Apple 5W Adapter Knock-offs: The Colorful A1265 Tear-Down

Going Out Without A Bang

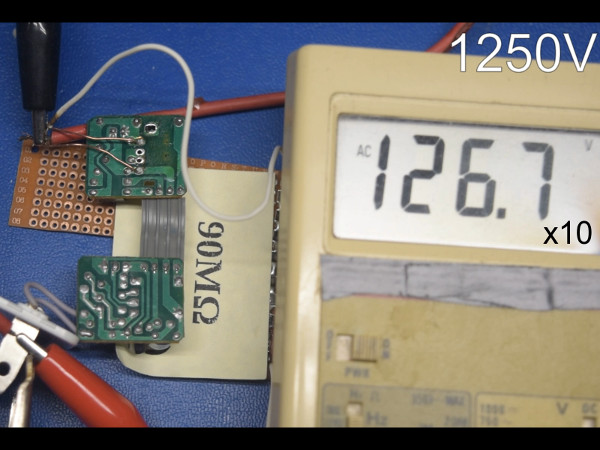

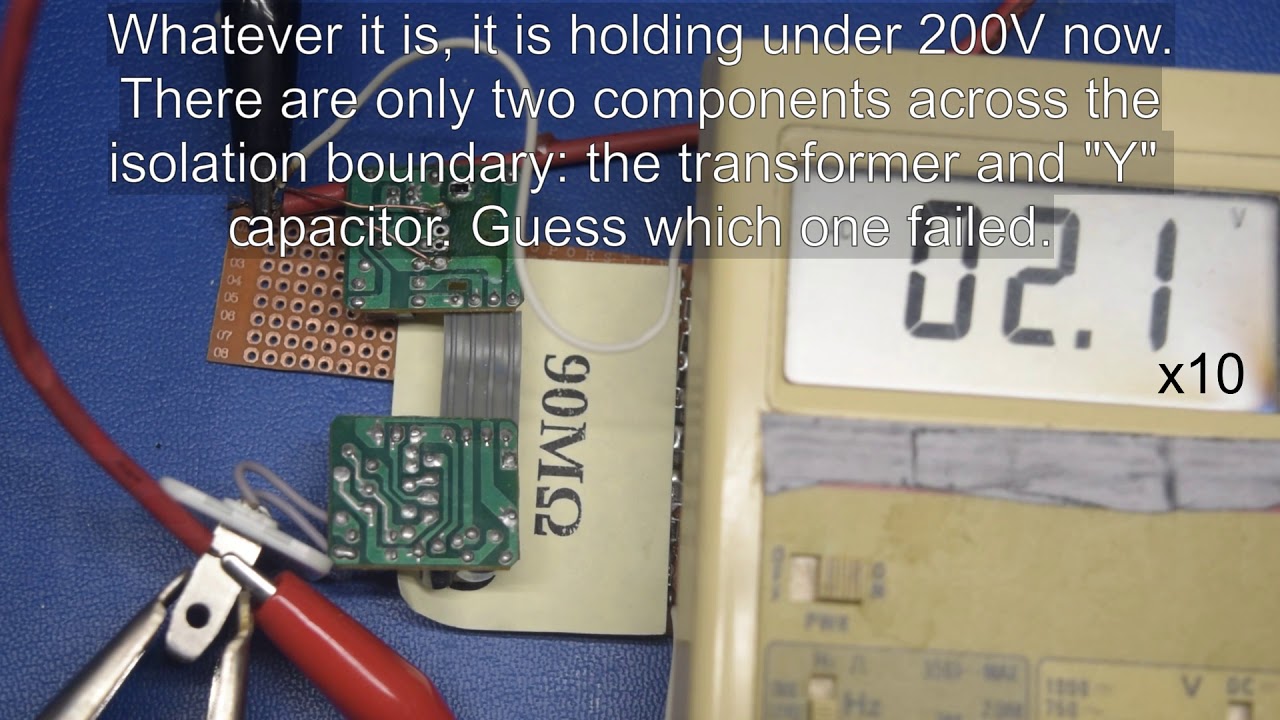

With the USB connector shield no longer providing a path between the optoisolator and output, the next thing to fail was the no-name 1kV capacitor at 1330VAC, which is 1875VPeak or almost twice its nominal rating and 3125V short of the proper Y2 capacitor that should have been there. After its failure, the capacitor’s leakage current increased in such a way that it clipped my 10mA transformer’s output to 180-200VAC somewhat like a MOV.

