EVGA SuperNOVA 1600 P2 Power Supply Review

EVGA recently introduced its flagship power supply, the SuperNOVA 1600 P2. In addition to monstrous capacity, it also features 80 PLUS Platinum efficiency, promises top performance levels and offers silent operation in semi-passive mode.

Why you can trust Tom's Hardware

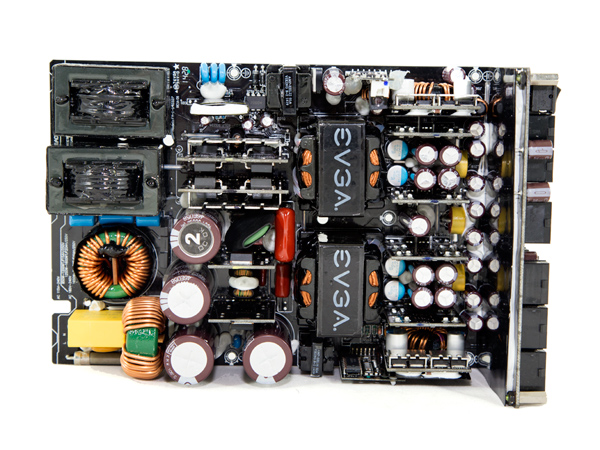

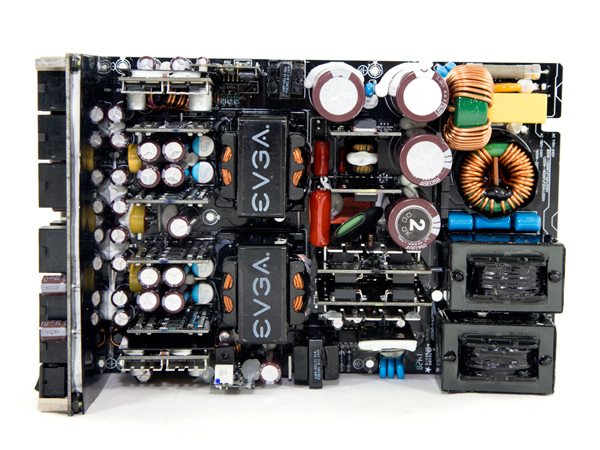

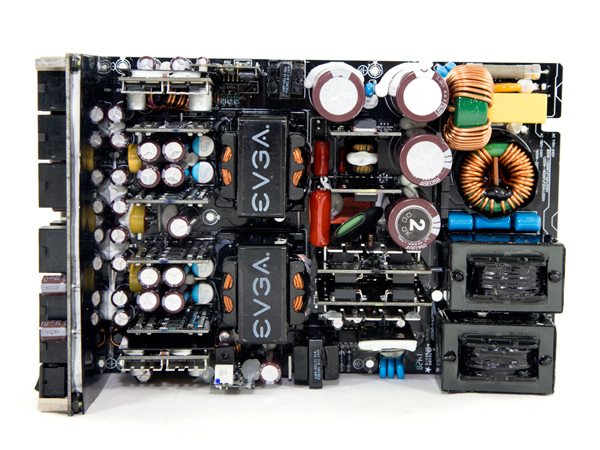

A Look Inside And Component Analysis

Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station and a Hakko 808 desoldering gun.

| EVGA 1600 P2 Parts Description | |

|---|---|

| Primary Side | |

| Transient Filter | 6x Y caps, 2x X caps, 2x MC chokes, 1x MOV, NTC Thermistor |

| Inrush Protection | NTC Thermistor & Electromagnetic Relay |

| Bridge Rectifier(s) | Bridgeless Design - 1x US30K80R & 8x Infineon MOSFETs |

| APFC MOSFETs | 8x Infineon MOSFETs |

| APFC Boost Diode | 4x CREE C3D08060G |

| Hold-up Cap(s) | 4x Nippon Chemi-Con (400V, 390uF each, 1560uF combined, 105 degrees C, KMW) |

