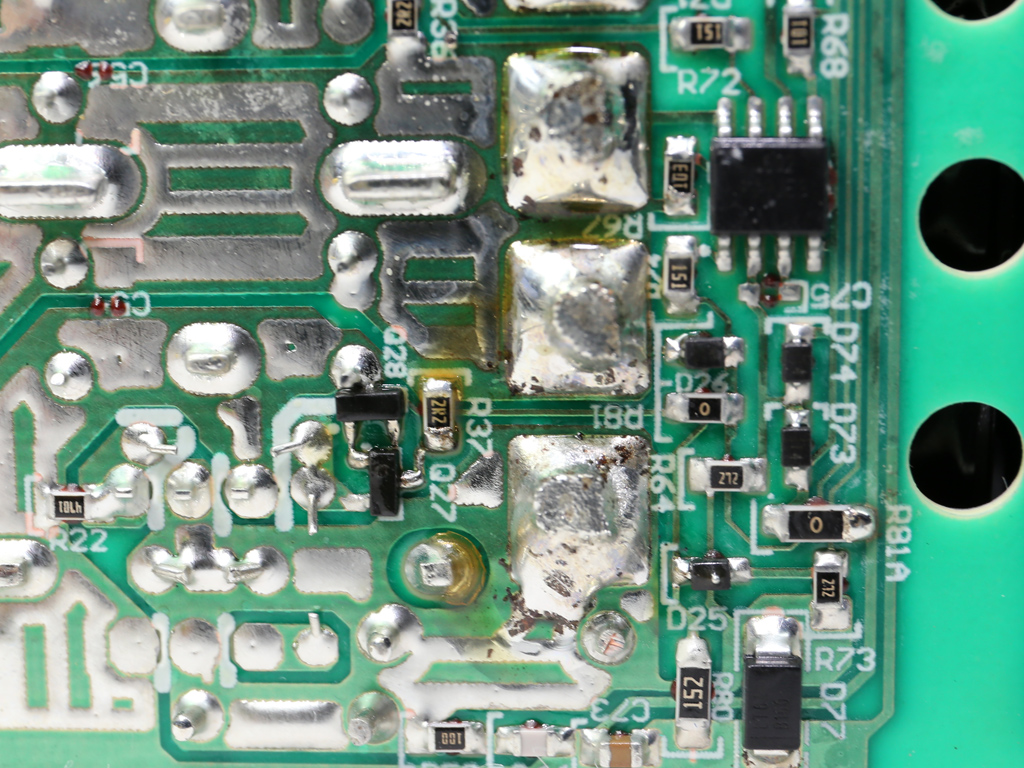

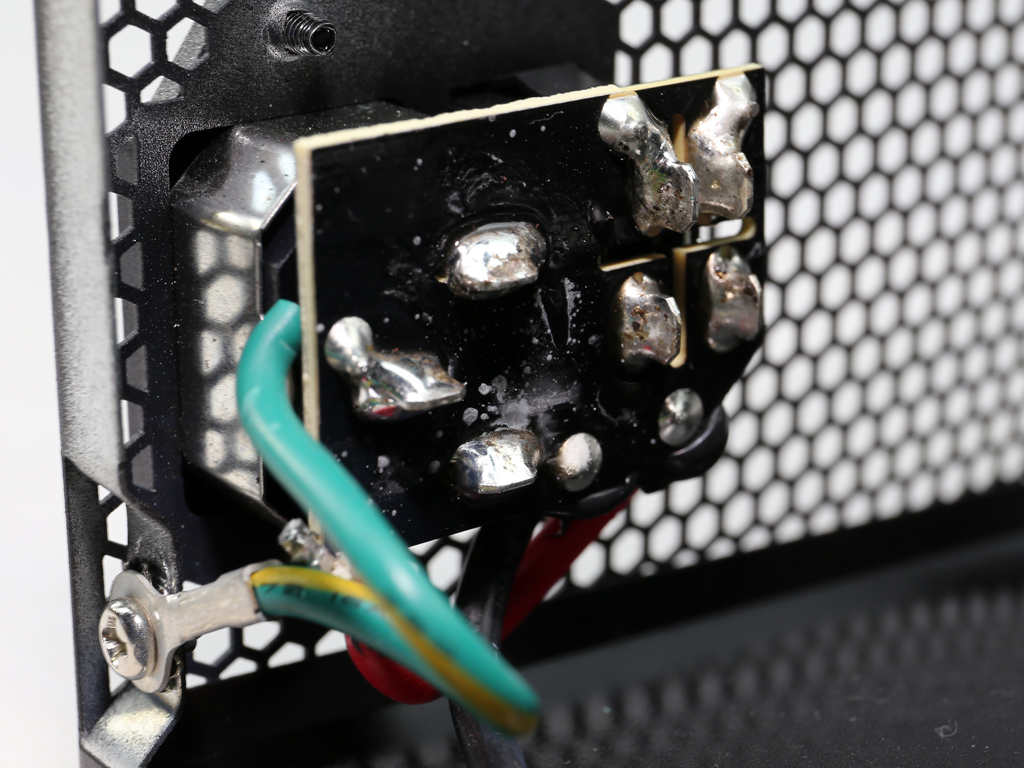

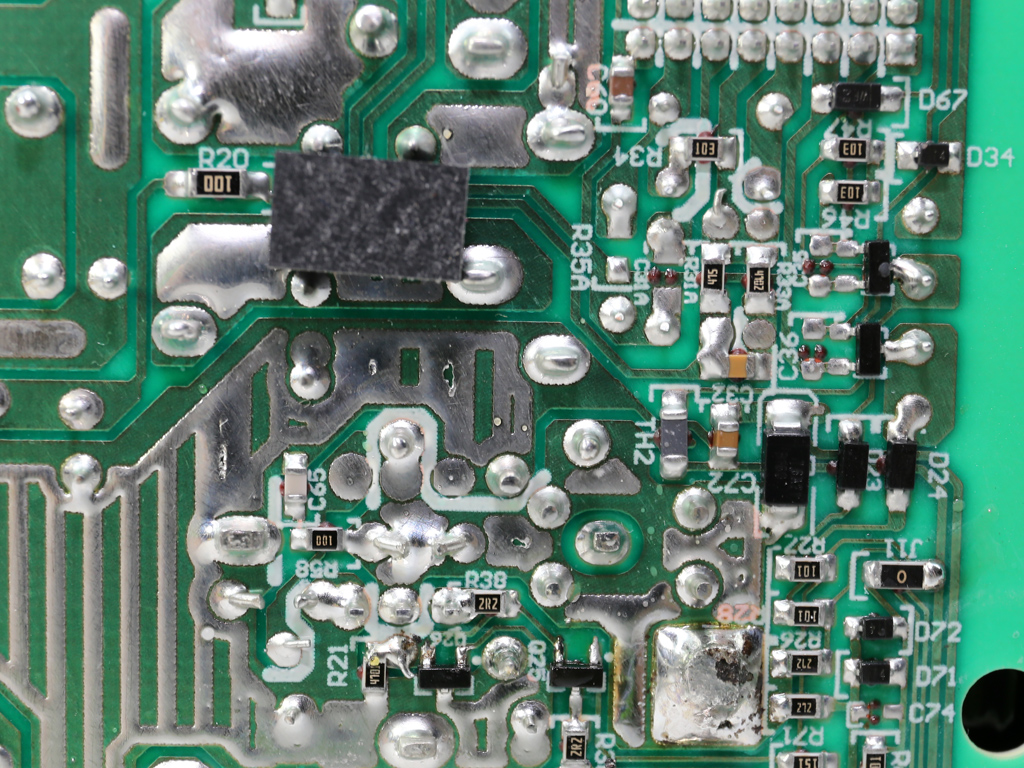

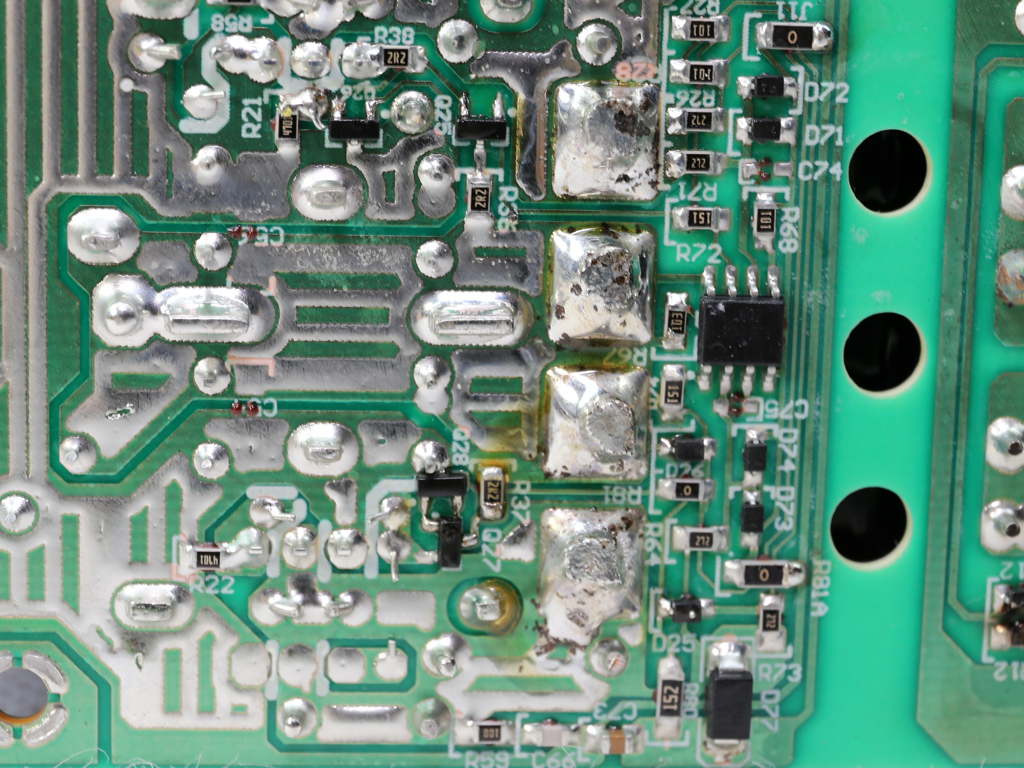

The design looks good. However, Super Flower apparently didn't choose its components well. We discovered this the hard way when the PSU blew up during our OPP evaluation process. This is a great shame, to say the least. Either OPP needs to be set lower or Super Flower needs to use components able to handle more amperage.

