SilverStone Strider Platinum ST85F-PT PSU Review

SilverStone's Strider Platinum series offers compact dimensions along with Platinum efficiency and a fully modular cable design. The 850W member of this line will be evaluated today. Its strong card against the competition is the 471W power density score.

Why you can trust Tom's Hardware

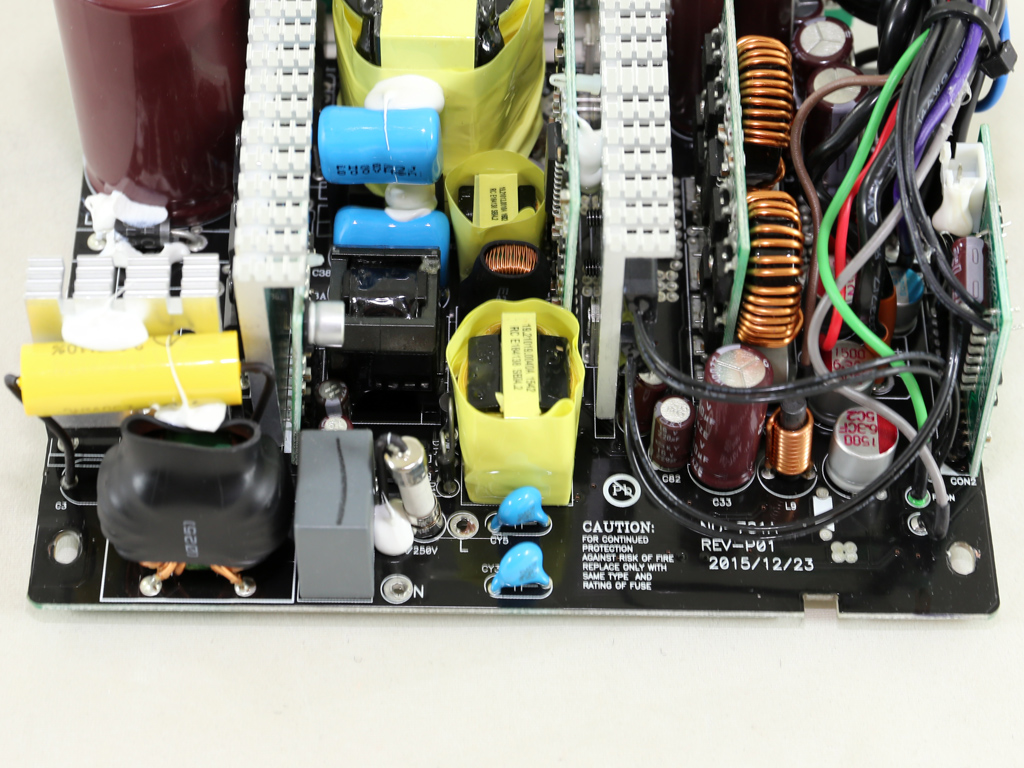

A Look Inside And Component Analysis

Parts Description

Before proceeding with this page, we strongly encourage you to a look at our PSUs 101 article, which provides valuable information about PSUs and their operation, allowing you to better understand the components we're about to discuss. Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station, and a Hakko FR-300 desoldering gun.