Could the capacitor fail as a low impedance and end up directly connecting mains to output? Certainly. That’s why safety standards require Y-class capacitors across isolation boundaries, making this as unlikely as practically possible.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

Undead Capacitor

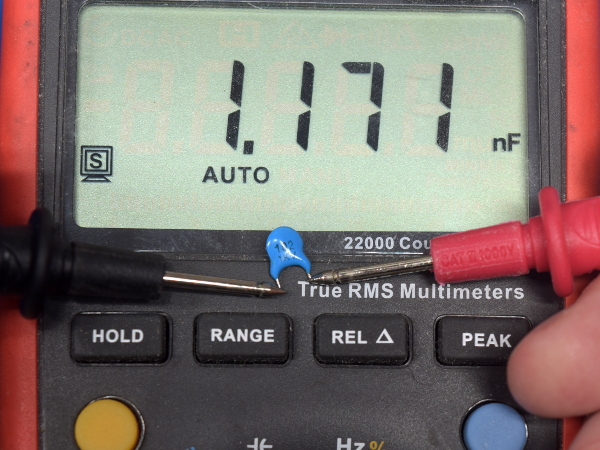

Although this 1nF capacitor is no longer capable of withstanding more than 250V or so of its 1kV nominal rating, it still reads 1.17nF on the capacitance range and overload (>100MΩ) on the resistance range. You wouldn’t know it failed without doing an actual voltage withstand test on it. When I re-did the voltage test on the capacitor after removing it from the adapter, its reading increased to 300VAC.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

What Does It Take To Kill This Thing?

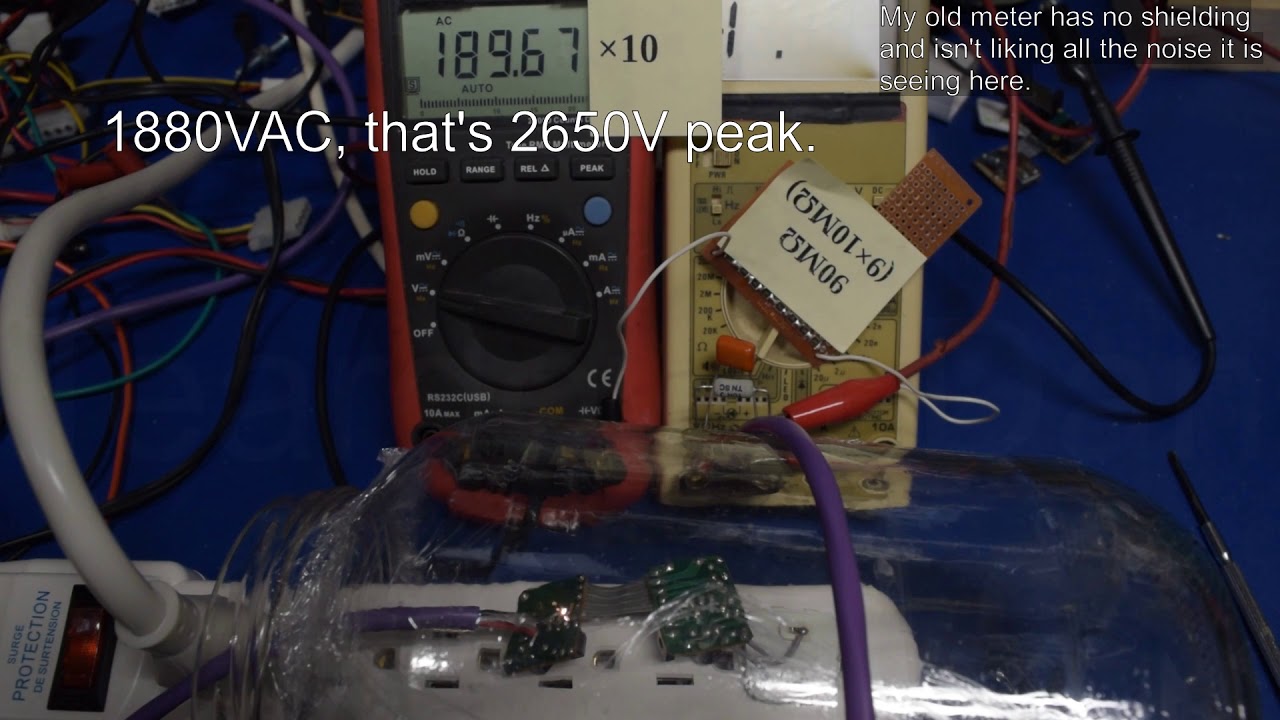

Does this adapter still work after the abuse so far? Surprisingly enough, the answer is yes. I decided to do this last round of isolation breakdown testing with the adapter live and being fed a 10Ω load. If arcs between the primary and output sides couldn’t kill the adapter outright, perhaps arc current through the live control circuit will cause a catastrophic failure.

