De-Lidding and Overclocking Core i7-7700K with Water and LN2

We're testing Kaby Lake's maximum frequency at various core voltages, the influence of de-lidding, and even applying a bit of liquid nitrogen. Get ready to learn more about overclocking Intel's latest architecture with a bunch of Core i7-7700K CPUs.

Intel Core i7-7700K: De-Lidded and Overclocked

Intel's Sandy Bridge-based Core i7 processors spoiled enthusiasts with the ease at which they could hit 5 GHz with CPU overclocking using air cooling. Sadly, these CPUs weren't well-suited for extreme overclocking, and we were never able to push past 6 GHz under liquid nitrogen.

Ivy Bridge saw Intel selling Core i7s that were less amenable to traditional overclocking efforts, but much more receptive to extreme measures. Record-setting efforts saw them break the 7 GHz threshold.

The sixth generation of Core i7 (Skylake) demonstrated the best efficiency in a CPU yet.

Now imagine a processor that overclocks like Sandy Bridge under air cooling, like Ivy Bridge with the help of liquid nitrogen, and with Skylake's efficiency. Could that be Kaby Lake? We're going to find out.

For this little experiment, we're using one of the latest motherboards to land in our French lab: MSI's Z270X XPower Gaming Titanium.

Of course, processors are subject to the silicon lottery's uncertainties, so we obtained multiple samples. You'll see that the spread in what's possible is large indeed.

