Tom's Hardware Verdict

The Monoprice Mini Delta V2 is compact, cute and speedy, but mediocre output quality and bugs hold it back.

Pros

- +

Affordable

- +

+ Auto Leveling

- +

+ No Assembly Required

- +

+ Ridiculously fun to watch

- +

+ Portable

Cons

- -

Small build volume

- -

Under powered cooling fan

- -

Software bugs

Why you can trust Tom's Hardware

The Monoprice Mini Delta v2 is a small, affordable and super fast printer aimed at beginners. It requires no assembly, has auto bed leveling, a color touch screen, Wi-Fi and easy-to-use slicing software.

Delta printers are amazingly fun to watch, with their three spider-like arms whirling away from the top of the machine. Naturally, I assumed this would be a printer to give to a kid interested in STEM or to use in a classroom situation. But it has a few problems to overcome.

Retailing at $179, the Monoprice Mini Delta v2’s flaws are hard to understand – especially with the outstanding Creality Ender 2 Pro, one of the best 3D printers on the market, available for a few bucks less. The print bed is wobbly, the cooling fan is underpowered, and the machine sometimes needs to be manually turned on and off to clear its memory between prints.

Specifications: Monoprice Mini Delta v2

| Machine Footprint | 220 x 247 x 355 mm ( 8.5 x 9.75 x 14 inches) |

| Build Volume | 110 x 120 mm (ø4.3 x 4.7 inches) |

| Material | PLA/PETG |

| Extruder Type | Bowden |

| Nozzle | .4mm |

| Build Platform | Textured Non-Removable Sticker on Heated Bed |

| Filament Runout Sensor | No |

| Bed Leveling | Full Auto Leveling |

| Connectivity | MicroSD, USB, Wi-Fi |

| Interface | Color Touch Screen |

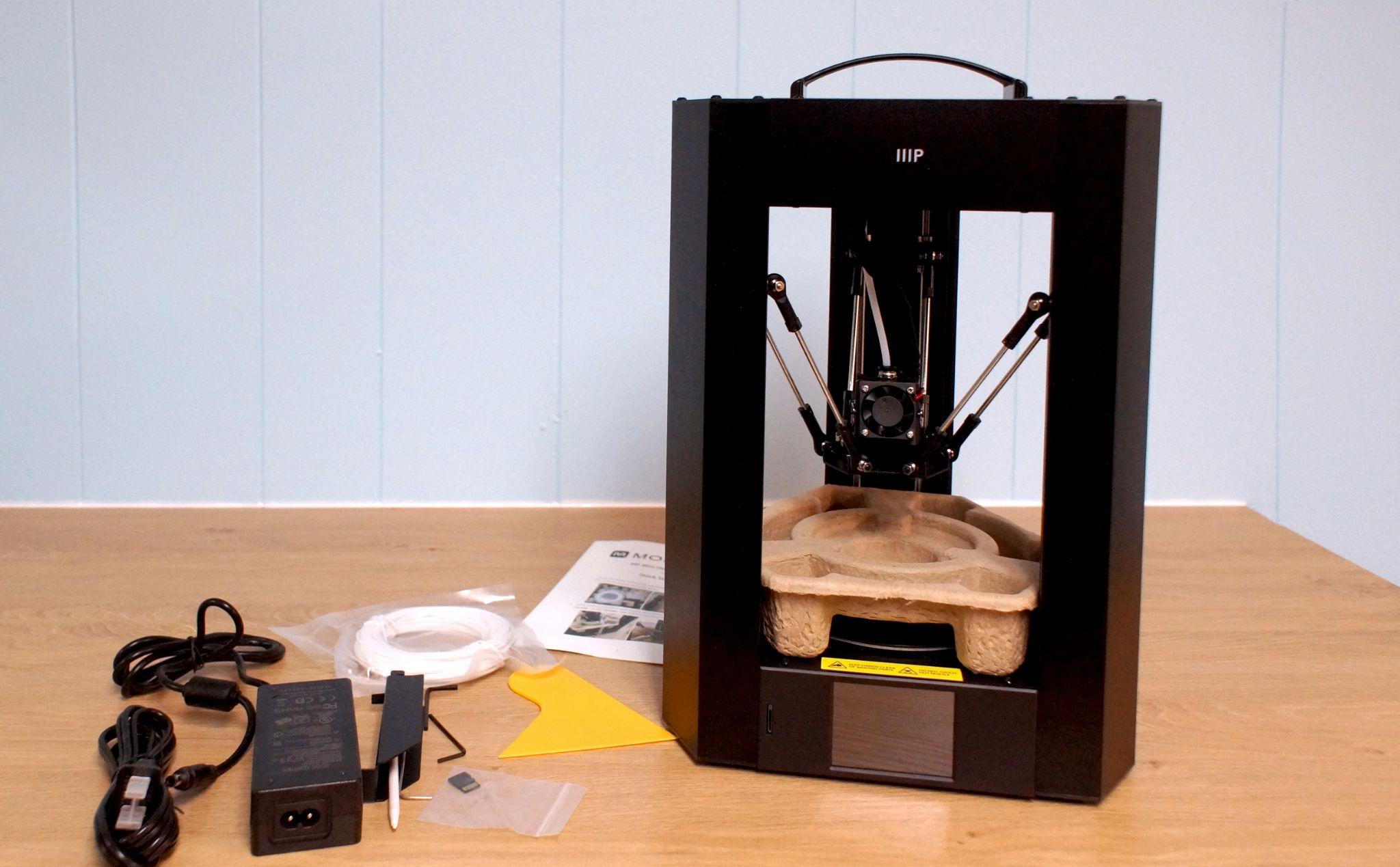

Monoprice Mini Delta v2: Included in the box

The Monoprice Mini Delta v2 comes with nearly everything you need to get started. You get tools to maintain the printer, a plastic scraper, a spare nozzle, a touch screen stylus, and a microSD card. There’s also a small sample of white PLA to print your first model.

You do not get a pair of side cutters for trimming the filament or an adapter for the microSD card. The manual is on both paper and a PDF. The microSD also has slicing software – Cura 4.3.0 and WiiBuilder – plus pre-sliced models to print.