My old meter freaks out from all the EMI it receives when the adapter begins to arc over at 1880VAC, while the adapter chugs along as if nothing happened between arcs.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

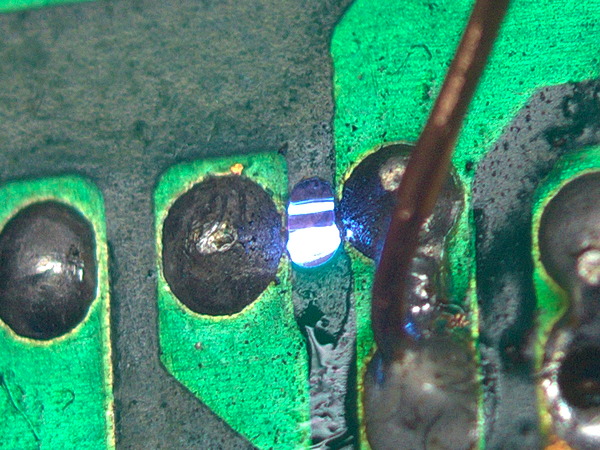

Close-Up

What does all of this arcing do to the circuit board? The hot plasma progressively eats away at the substrate material between solder joints, and in an open-air setup, that vaporized material wafts away, immediately filling the room with a pungent burning electronics smell.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

Digging A Hole

As you saw in the video, the first breakdown event occurred at 1880VAC but the residues left behind by the arcs allowed other arcs to occur at 1100-1300VAC across the same pads. Although the board looks spotless apart from a small crater the arc left behind, in an enclosed space without the benefit of airflow (within the adapter’s housing, for instance), the same material would sputter about the area and eventually yield a permanent resistive connection between traces or heavily contaminated areas with much lower breakdown voltage.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

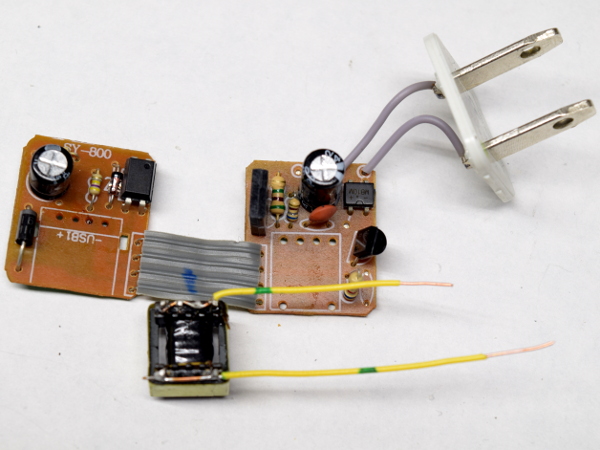

Transformer Test

Now that the circuit board has been abused as much as possible, and is the limiting factor to finding out how good the transformer’s insulation really is, we'll pull off the transformer and rig it for standalone testing. All of the primary-side windings are shorted together and connected to one terminal from my HV transformer. The same goes for the secondary side and other HV terminal.

The passing mark? 3500VAC (5kV peak) to match a proper Y2 capacitor’s 5kV pulse withstand rating.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

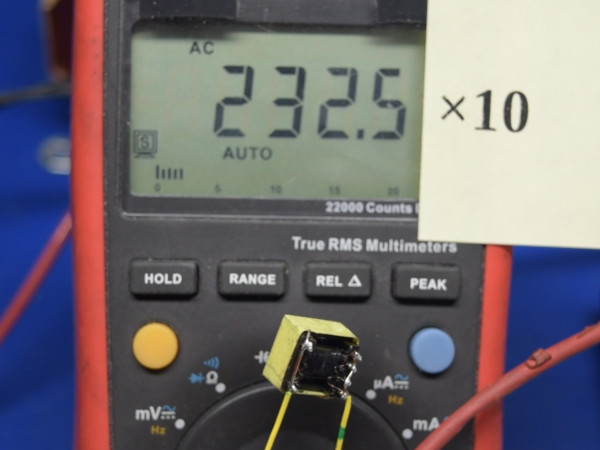

There Goes The Transformer

How much voltage does it take to fry the transformer’s insulation or get a failure of some sort? A small flash near the secondary side’s terminals answers that question at 2770VAC, 730VAC shy of a pass. Time to do an autopsy and find out how it failed.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