| Primary Side | |

|---|---|

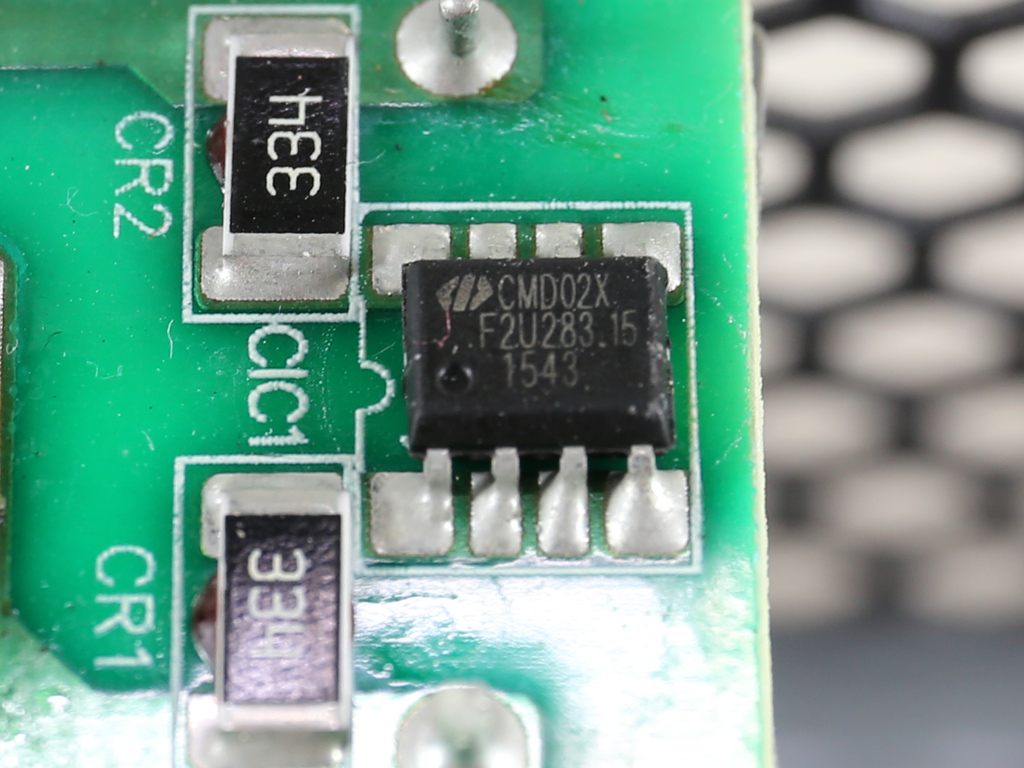

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV, 1x CMD02X |

| Inrush Protection | - |

| Bridge Rectifier(s) | 1x GBJ1506 (600 V, 15 A @ 100 °C) |

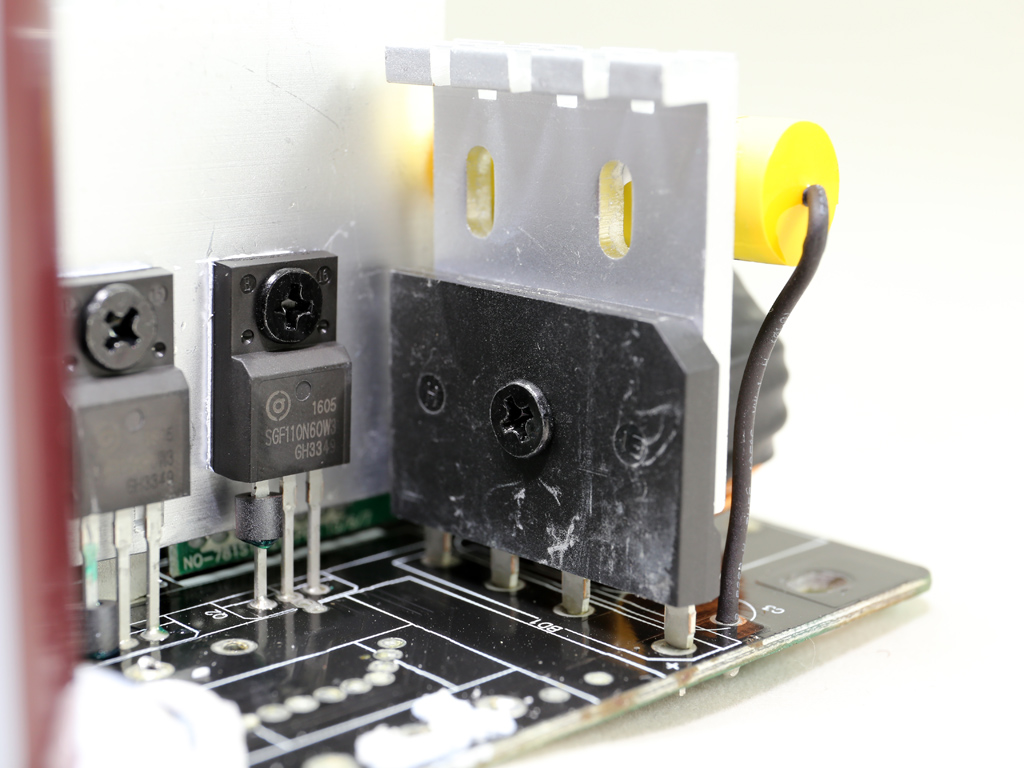

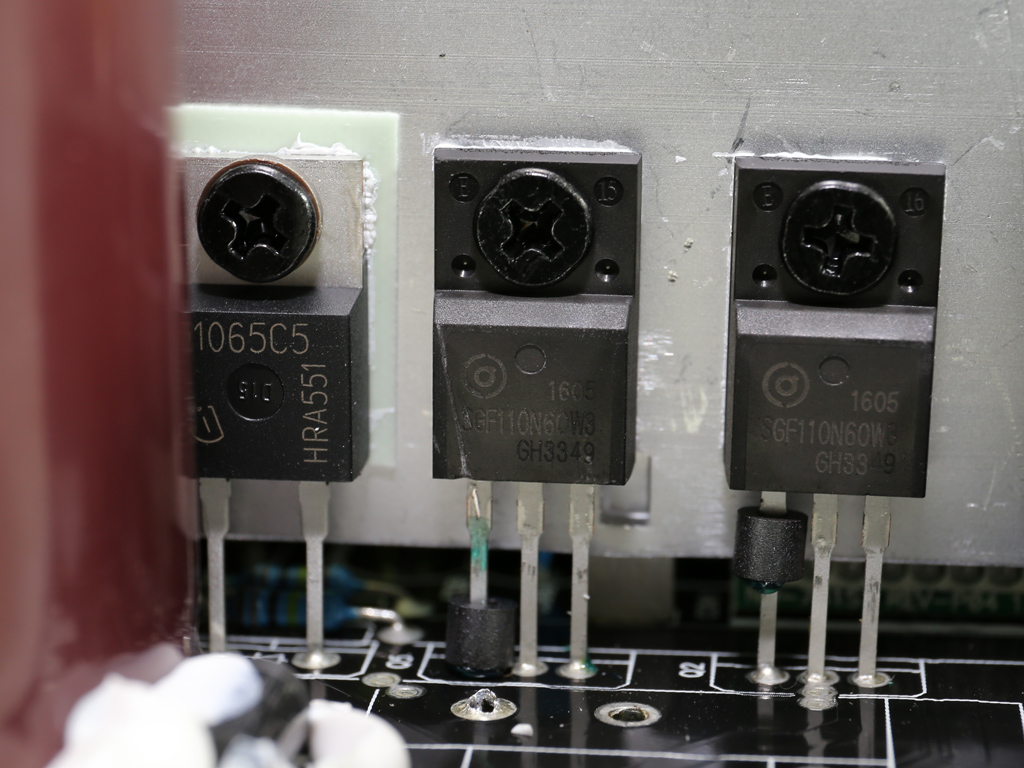

| APFC MOSFETs | 2x Sigmachip SGF110N60W3 (600 V, 16 A @ 100 °C, 0.11 Ω) |

| APFC Boost Diode | 1x Infineon IDH10G65C5 (650 V, 10 A @ 140 °C) |

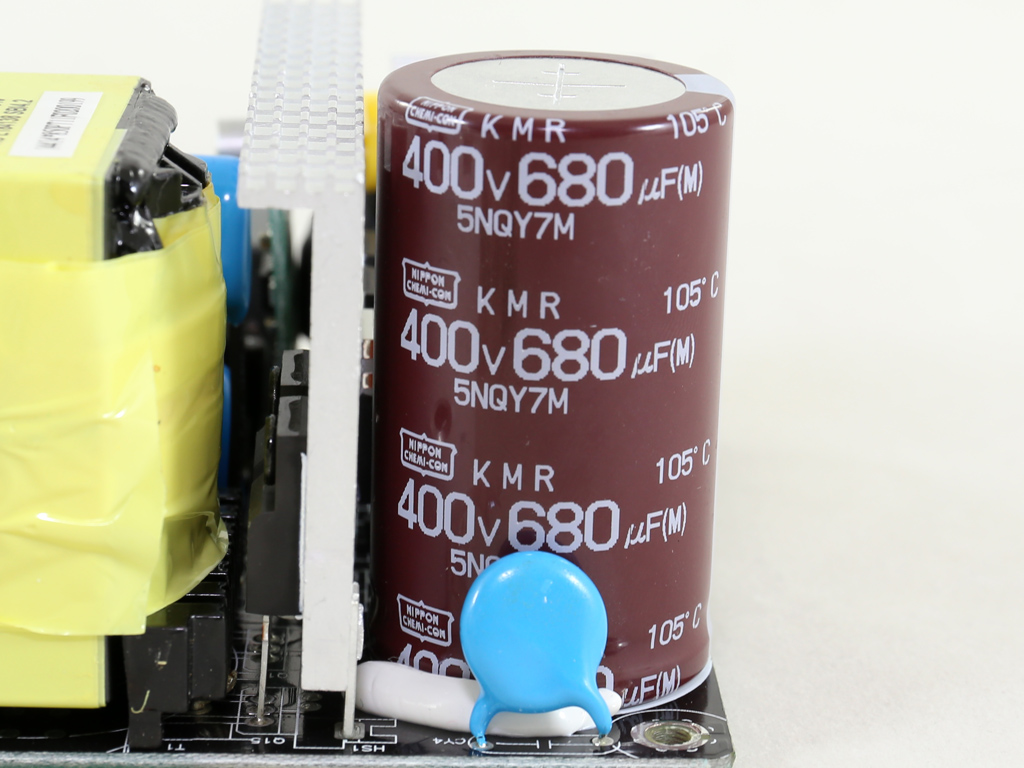

| Hold-up Cap(s) | 1x Nippon Chemi-Con (400 V, 680 uF, 2000h @ 105 °C, KMR) |

| Main Switchers | 2x Sigmachip SGF110N60W3 (600 V, 16 A @ 100 °C, 0.11 Ω) |

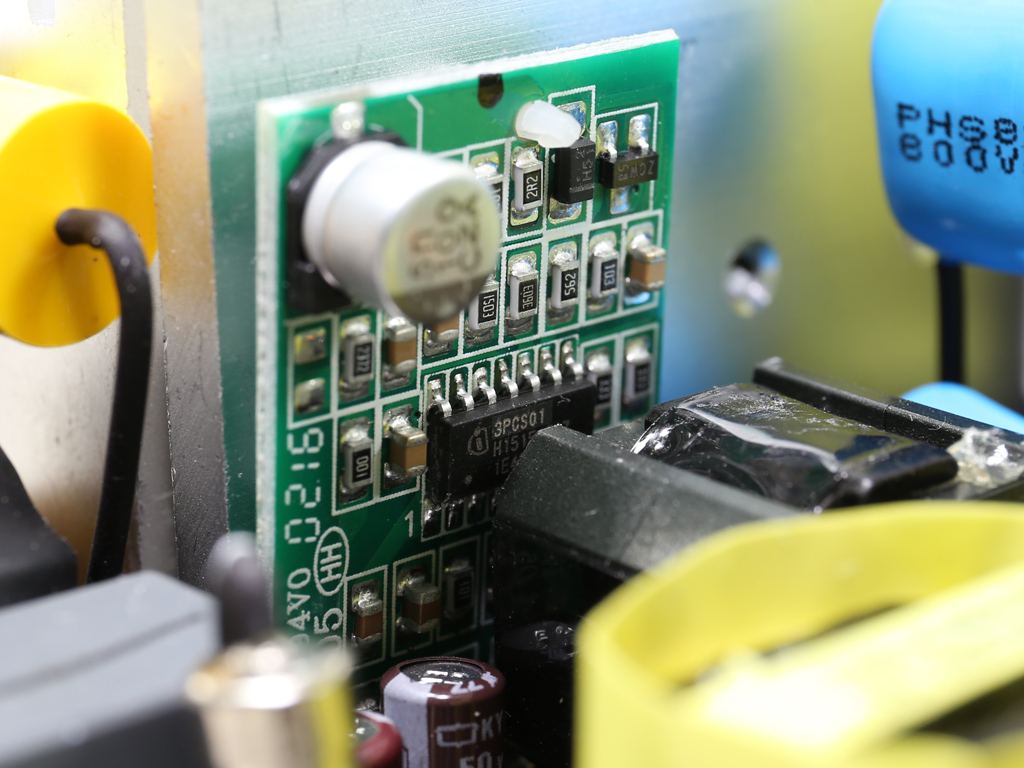

| APFC Controller | Infineon ICE3PCS01 |

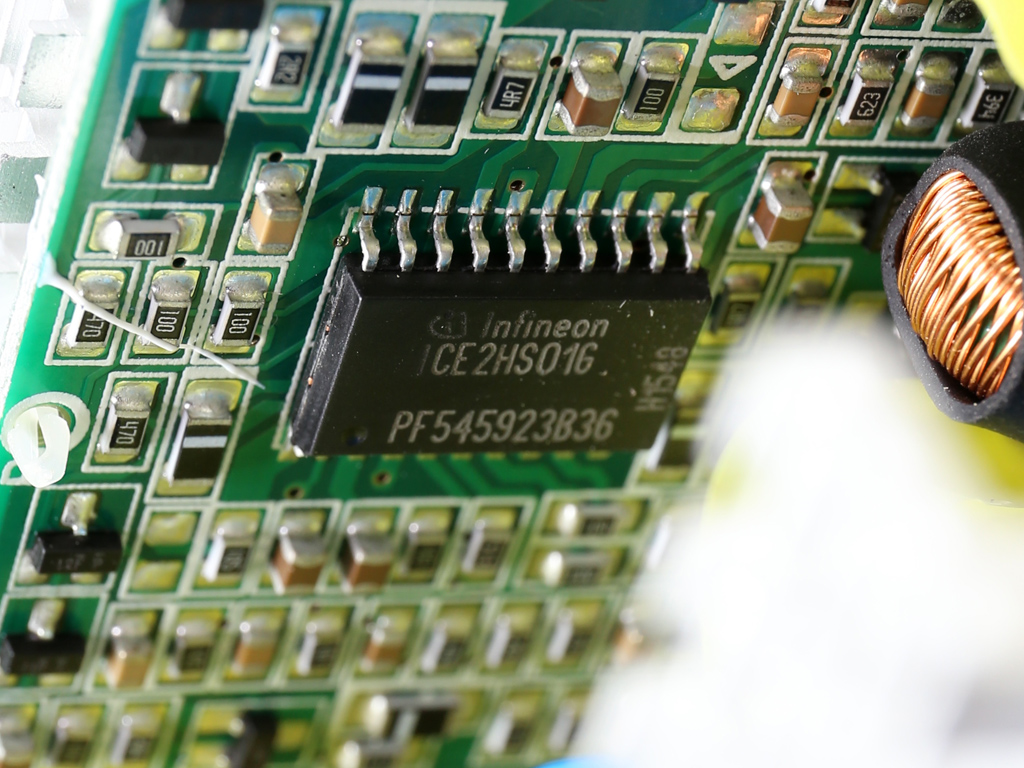

| Switching Controller | Infineon ICE2HS01G |

| Topology | Primary side: Half-Bridge & LLC Resonant Converter Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 4x Infineon IPP015N04N (40 V, 120 A @ 100 °C, 1.5 mΩ) |

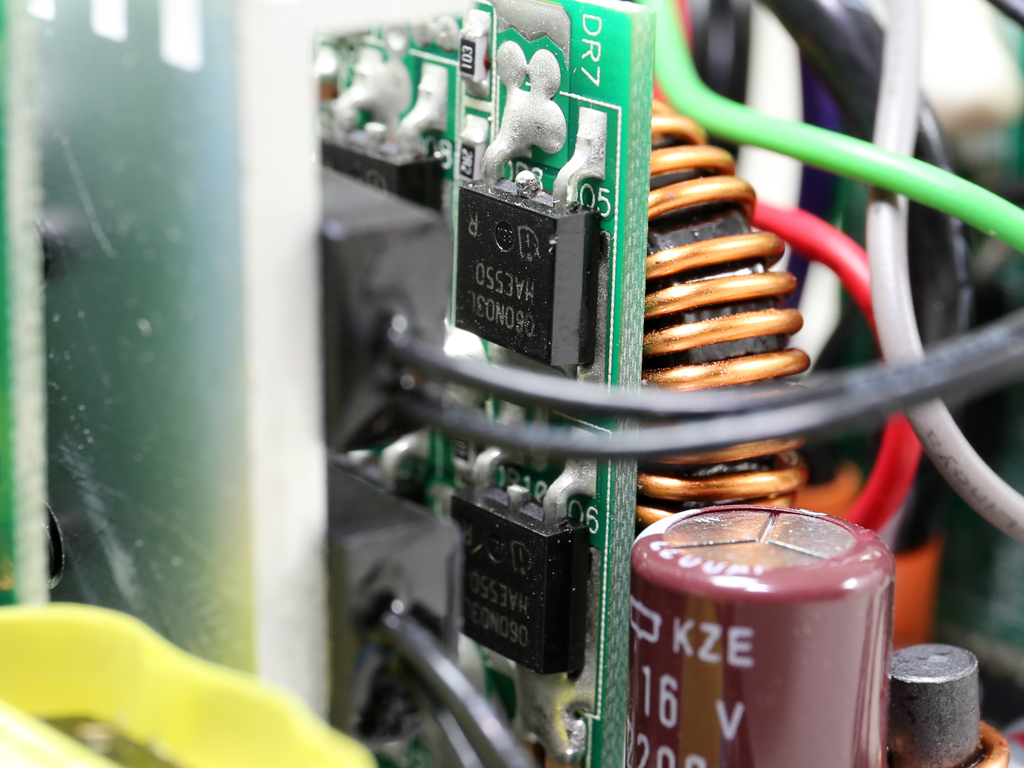

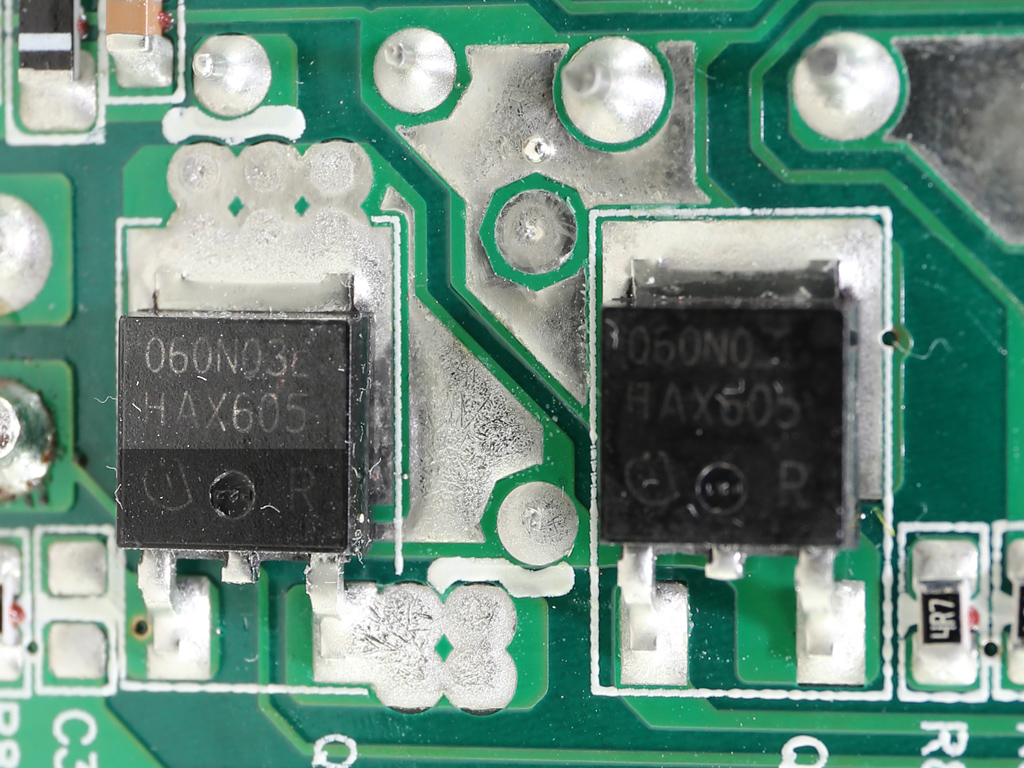

| 5V & 3.3V | DC-DC Converters: 8x Infineon IPD060N03L (30 V, 50 A @ 100 °C, 6 mΩ) PWM Controller: APW7159 |

| Filtering Capacitors | Electrolytics: Nippon Chemi-Con (105 °C, KY, KZE) Polymers: Teapo, Nippon Chemi-Con |

| Supervisor IC | SITI PS223 (OVP, UVP, OCP, SCP, OTP ) |

| Fan Model | Globe Fan S1202512L (120 mm, 12 V, 0.18 A, Fluid Dynamic Bearing) |