We found another problem, too: although the primary side was clearly shorted, the main fuse didn't blow. Thus, every time you connect the PSU to the mains network, you're treated to a fireworks show. Thanks to this platform's "special" feature, we were able to pull a nice prank on one of our lab engineers. See the video above.

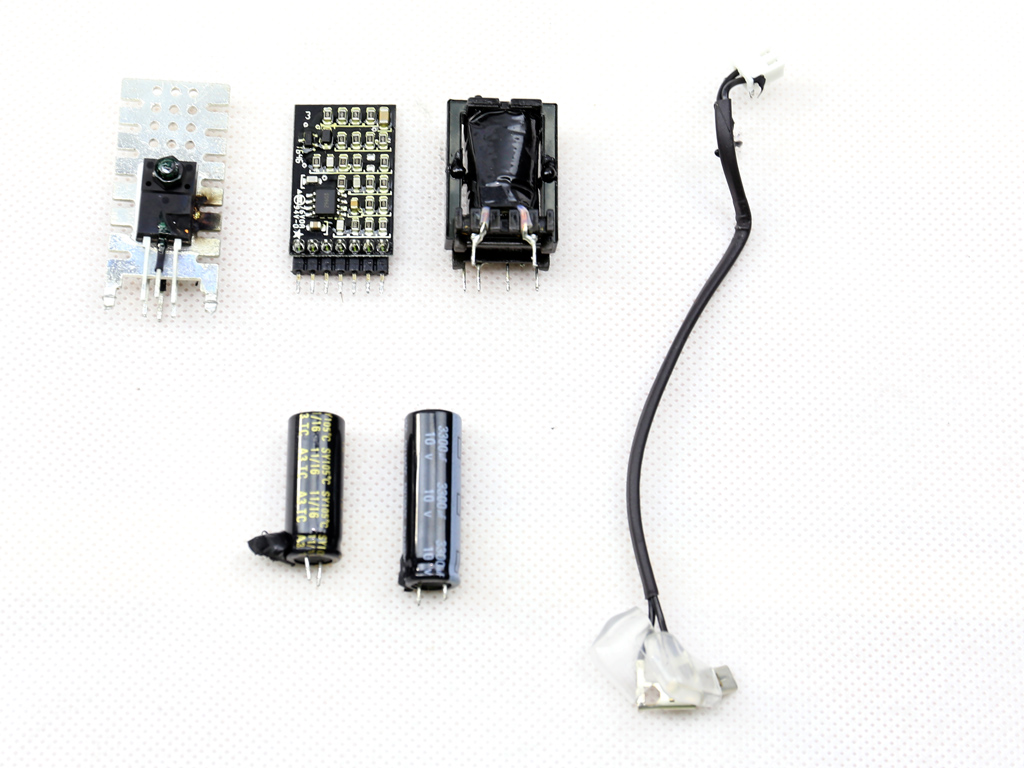

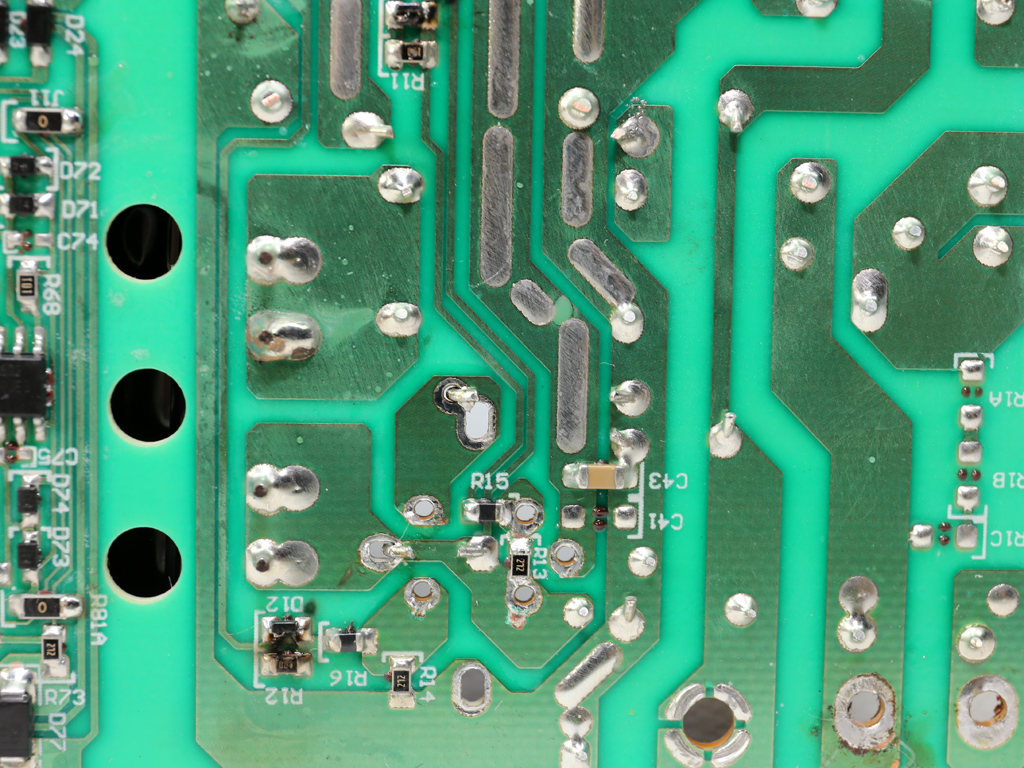

We desoldered enough parts to identify all of the PSU's components and shed more light on the failure under overload.