Design of the Monoprice Mini Delta v2

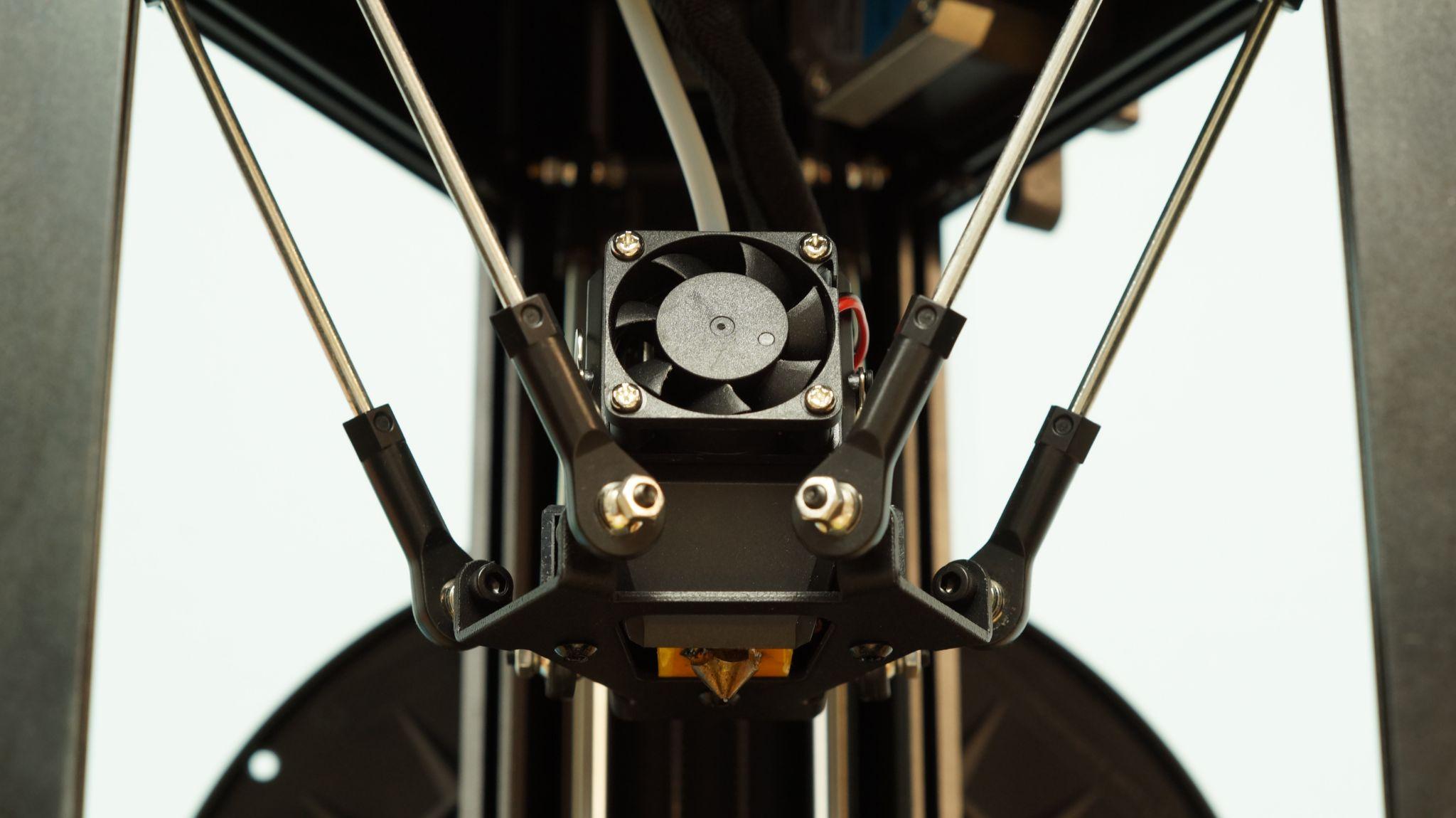

The Monoprice Mini Delta v2 has a futuristic design – a triangular black metal frame housing three delicate arms holding the hotend over a fixed round base. All the components are hidden away in the top and bottom compartments. It resembles an hourglass more than a 3D printer.

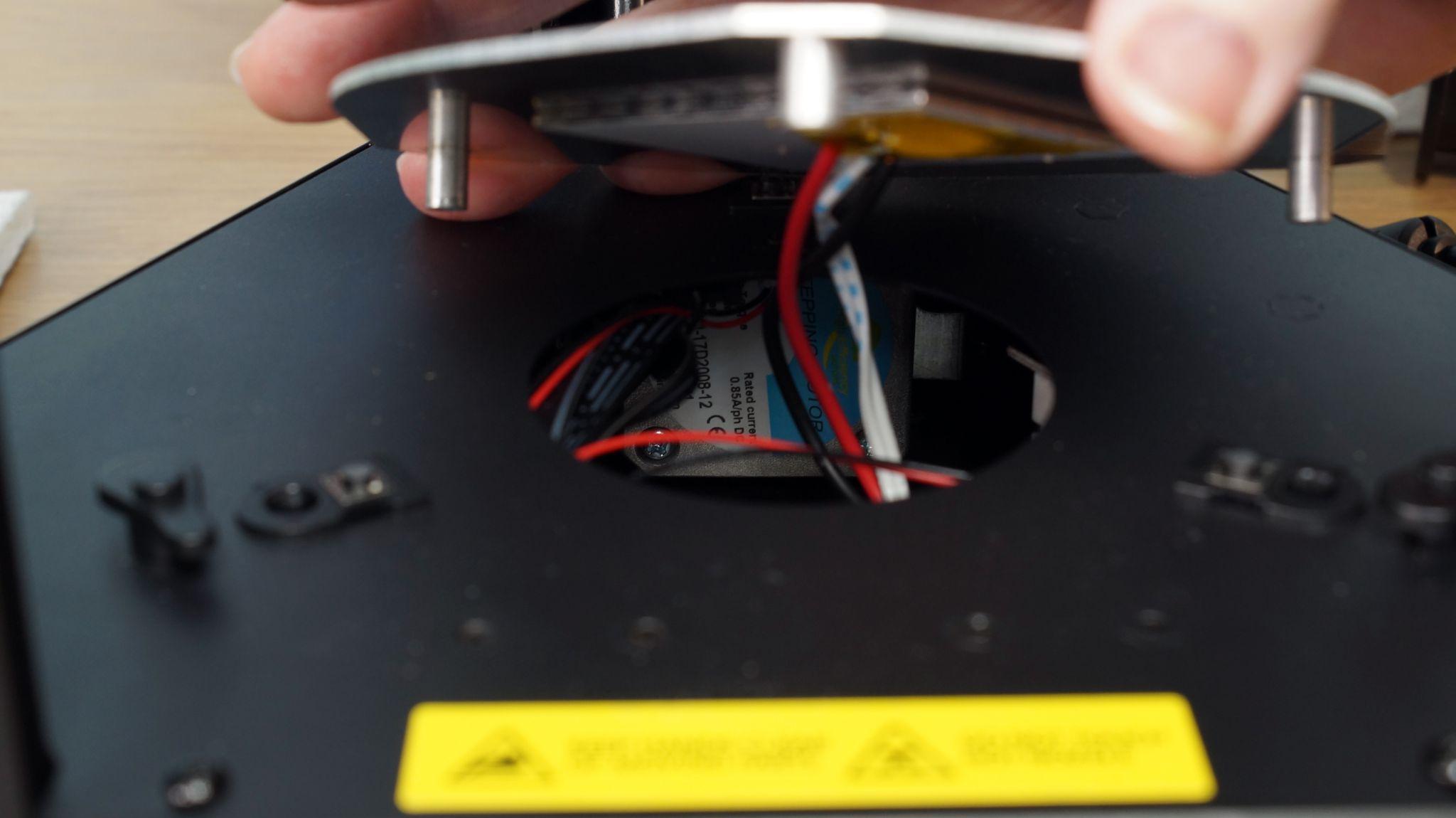

The PTFE lined hotend is extremely lightweight and takes an M6 nozzle. The tiny cooling fan is underpowered, leaving it unable to print much in the way of overhangs. Monoprice compensated for the fan by turning the wall speed down in the profiles for both WiiBuilder and Cura. More on this later.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