| 5VSB Circuit | |

| Rectifier | 2x IPD060N03L |

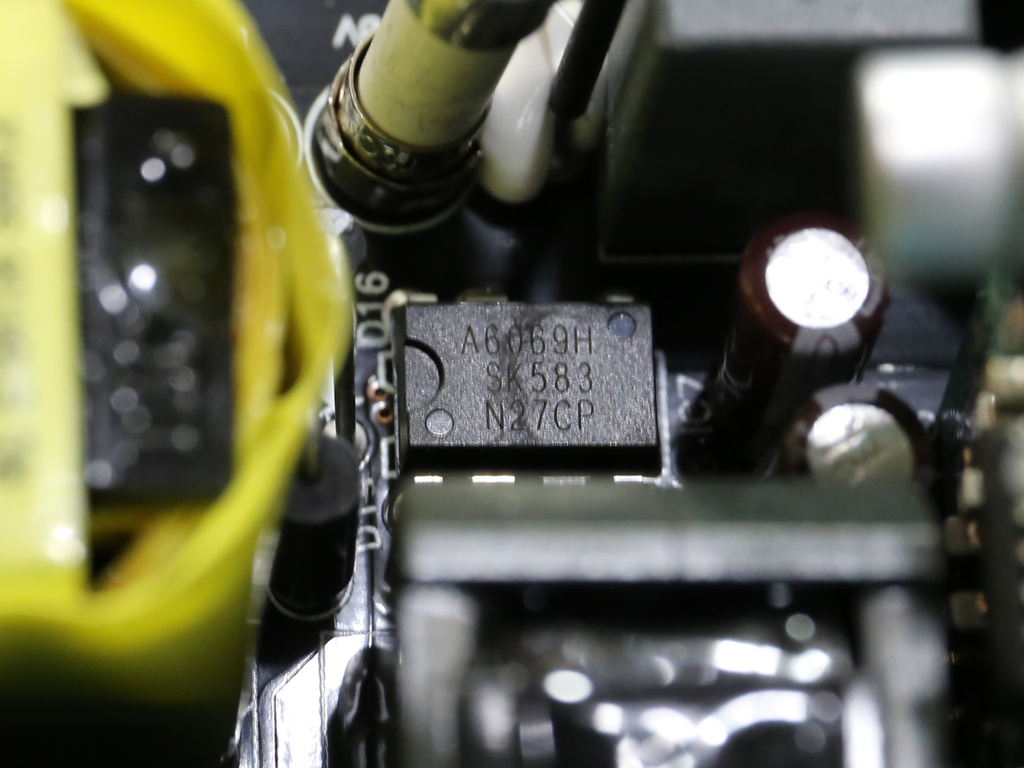

| Standby PWM Controller | Sanken STR-A6069H |

| -12V Circuit | |

| Regulator | KIA7912PI |

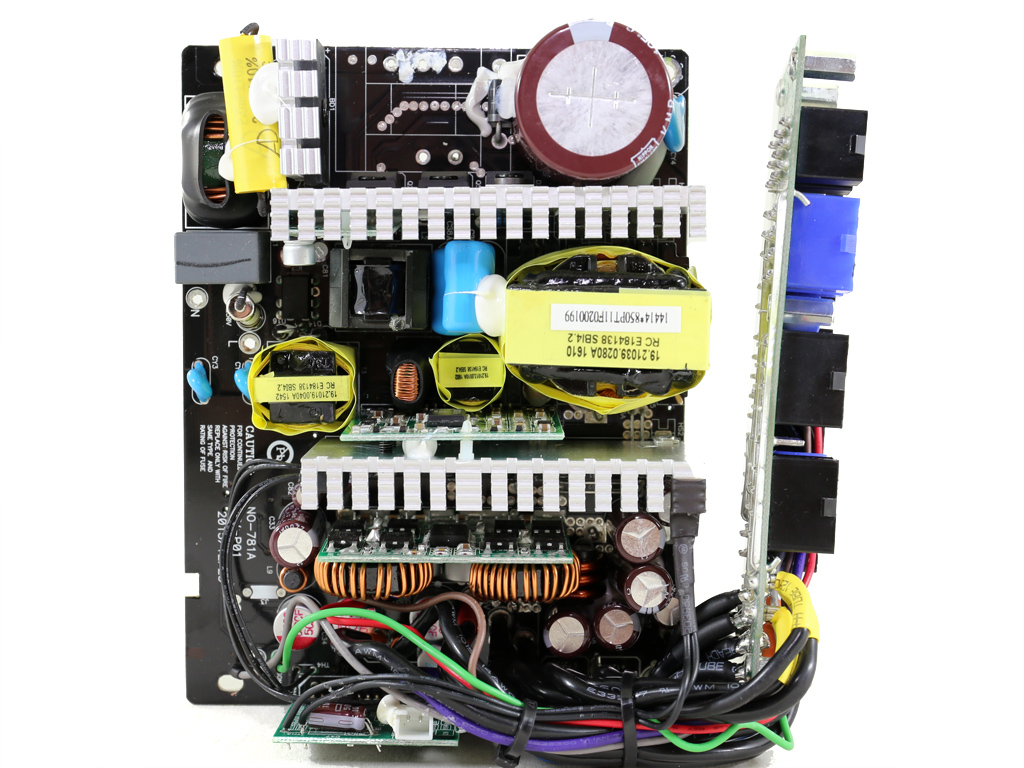

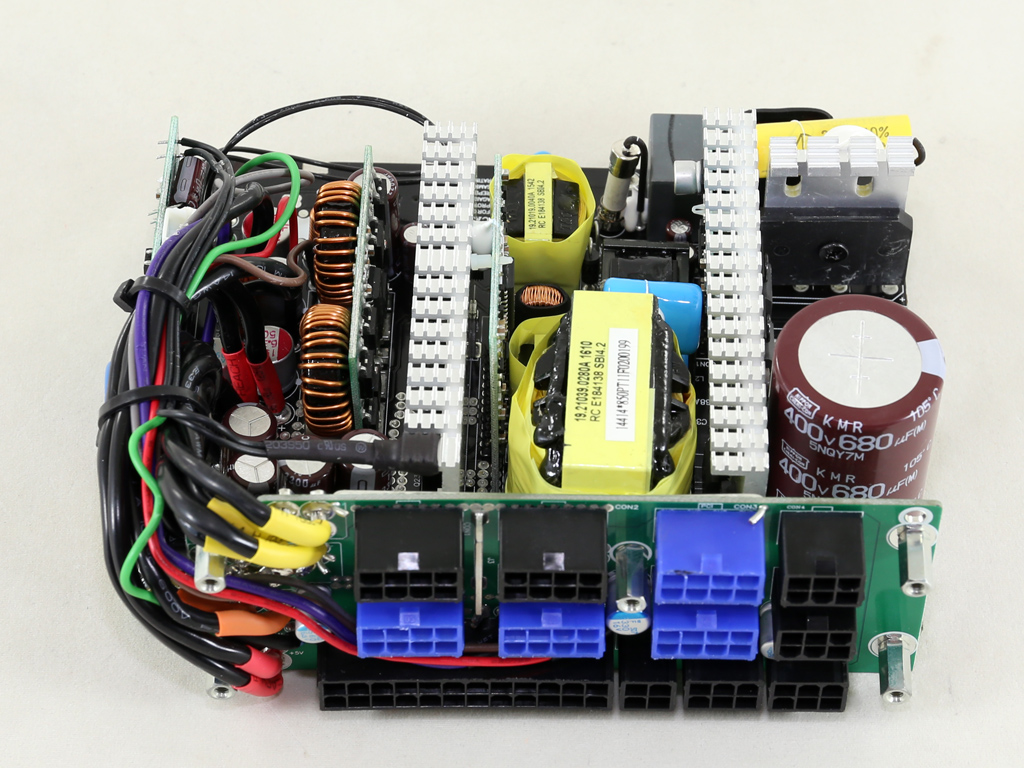

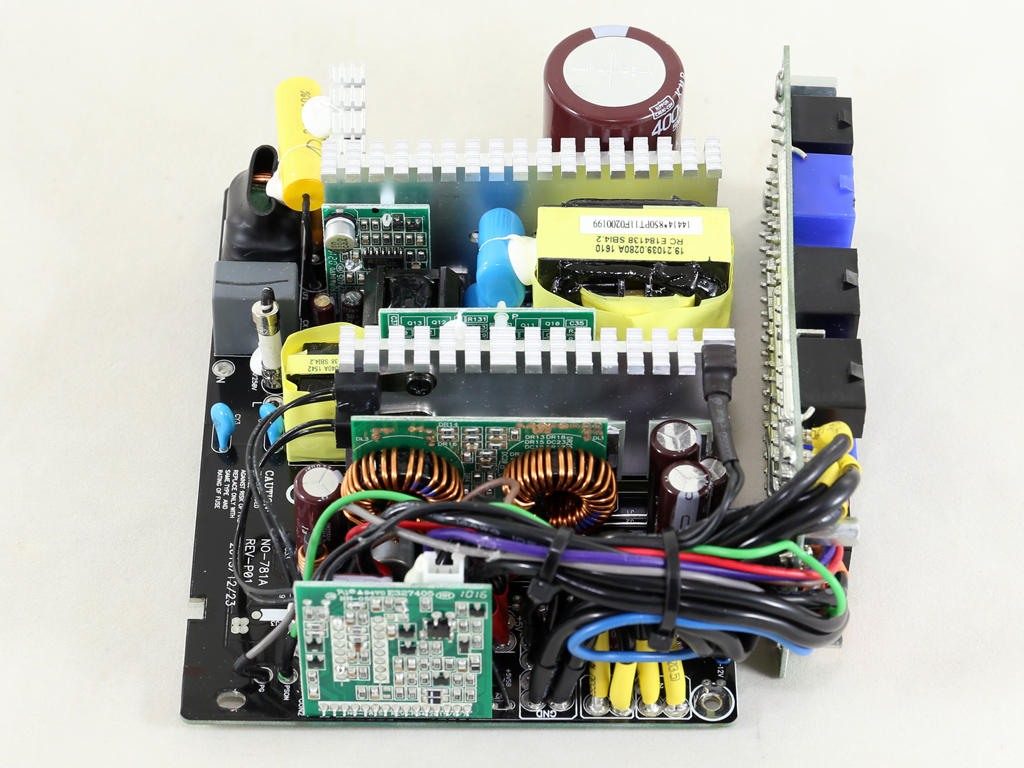

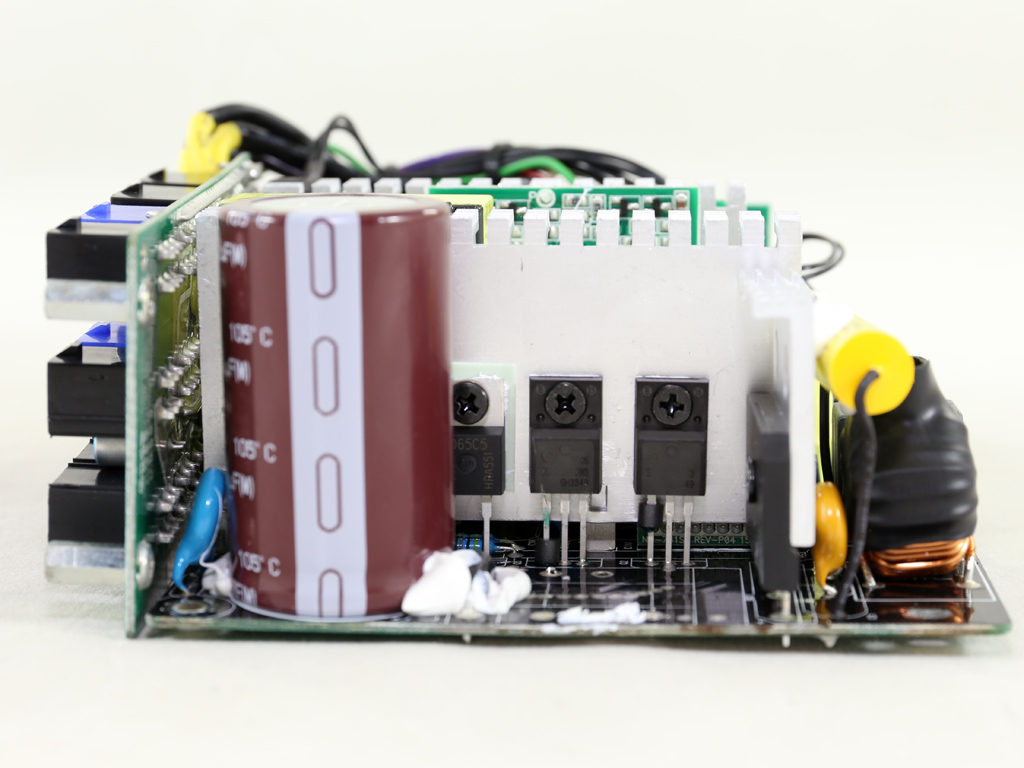

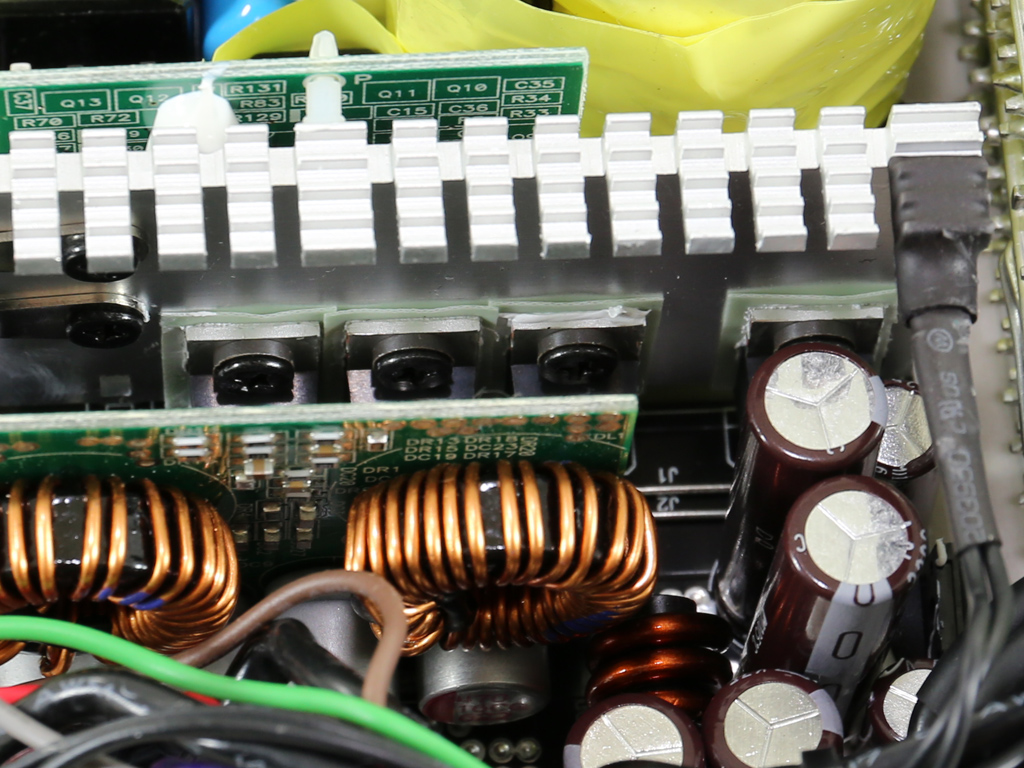

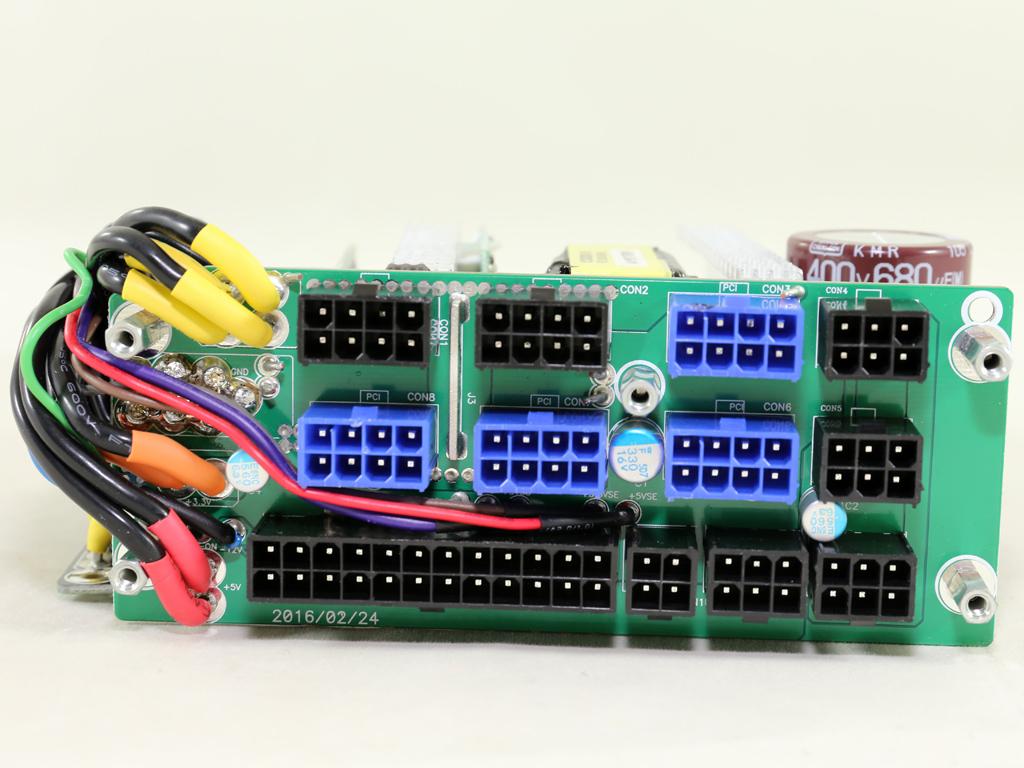

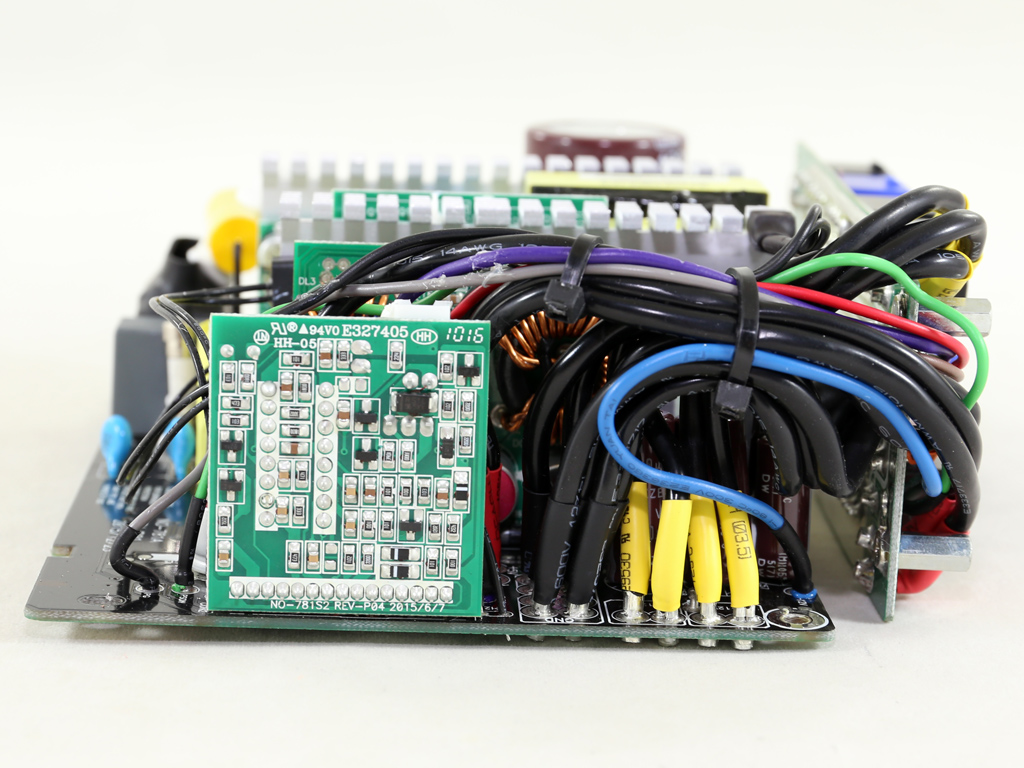