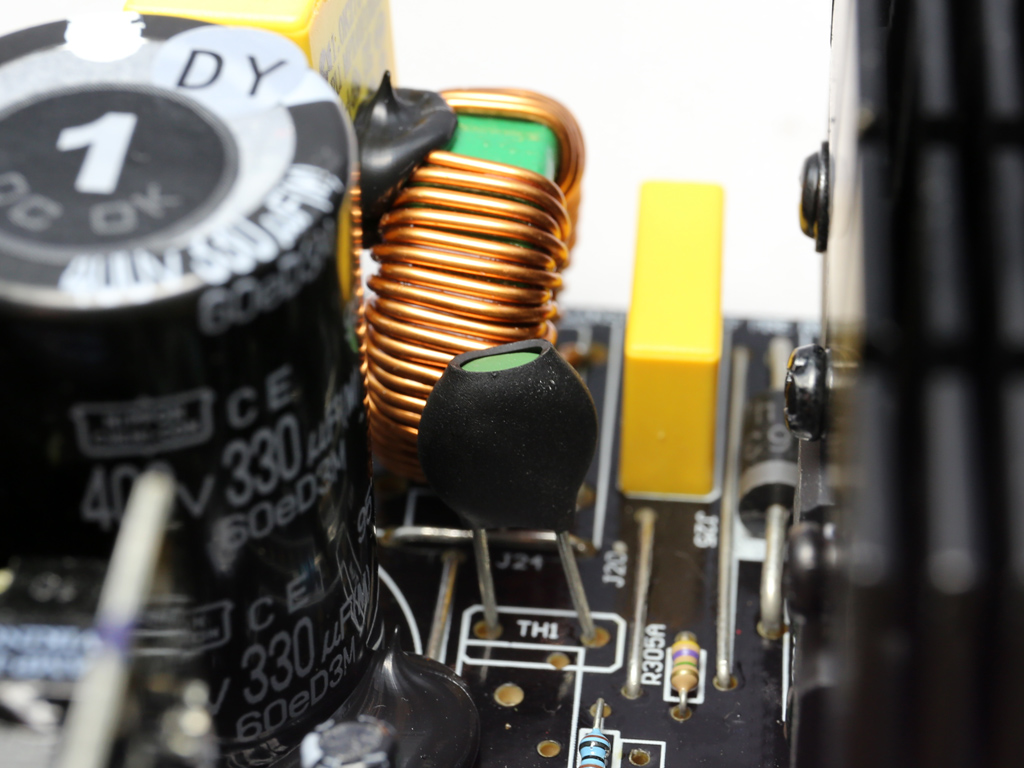

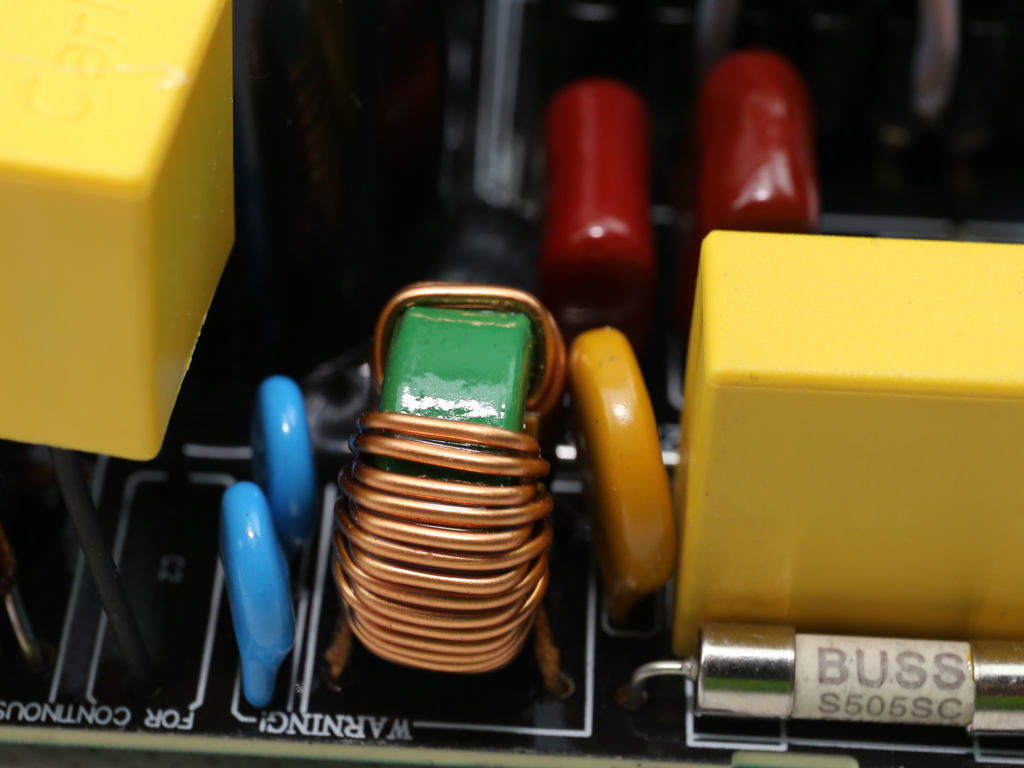

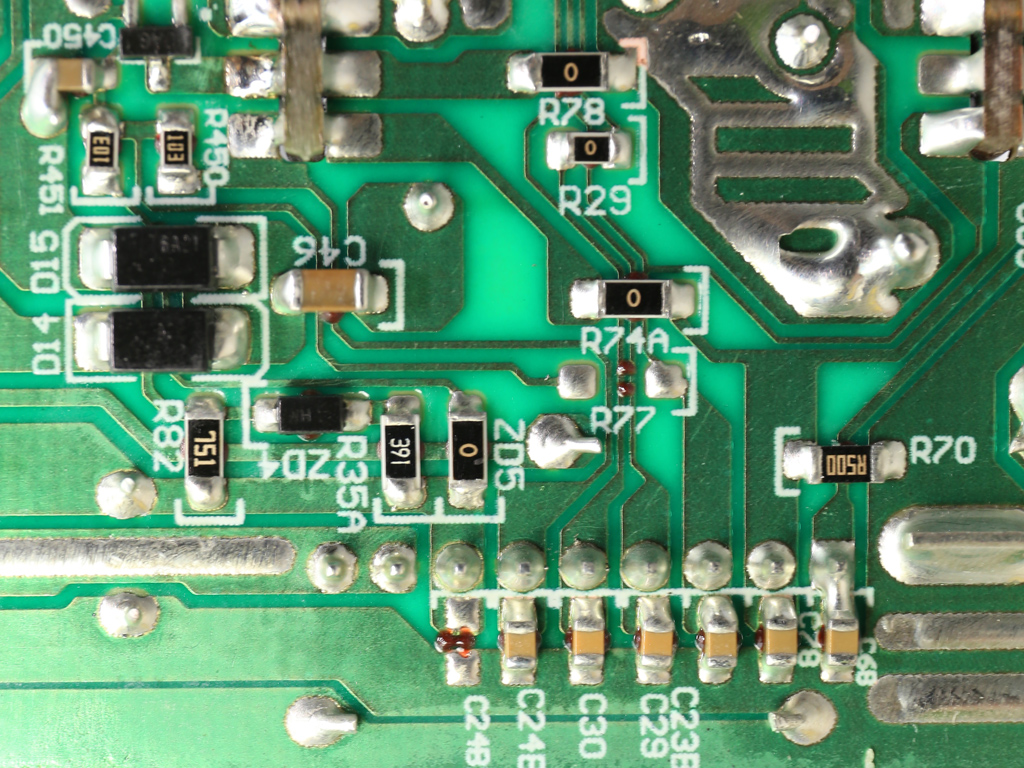

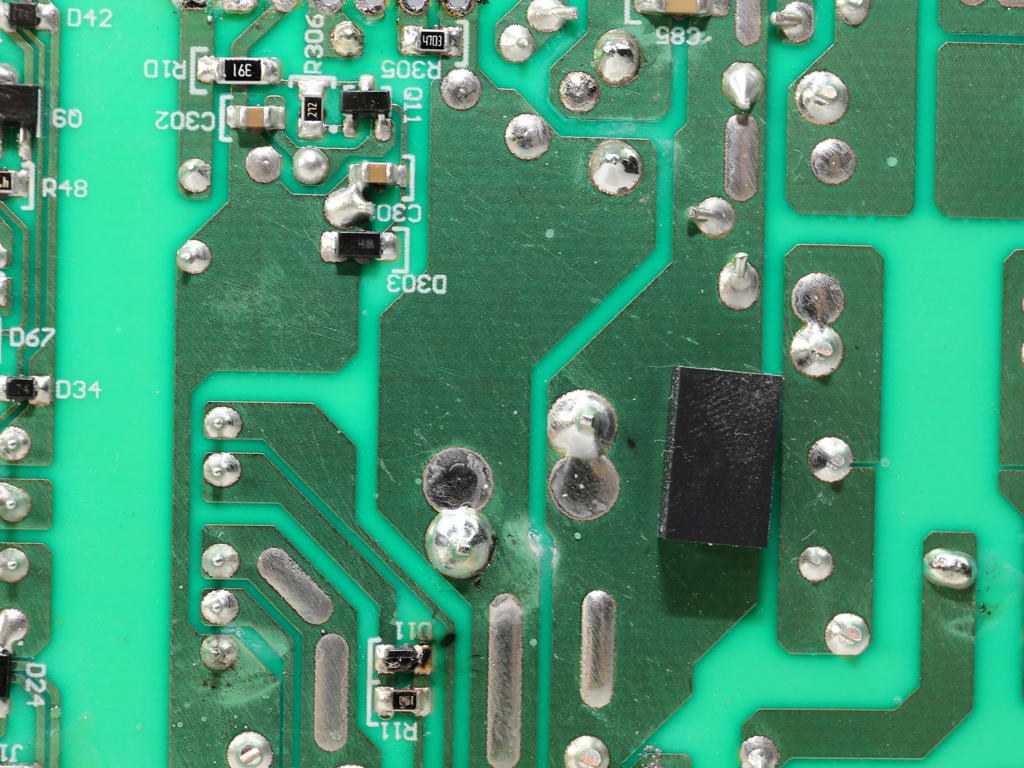

The PCB right behind the AC receptacle doesn't hold any EMI filtering components. The entire EMI filter is installed on the main PCB and consists of three X caps, five Y caps, two CM chokes, an MOV, and a TVS diode. All in all, the EMI filter is complete.

An NTC thermistor protects against large inrush currents. Since this is a low-efficiency unit, Super Flower doesn't implement a bypass relay.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

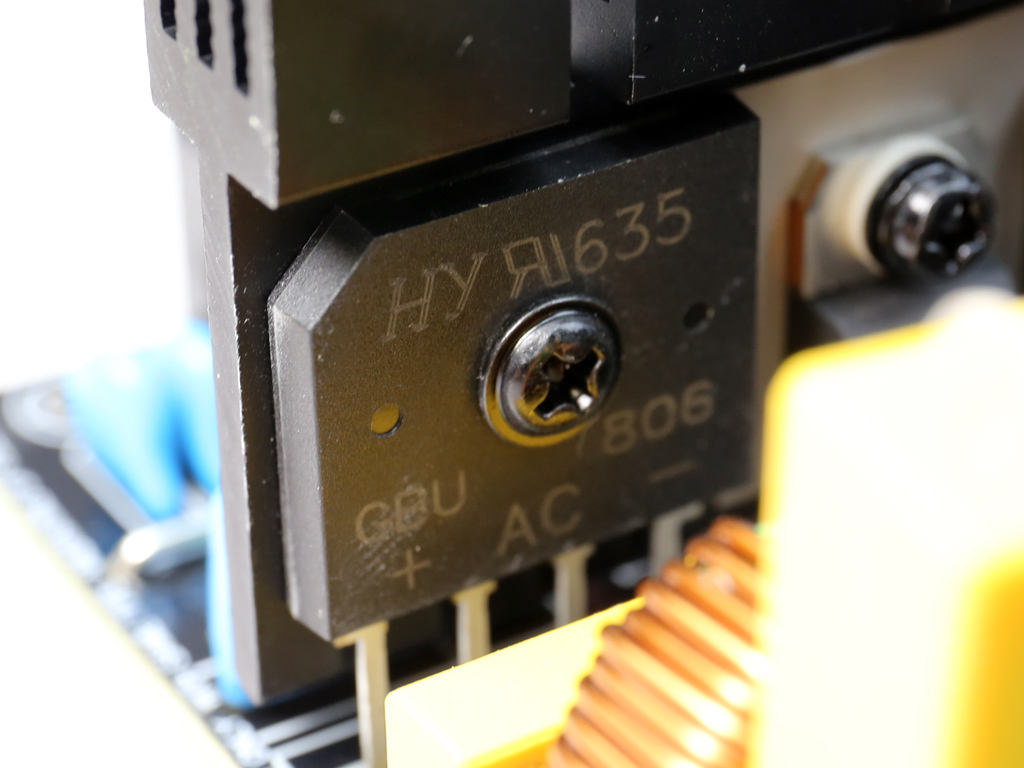

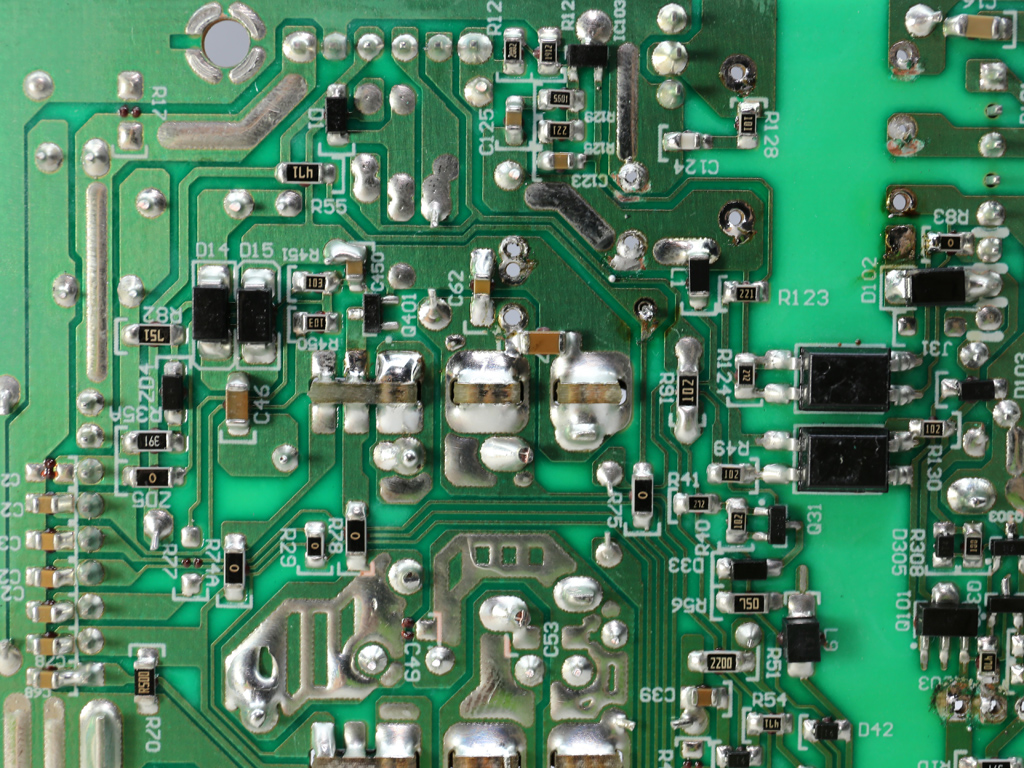

The single bridge rectifier, a GBU806, is installed on the primary heat sink. We would have picked a stronger bridge rectifier if given the choice, given the 450 B3's high OPP triggering point.

