Thermaltake Wants to Jazz up the Way You Apply Thermal Compound

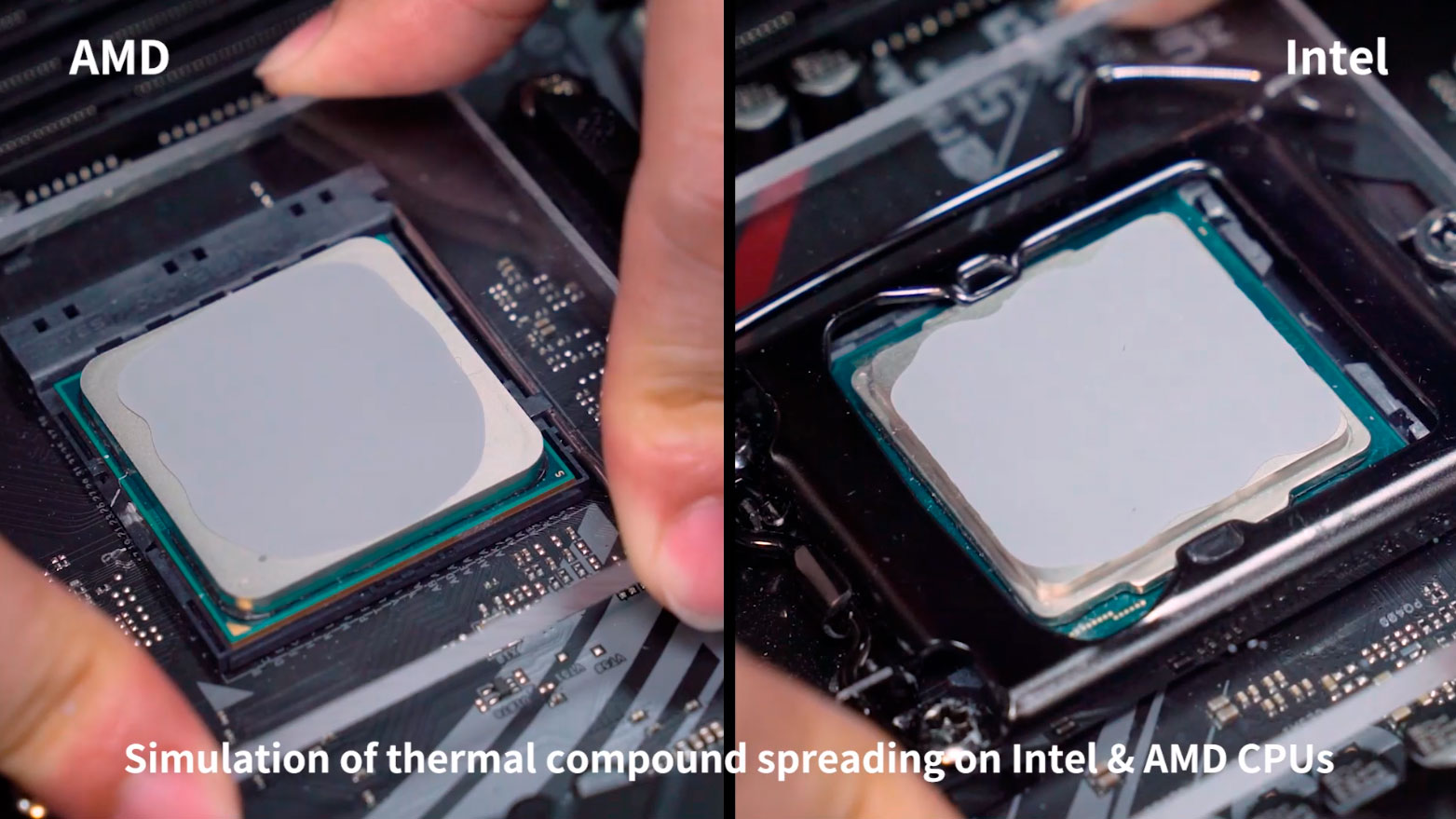

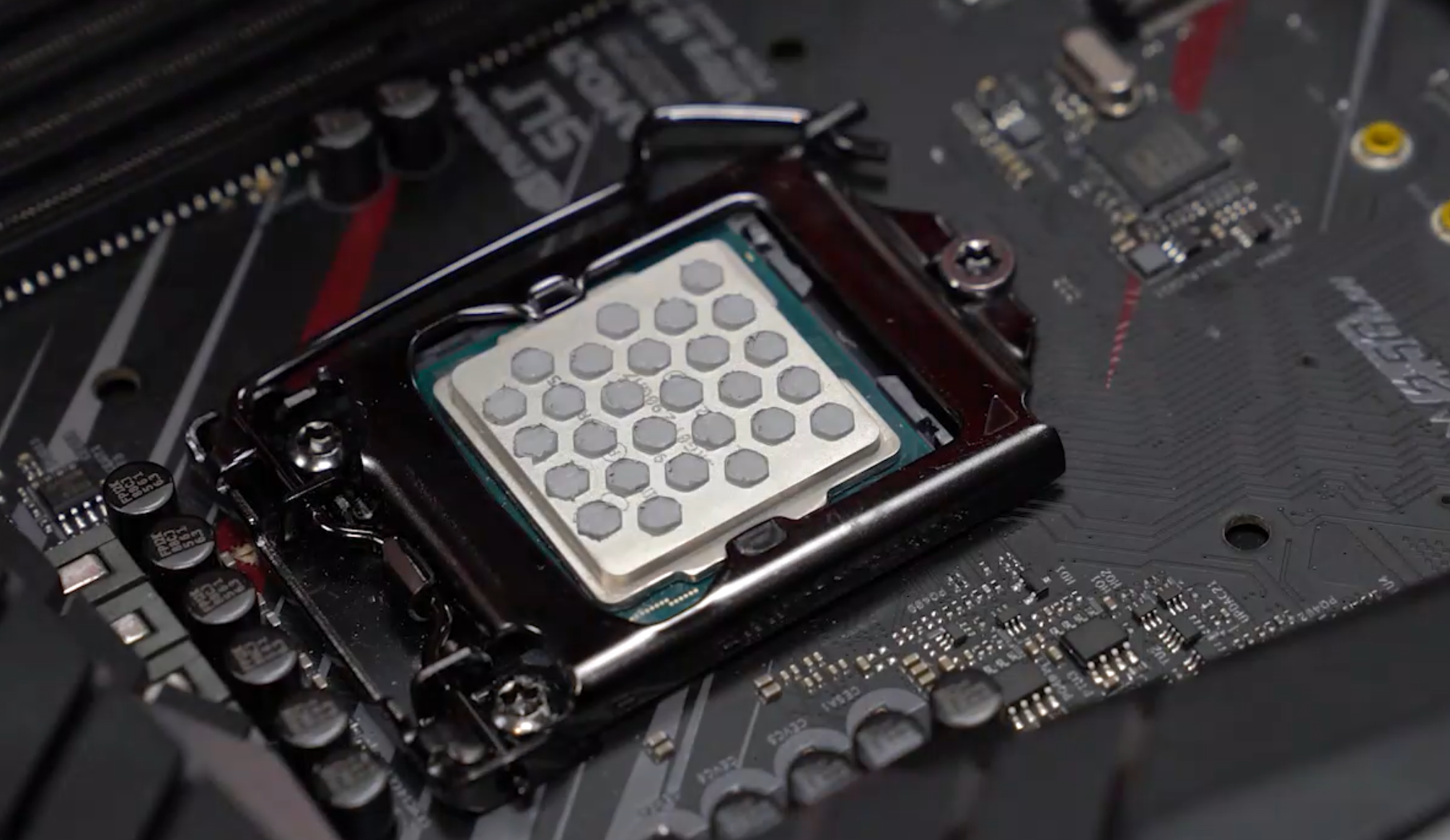

Thermaltake have launched the TG-30 and TG-50 thermal compounds that come with an interesting way of applying them to the processor's IHS (integrated heat spreader). The biggest novelty with the TG-30 and TG-50 is that Thermaltake includes a honeycomb-patterned stencil and a small spatula to paint the thermal compound over the IHS. The stencil is compatible with both Intel and AMD processors.

The company didn't reveal the thermal compounds' composition and the product page only hints to the presence of some mysterious diamond powder that reportedly helps with thermal conductivity. Thermaltake claims that the TG-30 and TG-50 don't dry up or crack easily either.

The rationale behind Thermaltake's idea is that the CPU cooler exerts uniform pressure over the honeycomb droplets so they spread and cover the entire IHS on the processor. Think of it as a simpler version of the credit card method. The only caveat we see with Thermaltake's approach is that you waste a good amount of thermal compound in the application process.