| Main Switchers | 4x 50R140CP |

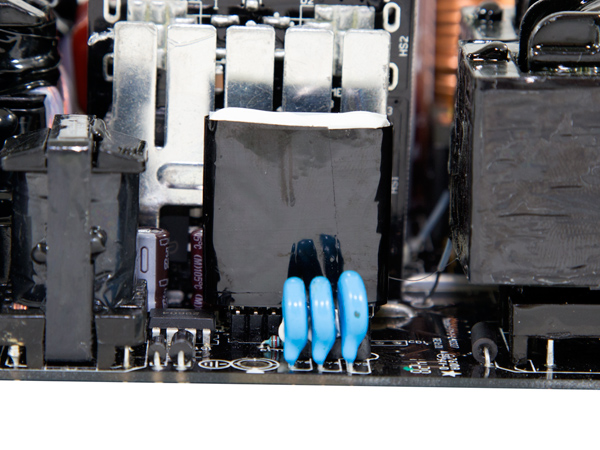

| APFC Controller | SF29603 |

| Switching Controller | SFAA9013 |

| Topology | Bridgeless PFC & Full-Bridge LLC & Resonant Converter |

| Secondary Side | |

| +12V MOSFETs | 16x Infineon BSC035N04LS |

| 5V & 3.3V | DC-DC Converters: 8x Infineon IPD060N03 FETs |

| Filtering Capacitors | Electrolytics: Chemi-Con, 105 °C, KY & KRGPolymers: Chemi-con |

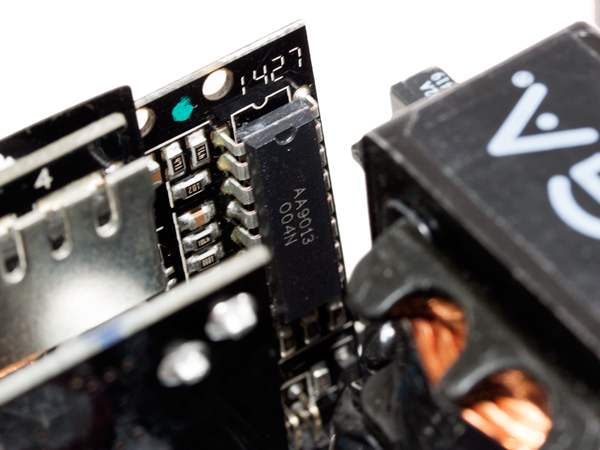

| Supervisor IC | AA9013 (probably) & LM324ADG |

| Fan Model | Globe Fan RL4Z-B1402512EH (140mm, 12V, 0.6A, 2000 RPM, 153.47 CFM, 39.5 dB(A), 70,000-hour MTBF) |