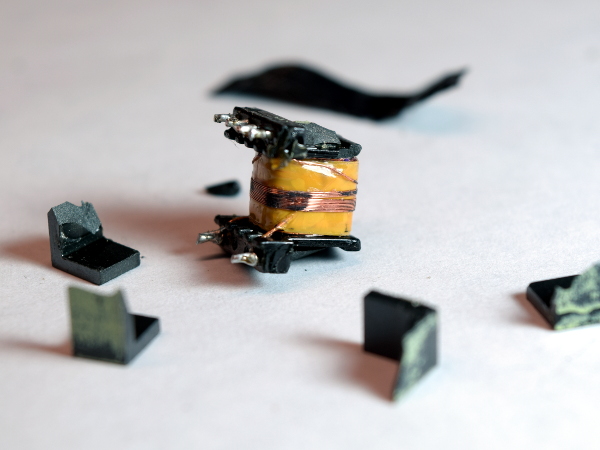

First Layer

I was hoping to at least salvage the transformer core and coil form from these adapters, but the cores are glued together inside the form, so I had to shatter the ferrite to gain access to the windings. Under two layers of thin black tape, we find the feedback winding sitting in the middle of the yellow tape with none of it anywhere near the spark area in the video. The spark source we’re looking for isn’t on this layer.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

Peeling Off

Insulating tape between the feedback winding and secondary got pulled taut around the secondary, and the feedback winding was wound so tight on top of it that the tape turned transparent in places from getting thinned out. While it didn’t fail, it may have been only a matter of time before pressure and heat caused the tape to flow out of the gap between windings and grow holes. Thicker tape or a third layer may be necessary here.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

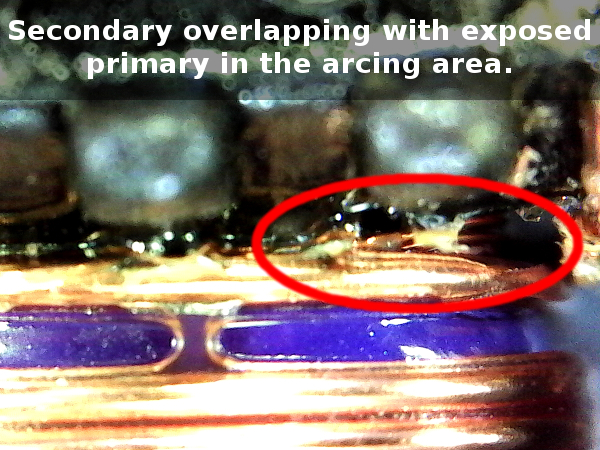

Failure Area

Upon removing the feedback winding and underlying yellow tape, we find the secondary-side winding. Near the secondary-side terminal leg (where the spark appeared), we also see three exposed turns from the primary winding underneath. The purple tape creased between the secondary’s top two turns, possibly from snagging on the coil form’s edge while wrapping, leaving the top few primary turns exposed and the last secondary turn wound on top of them.

There's no other way to put it: this is a literally fatal manufacturing flaw.

MORE: 10 Inexpensive Automotive USB Adapters Tested

MORE: Best Deals

-

sitehostplus This is no joke. I once fried a mp3 player in a usb wall charger before. So I now only use either my computer, or a geniune apple charger.Reply -

laura.morris.ga Thank you for this incredibly valuable information. It's nice to see someone out there looking out for the regular guy who doesn't have this level of knowledge about electronics.Reply -

omegaman2 This manufacturing, and marketing of imitation goods, and in this case electronic products can have very serious consequences, to the point of death, or serious injury. Thank you for your awareness, and knowledge about chargers that are not worth saving a couple of dollars.Reply -

Lutfij In my case, I'd wait to see what folks had to say about it so they would be my guinea pigs, of sorts. In most cases, I stay away from off quality hardware.Reply

Thank you for the write up though!