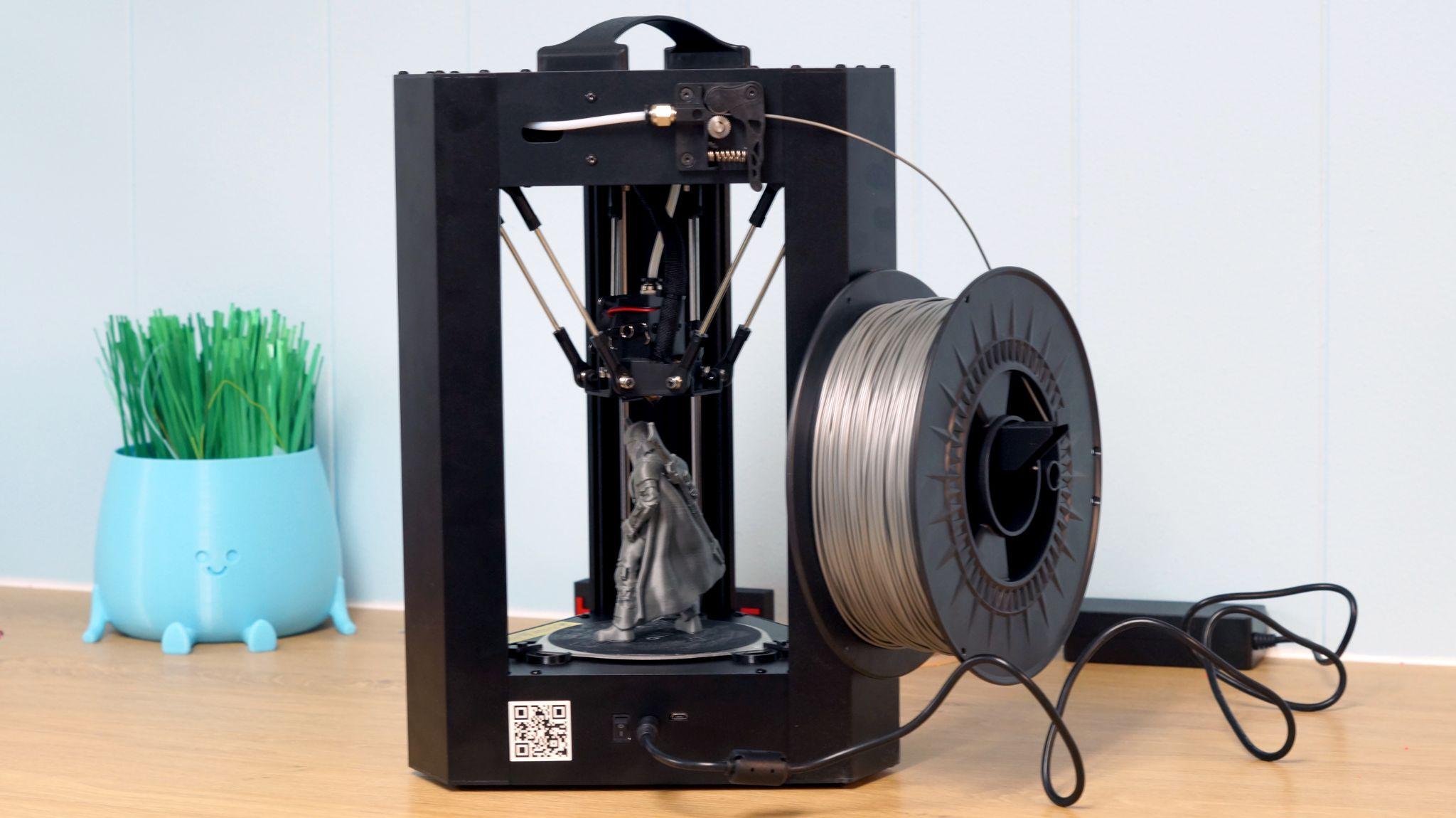

The filament holder for the Monoprice Mini Delta v2 is mounted on the side of the printer at a near 90° angle from the extruder. This makes for an awkward filament loading experience and might even put undue strain on the extruder.

The wobbly build plate is confounding – three clips loosely hold the plate in place, which causes noticeable horizontal lines in the print. The plate isn’t fully detachable, it’s tethered to the machine’s guts by the bed heater wires.

It would be helpful if the build plate could be removed because the prints stick to it like a beast. I’ve had to chisel a few off with a pallet knife and hammer.

The printer’s interface is delightfully bug free. It is a full color touch screen that displays a thumbnail of models that are sliced in Wii Builder. The menu is easy to understand and use.

Build volume is limited to 110mm diameter by 120mm tall, which is pretty darn small. Several prints that I tested out had to be sized down to fit.

However, something is glitchy in the firmware that causes the machine to get hung up after a print. The only solution I’ve found is to turn the printer on and off after a print.

Delta vs Cartesian: Monoprice Mini Delta v2

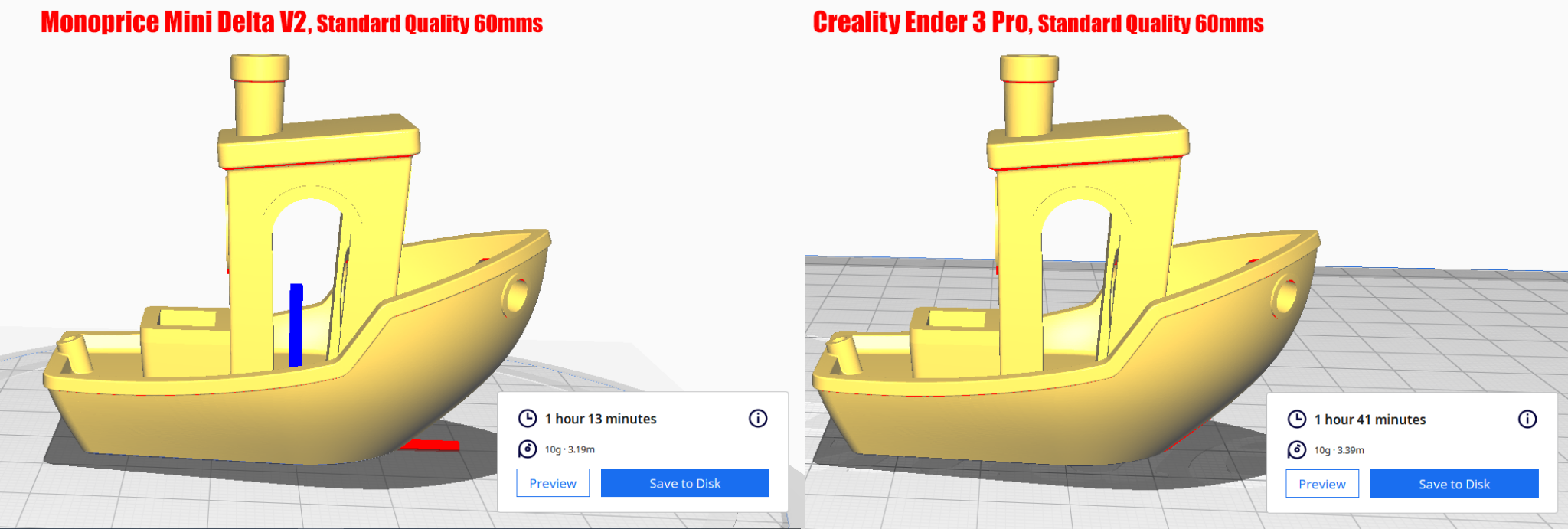

It’s worth mentioning that this printer, like other Delta style machines, is quite a bit faster than Cartesian style machines.