The APFC converter uses one AOTF14N50 FET and a single STMicroelectronics STTH8R06D boost diode. The bulk cap is provided by Chemi-Con and appears to be a special order from SF, since this is the first time we've seen a 95°C cap in a PSU. Lower-quality bulk caps fall into the 85°C category, while high-quality ones are rated for 105°C.

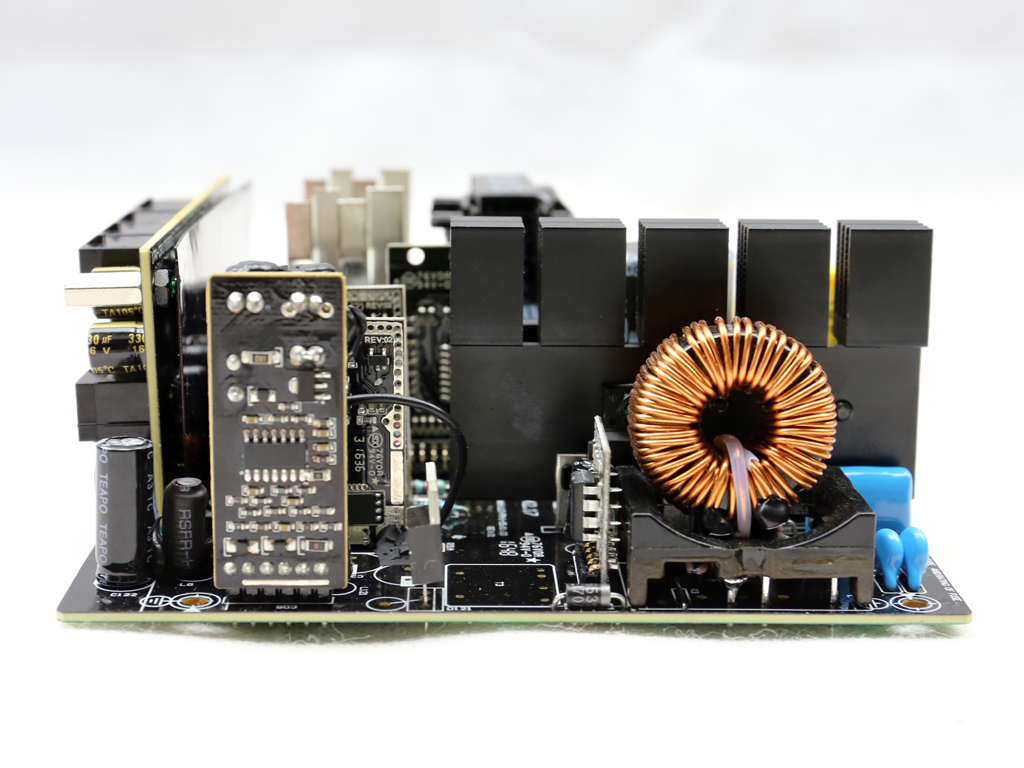

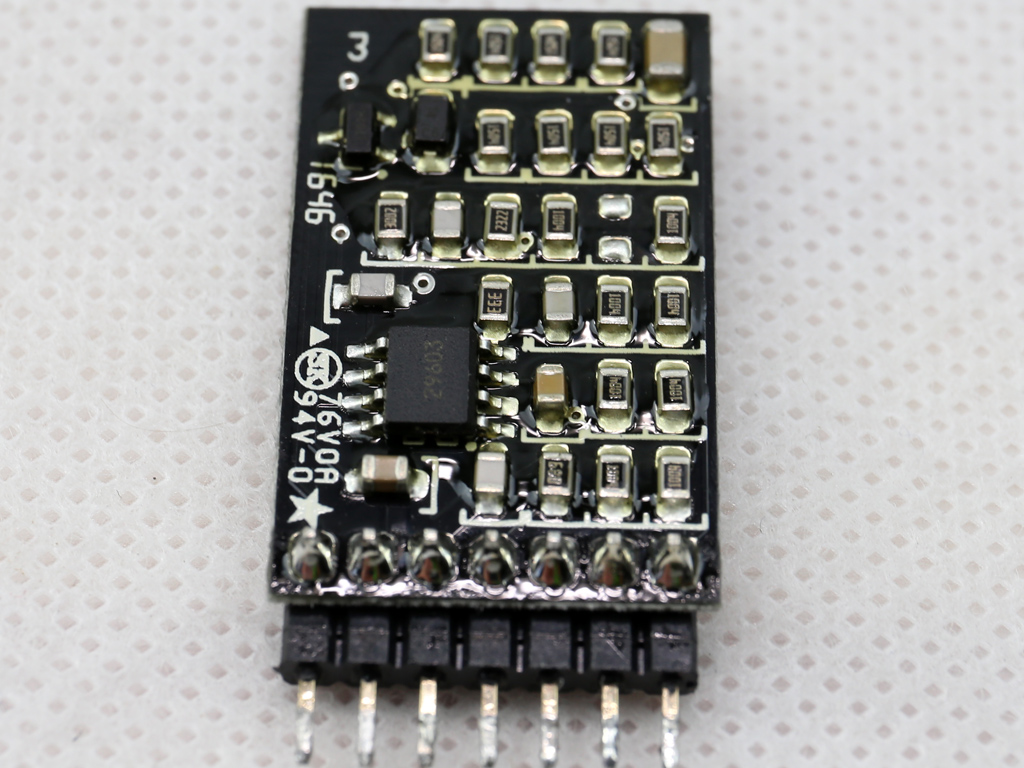

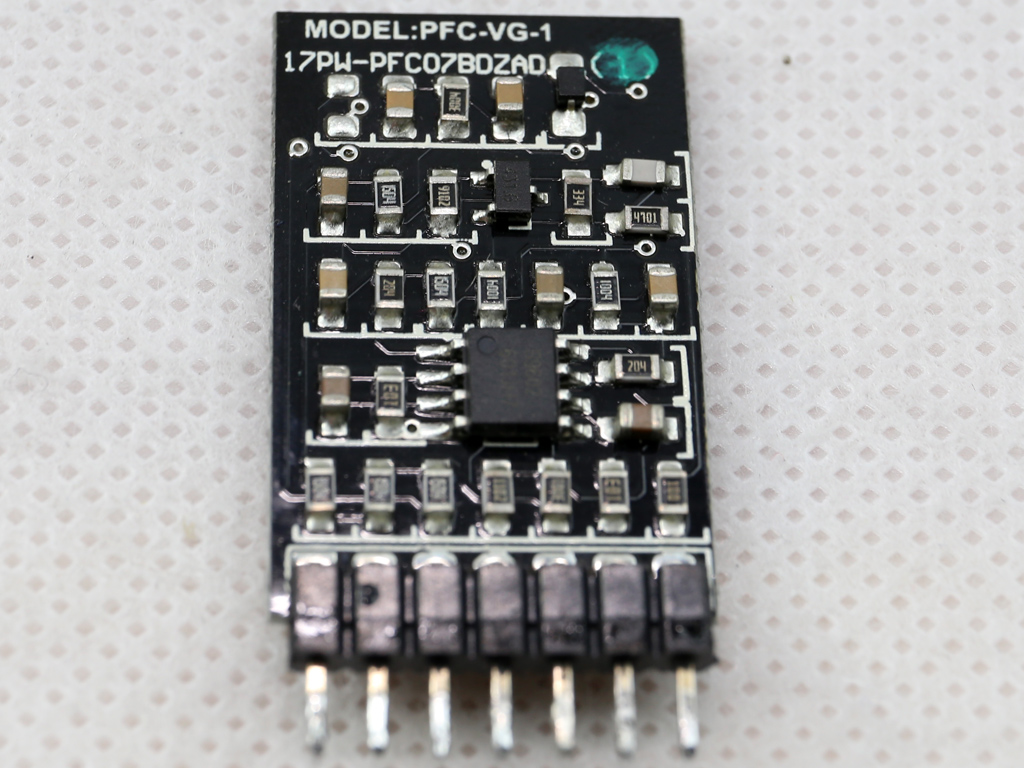

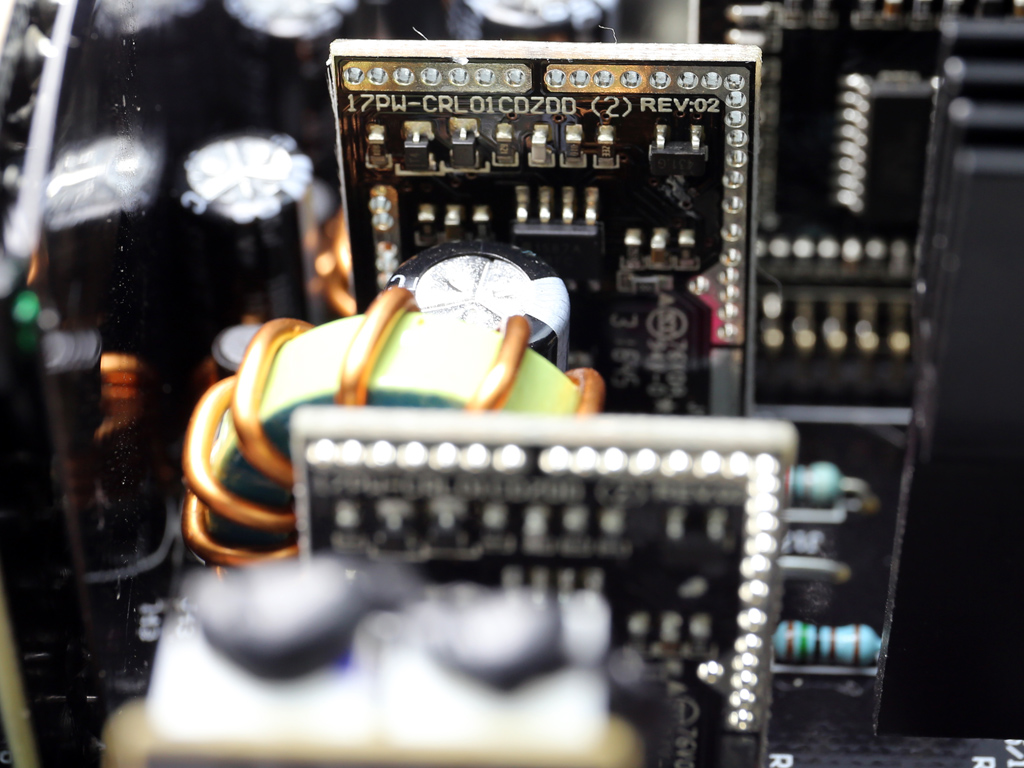

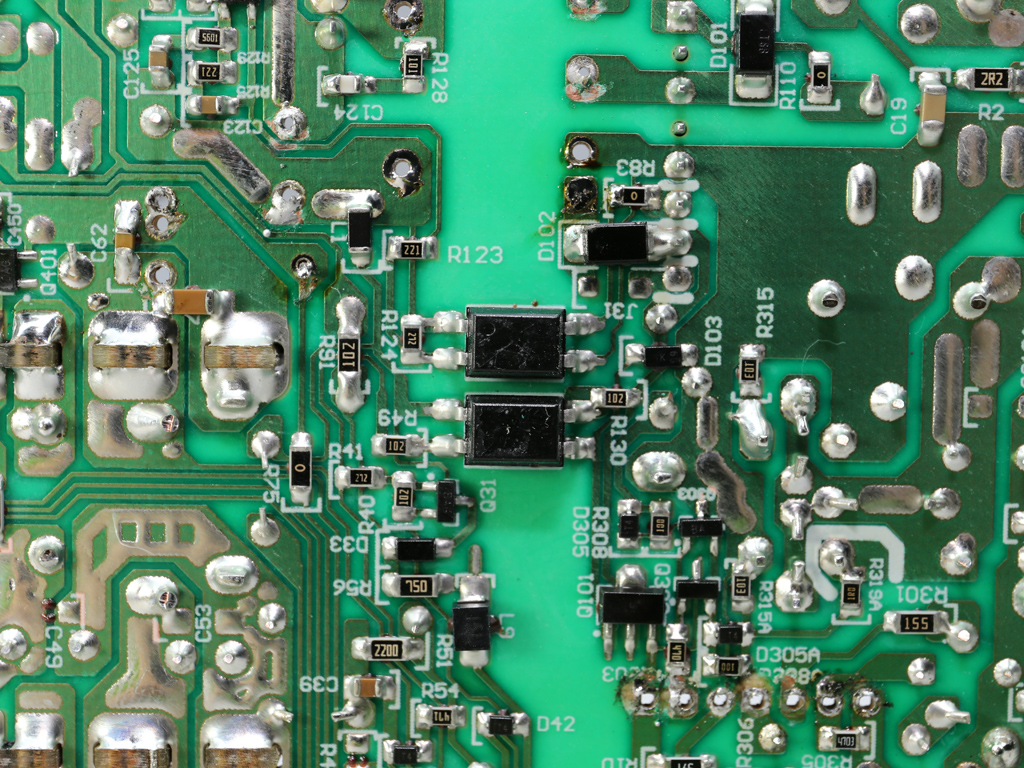

The PFC controller is a SF29603. On the same daughterboard that hosts the SF29603, we also find a S9602 IC. It likely plays a part in the APFC control.