;) -

canadianvice One of my critical rules for buying china: nothing connected to direct wall power.Reply

I do have one speaker lightbulb, but that's not powered when I'm not present, and it seems to have come from one of the better plants. Obviously, it's also less of a problem since I don't go out of my way to touch it on a regular basis. -

Kennyy Evony how about, listing an alternative without all the flaws? Complaining does not fix anything. List an adapter without all the flaws that costs exactly the same for people to buy? Wouldn't that be a better article? Same price, a lot less risks for consumers? win?Reply -

TMTOWTSAC Reply20566315 said:how about, listing an alternative without all the flaws? Complaining does not fix anything. List an adapter without all the flaws that costs exactly the same for people to buy? Wouldn't that be a better article? Same price, a lot less risks for consumers? win?

The title and description seem to imply that this is the first of several reviews to come. Since this first product presents an outright safety risk, I take zero issue with presenting it now rather than collating all results first. As far as producing a better article, you are presuming an alternative meeting your criteria does actually exists. While I have no doubt quality 5W adapters can be found cheaper than Apple's ($19 list price at Apple) I would be shocked if any of them could be found for $1.50. -

razor512 Reply20564820 said:This is no joke. I once fried a mp3 player in a usb wall charger before. So I now only use either my computer, or a geniune apple charger.

I fried mine also, but with a quality charger, Some MP# players do not play nicely with quickcharge 2.0 and 3.0 chargers.

Here are the photos of mine after it failed.

Funny thing was that the battery was perfectly fine, the protection circuit kicked in and cut the output and input to the battery for a few minutes, then it self-reset and the battery continued to work fine (it now runs a flashlight).

https://imgur.com/a/aOLQr

Beyond that, I have an old DIY USB charger that works really well, and has the lowest noise of any of the OEM chargers that I have used so far.

It is basically a USB port wired to the 5V rail of a 550 watt power supply. Even when charging my android tablet at 2 amps, the voltage is completely stable at 5V, and those cheap 5V amplifier circuits can run from it without filtering while on standard chargers that come with smartphones, will have lots of noise.

-

alextheblue Reply

Half my family uses Apple hardware and OE Apple accessories. The failure rate on the smaller Apple charging blocks is higher than I would have expected, given the cost. Since they have been conditioned to only use Apple accessories, I bought a couple of them the much larger Apple charging blocks you see used for iPads, to replace failed compact Apple blocks. Meanwhile I primarily use high-end third party chargers.20564820 said:This is no joke. I once fried a mp3 player in a usb wall charger before. So I now only use either my computer, or a geniune apple charger.

That depends on the charger. Just because it supports QC doesn't mean it is guaranteed to have issues like that. I've got a 2-port 39W (combined) Anker charger that supports QC 3.0 but it also supports what Anker calls PowerIQ. Works great with anything I've thrown at it, and I also use it with a 10W Qi mat.20566658 said:I fried mine also, but with a quality charger, Some MP# players do not play nicely with quickcharge 2.0 and 3.0 chargers. -

Daniel Sauvageau Reply

As the intro says, this adapter (hopefully) sets the low bar. I'm not "complaining" about the low quality, I am exposing it to drive awareness of how dangerous or even potentially lethal these cheap generics can potentially be. Increasing awareness reduces the number of people who will let themselves be tempted by suspiciously inexpensive adapters of questionable origins. Fewer people buying dangerous adapters will hopefully reduce demand and sufficiently reduced demand could potentially reduce offer. No awareness would allow propagation of these death traps to go completely unchecked.20566315 said:how about, listing an alternative without all the flaws? Complaining does not fix anything. List an adapter without all the flaws that costs exactly the same for people to buy?

As for suggesting better quality alternatives, as TMT already wrote, I seriously doubt there are any decent quality adapters around the $2 mark or at the very least, the chances of stumbling upon one are slim. There was an intro story to this series that was supposed to come out first but some publishing pipeline hiccups delayed it. I have about a dozen sub-$5 adapters in my presumed horror box and I'm not expecting them to achieve a passing grade. I also have a few $10 adapters which I'm hoping will at least get most of the way to a passing grade. I'll get to them in due time.

Right now, I'm half-way done testing a fairly promising aftermarket one (almost perfectly flat 5.06V from 0A through 8.6A regardless of test conditions with less than 20mV or RMS noise) but it is ~$25, so I'd be disappointed to get anything less. The next one after that will be a ~$10 adapter from a rising one-stop-for-everything home brand that I haven't taken out of its original box yet.

I'll probably rotate sub-$5, ~$10 and $20-and-up adapters until I exhaust my inventory for a given tier as exhausting my "horror-class" adapters first might get depressing. It also increases the chances that I may have something worth recommending once in a while, albeit at a higher cost.