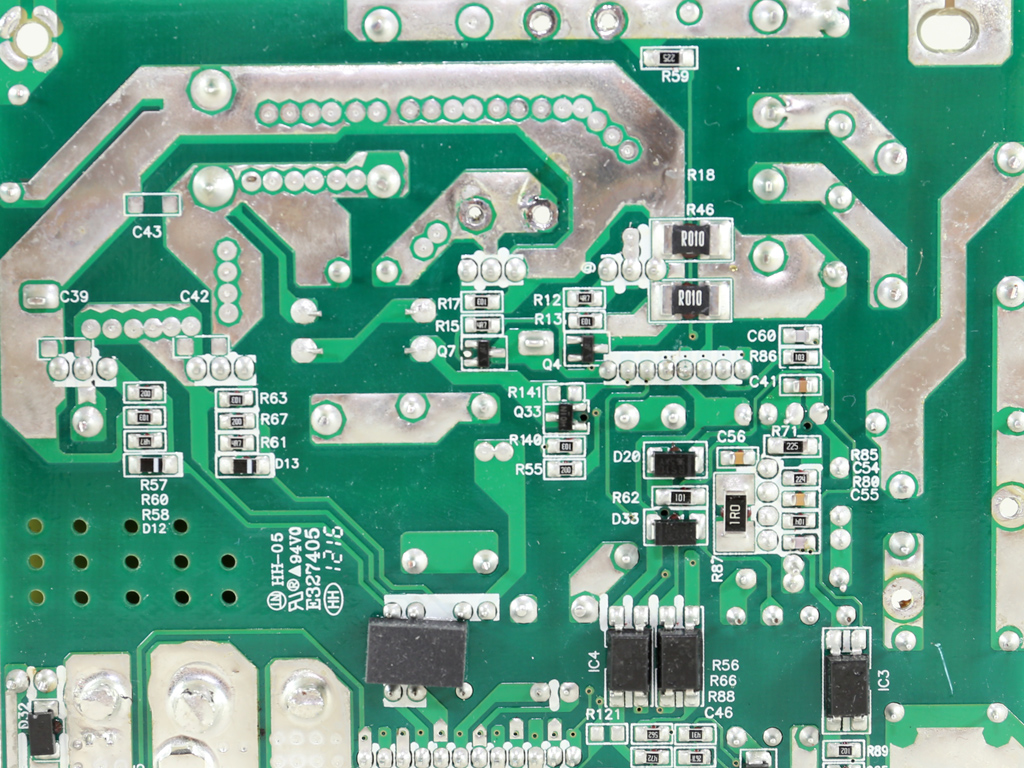

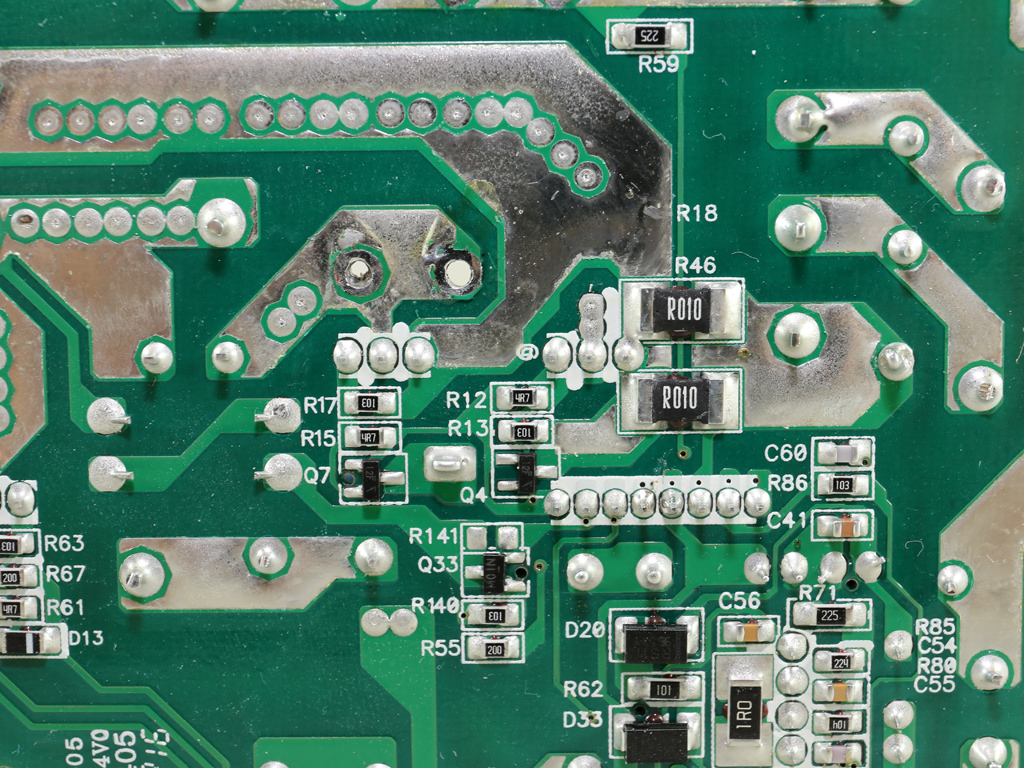

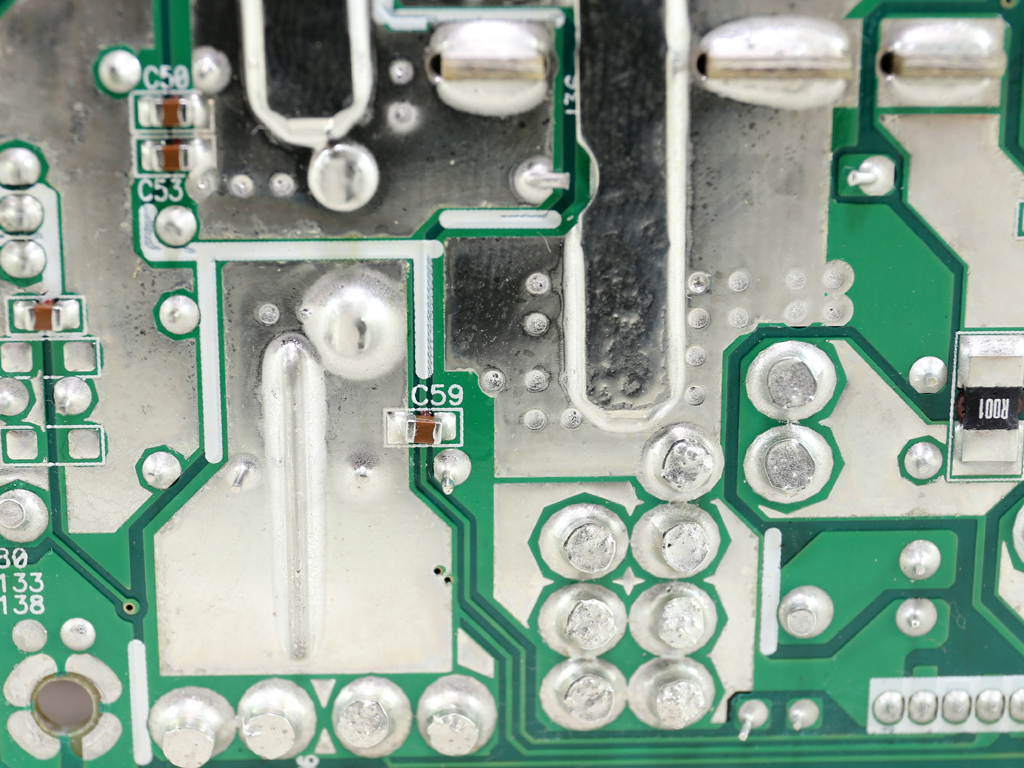

The Strider Platinum models with capacities ranging from 550 W to 850 W are made by Sirfa/Sirtec, while the 1 kW and 1.2 kW ones are made by Enhance Electronics. The main PCB is quite small, as are the heat sinks it hosts. In this price range we expected to find a double-layer PCB, but SilverStone surprised us with a single-layer one.