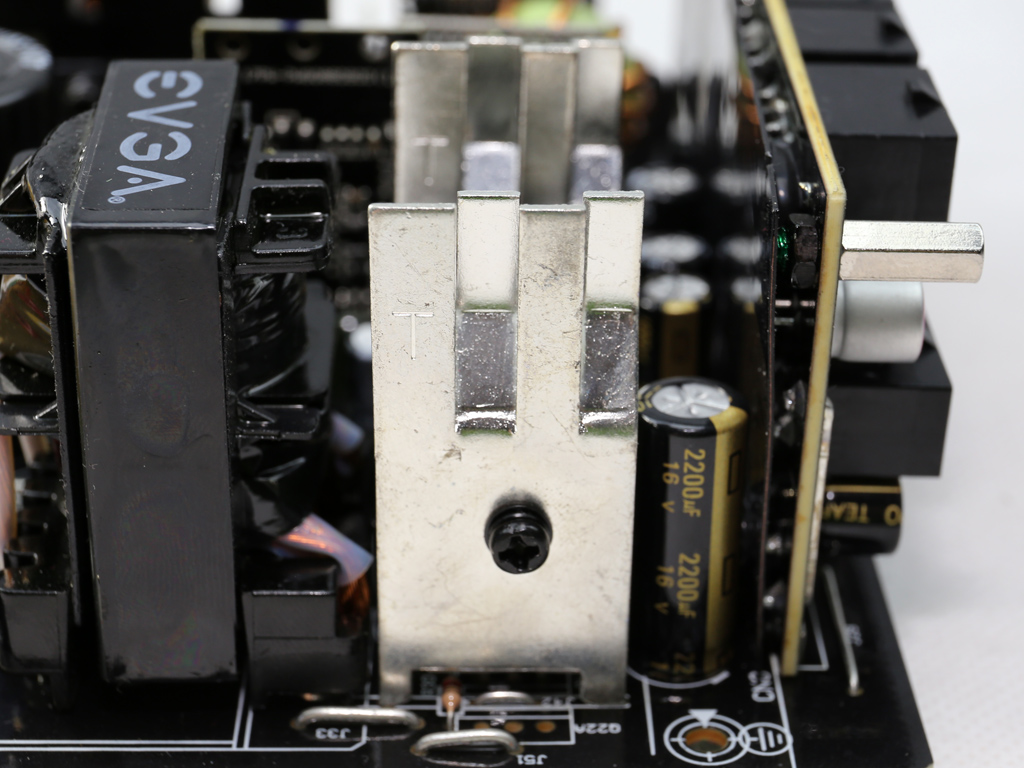

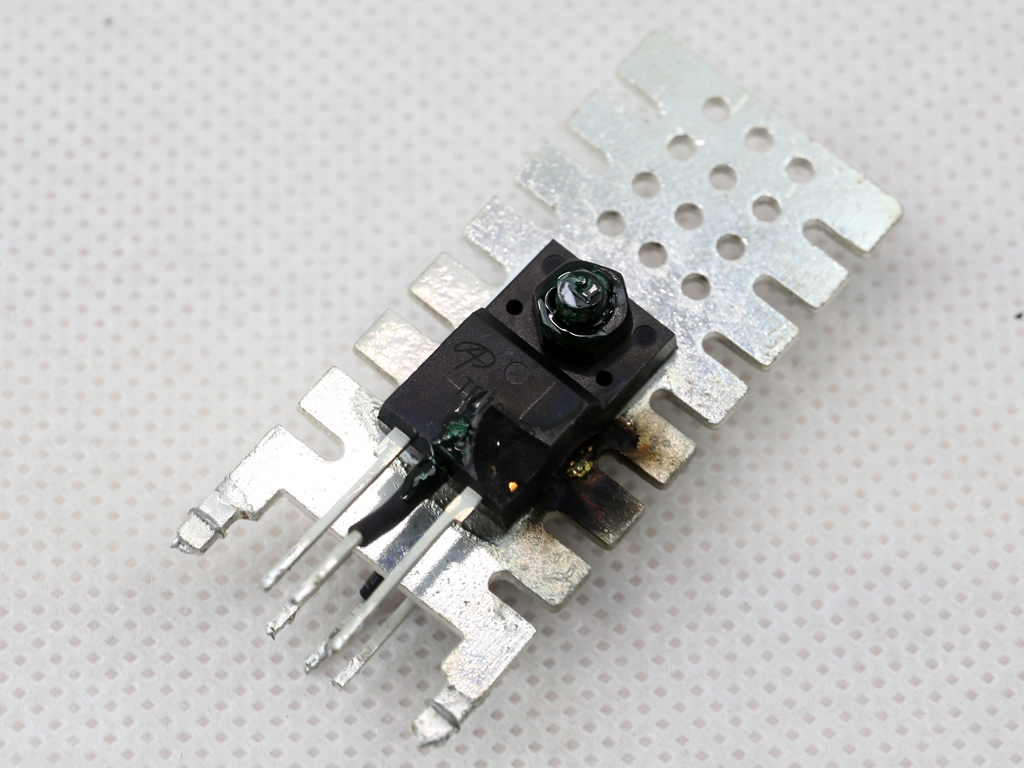

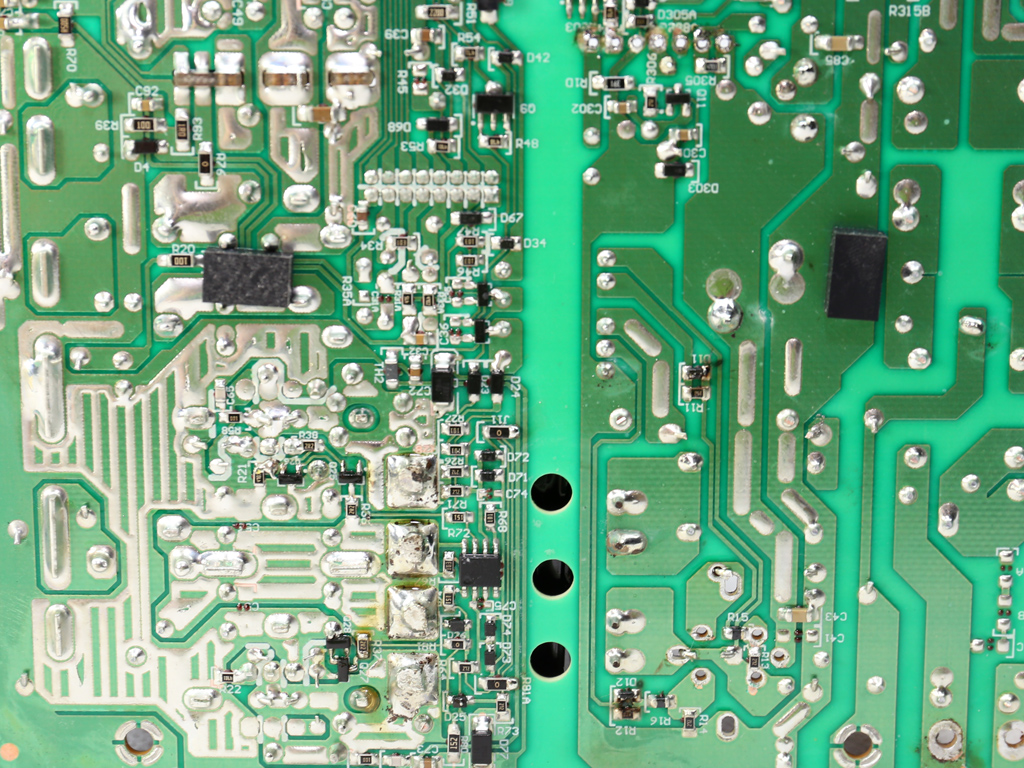

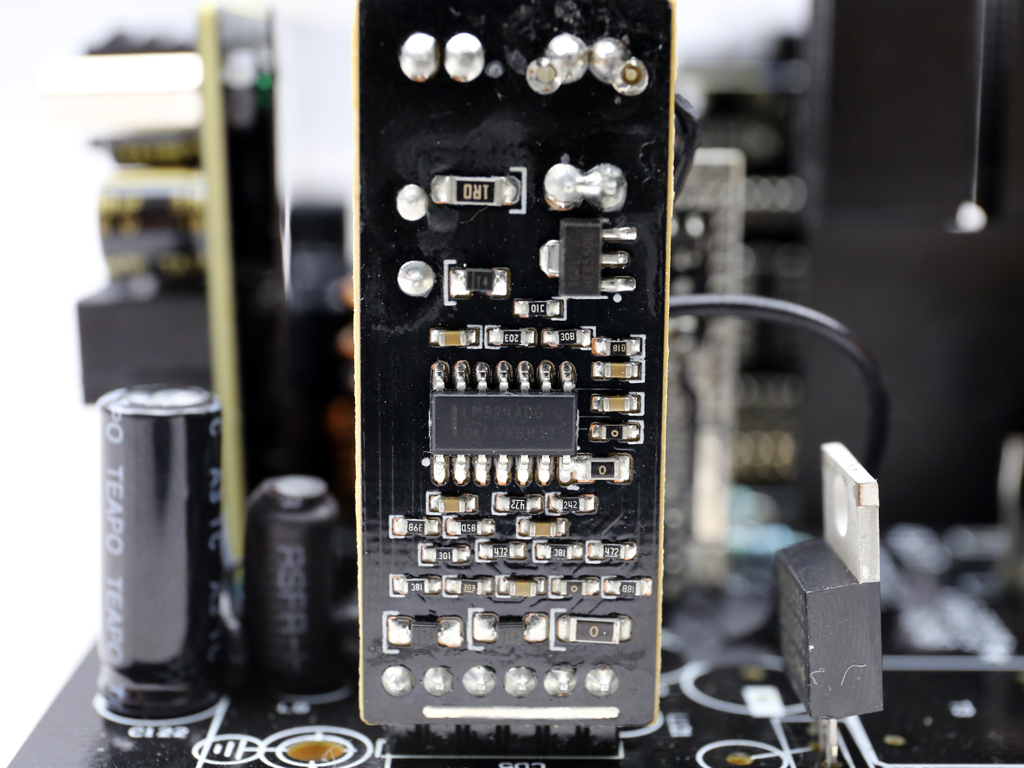

The primary FETs, two AOTF12N50s, are bolted onto a small heat sink. As mentioned, one of them died making lots of noise. The resonant controller is an SF29605 IC that likely handles the unit's protection