De-Lidding Intel's Core i7-7700K

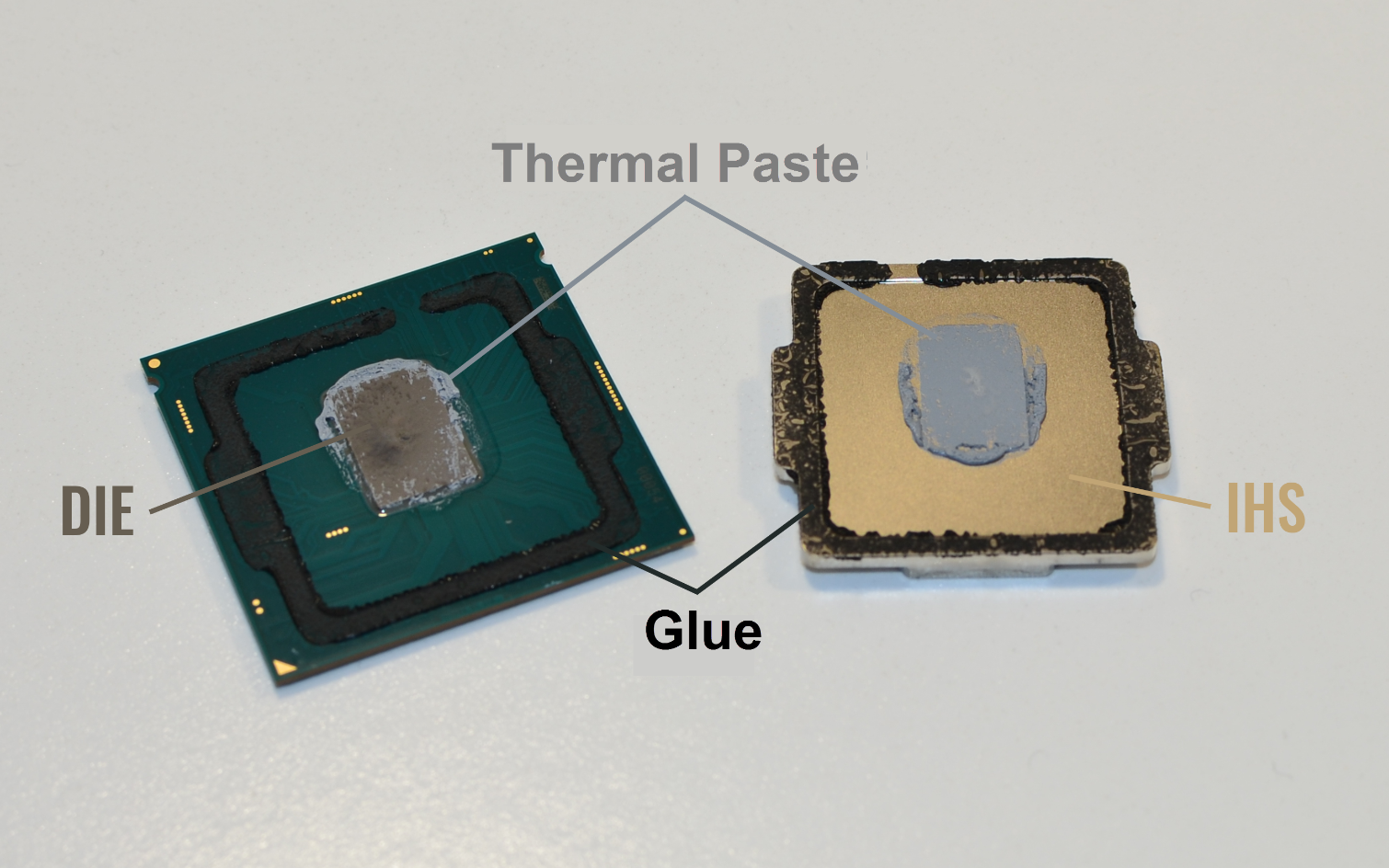

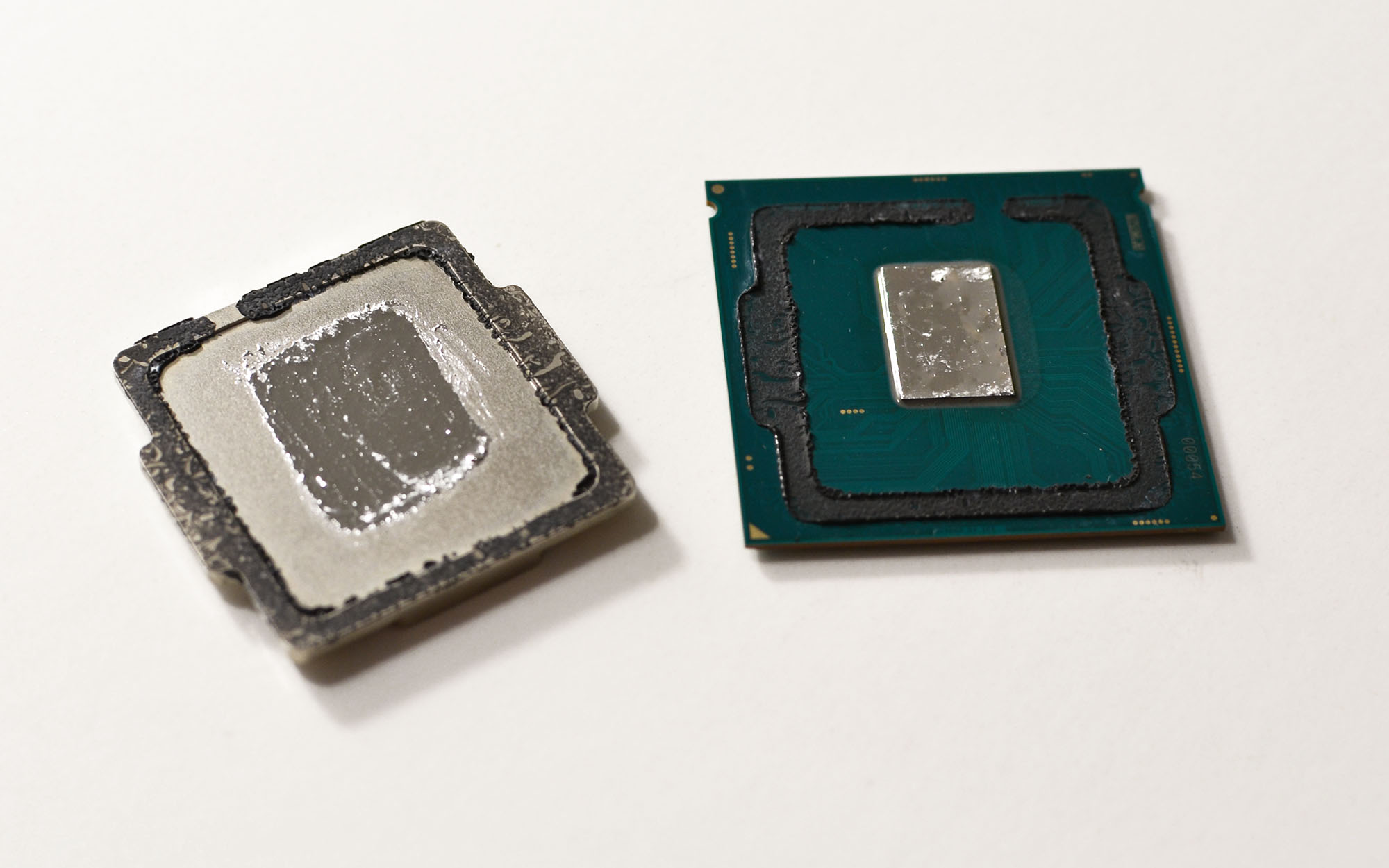

Quite simply, de-lidding is the process of removing the integrated heat spreader that typically sits atop your CPU. The primary function of the IHS is to protect the die underneath, but by adding this shield between the fragile silicon and bulky heat sink, thermal transfer is restricted somewhat.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The Procedure

Although de-lidding was once considered an extreme measure reserved for the most hardcore enthusiasts, the process became more popular when it became clear that Intel's Haswell-based CPUs ran hot, in part due to a different thermal interface material between the die and IHS.

It's no longer necessary to white-knuckle the procedure with a razor blade or workshop vice, though. To de-lid an Ivy Bridge, Haswell, Devil's Canyon, Skylake, or Kaby Lake processor, you need a tool like the Delid Die Mate, some good thermal paste, and glue (optional, silicone is preferred).

Simply place the processor on the correct side of the tool, oriented properly, close the tool, and turn the screw until the black glue breaks free when the two parts separate.

With the IHS removed, we can see Intel's thermal paste, which looks quite dry. For information on how to thoroughly clean a bare chip (CPU or GPU), take a look at How To: Optimizing Your Graphics Card's Cooling. We apply thermal paste (we're using Thermal Grizzly Conductonaut) to the die and IHS. All that's left is add a little glue and reseal the processor.