| Topology | Syncronous Rectification & DC-DC converters |

| 5VSB Circuit | |

| Rectifying Diode | Mosped S10C60C |

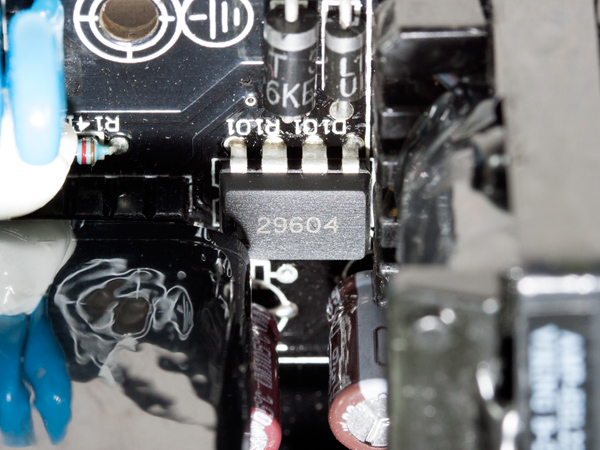

| Standby PWM Controller | 29604 |

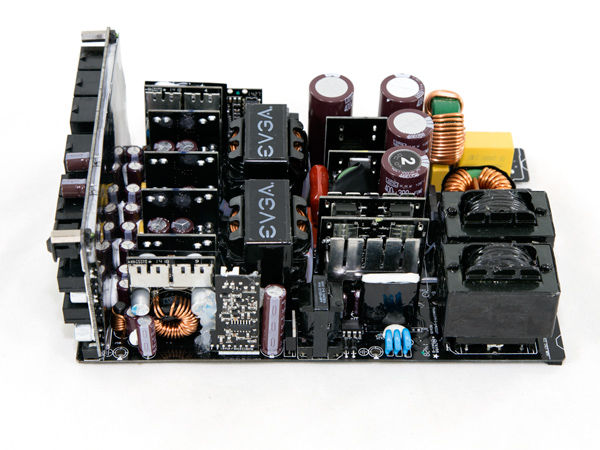

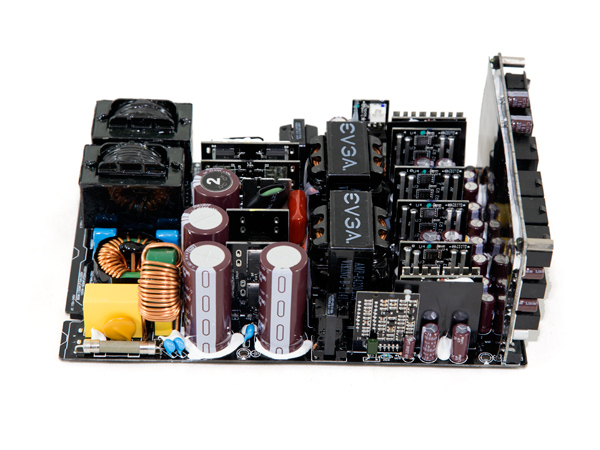

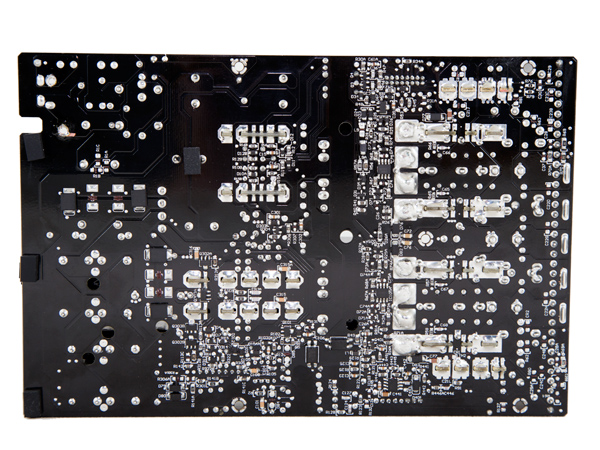

The original manufacturer of this PSU is Super Flower, which is behind most of EVGA's power supply offerings. The platform is the same as the one used in the Gold-rated EVGA 1600 G2, but sporting the modifications needed to pass the 80 PLUS Platinum requirements. This is a cutting-edge design with a bridgeless APFC converter in the primary side, along with a full bridge topology and a resonant converter for lossless switching. In the secondary side, synchronous rectification is used, meaning that the regulation of the +12V rail is handled exclusively by MOSFETs and a pair of DC-DC converters generate the minor rails.