features. On the same board that hosts the SF29605, there is also an LM339A Voltage Comparator, which supports the main supervisor IC.

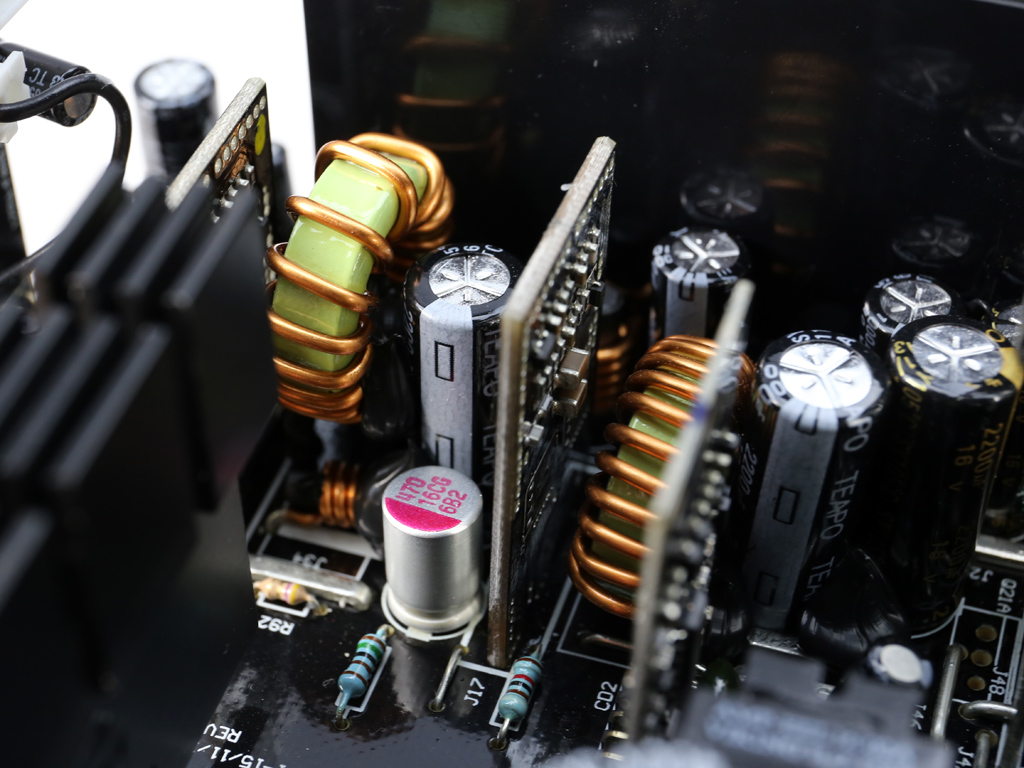

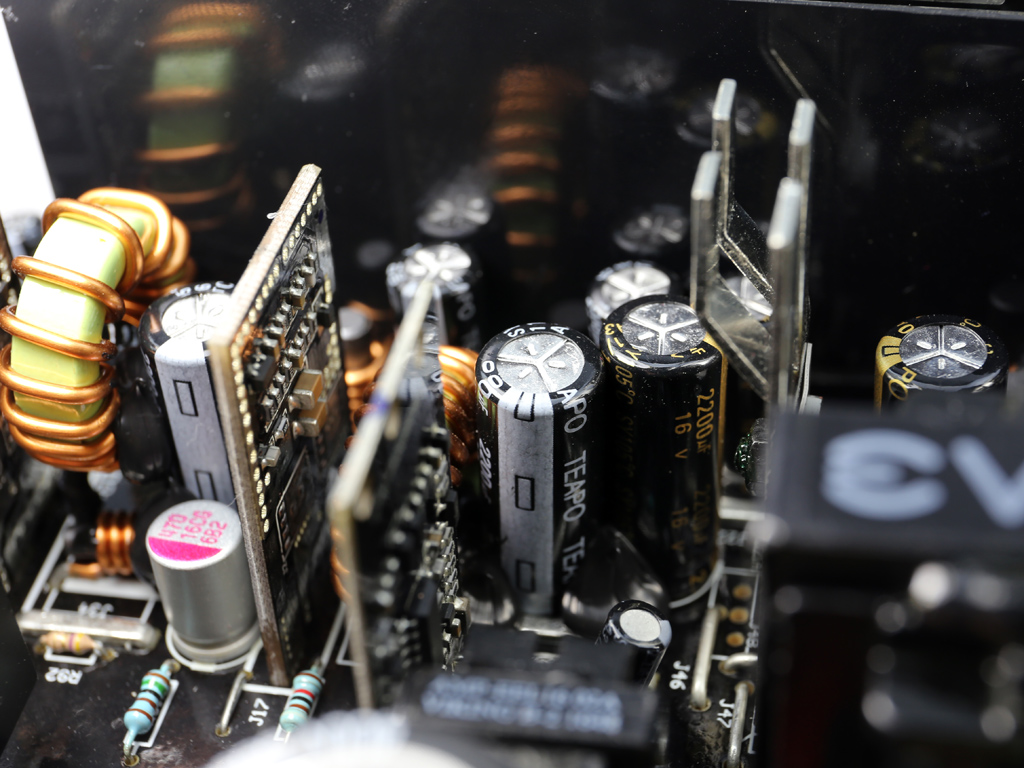

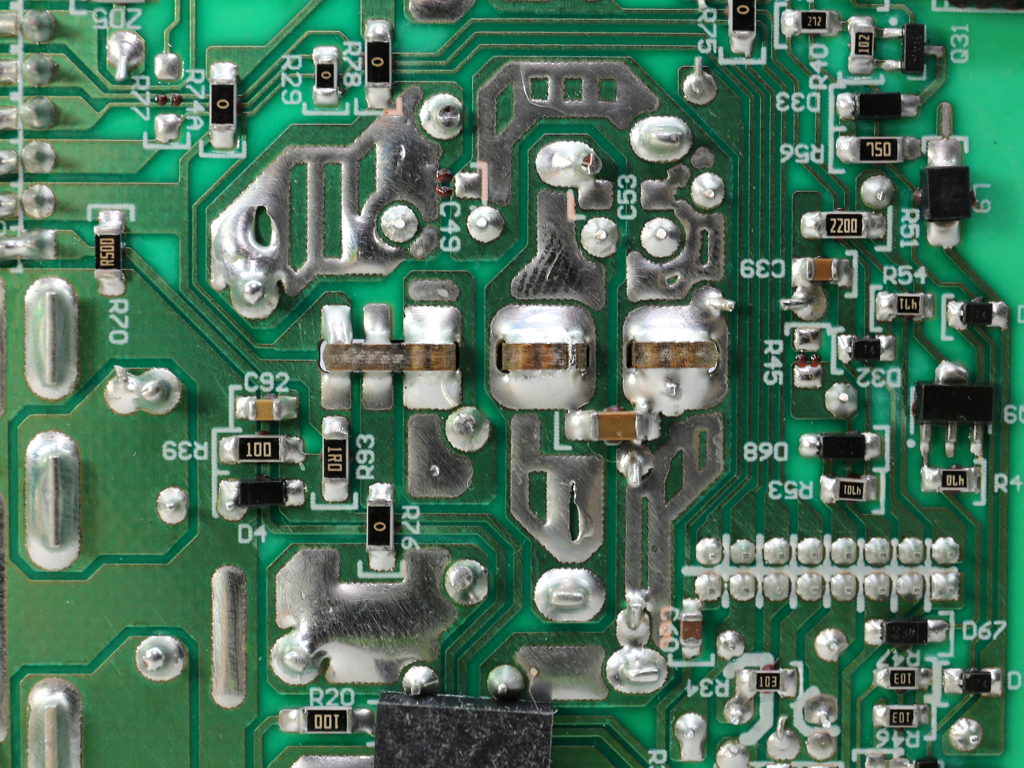

On the secondary side, a couple of small heat sinks hold two AOT240L FETs, which regulate the +12V rail.