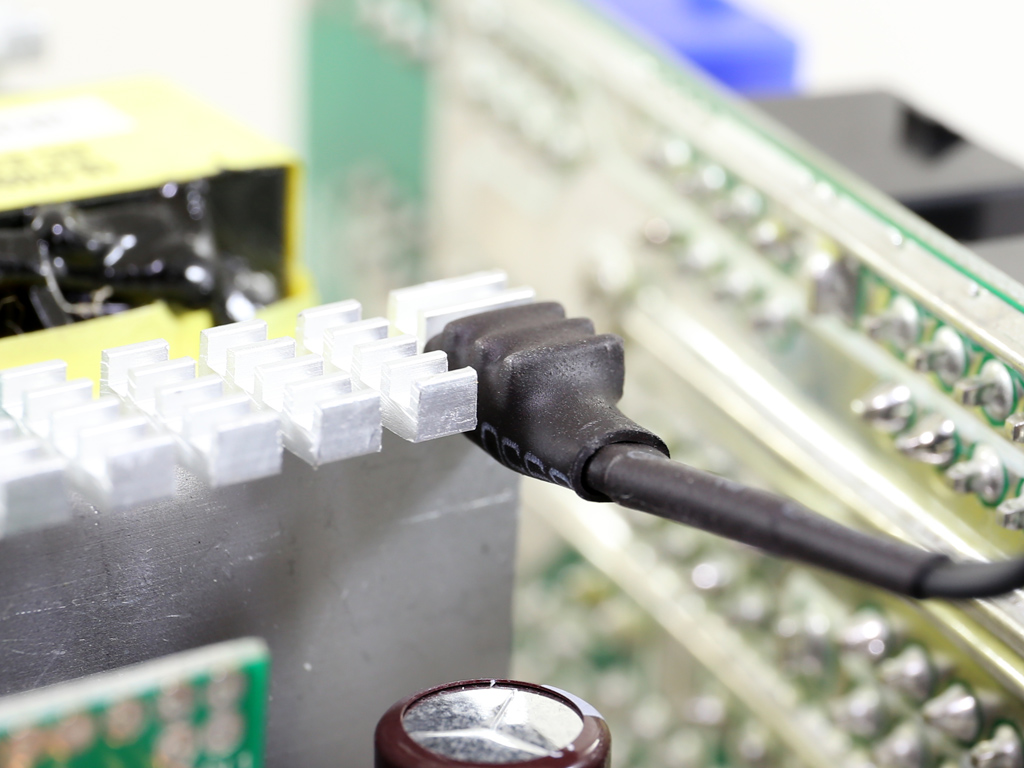

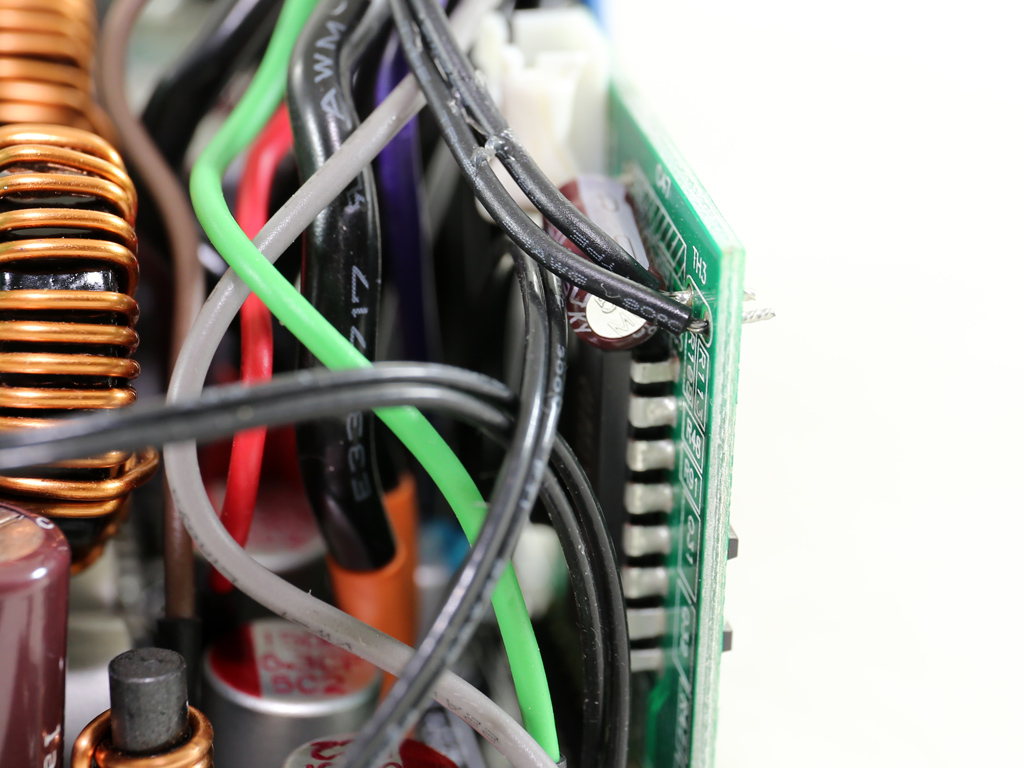

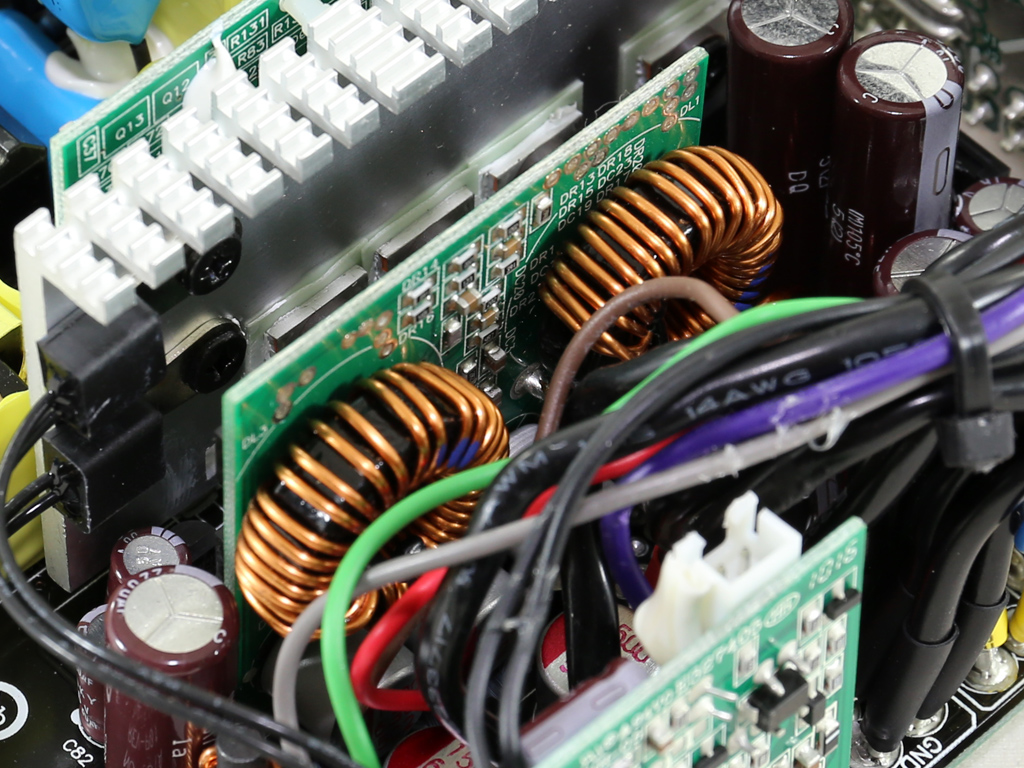

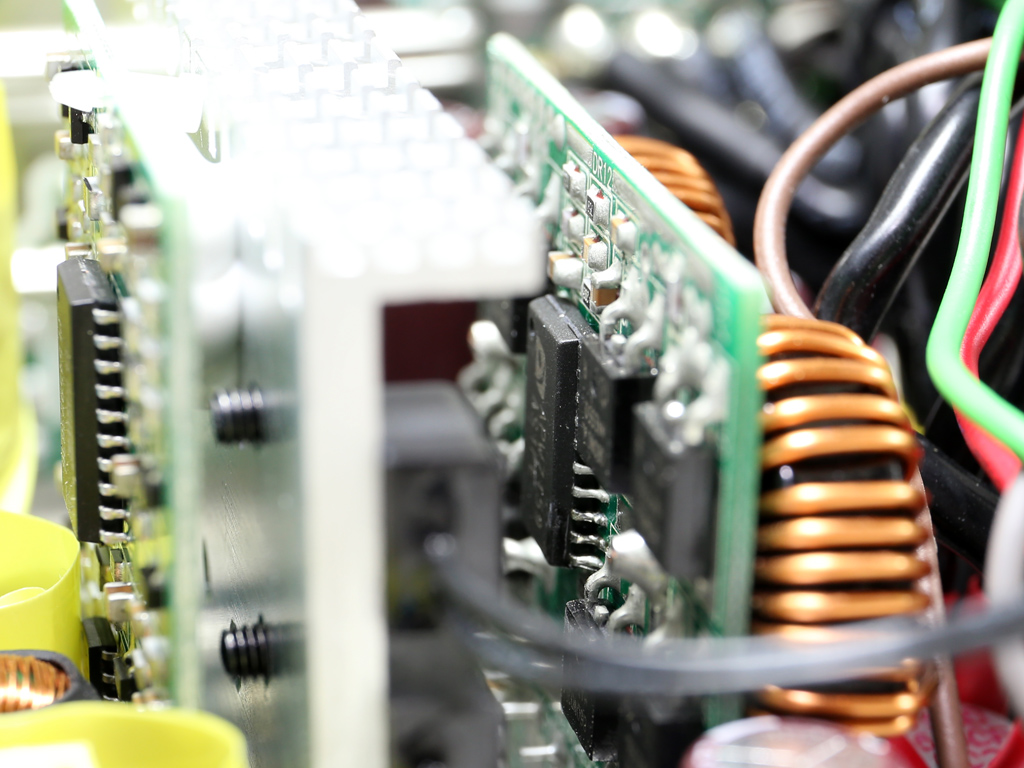

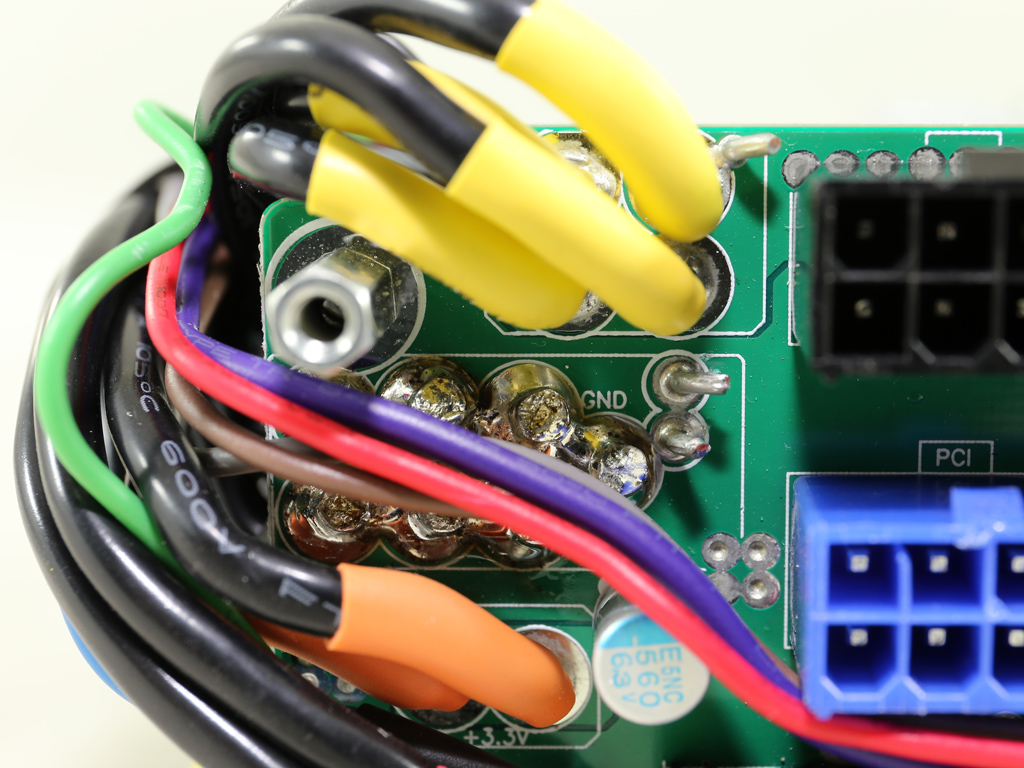

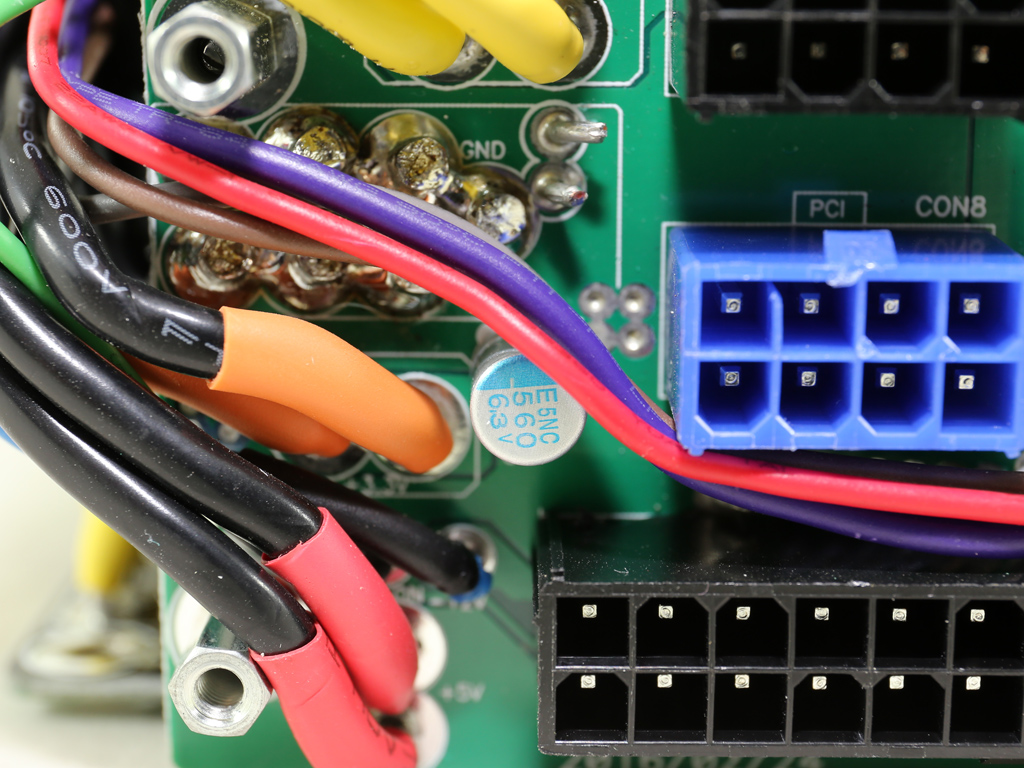

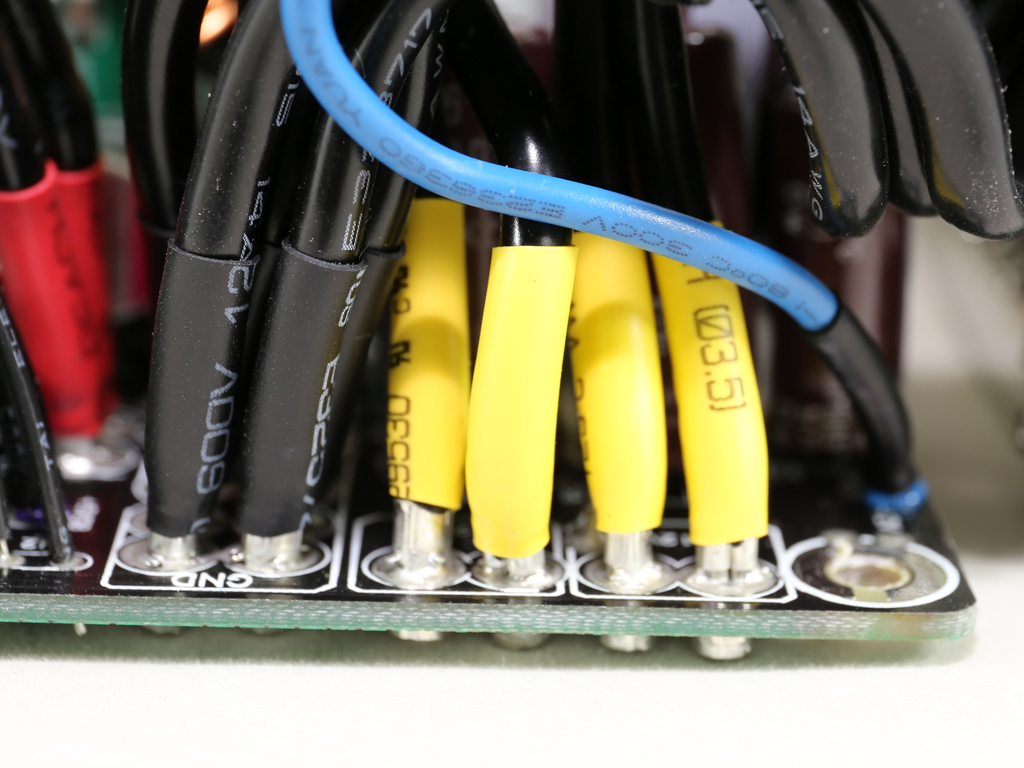

A half-bridge topology is used on the primary side, along with an LLC resonant converter, while on the secondary side we meet a synchronous design and two DC-DC converters for generating the minor rails. In other words, this is a typical high-efficiency platform. The only notable downside is that it doesn't transfer the rails to the modular board through bus bars or enhanced PCB traces, but rather through a lot of wires. Other manufacturers solder the modular board onto to the main PCB to avoid using those wires, which, aside from increased energy losses, also make it harder to cool the secondary side's filtering capacitors. Thankfully, all of this PSU's electrolytic caps come from a Japanese manufacturer and are of decent quality, so they should last a long time even with sub-optimal cooling.