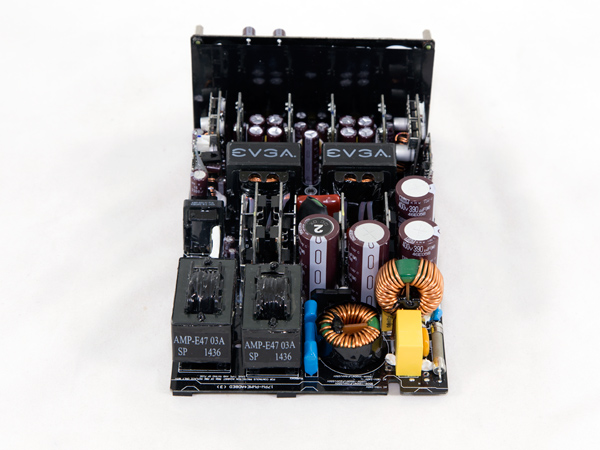

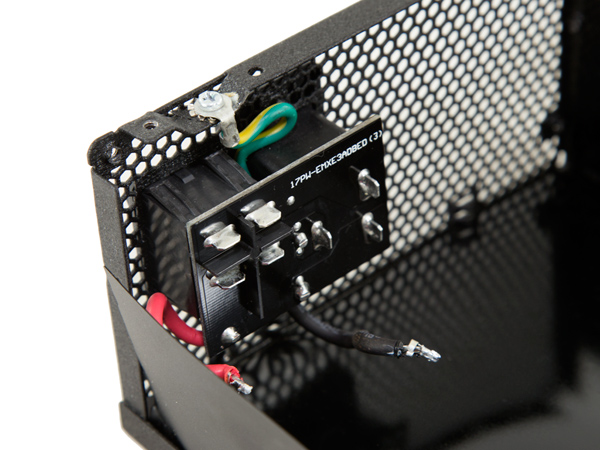

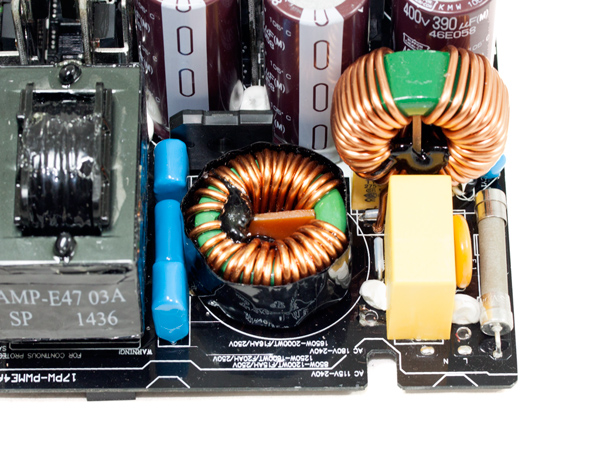

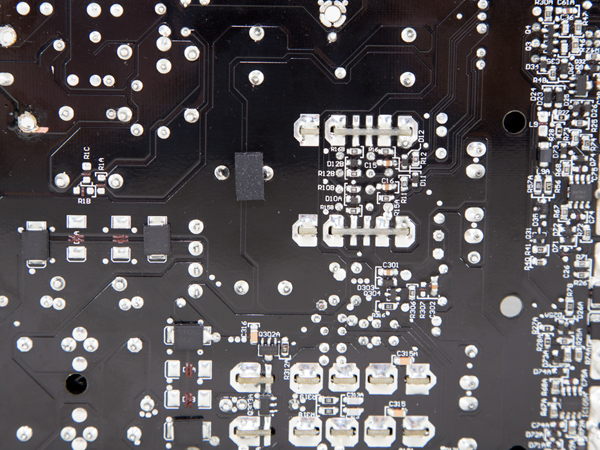

The small PCB behind the AC receptacle, strangely enough, doesn't host any part of the transient filtering stage. That's installed on the main PCB, and includes three pairs of Y caps, a pair of X caps, an MOV and two CM chokes. The transient filter is complete.

There is only a single bridge rectifier, a US30K80R, which most likely is used only by the 5VSB circuit, since the main rectification takes place in the APFC converter.

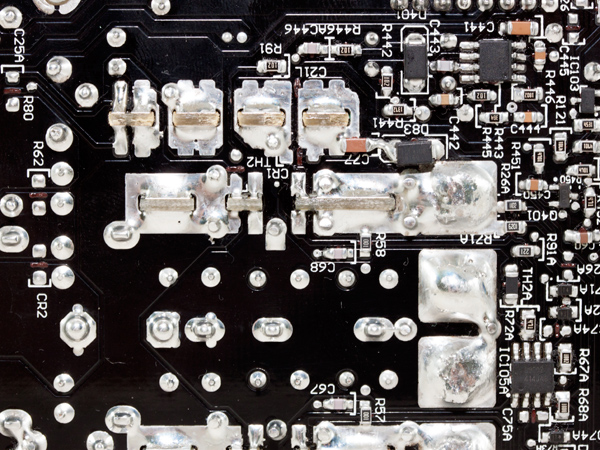

In the APFC converter, eight MOSFETs, which are much more energy efficient compared to diodes, fully rectify the incoming AC voltage. The aforementioned MOSFETs, which we were unable to identify, are hosted on two vertical daughter boards, along with four C3D08060G boost diodes. As bulk caps, four parallel Nippon Chemi-Cons (400V, 390uF each, or 1560uF combined, 105 °C, KMW) are used, and our tests demonstrate whether their combined capacity is enough to allow for at least 16ms of hold-up time.

