De-Lidding and Overclocking Core i7-7700K with Water and LN2

We're testing Kaby Lake's maximum frequency at various core voltages, the influence of de-lidding, and even applying a bit of liquid nitrogen. Get ready to learn more about overclocking Intel's latest architecture with a bunch of Core i7-7700K CPUs.

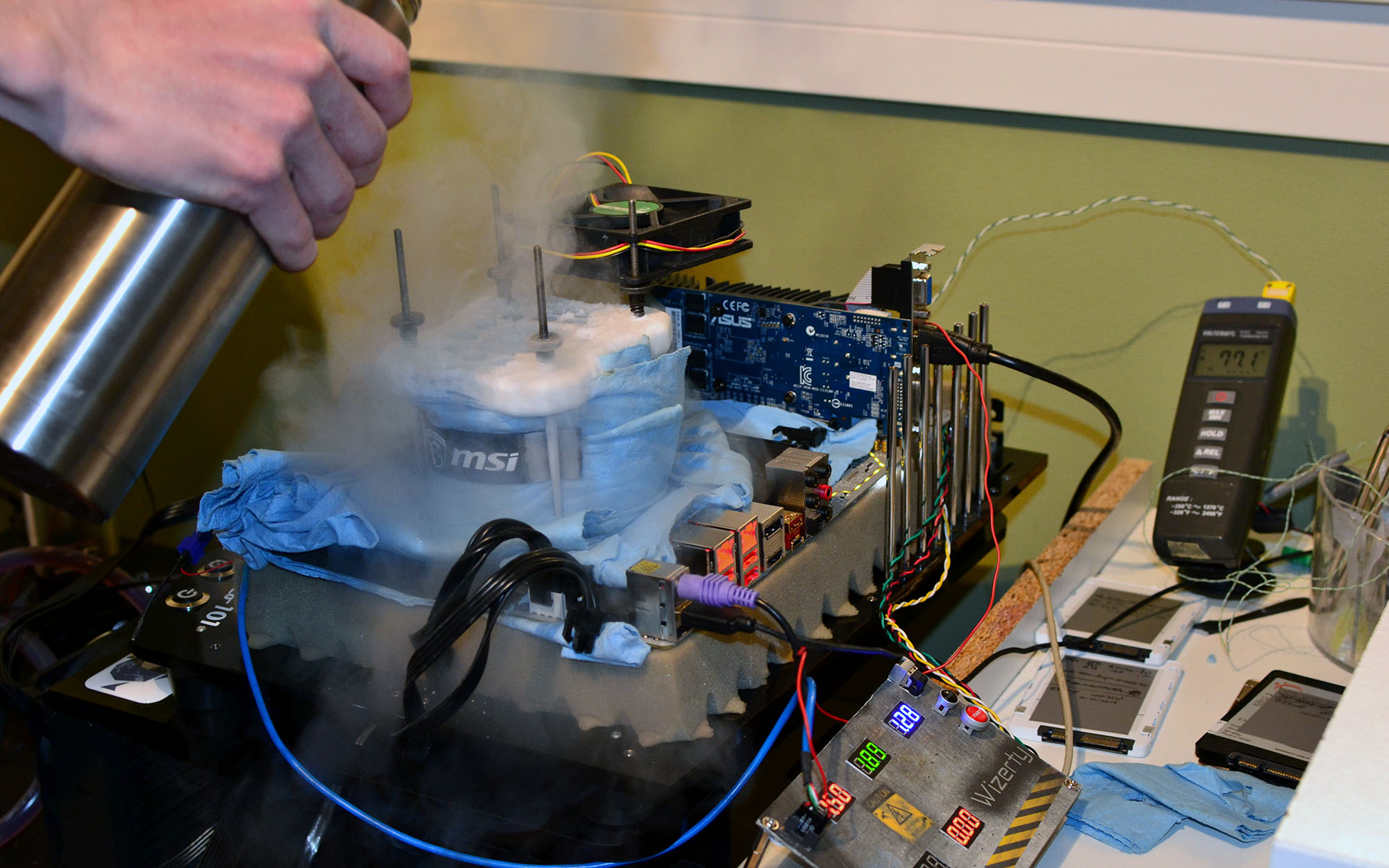

Overclocking with Liquid Nitrogen

The difference between conventional and extreme overclocking is largely a matter of temperatures. In theory, the distinction is subtle. But in practice, the latter involves major considerations (like condensation, for example). You have to take special care to protect your hardware from the ice (and related water droplets) that forms on the cooler.