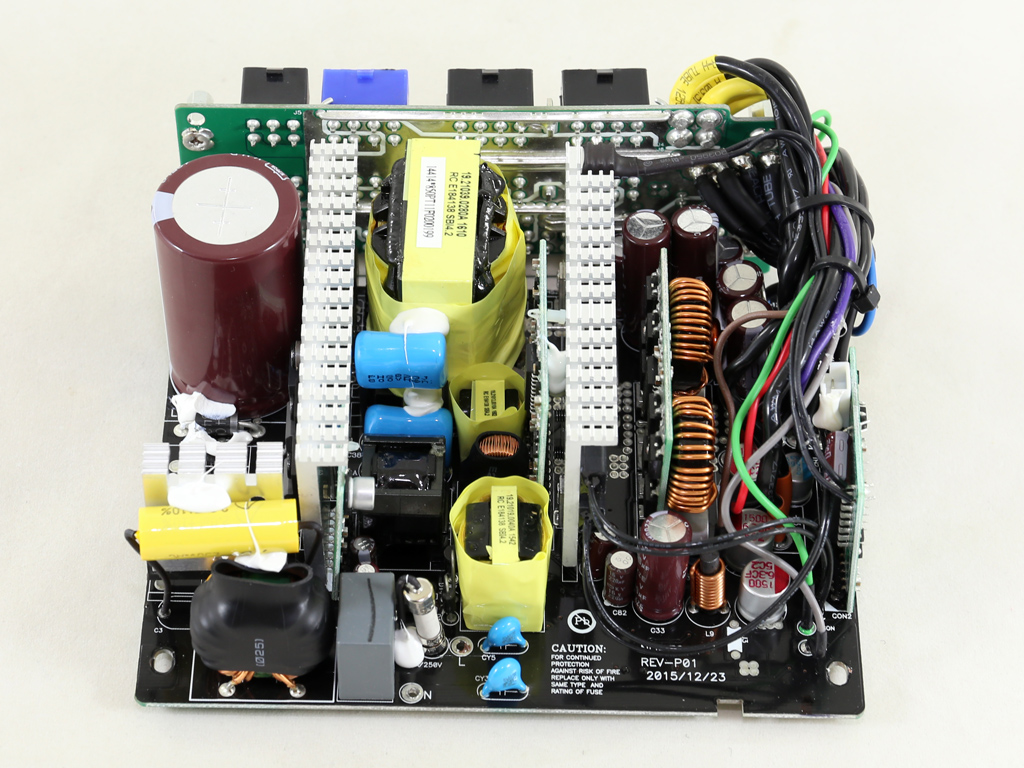

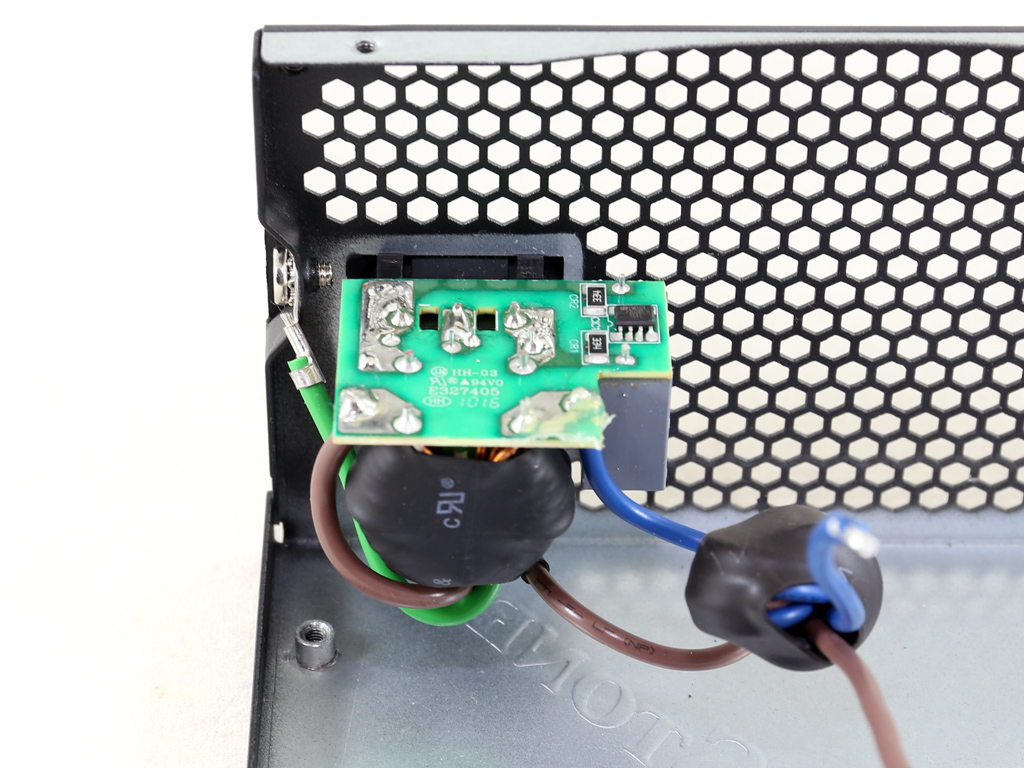

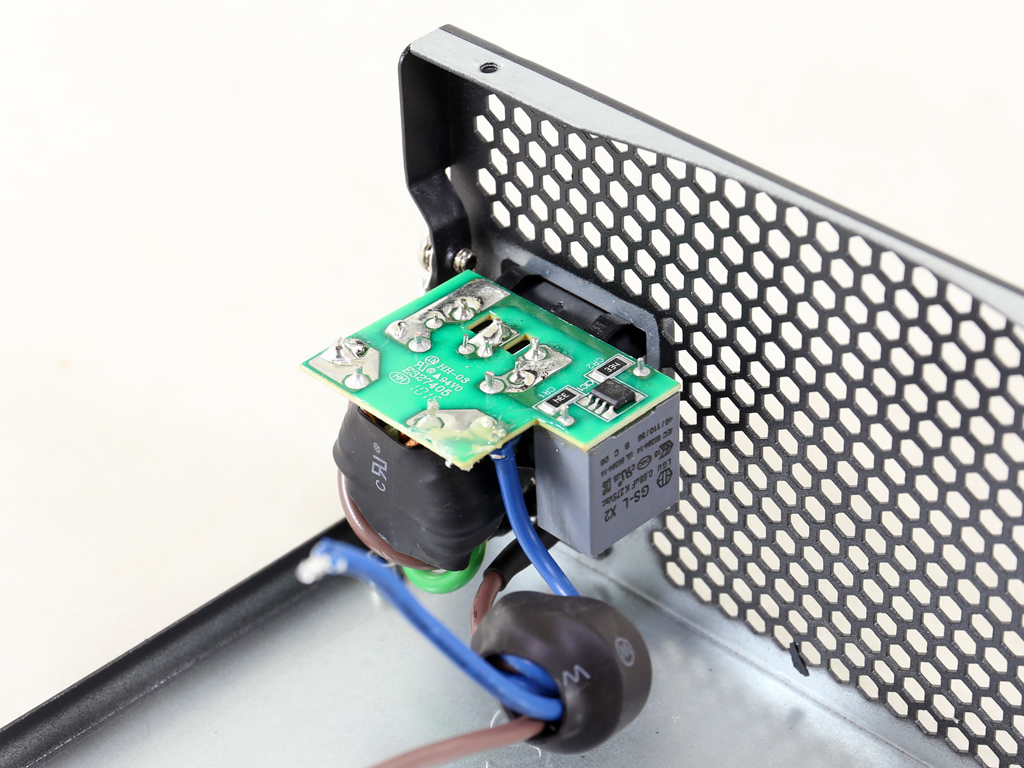

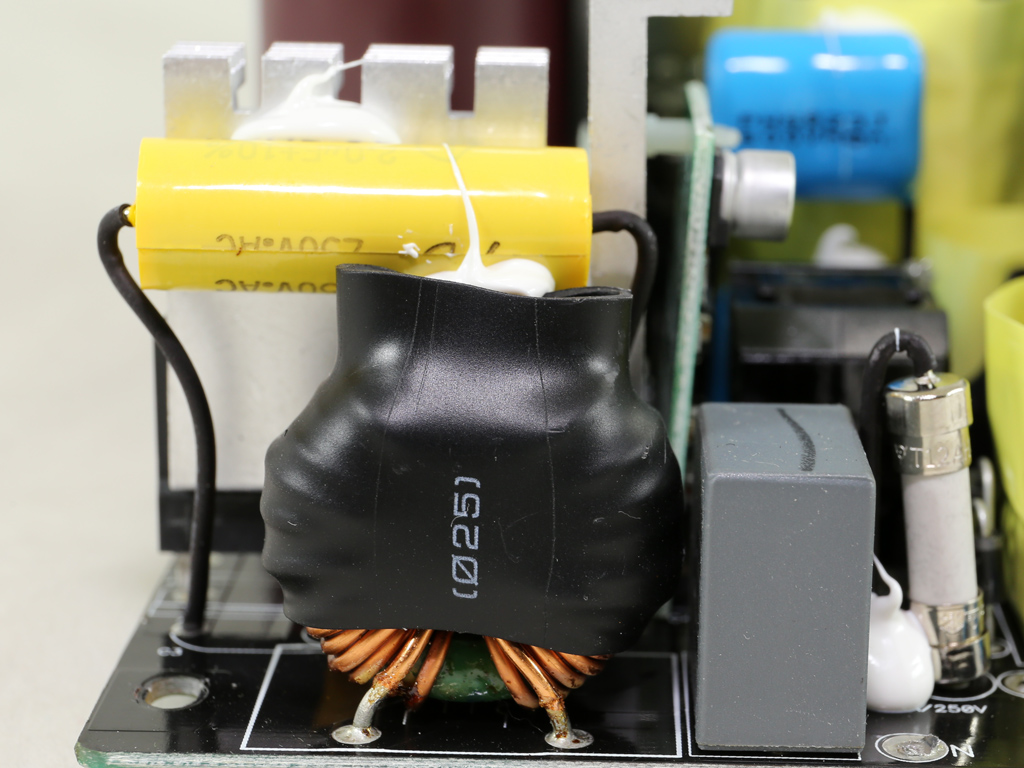

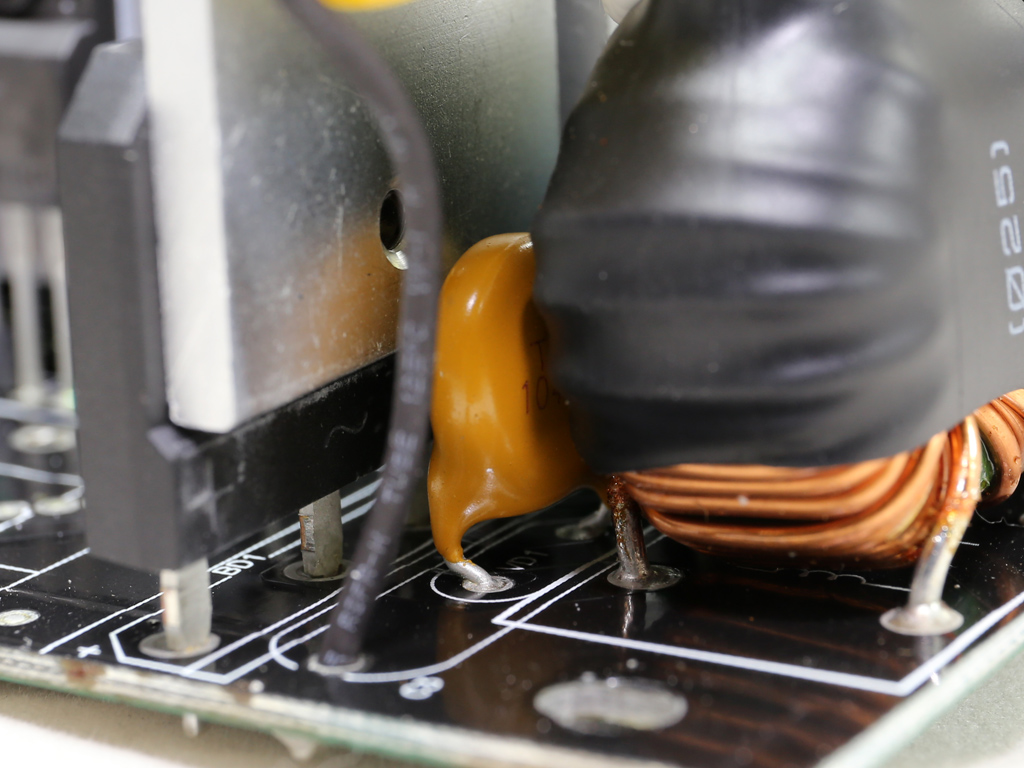

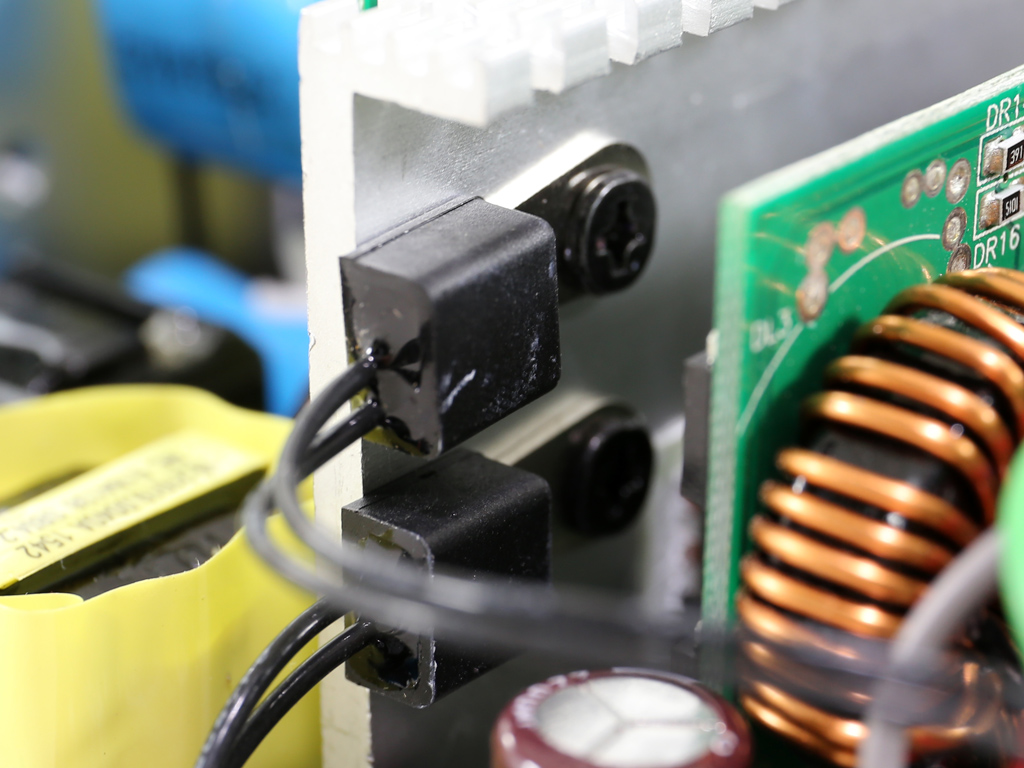

A small PCB holds the AC receptacle, the power switch, and the first part of the EMI filter consisting of two Y caps, a single X one, a CM choke, and a CMD02X IC that blocks current to the bleeding resistors when AC voltage is connected. The second part of the same filter is on the main PCB and includes two Y and one X caps, a CM choke, and an MOV. Strangely enough, the PSU isn't equipped with an NTC thermistor to protect against large inrush currents. Normally we'd expect an NTC thermistor and a bypass relay n a high-efficiency PSU. However, Sirfa, for its own reasons, decided that those parts weren't necessary. We anticipate very high inrush currents because of this silly omission.

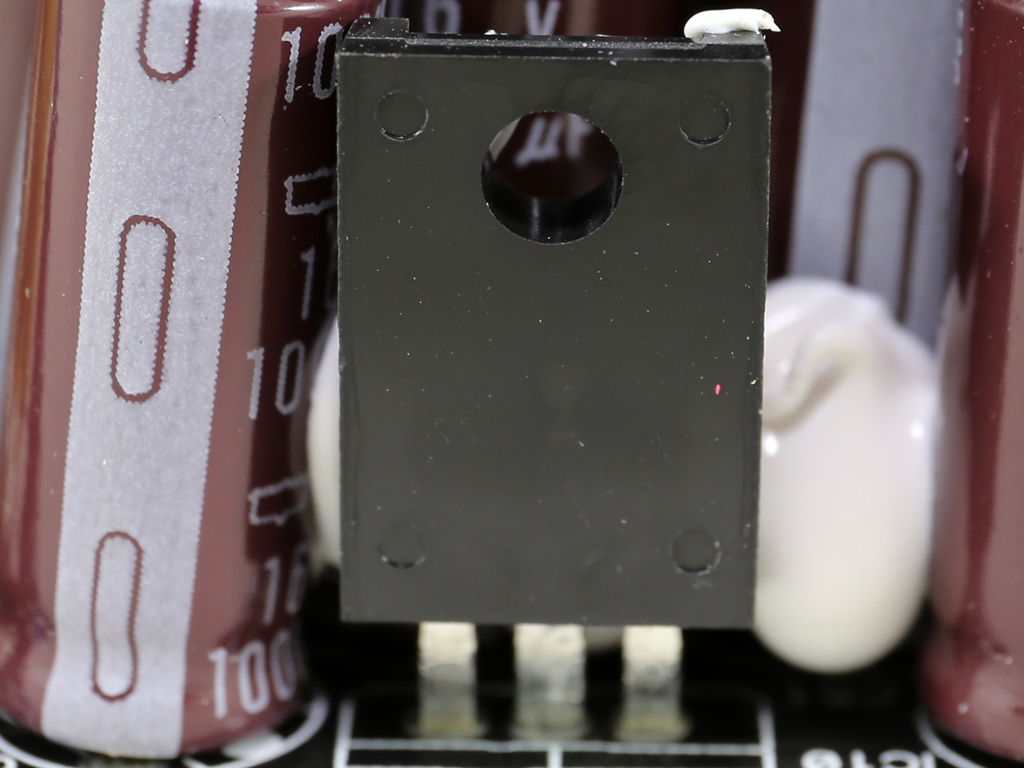

The single bridge rectifier, a GBJ1506, is installed on a dedicated heat sink. Its amperage handling is sufficient for this PSU's needs.

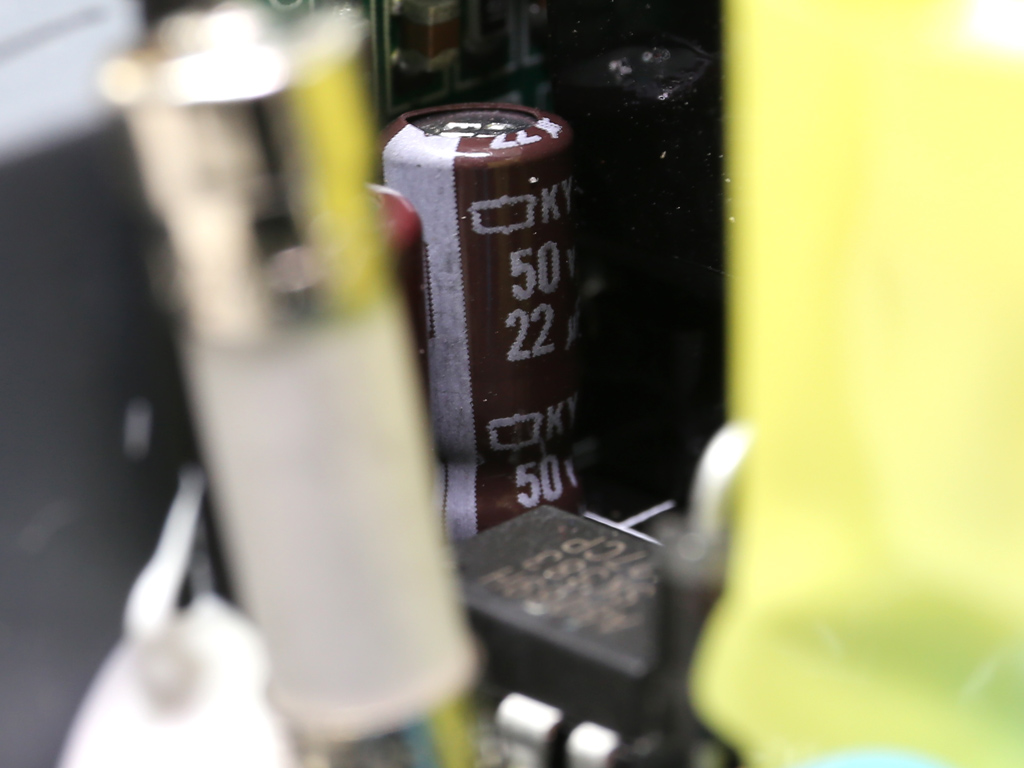

The APFC converter uses two Sigmachip SGF110N60W3 FETs along with a single Infineon IDH10G65C5 boost diode. The bulk cap is provided by

Nippon Chemi-Con (400 V, 680 uF, 2000h @ 105 °C, KMR) and its capacity is low for a 850 W unit. In addition, we would like to see a higher-voltage cap since 400 V comes close to the APFC's bus voltage (around 380 VDC).

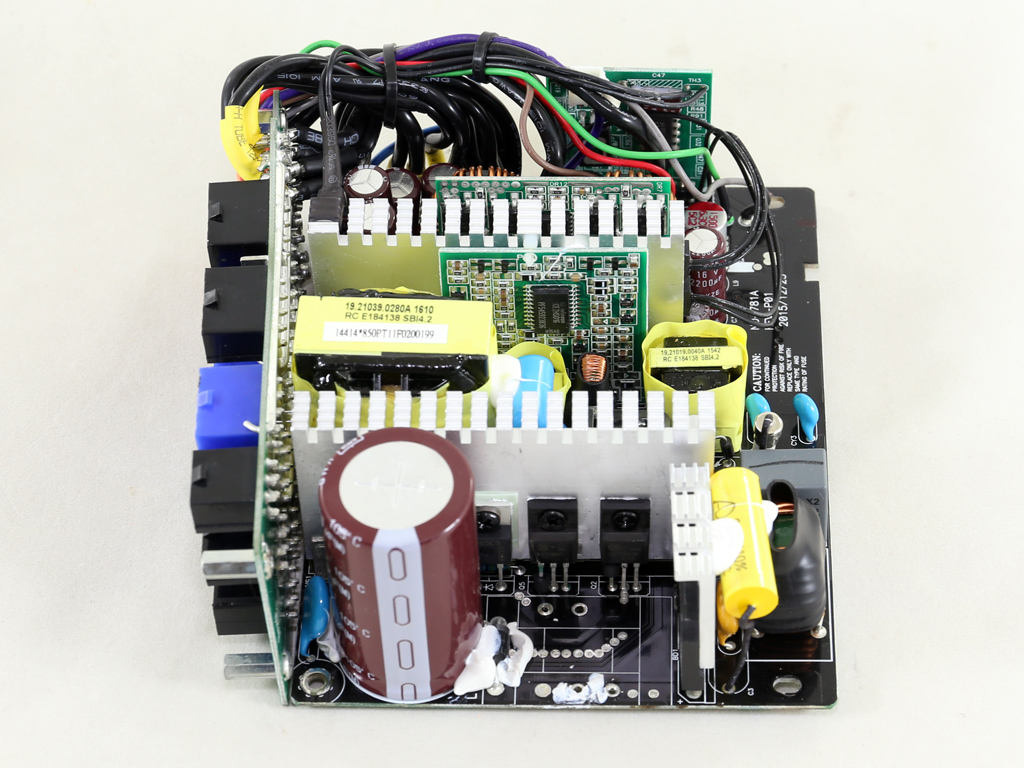

The PFC controller is installed on a small vertical daughterboard; it's an Infineon ICE3PCS01 IC.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The primary switchers are two Sigmachip SGF110N60W3 FETs arranged into a half-bridge topology.

The LLC resonant controller is an Infineon ICE2HS01G IC and it is installed on a vertical daughterboard.