A proprietary IC code-named SF29603 is used as a PFC controller. It is installed on the shielded PCB shown in the photo above.

There is a big NTC thermistor for protection against large inrush currents during the supply's start-up phase. A relay cuts it from the circuit once it finishes its job, allowing it to cool down and at the same time to restrict energy losses. This works because, in essence, an NTC thermistor is a temperature-controlled resistor.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

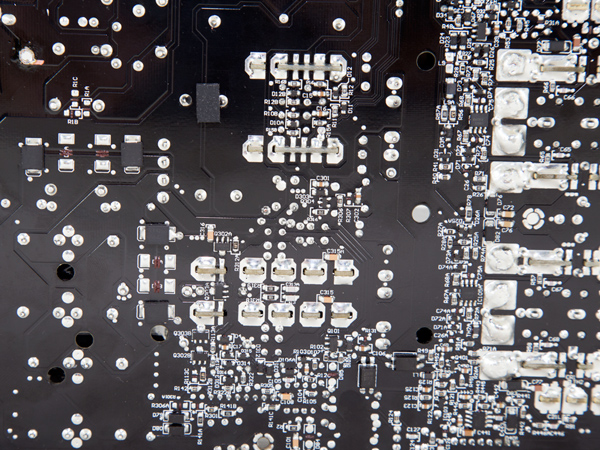

Two boards hold the main switchers, four Infineon IPP50R140CP, which are arranged into a full-bridge topology. An LLC converter is also used to boost efficiency through lossless (or at least close to lossless) switching.

The main transformer should be huge to meet this unit's needs. Apparently there wasn't enough space for it because Super Flower had to use two smaller, parallel transformers. Also in the secondary side, there are many high-quality Nippon Chemi-Con electrolytic (105 degrees C, KY series) and polymer caps, which are used for filtering purposes.