Cartesian printers – like the Anycubic Kobra or Creality Ender 3 Pro – are named because their movements use the same Cartesian coordinate system found in geometry (and Minecraft). These printers have three separate axes: X, Y and Z. Each axis can only move in two directions: side to side for X, back and forth for Y or up and down for Z.

Delta printers have three arms placed at three points of an equilateral triangle around its circular build plate. Each arm is equal and can move up and down, forward and back, plus side to side. This allows for smaller and faster movements.

For example, a Benchy sliced on Cura 4.13.1 for the Monoprice Mini Delta v2 takes 1 hour and 13 minutes, while the exact same Benchy takes 1 hours 41 minutes on a Creality Ender 3 Pro.

Assembling the Monoprice Mini Delta v2

The Monoprice Mini Delta v2 is 99% assembled. You only need to unpack it, slide the filament holder in place, plug it in and go.

Leveling the Monoprice Mini Delta v2

Leveling the Monoprice Mini Delta v2 is very simple. When you first unbox the machine, you should run a Delta Calibration, located under the Prepare Menu. The printer will take a few minutes to check the flatness of the build surface and determine how to compensate to give you a flat first layer.

Instead of a probe on the hotend, the machine has three buttons under the plate. To level itself, the nozzle double taps 9 points around the plate, clicking the buttons underneath.

The Delta Calibration isn’t perfect; you’ll still need to double check the Z Offset. Place a piece of paper over the build plate and press Z Offset in the Prepare Menu. The printer will tap several points around the built plate, then settle on the center point at 0mm. Adjust the Z Offset with the menu buttons until the paper is held gently by the nozzle but can still move.

Delta calibration and adjusting the Z Offset only need to be done when you feel the need, like after printer maintenance. The printer will also do a very brief level check before each print to make sure it’s all lined up.

Using Wi-Fi on the Monoprice Mini Delta v2

There’s also a smartphone app called PoloPrint Pro. However I was unable to get it to connect. It doesn’t

The Monoprice Mini Delta v2 has Wi-Fi capabilities that allow it to send files from your computer while using WiiBuilder. The printer will ask if you want to connect to Wi-Fi during setup.

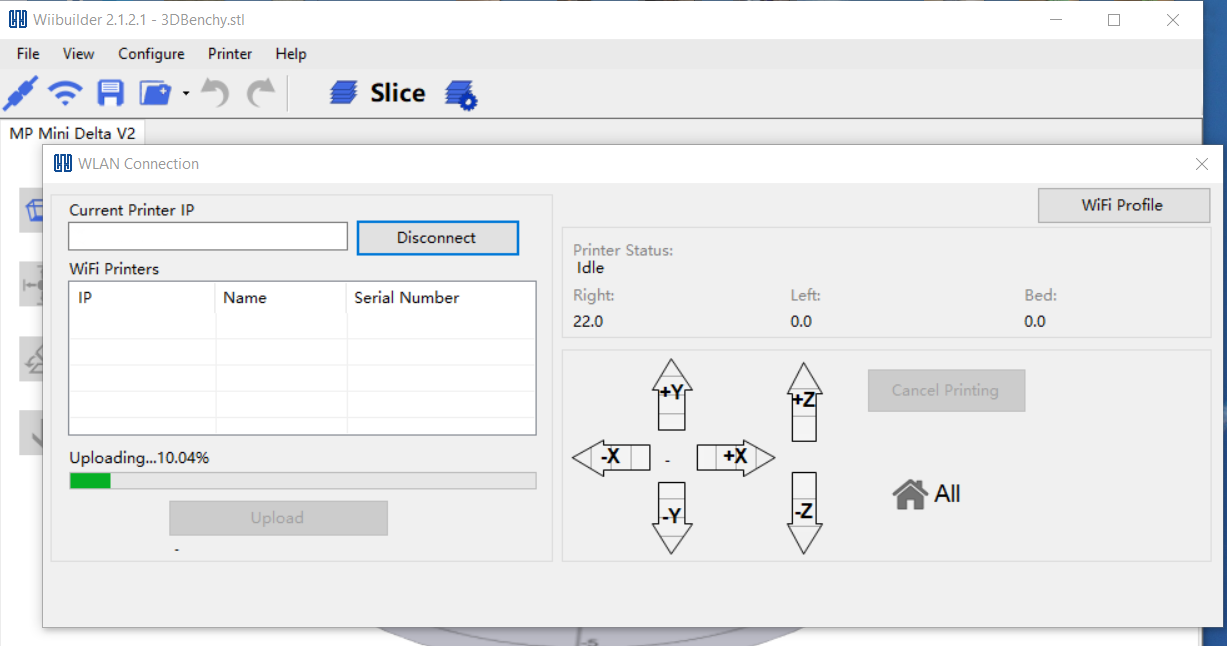

WiiBuilder was able to find the Delta Mini v2 by using a local web address. Keep a microSD card in the printer and you can send files remotely over your home’s Wi-Fi. Once the file is received, it will automatically start printing.

There’s no way to hook a camera into this system, but a Wyze camera or something similar is handy for monitoring your prints.

If you prefer to use Cura, you can slice your files, save them as a stl files, then load the files into WiiBuilder (do not slice it again) and send them wirelessly. It’s an extra step, but way better than walking an SD card back and forth.