Thermal Paste

If heat isn't removed from the die as quickly as it's generated, the CPU's internal temperature rises as a consequence. In order to minimize the IHS' effect on thermal transfer, we need a good paste, which fills surface imperfections and eliminates the tiny pockets of air that'd otherwise inhibit heat sink performance. In this role, not all thermal pastes are created equal.

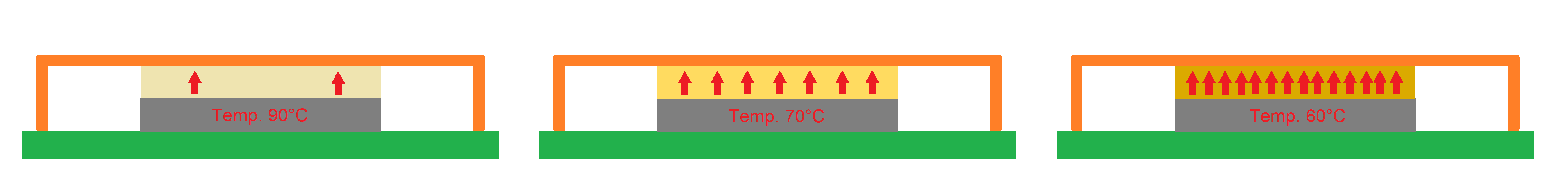

In the image above, the thermal paste on the left limits heat transfer, resulting in a hotter processor. The higher-quality compound in the middle performs better, helping our hypothetical CPU top out at 70°C. Finally, on the right, the die is covered with a premium product that keeps the processor's temperature at a maximum of 60°C.

We're going to compare three different thermal pastes:

- Original thermal paste (Intel)

- Thermal Grizzly Kryonaut

- Thermal Grizzly Conductonaut

Intel's thermal paste doesn't always perform very well, but it is applied to all of the Kaby Lake-based processors. Because it's unavoidable, it serves as a logical reference for our measurements.

Kryonaut is a solid performer with a conductivity of 12.5 W/mK. But it's quite expensive (an 11g tube can be found for around $26). Still, in this piece it plays second fiddle to an even higher-end product.