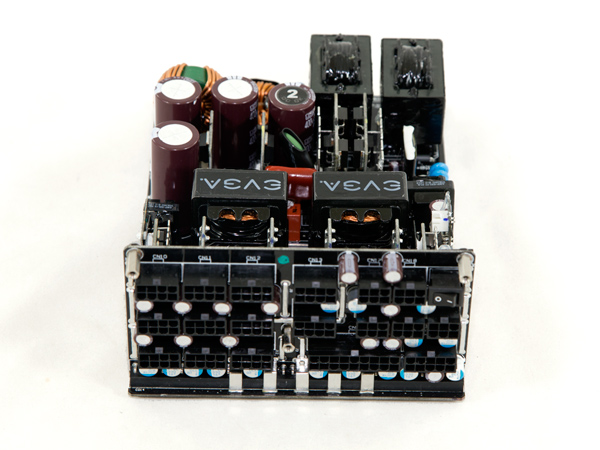

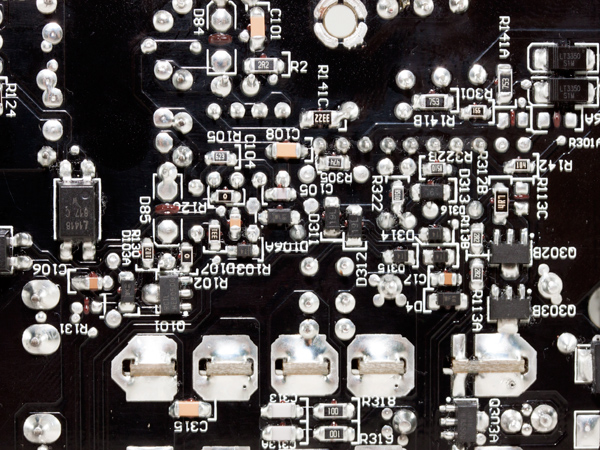

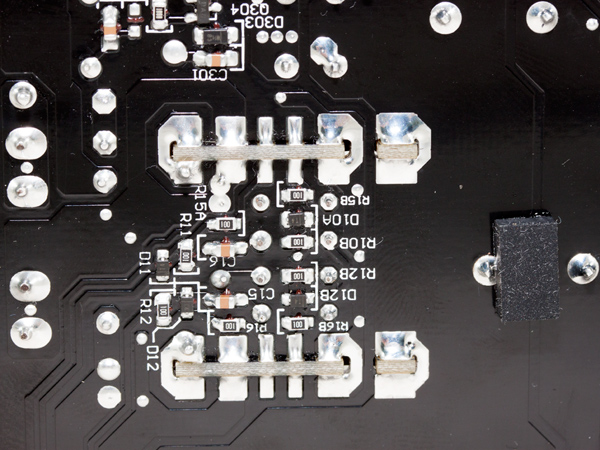

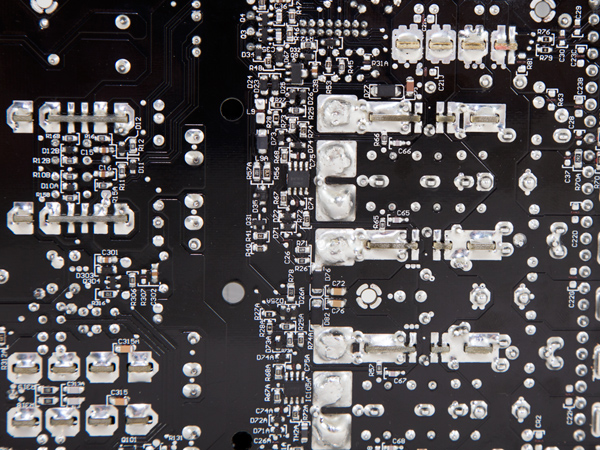

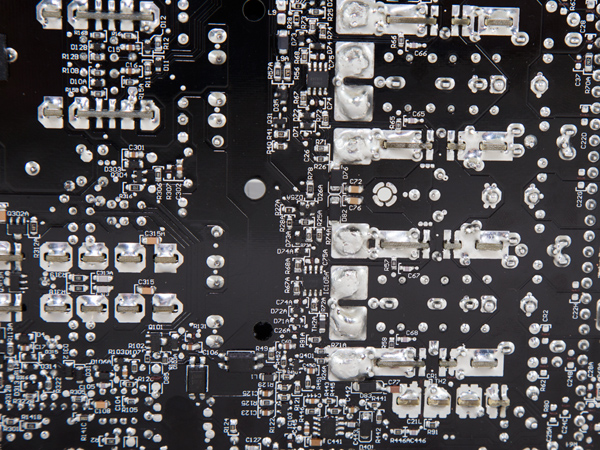

Four vertical PCBs house all MOSFETs that regulate the single +12V rail. In total, 16 Infineon BSC035N04LS FETs are used, as in the 1600 G2 unit. Two DC-DC converters handle the minor rails, and each converter uses four Infineon IPD060N03 FETs.

Next to one of the DC-DC converters is a PCB with the fan-controlling circuit and a Mospec S10C60C SBR that generates the 5VSB rail. The above PCB also houses an LM324ADG. Since this PCB is held in place only by the solder joints on its base, you can break it easily while trying to remove the fan header. So, we applied lots of glue around the base to secure it after learning our lesson the hard way on another high-end Super Flower PSU.

The standby PWM controller only has the number 29604 written on it, which doesn't prove useful in identifying this component.

On a vertical daughter board is the resonant controller, an AA9013 IC, for which there is no available information. There is also a well-hidden LM324ADG on the same board.