Preparation

There are multiple ways to prepare sensitive electronics for the rigors of extreme overclocking. Similar to the fashion industry, those styles evolve and come back in vogue years later. Without going into too many details, the most popular techniques are:

- Vaseline: Coat the surface to keep water from coming into contact with the PCB. It's quick and cheap, but hard to clean up. In addition, certain chips can be very sensitive and malfunction in its presence.

- Plasti Dip: This is a plastic that can either be applied with a brush or an aerosol can. Once the solvents have evaporated, the layer solidifies. It's more expensive (about $10 per can), but its inconveniences are the long application time and difficult clean-up.

- Kneaded eraser: This is a sort of modeling putty. It's also quite expensive at around $10 per motherboard. On the flip side, you can re-use the material, and it's easy to clean up (depending on how long it was in contact with your hardware).

- Neoprene: This is simply covering the motherboard with a layer of synthetic rubber. Clean-up can't get any easier than this, but the preparation time is quite long. This technique exposes more of the motherboard because there is not a tight seal. Water can therefore infiltrate.

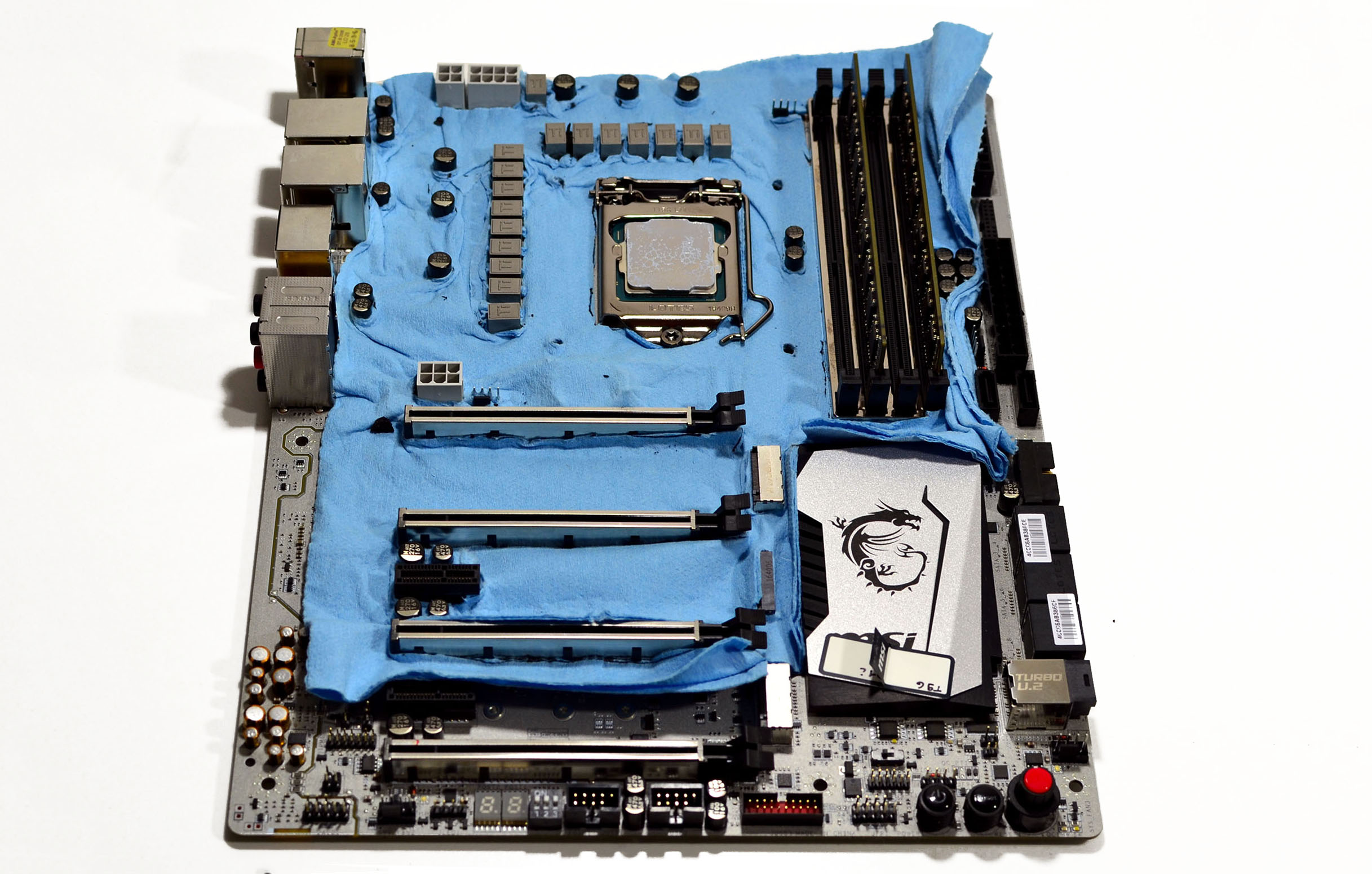

Having lost USB ports on multiple motherboards last year, I decided to skip Vaseline this time around. My motherboard is covered in paper towels cut to size, which serve as the final protection in case water gets under the first line of defense.

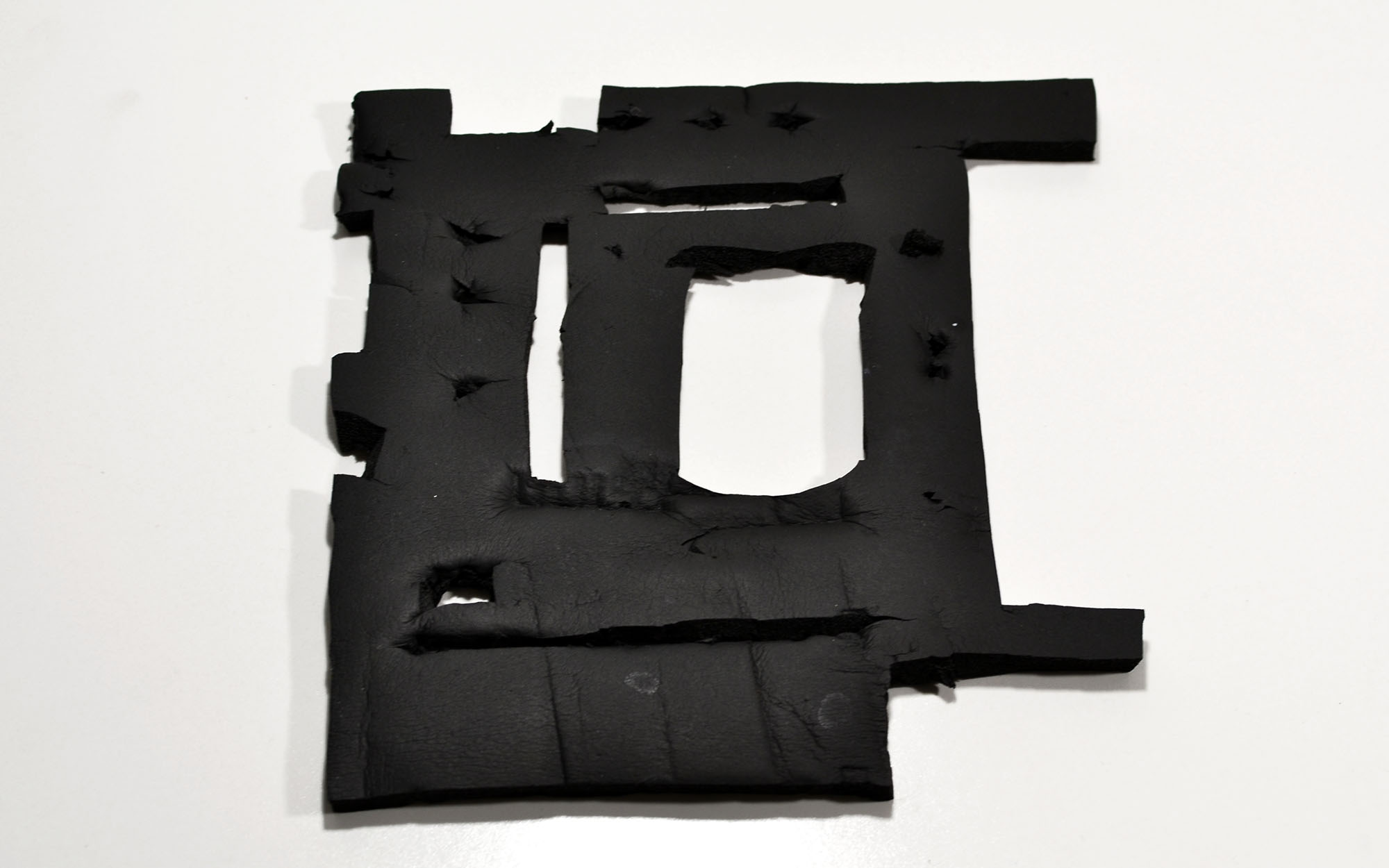

Extreme overclockers aren't interested in aesthetics. Though it's far from beautiful, this piece of neoprene is trimmed to hug the motherboard's PCA as tightly as possible. Cutouts accommodate the processor interface, inductors, capacitors, and PCIe slots. Once finished, it will be coated in adhesive for support and partial waterproofing.

