Creality Launches a Color 3D Printer for its 10th Birthday Party

The K2 will go toe to toe with Bambu Lab’s X1 Carbon

April 9th marks 3D printing powerhouse Creality’s tenth year in business, and it is celebrating with a new line of color printers, a laser, and two scanners.

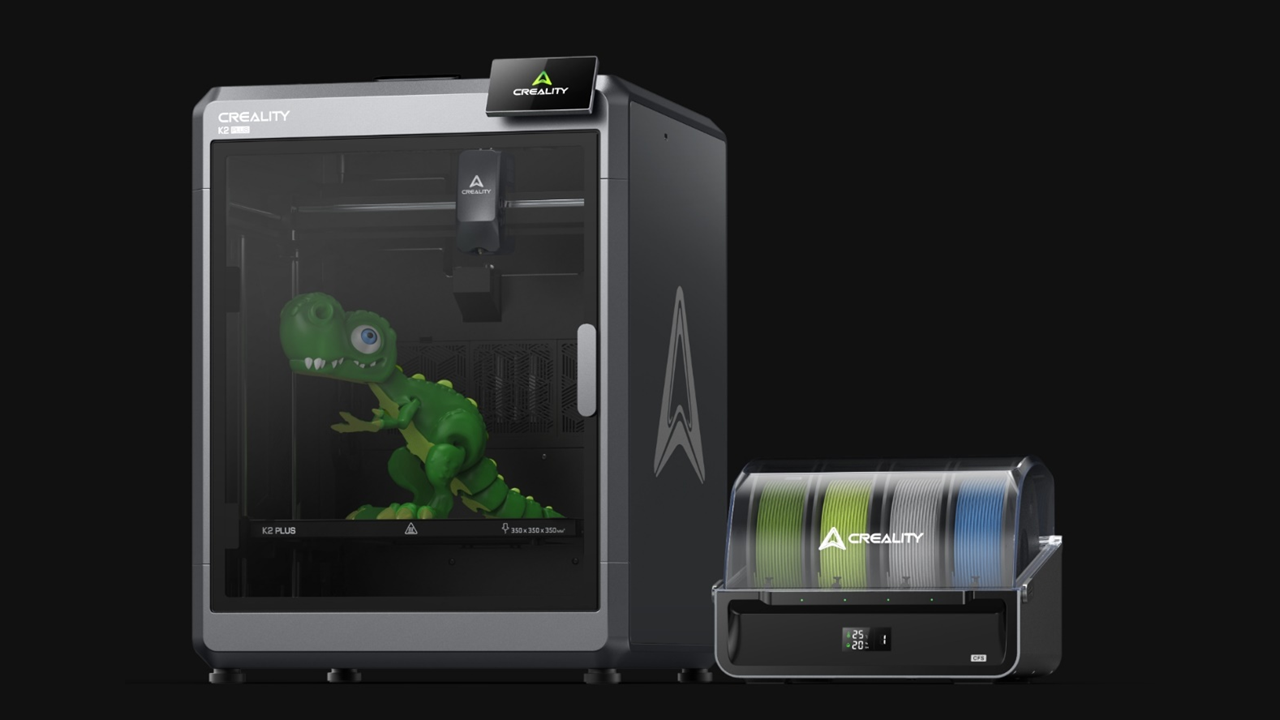

Creality focused on speed during 2023, releasing several high-speed printers such as the K1, K1Max, and Ender 3 V3 KE. The long wait for Creality’s entry into multicolor printing will end this summer with the launch of the K2 Plus and the Creality Filament System (CFS).

The K2 Plus will have a 350 mm cubed build volume, making it larger than the K1 Max and, more importantly, larger than competitor Bambu Lab’s X1 Carbon. Creality said the K2 Plus will be the first in a series of K2 printers, but did not indicate the size of the other machines in the lineup.

Like the X1 Carbon, the K2 Plus will have an optional four-spool material handler that can be daisy-chained with additional CFS units to produce 16-color prints. It will likewise have an RFID reader to automatically identify marked spools. The CFS unit will provide a temperature and humidity controlled environment.

It's unlikely that Creality’s CFS will be able to read Bambu Lab filament RFID tags, as that information is proprietary. Creality has been building a library of its own high-speed filament, which currently includes ten colors of PLA. They also have PETG, ASA, and ABS in limited colors.

Creality has been a supporter of Open Source, which hopefully will allow the CFS to use 3rd party filaments without the need for branded RFID tags.

The press release also said the K2 Plus will have active chamber heating, which should greatly improve the quality of advanced filaments like ABS and ASA. Creality is also promising improved AI monitoring and auto leveling.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Hot on the heels of the Ender 3 V3, Creality announced a new large format version, the Ender 3 V3 Plus. The machine will be a Core XZ bed slinger with a 300x300x330 mm build volume. Tom’s Hardware has yet to receive a V3 for review, but the V3 promises 600mm/s print speeds backed by a sturdy all metal frame and high flow hotend.

Creality also announced a 14K resin 3D printer, the HALOT-Mage S, with a 10.1” mono LCD. The printer promises sharp prints with high speed and an odor free experience thanks to a built-in air purifier.

The company will also launch a powerful 60W laser that is fully enclosed and guided with a built-in camera. The Creality Falcon 2 Pro will have a “bonus” 1.6 W laser for ultra-fine engraving.