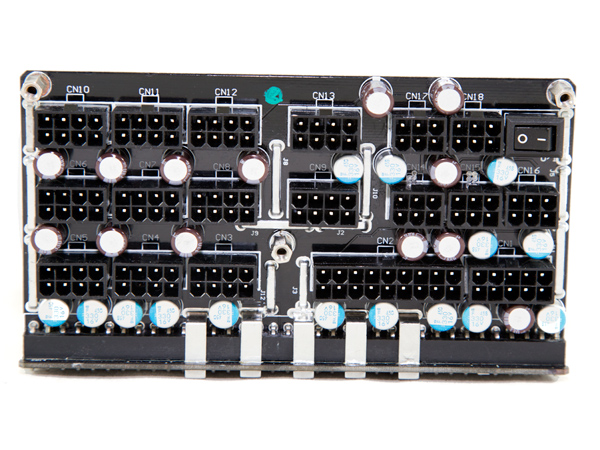

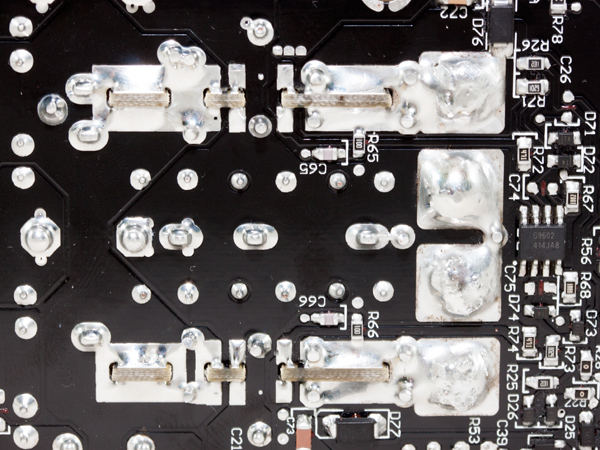

The many polymer and electrolytic caps on the modular PCB's primary side provide further ripple filtering. These caps ensure that the output DC voltages are clear of AC fluctuations (ripple).

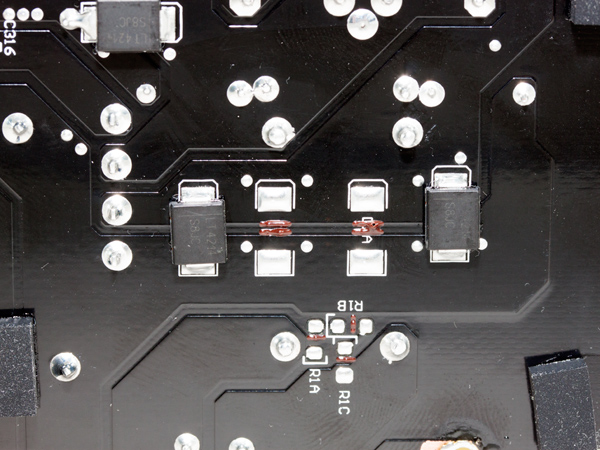

Soldering quality is good. It may lag behind Flextronics and Delta, but it is close enough. Super Flower has made huge steps forward in this area over the last few years.

The cooling fan is provided by Globe Fan, and is the same one found in the 1600 G2 and 1200 P2. Its model number is RL4Z-B1402512EH (140mm, 12V, 0.6A, 2000RPM, 153.47 CFM, 39.5 dBA, 70,000-hour MTBF), and it is equipped with dual ball-bearings for increased longevity. This unit, in contrast to the 1600 G2, features a semi-passive mode that makes it much quieter under light loads.

Current page: A Look Inside And Component Analysis

Prev Page Packaging, Contents And Exterior Next Page Load Regulation, Hold-Up Time And Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

damric Good review, but missing the hot box testing to see if this thing regulates and suppresses ripple at 50C as advertised.Reply -

Aris_Mp All tests were conducted at high ambient temperatures which during full load were above 47C. Only the Cross-Load tests were conducted at 28-30C.Reply -

Giannis Karagiannis Very detailed review indeed. There isn't really anything that could be covered and it is not. I don't think that there are many PSU manufacturers out there that can test their products so extensively.Reply -

Aris_Mp I had the opportunity to test the 2 kW model (from Super Flower) and it is indeed superb. But it will provide 2 kW only with 230 VAC input since a normal socket can deliver only up to 15 A of current.Reply -

damric Reply15234131 said:Too light for me I have the 2000w coming from Dabs when it comes to retail.

Where are you from that you need all that power? Cybertron? -

damric Reply15233469 said:All tests were conducted at high ambient temperatures which during full load were above 47C. Only the Cross-Load tests were conducted at 28-30C.

47C ambients? Must have been sweating your language, please off, or you are language, please me. -

damric Reply15234630 said:I'm going to power my Skynet build with it.

One day you need to show us a picture of everything. I've seen little snapshots here and there, but I'd like to see it all in one thread.