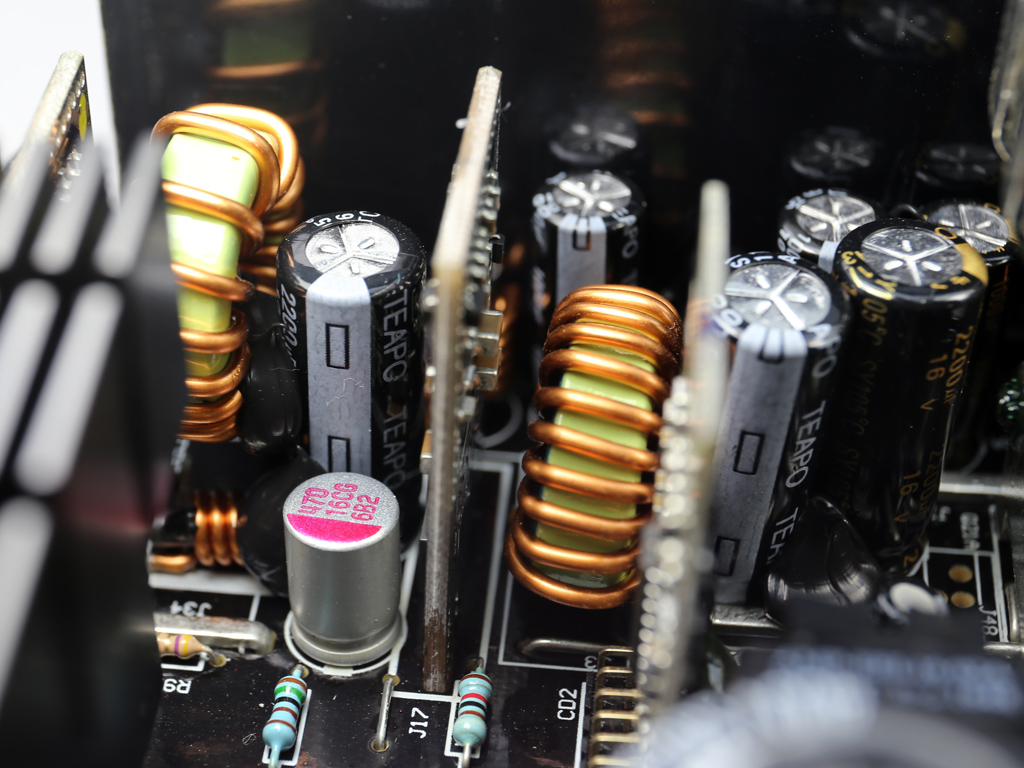

A couple of DC-DC converters generate the minor rails through the +12V rail. Each converter uses a NCP1587A PWM controller and two AON6516 FETs.

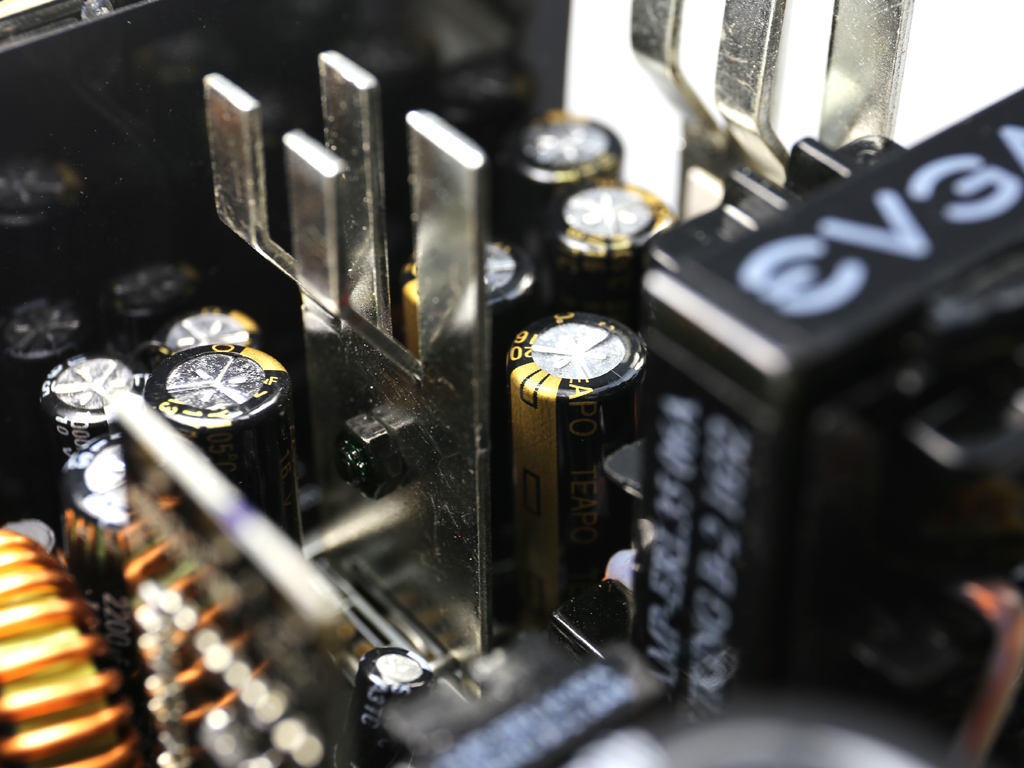

All filtering caps (electrolytic and polymer) on the secondary side are provided by Teapo. At least Super Flower went with a decent-quality line from the company (SY), rather than its cheaper SC family. That would have sacrificed useful life, for sure.

The 5VSB circuit is generated through a Mospec S10C60C SBR. The PWM controller is a propriety (and poorly documented) 29604 IC.