Creality will continue its fondness for animal-themed scanners with the introduction of two new portable scanners, the CR-Scan Otter and CR-Scan Raptor.

The CR-Scan Otter is a handheld scanner with four lenses that can scan in 24-bit color with high detail. It has a wide range, with the ability to capture objects as small as 10mm up to 2000mm. It has an anti-shaking feature for smooth scanning and reportedly can capture black and metal objects without the need for a spray coating.

The CR-Scan Raptor is an ultra-high accuracy scanner, capable of capturing details as fine as 0.02mm and speeds up to 60 fps. It uses infrared structured light scanning with seven laser lines to record objects as small as 5mm and up to 2000mm.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

pbcrunch ReplyCreality has been a supporter of Open Source

Not true. Creality has been a major beneficiary of the open source community, but has only contributed back to the community when it has had no other choice. -

edzieba Yup. When they had Naomi Wu working with them they had an open source advocate regularly and loudly and publicly yelling at them directly to do the right thing (why Creality ever released any of their Marlin code changes at all). With that no longer the case, any source releases are occasional at best. For example, the K1: it technically runs Klipper, but with a locked down interface and a bunch of proprietary bits (e.g. to support their load cell implementation) and no source code available.Reply -

peachpuff Really wish bambu labs would release a bigger printerReply

Its easily rootable and upgradeable to klipper, that's crealitys only gift to the community.edzieba said:For example, the K1: it technically runs Klipper, but with a locked down interface and a bunch of proprietary bits (e.g. to support their load cell implementation) and no source code available. -

dmitche31958 I love the idea of multiple filament printing, what I don't like is the waste that occurs with each change of filament. From what I've read that amounts to a lot of time and wasted material. I hope that I'm wrong about that and someone can tell me just how much is spent with a change. I would imagine that it wouldn't be more than 50mm but it appears to be even more.Reply -

peachpuff Reply

You're not wrong, there are ways to reduce it but waste is still there. Only other option is the prusa xl which almost has no waste but that's thing is still in beta imo.dmitche31958 said:I love the idea of multiple filament printing, what I don't like is the waste that occurs with each change of filament. From what I've read that amounts to a lot of time and wasted material. I hope that I'm wrong about that and someone can tell me just how much is spent with a change. I would imagine that it wouldn't be more than 50mm but it appears to be even more. -

USAFRet Reply

No, that IS a large issue.dmitche31958 said:I love the idea of multiple filament printing, what I don't like is the waste that occurs with each change of filament. From what I've read that amounts to a lot of time and wasted material. I hope that I'm wrong about that and someone can tell me just how much is spent with a change. I would imagine that it wouldn't be more than 50mm but it appears to be even more.

This, from my X1-Carbon w/ AMS.

Model that finished a couple of days ago.

About 80mm tall.

4 color, in ABS.

610 color changes. Many layers changed between all 4 colors.

Model weight - 46.37g

Flushed - 216.49g

Purge tower - 38.28

So the actual model was about 20% of the total consumed filament.

80% wastage.

The finished dragon:

https://i.imgur.com/qQvmd7m.jpg -

edzieba Reply

The most recent update (as of a yesterday) significantly cuts down on purge volumes by lifting the melt-zone before filament changes (so there is no cold length of filament left in the nozzle that needs to be purged, just the melt plug). This reduces purge volumes and filament change times.USAFRet said:No, that IS a large issue.

This, from my X1-Carbon w/ AMS.

Model that finished a couple of days ago.

About 80mm tall.

4 color, in ABS.

610 color changes. Many layers changed between all 4 colors.

Model weight - 46.37g

Flushed - 216.49g

Purge tower - 38.28

So the actual model was about 20% of the total consumed filament.

80% wastage.

The finished dragon:

https://i.imgur.com/qQvmd7m.jpg

In addition: since multiplexer-type material changers only perform changes as per-layer operations, the absolute filament purge penalty remains fixed regardless of the number of objects on the build plate: by printing multiple at the same time, the percentage purge volume starts to become pretty tiny compared to printed volume. That's less help when you only want one part, though.

IDEX and other multi-head machines may avoid filament purge waste, but they still require re-priming (hence why the Prusa XL still prints a prime tower) so waste is just reduced rather than eliminated. A solution for standing-start static nozzle priming would need to be found to eliminate that, and I have not seen anything that even attempts to tackle that problem yet. -

USAFRet Reply

I just updated mine last night, so we shall see.I'll have to go get the 1.9.xxxedzieba said:The most recent update (as of a yesterday) significantly cuts down on purge volumes by lifting the melt-zone before filament changes (so there is no cold length of filament left in the nozzle that needs to be purged, just the melt plug). This reduces purge volumes and filament change times.

Indeed.edzieba said:In addition: since multiplexer-type material changers only perform changes as per-layer operations, the absolute filament purge penalty remains fixed regardless of the number of objects on the build plate: by printing multiple at the same time, the percentage purge volume starts to become pretty tiny compared to printed volume. That's less help when you only want one part, though.

Printing 1 or 10...purge vol is pretty much the same. -

USAFRet Reply

This says $1000 - $1200, "expected".thisisaname said:Sadly no indication of price.

The larger one (350mm) $100 more.

And then extras...

https://www.antonmansson.com/3d-printing-blog/creality-k2-plus-3d-printer-with-multi-material-printing