The back side of the motherboard is less vulnerable, but still important to protect. We use a combination of kneaded eraser and an anti-static bag. Just the putty would be sufficient, but covering the entire motherboard with it takes a long time and costs quite a bit. Therefore, we created a barrier of kneaded eraser around the border of the motherboard and covered all openings, then sealed everything water-tight with the anti-static bag. Anti-static? Only because it was sitting around when we were searching for a solution!

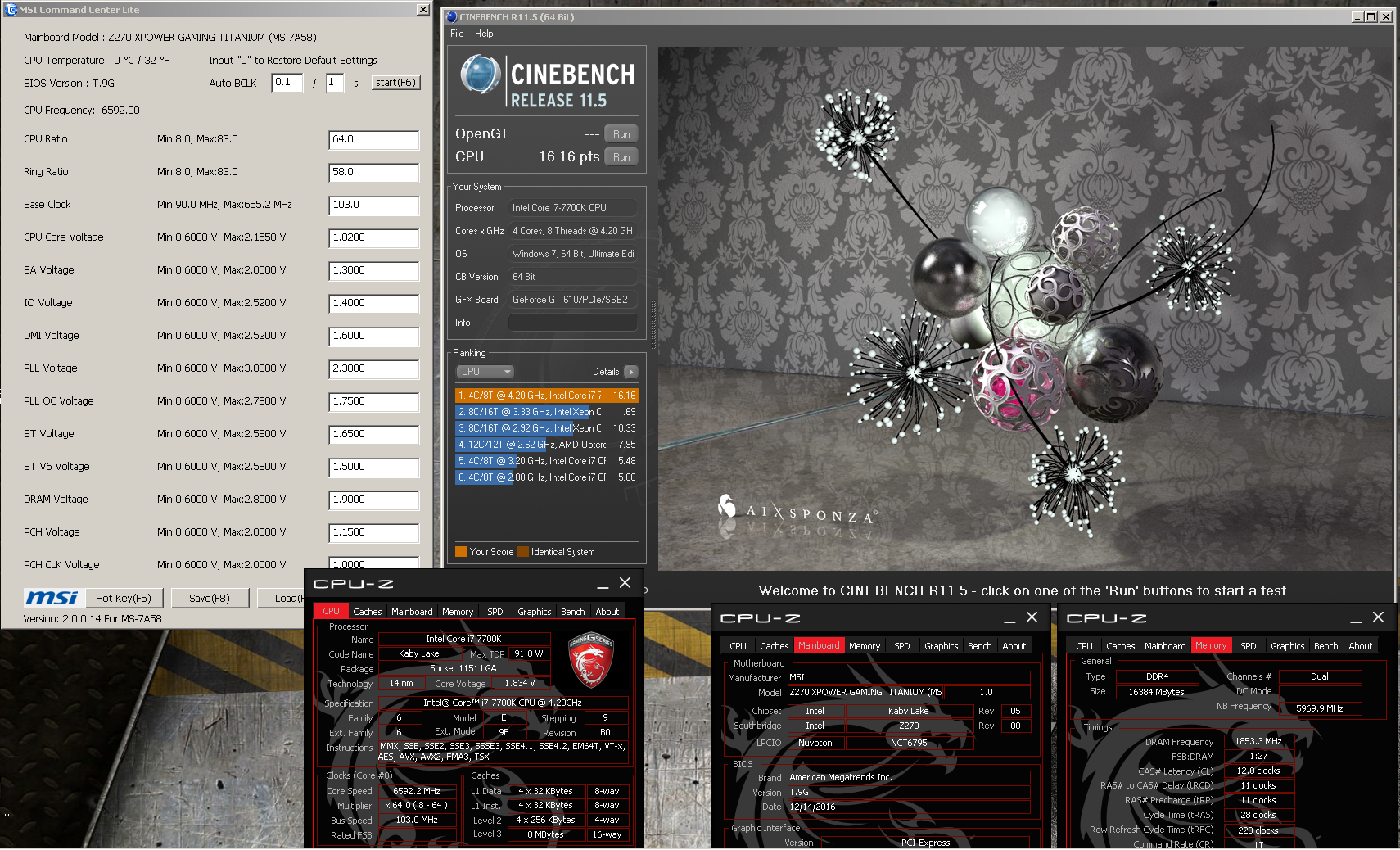

After many hours spent in the motherboard's BIOS, we came to a realization that only become funny later: our first three sessions failed and were a complete loss due to a small and trivial voltage setting. Without it, we couldn't get the multiplier above 60x.

The problem wasn't related to stability. A combination of 102 MHz x 59 yields a frequency above 6 GHz, and that was completely stable. But the system would hang without fail if we switched to 100 MHz x 60. After tens of liters of liquid nitrogen, a bottle of gas, and more than 10 hours of chilling to test the BIOS, processor, RAM, and operating system, we finally stumbled on a solution: the “PLL SFR” setting must also be increased to more than 1.1V instead of 0.9V to unlock the higher multiplier.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

After hurdling this roadblock, we were able to push our -7700K a little harder.

We reached about 6.6 GHz on Cinebench R11.5. World records won't be broken with this sample, but for a first attempt with a -7700K that wasn't hand-selected, it is quite satisfying.