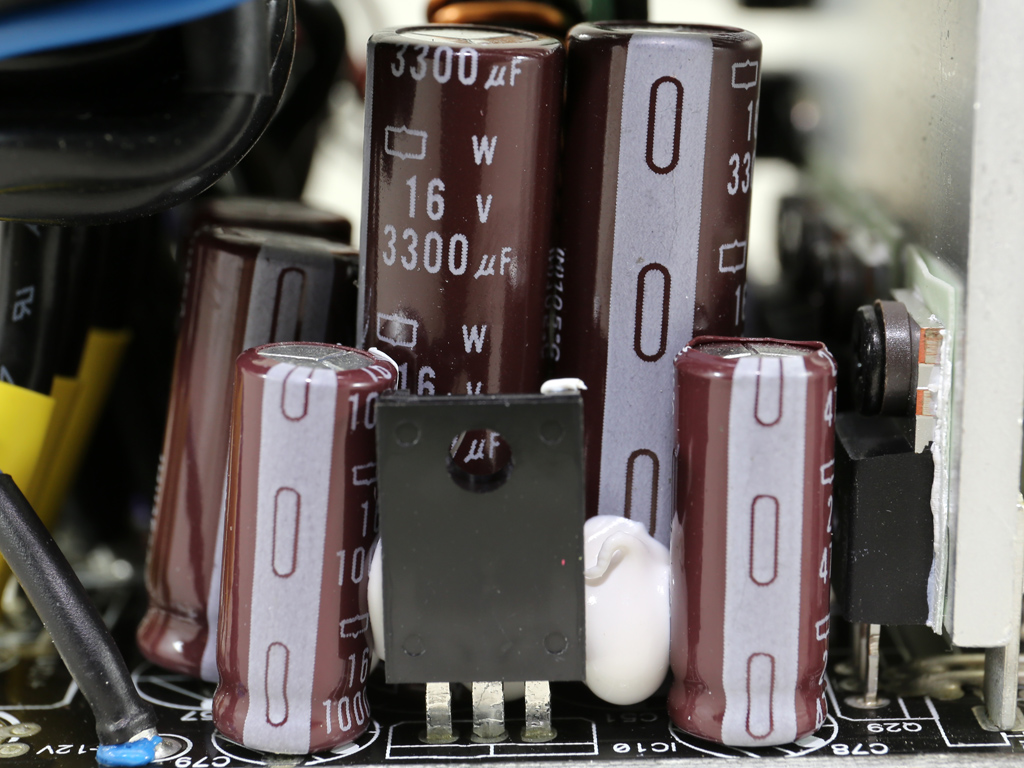

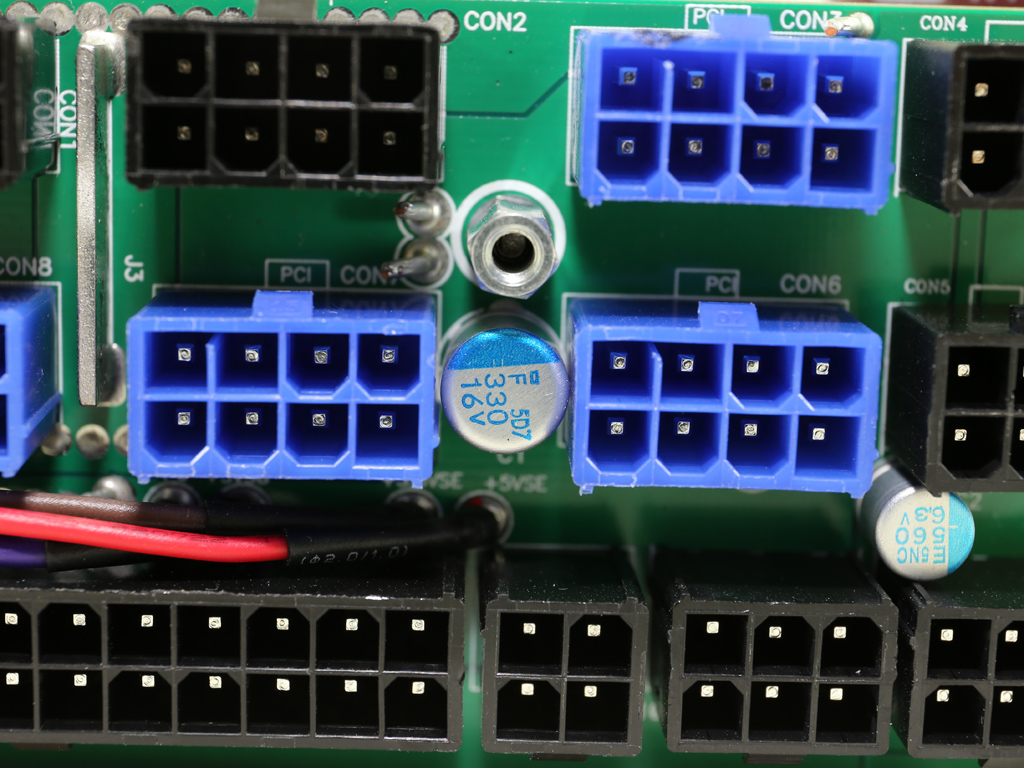

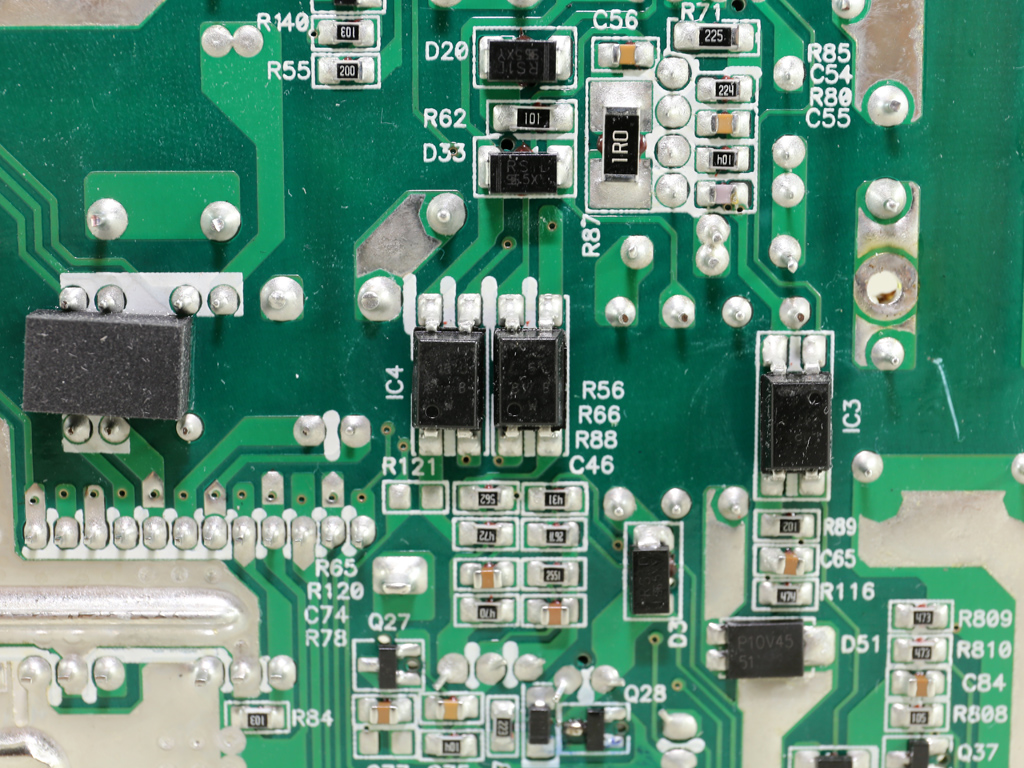

On the secondary side, four Infineon IPP015N04N FETs regulate the +12V rail.

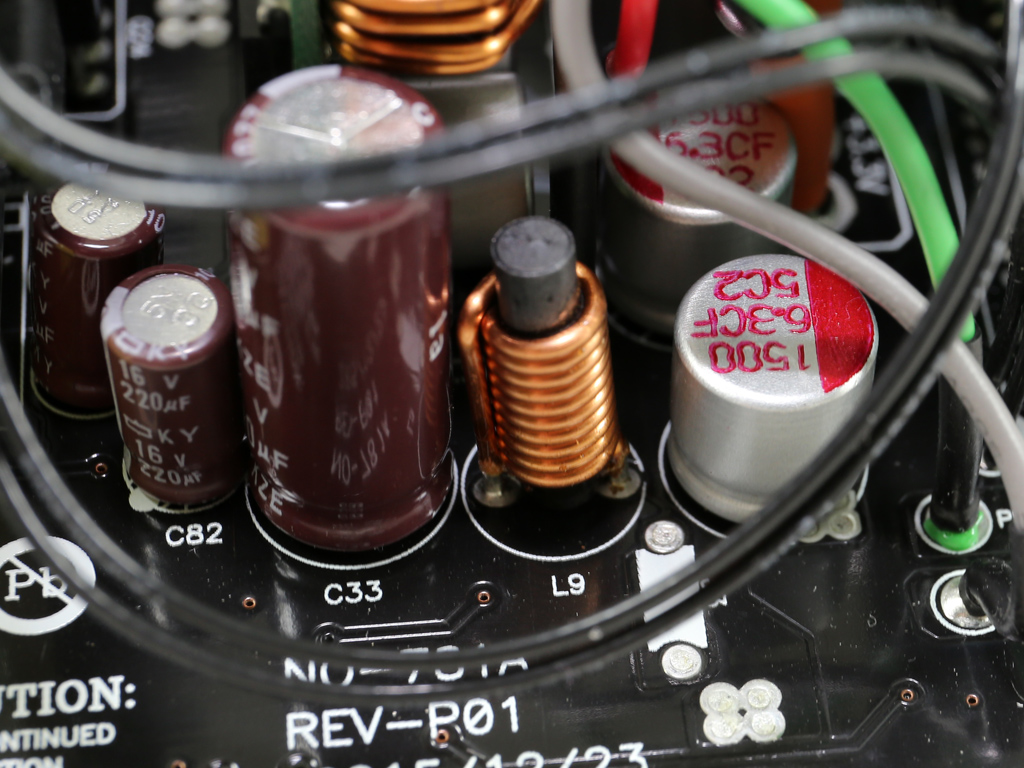

We find three NTC thermistors on the secondary heat sink, which provide temperature information to the protection and fan control circuits.

The +12V rail's filtering on the main PCB is done through several Chemi-Con electrolytic caps (KZE, KY, 105 °C) and a small number of Teapo and Chemi-Con polymer caps. It is always nice to see polymer caps used in PSUs since they are more heat-tolerant; they have a longer rated life than electrolytic caps. The cherry on top is their low impedance at high frequencies. On the other hand, polymer caps are expensive and more sensitive to voltage spikes. Moreover, polymer caps have higher leakage current compared to plain electrolytic ones. Normally, all caps totally block DC voltage. However, with a level of DC bias, an amount of DC current flows through them. This current is called leakage current.

A KIA7912PI voltage regulator handles the -12V rail's generation.

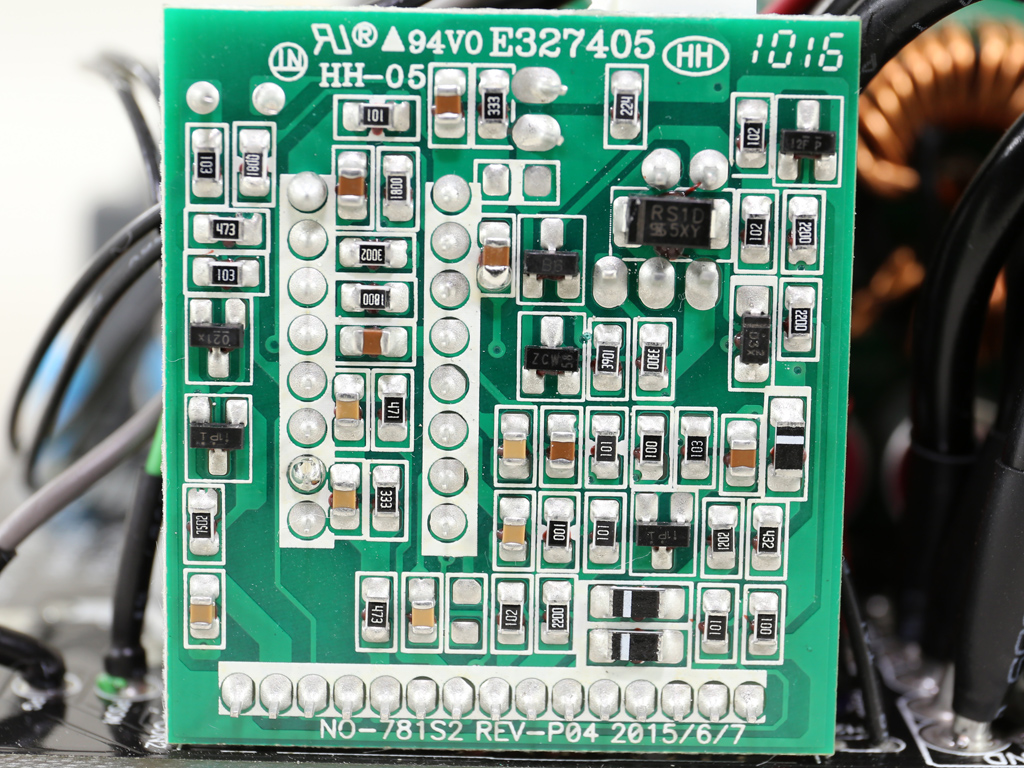

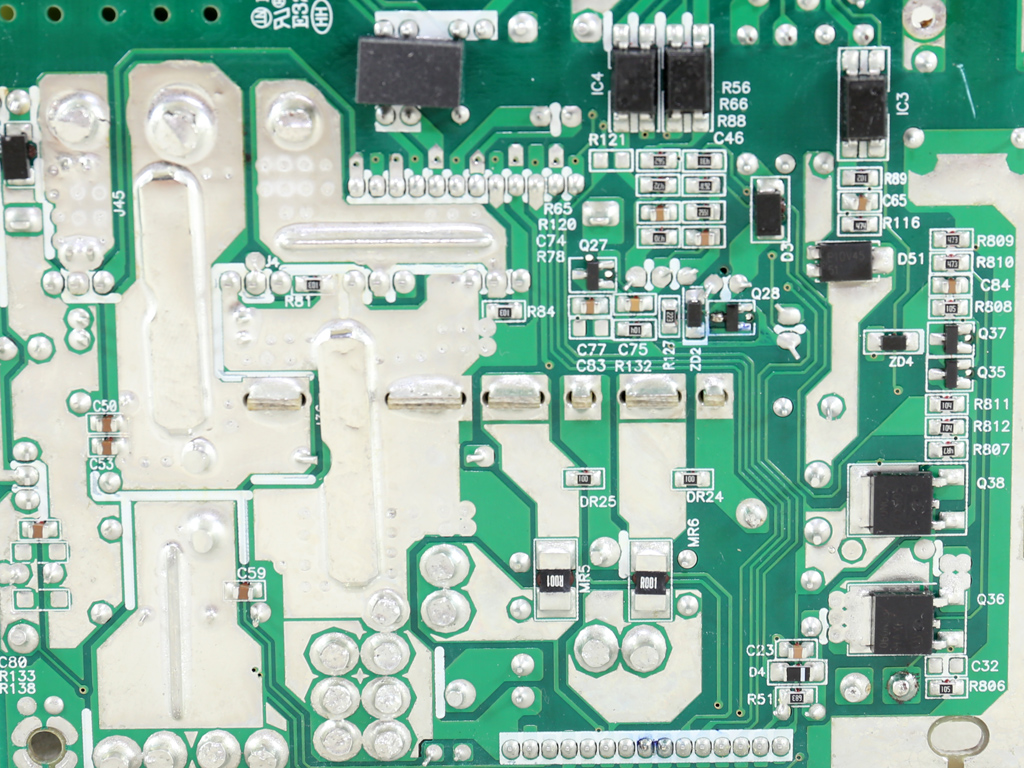

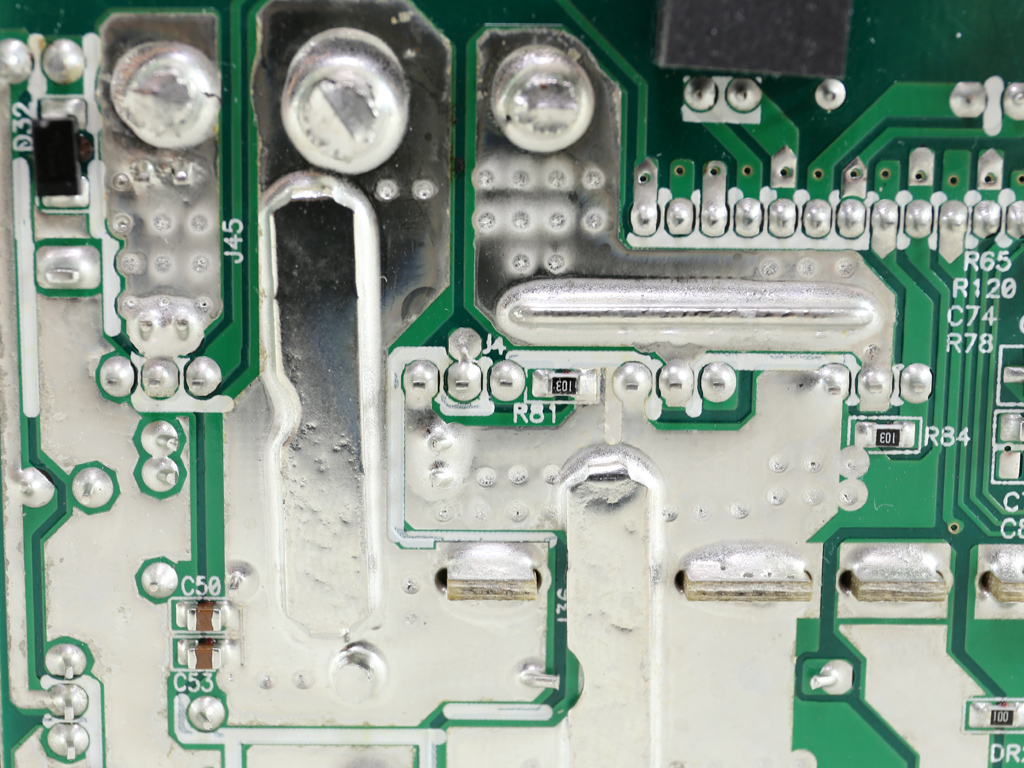

The pair of DC-DC converters is installed on the same vertical board. In total, eight Infineon IPD060N03L FETs are used and the common PWM controller is an ANPEC APW7159 IC. Lastly, four Teapo polymer caps filter the minor rails.