Thermaltake sells the TG-30 and TG-50 in 4g syringes. In addition to the stencil and spatula, the brand also includes two alcohol rubs to remove existing thermal compound from your processor or for cleaning the stencil after use.

The TG-30 boasts a thermal conductivity of 4.5 W/m-k, while the TG-50 delivers up to 8 W/m-k. Thermaltake sells the TG-30 and TG-50 for $8.99 and $11.99, respectively.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Zhiye Liu is a news editor, memory reviewer, and SSD tester at Tom’s Hardware. Although he loves everything that’s hardware, he has a soft spot for CPUs, GPUs, and RAM.

-

Giroro A stencil makes a lot of sense.Reply

It makes so much sense that most of their competitors' R&D have probably already tried/rejected this idea, for some reason. -

husker That comment makes a lot of sense.Reply

It makes so much sense that most other readers have probably already thought/rejected this comment, for some reason. -

Phaaze88 WTH is this garbage?Reply

That is such a waste of paste... this has me wanting to pull my hair out.

Screw you, Thermalfake.

As long as the paste covers the area of the die underneath, that's all that matters. Why all this? -

madmatt30 ReplyPhaaze88 said:WTH is this garbage?

That is such a waste of paste... this has me wanting to pull my hair out.

Screw you, Thermalfake.

As long as the paste covers the area of the die underneath, that's all that matters. Why all this?

Its the kind of tat that would appeal to a complete novice maybe?

Problem being that kind of novice would probably buy a prebuild rendering the whole idea pointless. -

AnimeMania It makes sense to me, the stencil's shape can ensure complete coverage and the thickness of the stencil can ensure a consistent amount of paste is applied. I just hope people remember to remove the stencil before seating the cooler.Reply -

Phaaze88 Reply

Why, of course, take advantage of people who wouldn't know any better... how typical.madmatt30 said:Its the kind of tat that would appeal to a complete novice maybe?

/cynicism

That's the thing. Complete coverage of the IHS is pointless. The user only needs to apply enough - bar cooler mounting pressure - to cover the silicon dies beneath the IHS.AnimeMania said:It makes sense to me, the stencil's shape can ensure complete coverage...

This product is expensive, as it serves to make users spend more paste than needed per serving.

None of today's cpus have dies that take up the entirety of the IHS they're under. If the user has a general idea, or actually knows the size and location of the die(s), they can avoid wasting paste needlessly.

This junk here goes in the opposite direction.

Intel's monolithic dies? The center application will take care of them. For the larger X series dies, a short line horizontally or vertically(depends on the cooler) and they'll be good.

AMD's Ryzen 3000? 3 dots will cover a 3950X. 3600? 2 dots - one at the side, and another in a corner.

Threadripper? Do a big X or +. -

PapaCrazy ReplyPhaaze88 said:That's the thing. Complete coverage of the IHS is pointless. The user only needs to apply enough - bar cooler mounting pressure - to cover the silicon dies beneath the IHS.

This product is expensive, as it serves to make users spend more paste than needed per serving.

None of today's cpus have dies that take up the entirety of the IHS they're under. If the user has a general idea, or actually knows the size and location of the die(s), they can avoid wasting paste needlessly.

This junk here goes in the opposite direction.

Intel's monolithic dies? The center application will take care of them. For the larger X series dies, a short line horizontally or vertically(depends on the cooler) and they'll be good.

AMD's Ryzen 3000? 3 dots will cover a 3950X. 3600? 2 dots - one at the side, and another in a corner.

Threadripper? Do a big X or +.

I used to think this until I heard Debaur say it was more effective to cover the entire IHS by spreading out compound so the whole surface could conduct heat. Not what I expected to hear, but I think he has more experience than anyone. -

Phaaze88 Reply

Well, ok. Do what works for you.PapaCrazy said:I used to think this until I heard Debaur say it was more effective to cover the entire IHS by spreading out compound so the whole surface could conduct heat. Not what I expected to hear, but I think he has more experience than anyone.

I mean, it's not like I didn't personally test different paste applications myself to sate my own curiousity... how hard is that?

I could just go and take some popular(?) individual's... opinion(?) - IDK what to call it - as fact and not bother, right? -

hotaru251 Reply

likely its not cost effective.Giroro said:A stencil makes a lot of sense.

It makes so much sense that most of their competitors' R&D have probably already tried/rejected this idea, for some reason.

like article said (and u can easily see why) you waste thermal paste.