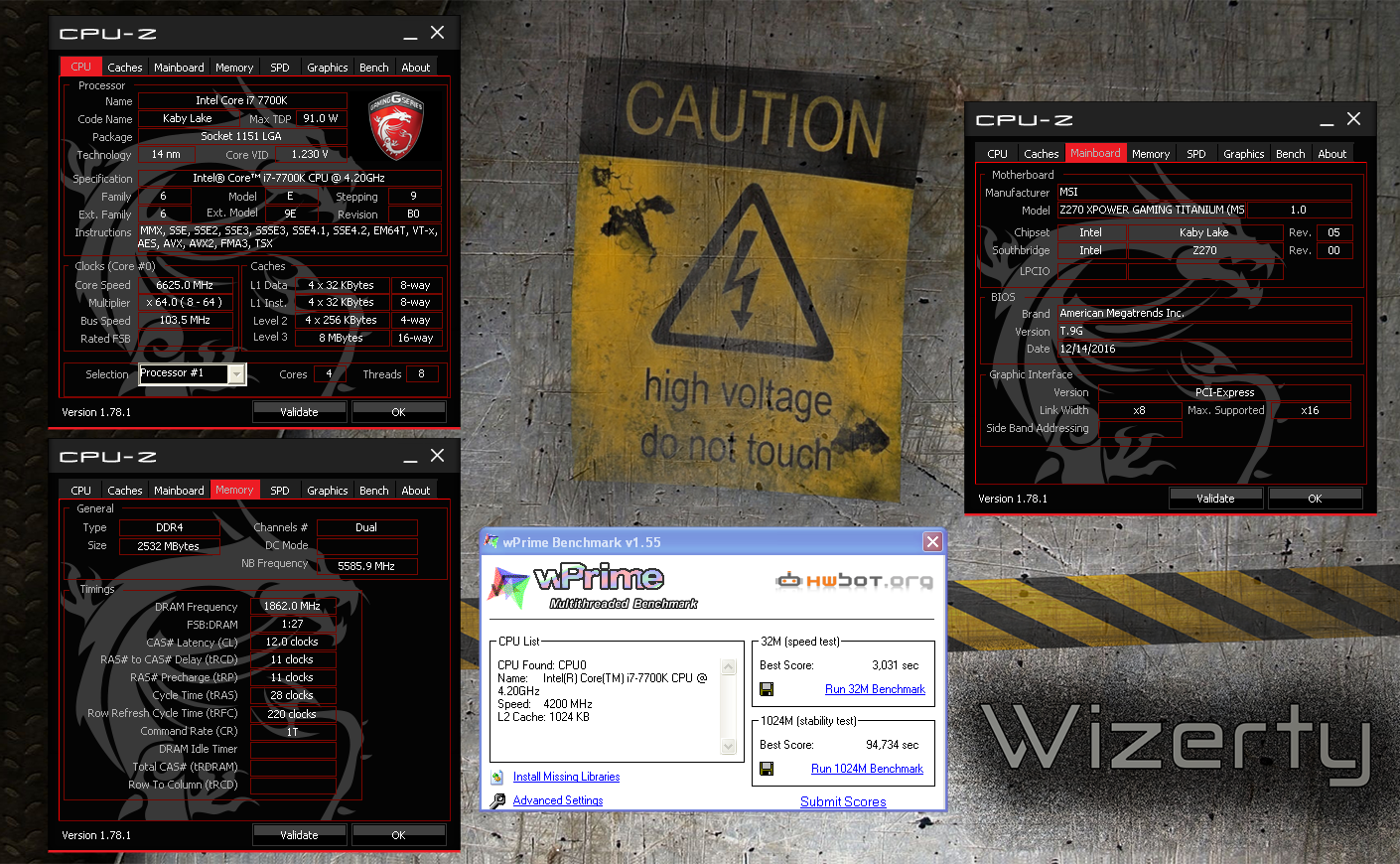

We achieved a little more than 6.6 GHz under Wprime 32M and 1024M.

In the end, we logged about a dozen results, and they're all available on HWBOT. Without question, these will be vastly improved in the weeks to come. This was just a first attempt.

MORE: Best CPU Cooling

MORE: Best PC Builds

Current page: Overclocking with Liquid Nitrogen

Prev Page Overclocking with Water Cooling Next Page How'd We Do with 20 Core i7-7700K CPUs?-

rantoc Intel should be ashamed of themselves for applying such useless TIM to save a few cents in a "high end" product as they like to call it!Reply -

AgentLozen Very fun article to read.Reply

You guys were using water cooling and liquid nitrogen for this experiment. I wonder how well aggressive air cooling would have held up. -

InvalidError Reply

The quality of Intel's TIM is perfectly fine. The problem is the thickness as the gap between the die and IHS is many times wider than necessary. Most of the cooling performance gain from de-lidding comes from reducing or eliminating the adhesive thickness.19451139 said:Intel should be ashamed of themselves for applying such useless TIM to save a few cents in a "high end" product as they like to call it!

To make a fair comparison against Intel's stock TIM, you'd need to shim the IHS to achieve the same total package thickness. Any TIM will perform much worse when it is 5X thicker than the minimum necessary. -

Xajel I miss the days of Phase Change cooling, while LN is more extreme, you just can't use it in real world usage, just to see how far you can go with it without going for more extreme cooling ( eg. LHe ), With Phase Change, you can even go 24/7 If you have the build correctly ( isolation from humidity )Reply -

Math Geek i'd love to know how much power it took to get those results :)Reply

folks ask all the time how much extra power they need for overclocking and this looks like a good opportunity to get some solid numbers if they'd like to share them. what kind of wattage does this use at 6.6 ghz??? -

rantoc Reply19451237 said:

The quality of Intel's TIM is perfectly fine. The problem is the thickness as the gap between the die and IHS is many times wider than necessary. Most of the cooling performance gain from de-lidding comes from reducing or eliminating the adhesive thickness.19451139 said:Intel should be ashamed of themselves for applying such useless TIM to save a few cents in a "high end" product as they like to call it!

To make a fair comparison against Intel's stock TIM, you'd need to shim the IHS to achieve the same total package thickness. Any TIM will perform much worse when it is 5X thicker than the minimum necessary.

Sure the distance the TIM have to transfer the heat is one of the variables for thermal conductivity but there are tons of documented straight out switches of only the TIM after deliding (without any changes in the IHS height above the CPU) that have resulted in similar improvements like this articles when overclocking the CPU. Sure the tim is sufficient for non overclocking use but intels stock tim is clearly holding the CPU back when pushing that overclock. -

InvalidError Reply

If you include the nitrogen separator and helium chillers needed to generate a sufficient stream of LN2 to keep the overclock running, probably in the neighborhood of 10kW :)19451369 said:what kind of wattage does this use at 6.6 ghz??? -

InvalidError Reply

I have only seen one site report on attempting to maintain the same thickness with Ivy Bridge and that site's results showed worse performance with most aftermarket pastes. All other deliddings I have seen removed the glue and did not put anything back in its place to duplicate its thickness or when they did (ex.: deBauer), they minimized that thickness by pressing the IHS against the substrate before curing.19451405 said:Sure the distance the TIM have to transfer the heat is one of the variables for thermal conductivity but there are tons of documented straight out switches of only the TIM after deliding (without any changes in the IHS height above the CPU) that have resulted in similar improvements like this articles when overclocking the CPU.