Preparing Files and Uploading with Wi-Fi

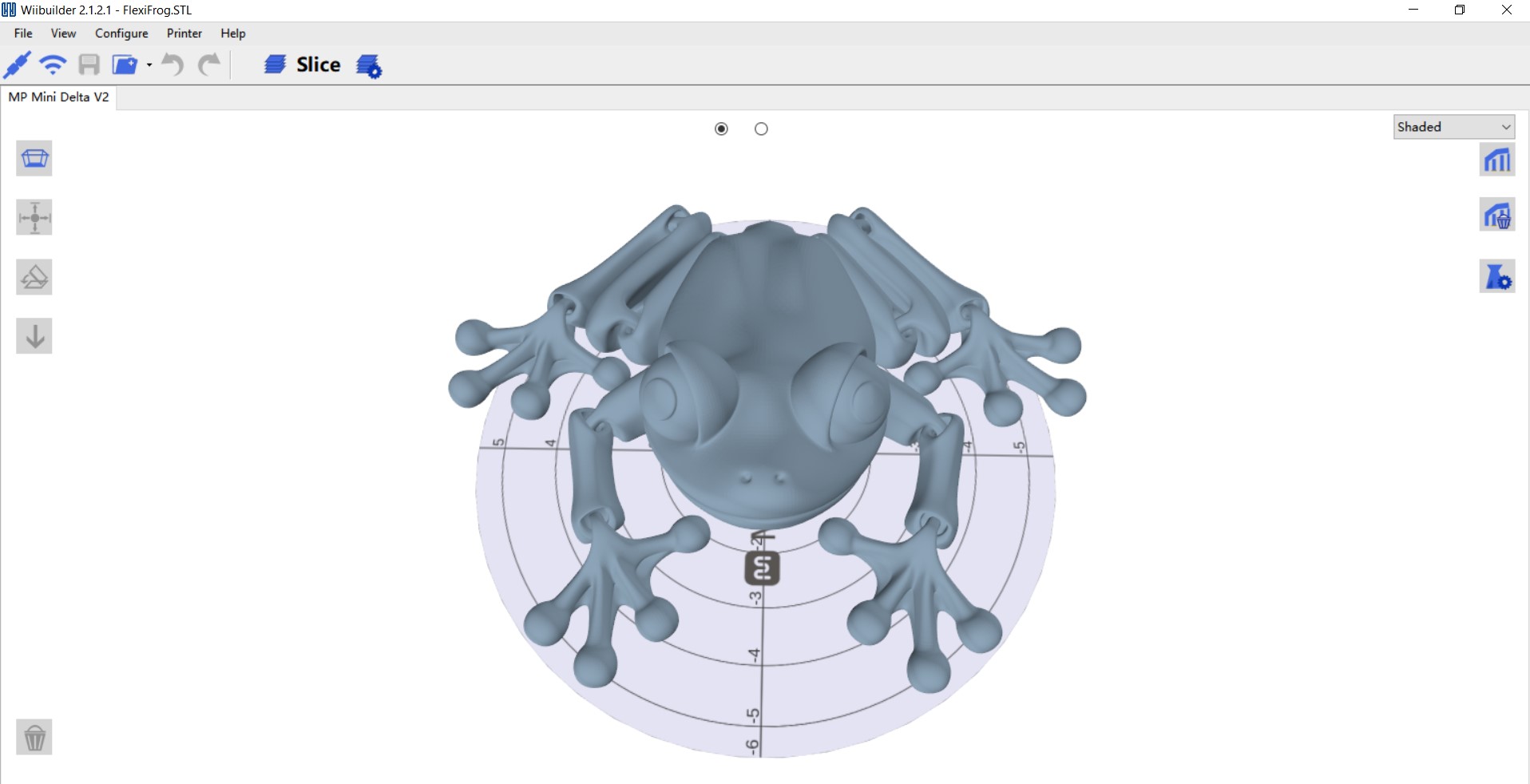

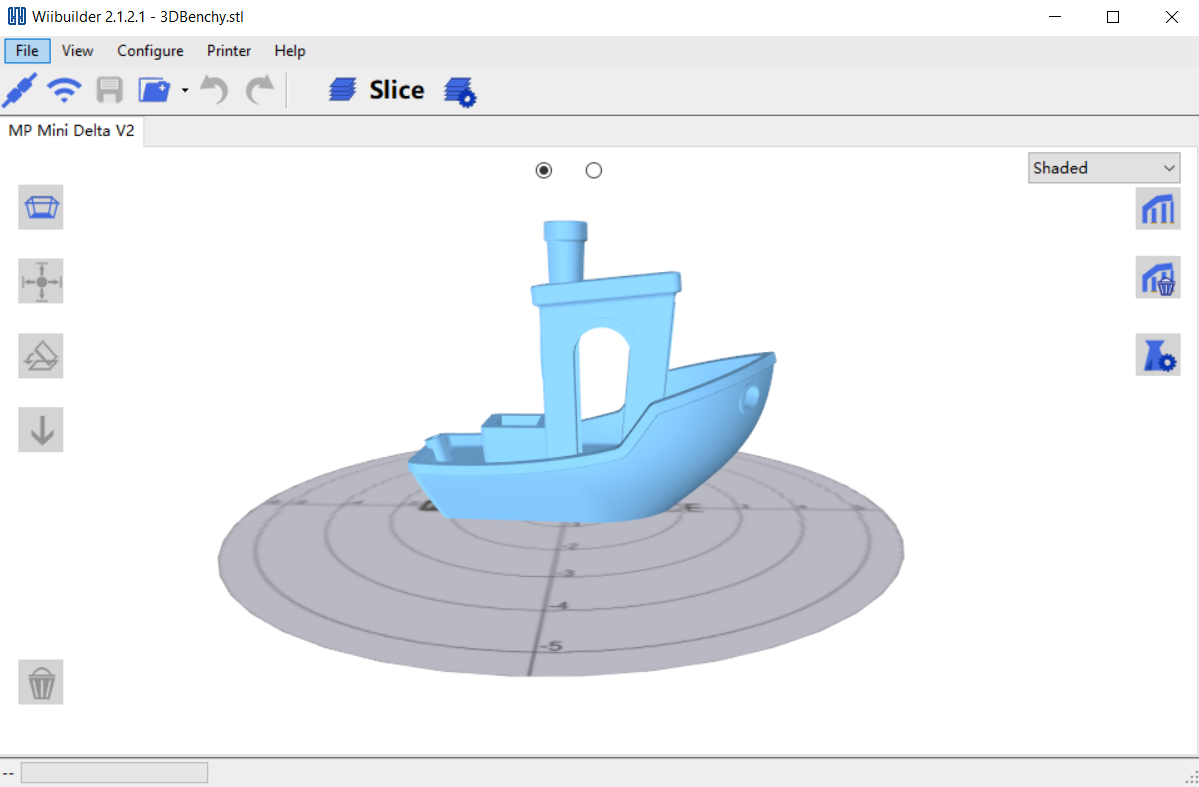

The Monoprice Mini Delta v2 comes with a copy of WiiBuilder 2.1 and Cura 4.3.0. Both programs come with custom profiles to squeeze as much quality from the machine as possible.