At the top of our hierarchy we have Conductonaut, a metallic paste that is conductive. Its thermal conductivity is listed as 73 W/mK. But you cannot use it below freezing, or on aluminum surfaces. Its price is as high as its performance, at about $11 per gram!

Results

Of course, results can vary from one processor to the next, but the delta between cooling solutions remains fairly similar. To show the disparity, we're using Prime95 with a CPU core voltage of 1.3V.

| Intel | 82.5°C |

|---|---|

| Kryonaut | 76.5°C |

| Conductonaut | 60.5°C |

As expected, Intel's thermal interface material trails. The Kryonaut performs only 6°C better. And the Conductonaut gives us a -22°C temperature drop.

Our screen captures show that the temperatures are more homogeneous between cores once the thermal paste is upgraded. For the tests that follow, we are going to keep Intel's paste as a reference, and the Conductonaut as its replacement.

MORE: Overclocking GeForce GTX 1080 Ti To 2.1 GHz Using Water

MORE: CPU Overclocking Guide: How (and Why) to Tweak Your Processor

Current page: Intel Core i7-7700K: De-Lidded and Overclocked

Next Page Overclocking with Water Cooling-

rantoc Intel should be ashamed of themselves for applying such useless TIM to save a few cents in a "high end" product as they like to call it!Reply -

AgentLozen Very fun article to read.Reply

You guys were using water cooling and liquid nitrogen for this experiment. I wonder how well aggressive air cooling would have held up. -

InvalidError Reply

The quality of Intel's TIM is perfectly fine. The problem is the thickness as the gap between the die and IHS is many times wider than necessary. Most of the cooling performance gain from de-lidding comes from reducing or eliminating the adhesive thickness.19451139 said:Intel should be ashamed of themselves for applying such useless TIM to save a few cents in a "high end" product as they like to call it!

To make a fair comparison against Intel's stock TIM, you'd need to shim the IHS to achieve the same total package thickness. Any TIM will perform much worse when it is 5X thicker than the minimum necessary. -

Xajel I miss the days of Phase Change cooling, while LN is more extreme, you just can't use it in real world usage, just to see how far you can go with it without going for more extreme cooling ( eg. LHe ), With Phase Change, you can even go 24/7 If you have the build correctly ( isolation from humidity )Reply -

Math Geek i'd love to know how much power it took to get those results :)Reply

folks ask all the time how much extra power they need for overclocking and this looks like a good opportunity to get some solid numbers if they'd like to share them. what kind of wattage does this use at 6.6 ghz??? -

rantoc Reply19451237 said:

The quality of Intel's TIM is perfectly fine. The problem is the thickness as the gap between the die and IHS is many times wider than necessary. Most of the cooling performance gain from de-lidding comes from reducing or eliminating the adhesive thickness.19451139 said:Intel should be ashamed of themselves for applying such useless TIM to save a few cents in a "high end" product as they like to call it!

To make a fair comparison against Intel's stock TIM, you'd need to shim the IHS to achieve the same total package thickness. Any TIM will perform much worse when it is 5X thicker than the minimum necessary.

Sure the distance the TIM have to transfer the heat is one of the variables for thermal conductivity but there are tons of documented straight out switches of only the TIM after deliding (without any changes in the IHS height above the CPU) that have resulted in similar improvements like this articles when overclocking the CPU. Sure the tim is sufficient for non overclocking use but intels stock tim is clearly holding the CPU back when pushing that overclock. -

InvalidError Reply

If you include the nitrogen separator and helium chillers needed to generate a sufficient stream of LN2 to keep the overclock running, probably in the neighborhood of 10kW :)19451369 said:what kind of wattage does this use at 6.6 ghz??? -

InvalidError Reply

I have only seen one site report on attempting to maintain the same thickness with Ivy Bridge and that site's results showed worse performance with most aftermarket pastes. All other deliddings I have seen removed the glue and did not put anything back in its place to duplicate its thickness or when they did (ex.: deBauer), they minimized that thickness by pressing the IHS against the substrate before curing.19451405 said:Sure the distance the TIM have to transfer the heat is one of the variables for thermal conductivity but there are tons of documented straight out switches of only the TIM after deliding (without any changes in the IHS height above the CPU) that have resulted in similar improvements like this articles when overclocking the CPU.