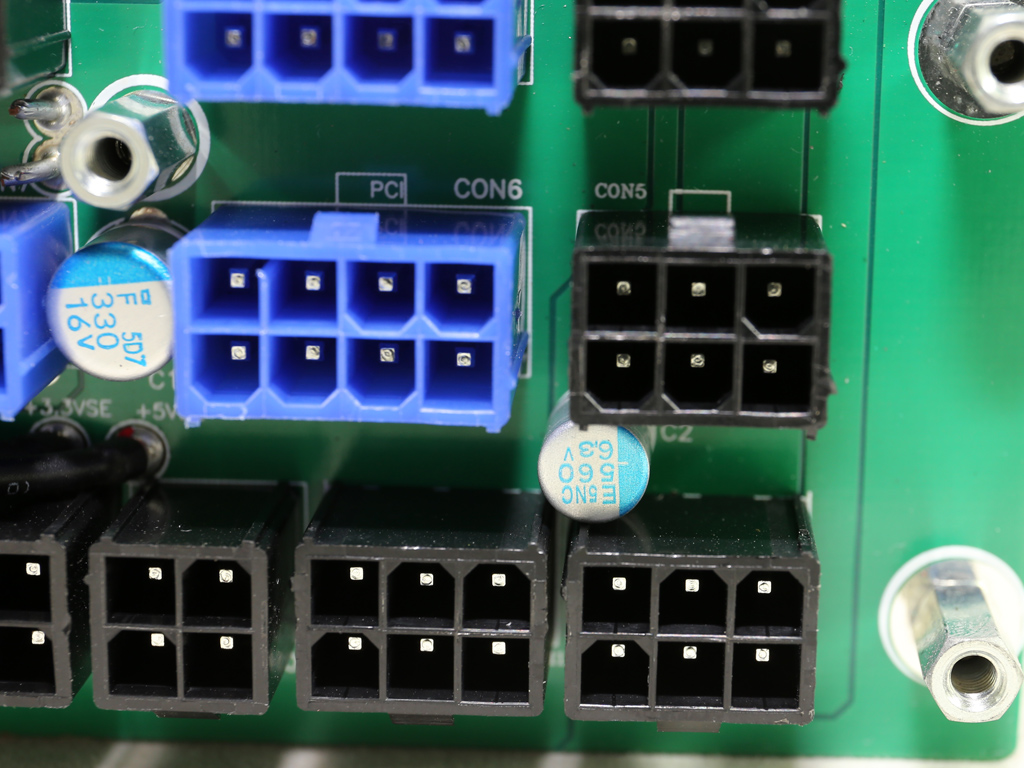

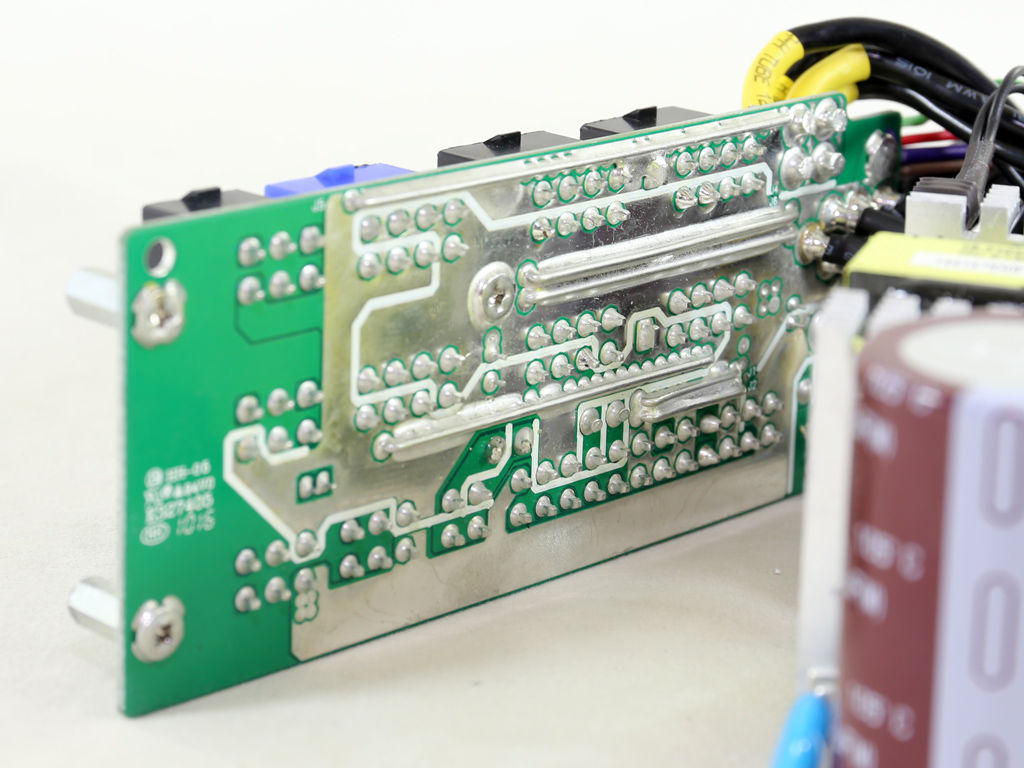

At the front side of the modular board we meet a small number of Chemi-Con polymer caps used for filtering purposes. The solder side of the same board is protected against shorts by a plastic shield.

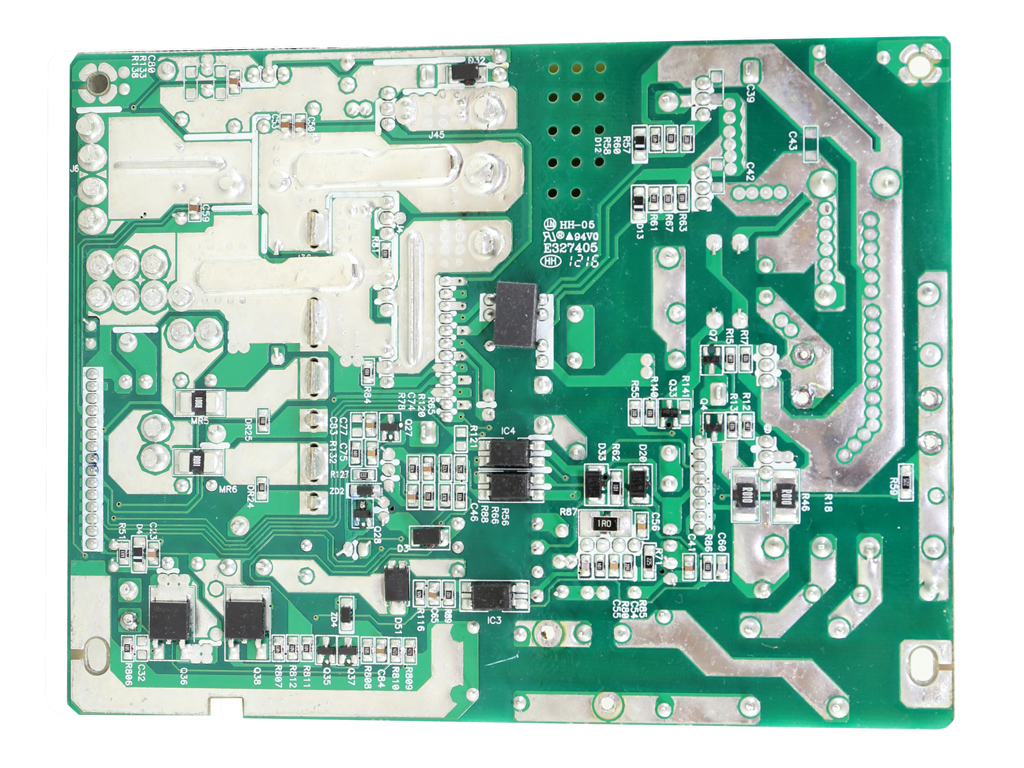

The standby PWM controller is a Sanken STR-A6069H, and on the solder side of the main PCB are a couple of IPD060N03L FETs. One of these most likely regulates the 5VSB rail, while the other probably engages the 5V rail once the PSU starts.

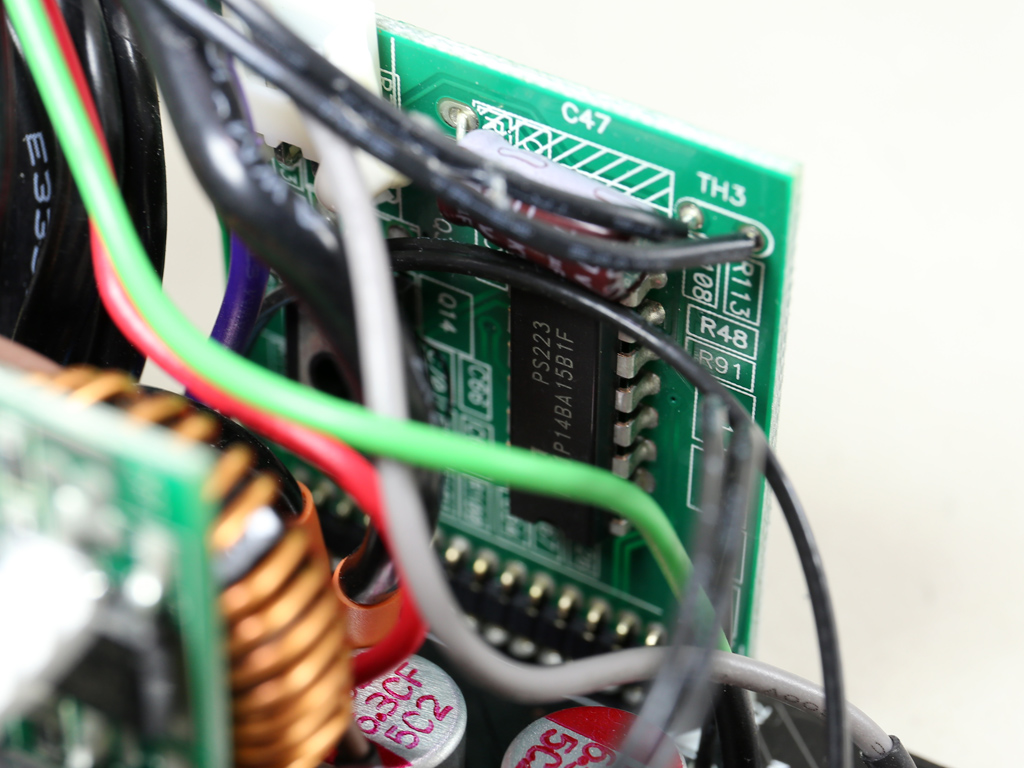

Housekeeping is handled by a SITI PS223 IC, which is one of the few supporting over-temperature protection.

The soldering quality is quite good overall. Copper bars are used on the secondary side to increase conductivity and lower energy losses at higher loads.

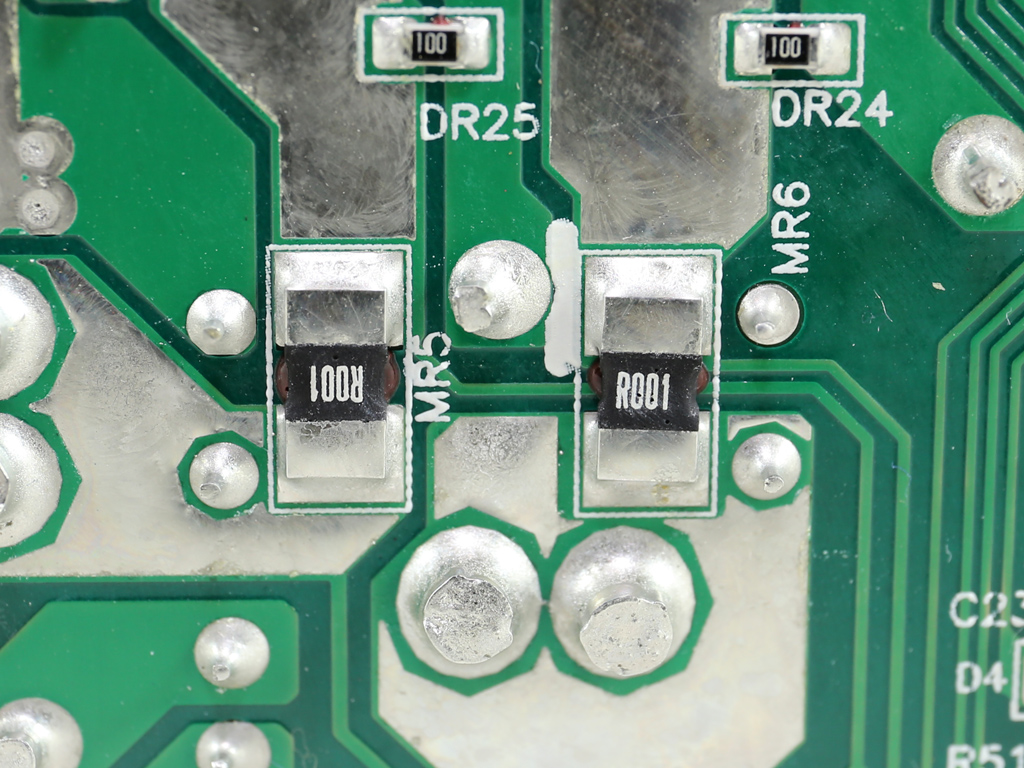

We spot two shunt resistors under the +12V islands, which are utilized by the OCP circuit since they provide amperage data. In case this unit features two +12V rails, OCP on them has to be very high to create a single +12V rail configuration under real-life conditions.

The cooling fan comes from Globe Fan and its model number is S1202512. It uses a Fluid Dynamic Bearing, ensuring a long useful life. With a max speed around 1600 RPM, this isn't a particularly noisy fan. However, once the power supply exceeds 40 °C, the profile gets aggressive. At lower operating temperatures and under light loads, a passive mode is activated and the fan doesn't spin, resulting in an output noise measurement of zero.

As with the ST75F-PT, the semi-passive mode's trigger point depends more on load and less on the secondary heat sink's temperature, which can be problematic. We highly stressed the PSU under high ambient temperatures and applied a light load afterwards. This made the fan stop spinning, even though it was very hot inside. Consequently, the OTP tripped, shutting down the PSU. We had to wait several minutes until the power supply could resume normal operation again. We'd rather see the fan control circuit prioritize temperature and not load.

Current page: A Look Inside And Component Analysis

Prev Page Packaging, Contents, Exterior, And Cabling Next Page Load Regulation, Hold-Up Time, And Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

panathas I don't understand, first you said: "On the other hand, it doesn't have an issue with inaccurate power-good signals that last longer than the corresponding hold-up time" and your last words were: "It is a great shame though that it is affected by the inaccurate power good signal disease". Which one is true? Also in the CONS section you only mentioned the Hold-up time and not the power good signal.Reply -

turkey3_scratch Reply18699506 said:I don't understand, first you said: "On the other hand, it doesn't have an issue with inaccurate power-good signals that last longer than the corresponding hold-up time" and your last words were: "It is a great shame though that it is affected by the inaccurate power good signal disease". Which one is true? Also in the CONS section you only mentioned the Hold-up time and not the power good signal.

First one must have been an mistake since it does drop the PWR_OK after the voltages are already out of spec. -

Aris_Mp Yes something was way out in this phrase. It is fixed now.Reply

This PSU is affected by a fake power good signal, which usually is the case in Sirfa's platform.

In the cons section. Sometimes I don't mention the fake power good signal, when the hold-up time is already too low. But I will make sure that I do from now on. -

Virtual_Singularity ty for the review. So, I know it's kind of not really adequate for comparison considering the watt difference. But, looking at the performance of that last Lian Li sfx reviewed, and this thing, still must say that LL didn't do so badly, though they could really help things if they extended that warranty by at least a year or more.Reply -

Co BIY I think the exterior photos need something for scale. Full-size black boxes and tiny high efficiency black boxes look the same size on a screen without something for scale.Reply

No comment on vacant modular socket plugs. First time I've seen that. Also the copper bars aren't a feature I've seen commented on before.