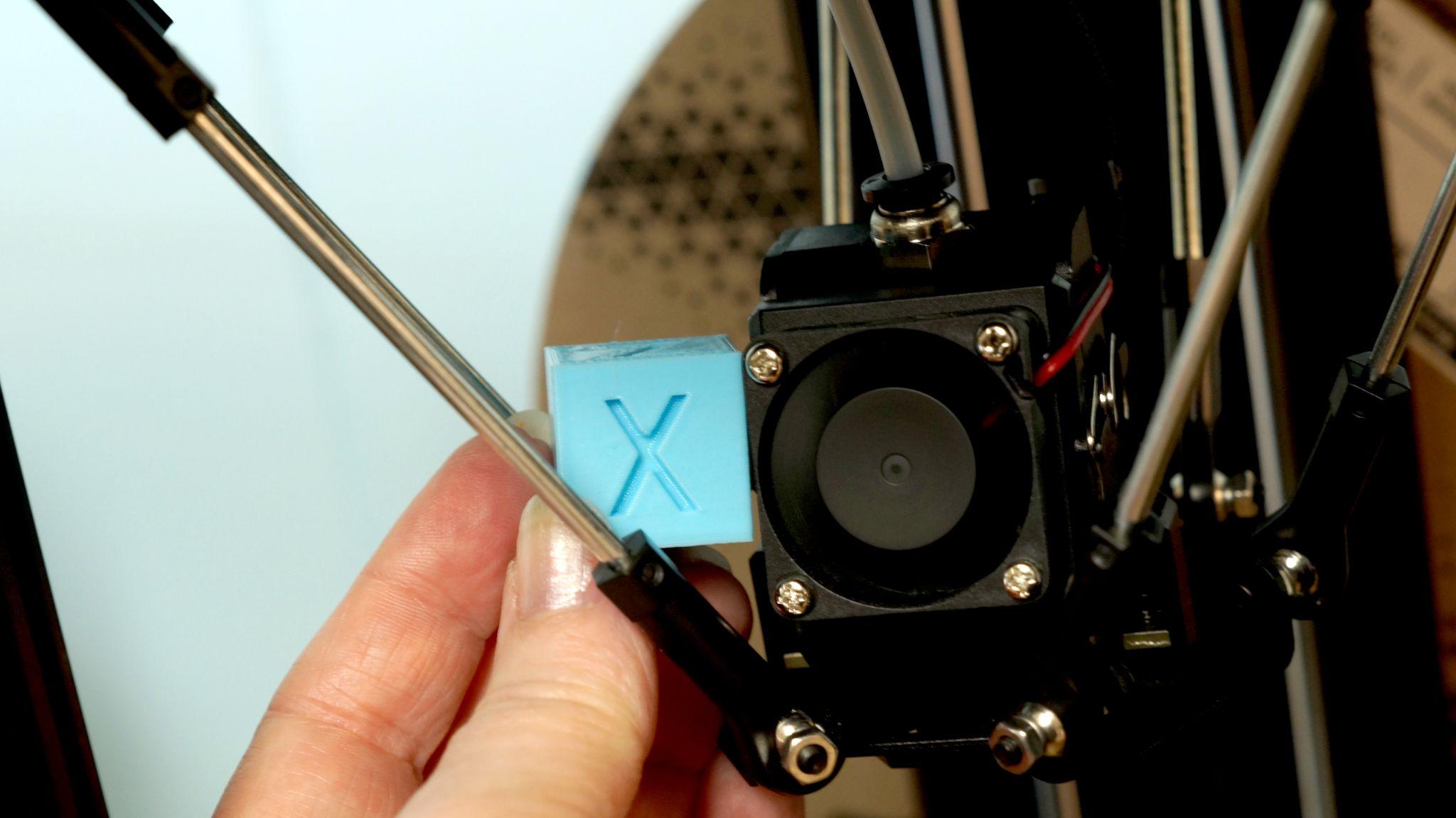

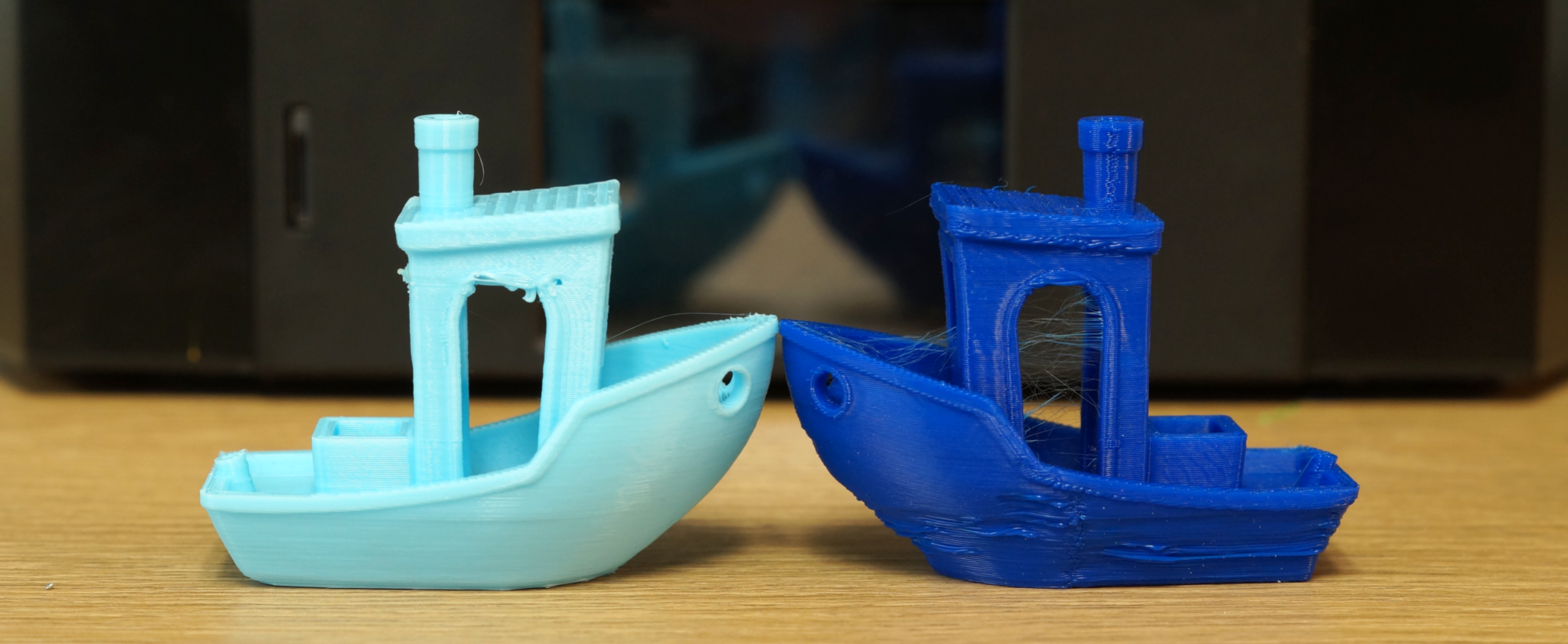

Both slicers have profiles that restrict wall speed to 25mms, which helps compensate for the underpowered cooling fan. Normally, Cura calculates wall speed at 50% of the overall printing speed. Below are two Benchies to show why you need to stick to the profile: the light blue was printed with the provided Cura profile while the dark blue was printed using Cura and a default standard profile at 65mms. Notice how the overhang on the bow is extremely rough with a wall speed of 32.5 mms.

Normally I like to stick to Cura, but in this case WiiBuilder is worth using for its built-in Wi-Fi capabilities. To access Wi-Fi, slice your model then click the Wi-Fi symbol on the menu bar. This opens a WLAN Connection. Click the connect button, then upload. The printer will automatically start the print as soon as it receives it.

Note that the Monoprice Delta Mini v2 needs a microSD card for Wi-Fi printing to work – it doesn’t have internal storage.

Printing on the Monoprice Mini Delta v2

The Monoprice Mini Delta v2 includes 7 pre-sliced models of toys – a good indicator of their target market. All the files printed in a few hours with .2mm layers, no support and rafts turned on. I didn’t think the quality was all that great, which is odd since manufacturers try to really impress you with that first print.

All the files are old classics from Thingiverse. I recognized Lucky Cat, Dorus the Dragon and LFS_elephant. In my testing, I printed them in Inland Turquoise PLA.