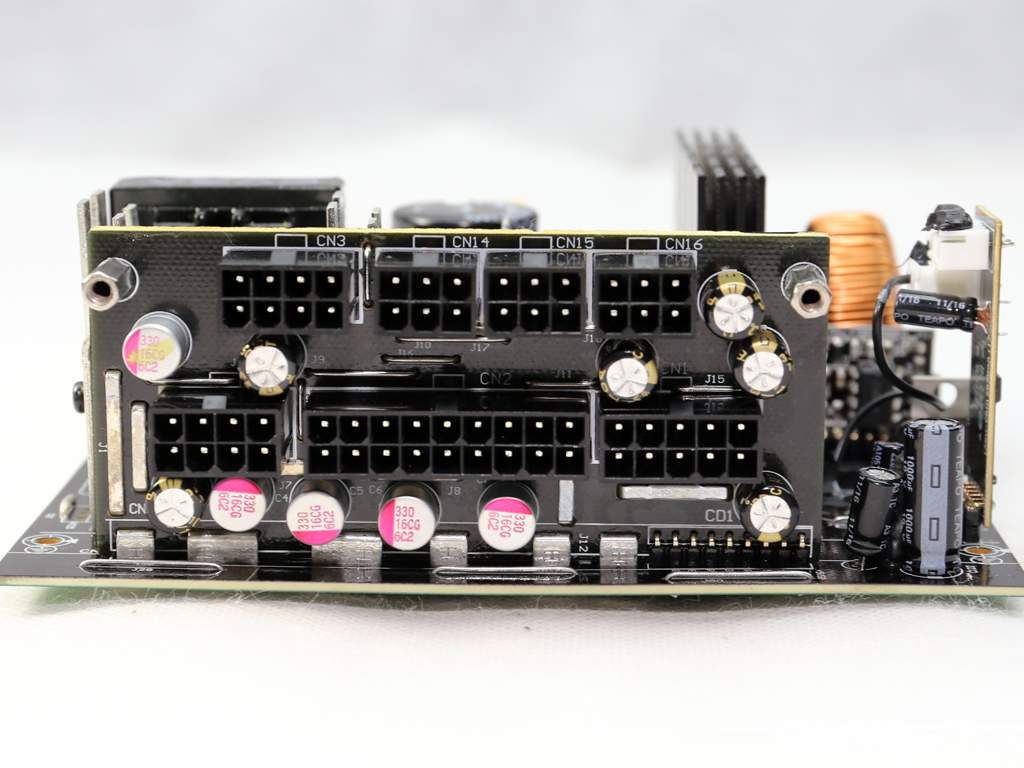

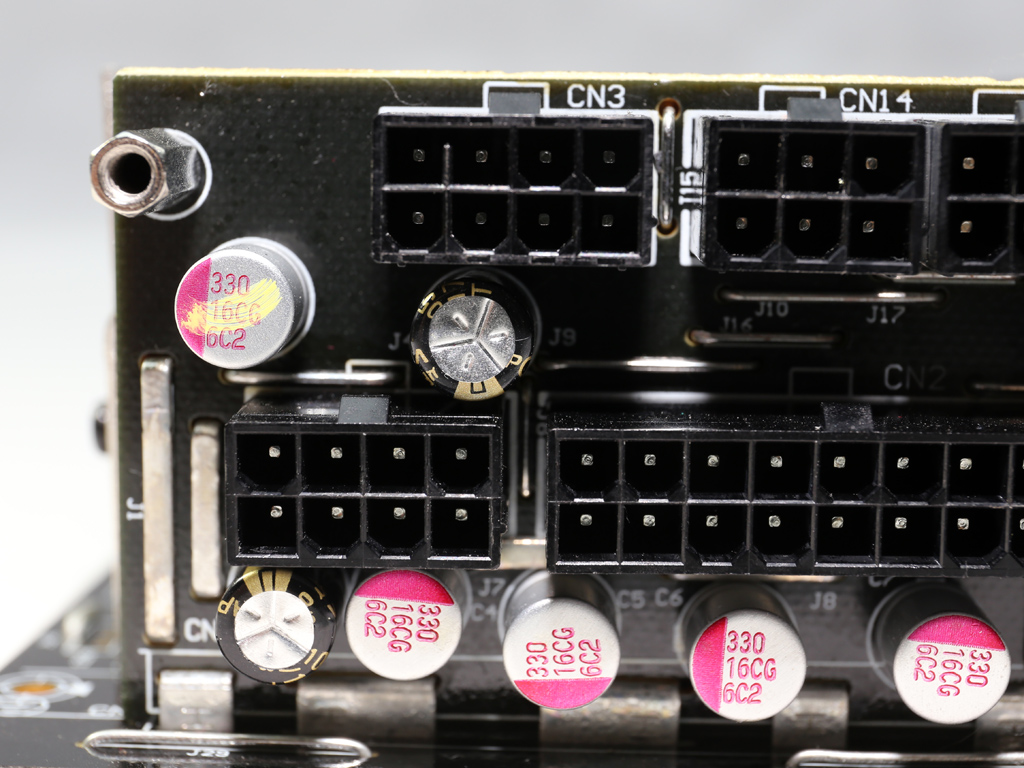

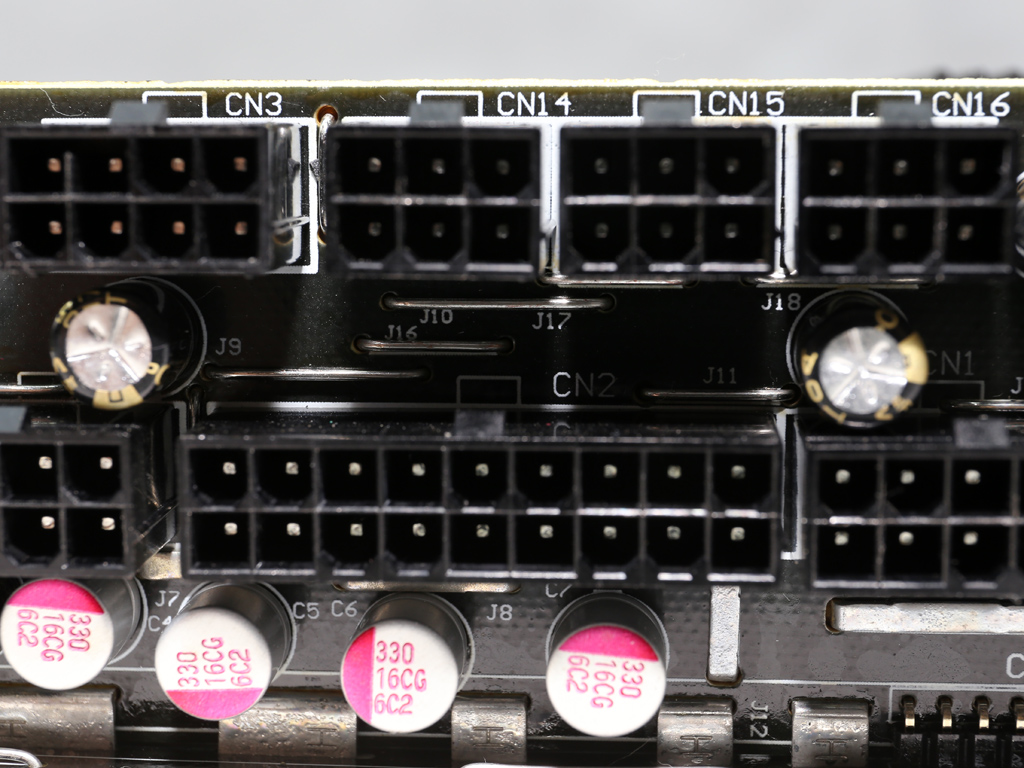

At the front side of the modular PCB, several Teapo electrolytic and polymer caps form an extra layer of ripple filtering.

The soldering quality clearly shows that this unit didn't come from Super Flower's manufacturing line, but from another factory (most likely RSY's). This doesn't surprise us. We know SF has limited capacity, so it has to enlist subcontractors for help with lower-cost PSUs to keep up with EVGA's demand

The fan's model is S1282412H. It measures 130mm across and uses a sleeve bearing. There is no room in this price range for a higher-quality fan, unfortunately. Its controller is the same as what we find in other Leadex platforms, and it is installed on a vertical PCB that'll snap off its base if you aren't careful with it.

MORE: Best Power Supplies

MORE: How We Test Power Supplies

MORE: All Power Supply Content

Current page: Teardown & Component Analysis

Prev Page Packaging, Contents, Exterior & Cabling Next Page Load Regulation, Hold-Up Time & Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

InvalidError Throwing higher current components at a problem isn't always the correct solution, especially when a 450W PSU is delivering somewhere north of 550W. The B3's components are clearly vastly sufficient to handle its rated load or even the 580W overload, which means the most likely reasons why a FET blew up are either a design flaw or manufacturing defect and the flaw/defect isn't necessarily in the FET or its immediately related circuitry.Reply

In this case, it seems like EVGA/Superflower may have incorrectly set the OCP on the 12V rail. I hope they meant to set it to something more conservative like 40A instead of the 50+ it may have been at here.

As for the main fuse not blowing, that is normal: the fuse lives upstream from the APFC choke and most other filtering components while both the APFC and main switching transistors are connected to the APFC-boosted input hold-up capacitor. The transistor's lead blows up from the capacitor dumping its several joules of energy into the lead, the APFC chokes smooth out the current spike and the current seen by the fuse comes nowhere close to reaching its i2t rating. It is the capacitor's charge that blows up the transistor, not AC input current. -

Aris_Mp I strongly disagree. The main fuse has to blow when there is a short on the primary side, which clearly is the case here, else the PSU is a fire hazard if the automatic relay on the home's main electrical panel doesn't work as it should. The spark every time we connect the PSU to the mains means that high current passes through the circuit, however the fuse still remains intact. Another clue here is that our lab's relay on the electrical panel automatically dropped (saving the day), meaning that more than 15 Amps of current were drawn from this particular AC socket!! So clearly the PSU's fuse should have blown. Finally, I have seen a great number of blown PSUs so far and all have some common component failures: primary or APFC FETs, bridge rectifier(s), main fuse. In any case the main fuse has to go else the design has a serious flaw.Reply

Some FETs might have increased Amps on papers, however in real life things can be different especially when the high RDS (on) values increase the operating temperatures. The part though in this PSU which I am not so sure about is the bridge rectifier, since it can only handle 8 Amps at 100C and usually I see more than 100C at the bridge. So if the bridge goes up to 115-120C its max current drops close to 5A according to its spec sheet so we only have 575W handling, which is much below the 700-720W that the PSU draws from the wall with 580W load.

The APFC choke isn't for filtering purposes, but mainly for boosting voltage, this is why it is also called boost inductor. More about how the APFC converter works and an explanation on both most popular types (DCM, CCM) can be found here: http://www.tomshardware.com/reviews/power-supplies-101,4193-10.html. I think it is pointless to explain APFC's operation here since there is an entire section about it. The bulk cap's charge didn't exactly blow the FET, the FET just couldn't handle the increased Amperage that the cap provided because of the high load. Also the bulk cap drew this load from the mains network and didn't make it out of thin air!

Finally please don't lose sight of the forest for the trees and confuse the readers on a subject that is clear. The fuse that protects the socket into which the PSU was connected dropped, meaning that more than 15 Amps passed through it! Given that this PSU's bridge can only handle up to 8 Amps normally its fuse should be less than 8A, however it survived not once, but both times that we tried it! This clearly shows a major flaw and on the same times proves that there is a short on the PSU's primary side, which draws LOTS of current! In any case the main fuse should open the circuit in order to protect the user and the equipment from damage or even fire. The main fuse not blowing is anything else but normal! I just have to point this out -

kalmquist $50 for a modular power supply seems like a great deal, even with merely Bronze efficiency. This is a good reminder not to gamble on a PSU that hasn't been reviewed by a site like Tom's Hardware.Reply -

InvalidError Reply

Put a 1mH APFC choke in series with a short circuit and 350V, it'll limit current rise time seen from the input side to 350A/ms, so it does filter regardless of what its other purposes in the circuit is just like any inductor would.20089501 said:The APFC choke isn't for filtering purposes

I missed the paragraph about the breaker tripping. If you have RCDs or AFCI breakers, they could be tripping due to faults other than a short-circuit. If you have class-A relays, it could also be tripping faster than the fuse is able to blow.

Edit: missing a 0... 350V/1mH = 350A/ms. -

AndrewJacksonZA Is this the PSU in the video at JG of the PSU that blew up in your lab, Aris? :-)Reply -

10tacle ReplyBut we are seriously troubled by its issue and EVGA's lack of a response when we probed for possible causes.

That is deeply troubling, especially coming from a highly reputable hardware vendor like EVGA and who I have nothing but the highest respect for (I've been buying their GPUs solely since the GTX 275).

I sincerely hope EVGA isn't quick to get back because they are trying to find a root cause with Superflower and rule in or out a bad manufacturing batch that got past Superflower, or a bad design. I hope for EVGA it's the former.

-

Aris_Mp @INVALIDERROR I will try this in a circuit simulation program I have, once I find some free time.Reply

@ANDREWJACKSONZA If you mean about the blowing PSU in smokes, nope this is another PSU.

@10TACLE Once we have a response from EVGA we will post it of course. To be frank I waited for a second sample from the time I notified about this problem, however I was not offered one. Also from the start EVGA didn't send any B3 samples and this is why I had to buy them on my own (given the popularity of this line), in order to check them out. With the first chance I will also buy affordable PSUs from other vendors, which usually aren't offered as review samples, in order to evaluate them.

I would buy another 450 B3 but it is out of stock every where I searched in Europe. If I manage to find one I will try the same test again of course. Nonetheless I faced problems with other B3 models as well, which I will mention in the next B3 review. -

80-watt Hamster I don't find it all that surprising that they didn't shoot for a higher efficiency rating. EVGA's primary market is the US (correct me if I'm wrong), and Silver is basically a non-entity here. Bronze is the volume segment, so having a strong contender there is a necessity, and pushing it to Gold would add to an already-crowded segment of their product stack.Reply -

Onus As nasty as that blow-up might be, if used in a machine that doesn't need more than 450W, is it really a problem? Arguably, someone who tries to run a 600W PC using a 450W PSU deserves what he gets. For low-end systems, this looks like a perfectly viable choice.Reply