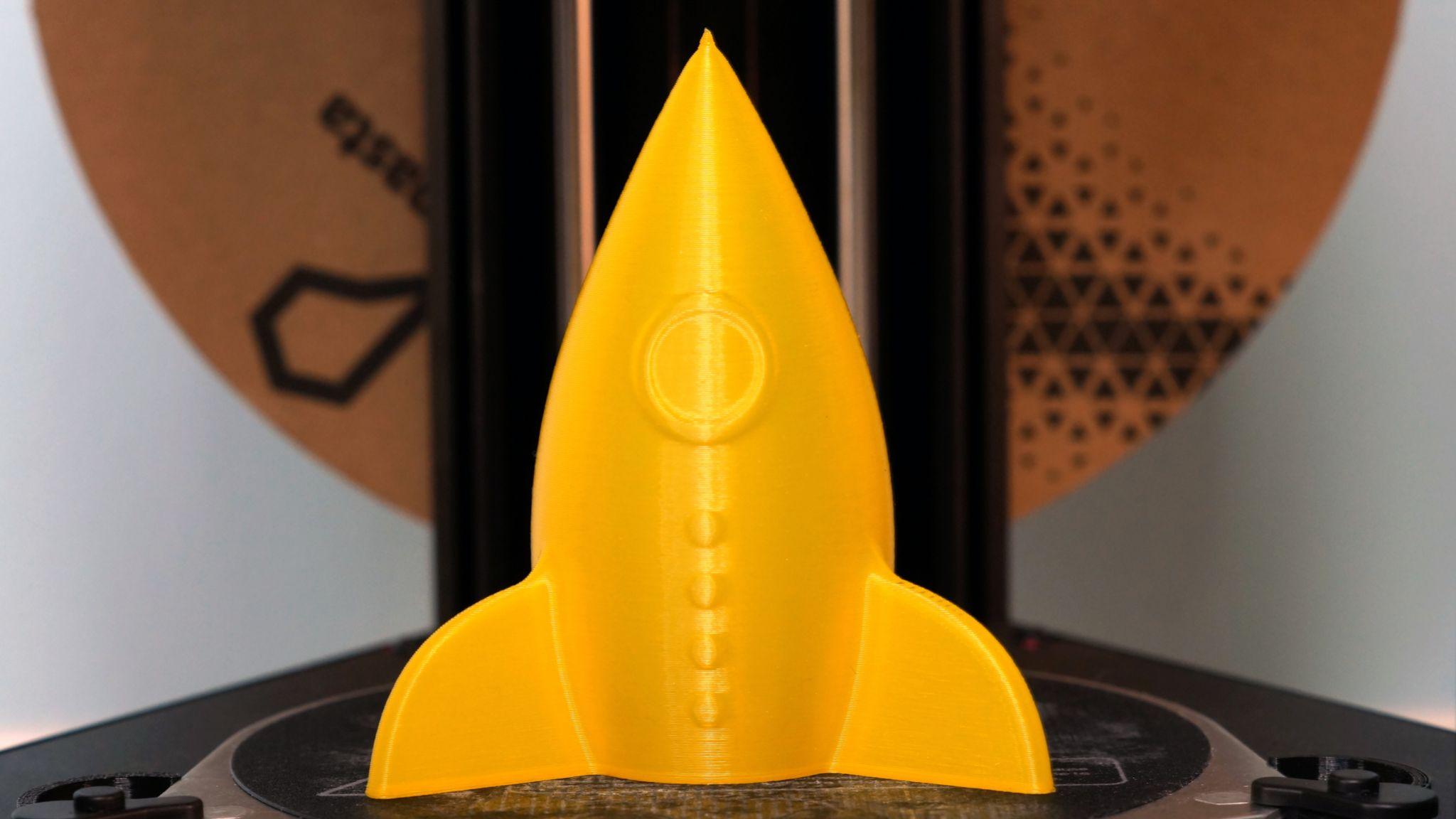

I wanted to see how the Mini Delta V2 could do without a raft, so I printed a vase mode rocket by DeJennes in PolyLite Yellow PLA. This model doesn’t have any overhangs and printed beautifully.

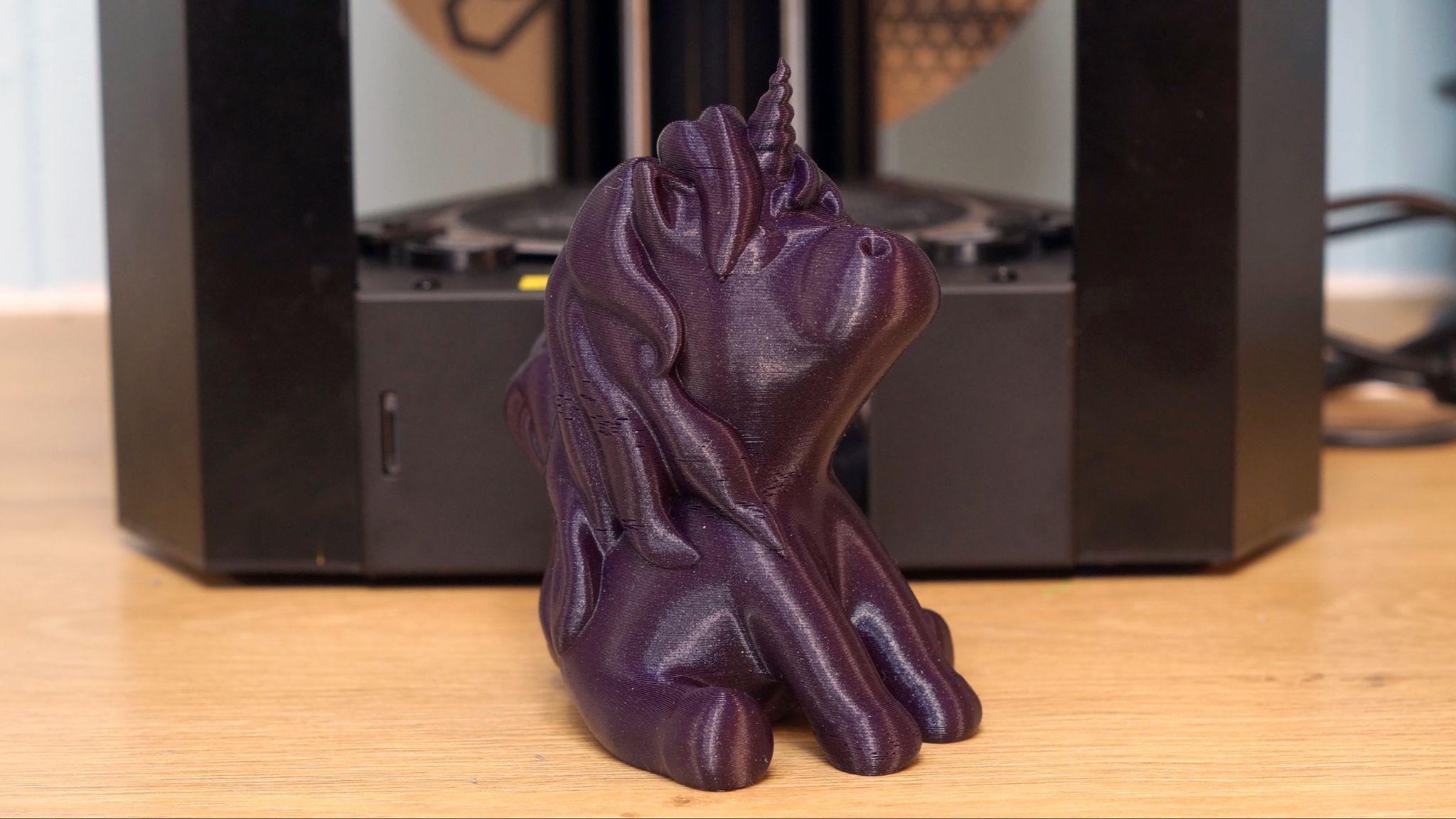

Here’s ChaosCoreTech’s Cute Unicorn, another print without overhangs. Once again, it printed really nicely and ProtoPasta’s recycled Still Colorful 002 PLA helped hide some of the layer lines, but not the occasional extrusion gaps in the mane.

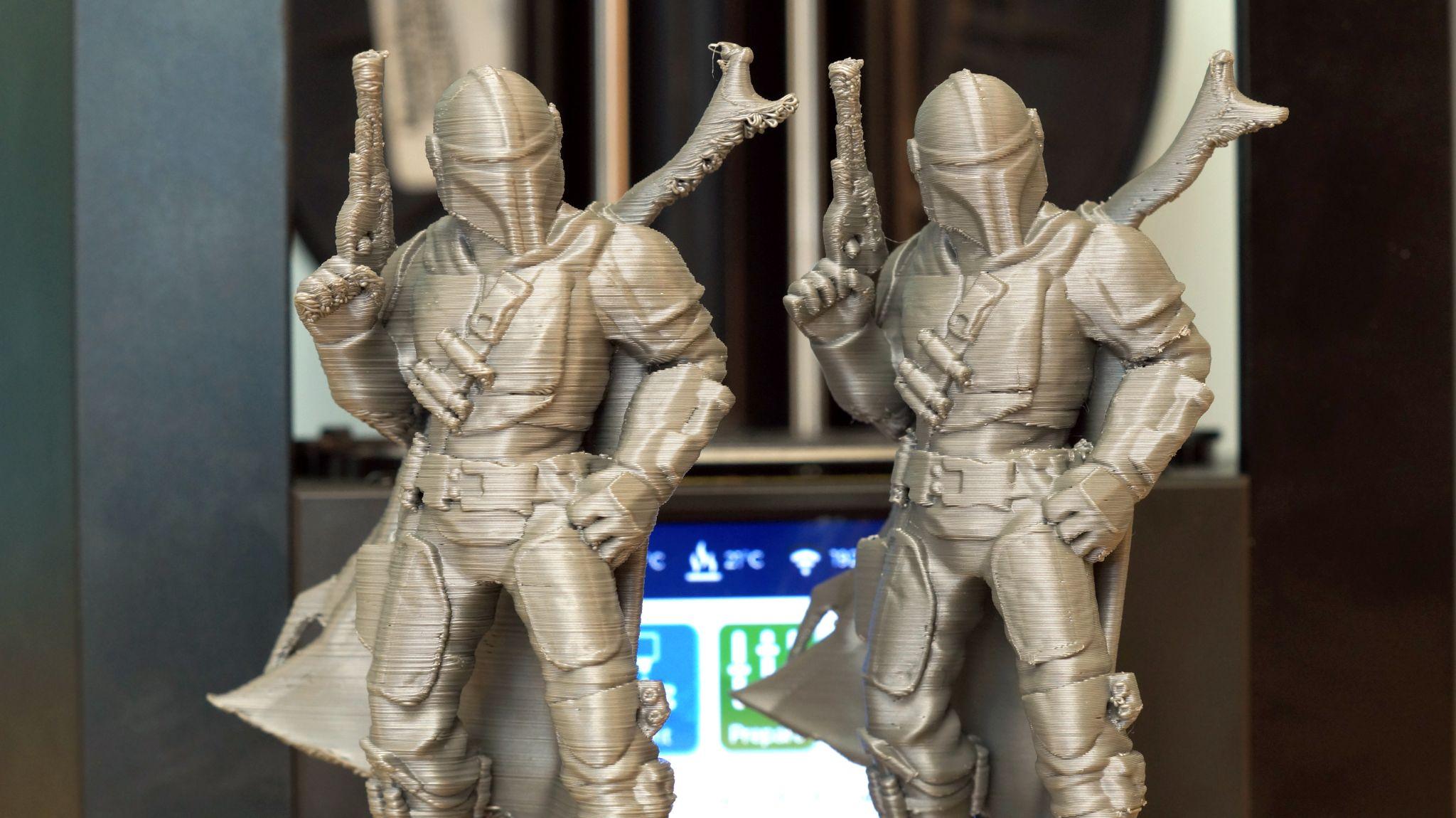

The last print surprised me. The Mandalorian Support Free Remix by Iczfirz usually prints great on any machine. But the Monoprice Mini Delta v2 wasn’t able to handle the overhangs on the weapons and cape with its tiny cooling fan. I added supports, which helped a little. These two are printed in Matterhackers Build Series Silver PLA. In the pictures below, Left Mando had no supports, but Right Mando had supports.

Bottom Line

Monoprice’s Mini Delta v2 is vexing. On paper, it has everything I want in a printer: it’s cheap, fast, compact and easy-to-use. It has auto leveling, built in Wi-Fi and ships with a custom slicer profile. It’s literally plug and play. The size and price point suggest that it’s a good value for beginners and kids interested in STEM.

But why should you accept low print quality when there are other budget printers that actually perform well with all kinds of models? The Creality Ender 2 Pro is one of those machines, and is our pick for best 3D Printer under $200.

If you think the Monoprice Mini Delta v2 is just too intriguing to pass up, I would highly suggest checking out this Facebook group dedicated to modding the machine. They have clever suggestions on how to upgrade the printer, tune it with a guitar app or make 3D printed clips to steady the bed.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

durahl The reason Delta 3D Printers are usually faster can, mostly be attributed to the only moving part being the considerably lighter toolhead and its equally lightweight kinematics support structure whereas a Cartesian 3D Printer will have to deal with both a print bed running on at least one axis that not only is heavier to begin with but gets heavier the larger and longer a print progresses posing some issues with calibrating it for resonances but also the toolhead running on another Axis with entirely different characteristics but still bound to the slowest denominator - The Print Bed.Reply

IMHO, CoreXY 3D Printers are somewhat the best of both worlds - A system like a Voron 2.4 with its Flying Gantry is essentially the equivalent of a Delta with a completely stationary print bed capable of brute forcing the speed ( I run mine stock at 300mm/s with almost 6'000 Accel = 29min Benchy ) by simply using beefy Steppers on the essentially identical X/Y Axis with the added benefit of not having the vertically wasted space of a Delta.

As far as I'm aware - Deltas also aren't exactly a prime candidate for 3D printing Parts requiring high precision - Something, something about their Kinematic System being iffy making things both perfectly straight and/or round 🤔