HDD Areal Density Growth Slows as Capacity Increases

Bring on HAMR and MAMR

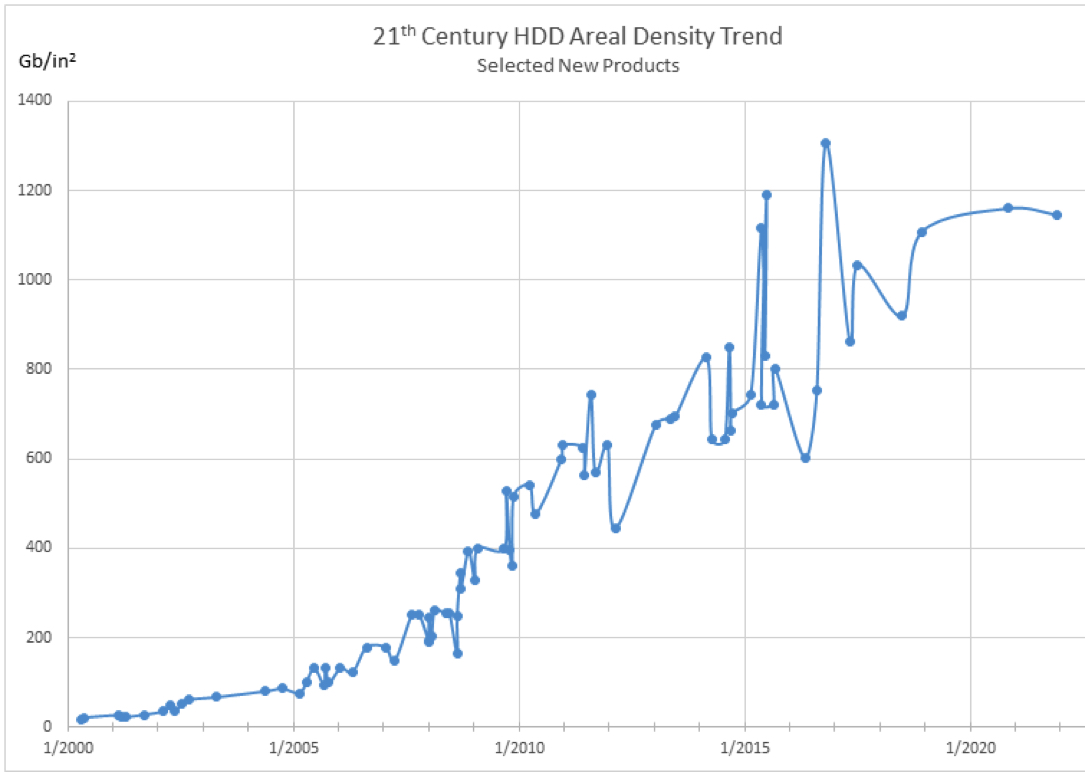

While the capacity of hard disk drives increased from 10TB in 2016 to 20TB in 2021, the areal recording density of high-capacity HDDs hasn't increased nearly as much. Areal density is stagnating, observed Tom Gardner, a technology and intellectual property consultant as well as webmaster at IEEE Silicon Valley History Committee.

The report notes that areal recording density of HDDs has been sitting at around 1.1 Tbit/inch^2 (that's terabits per square-inch) for the past several years (via StorageNewsletter). Furthermore, manufacturers of hard drives no longer highlight this metrics in their specifications. It's still increasing, but far slowly than in the past.

Historically, makers of hard drives and HDD platters bragged about the record areal densities achieved either for commercial products or in their labs. But as the transition to energy-assisted magnetic recording (EAMR) technologies is taking longer than expected, we no longer see HDD makers advertising this metric. It's similar to how CPU designers have ceased to highlight processor frequencies.

Could this be some fundamental shift in hard drive evolution, or is it just a minor hiccup? It's probably a bit of both, actually.

Perpendicular magnetic recording has been running out of steam for quite a while, which is why Seagate, Toshiba, and Western Digital started using shingled magnetic recording (SMR) as well as two-dimensional magnetic recording (TMDR) technologies in the recent years. While these two technologies allow for increased areal density, they alone cannot enable tangible increases in nearline HDD capacity every year.

To overcome this, all manufacturers have also increased the number of platters from seven to nine in their range-topping drives in recent years. Many are either shipping or are getting ready to ship 10-platter HDDs in the coming quarters.

There's nothing bad in packing more platters into nearline hard drives, provided their power consumption and heat dissipation stay in check and they continue to be drop-in compatible with the existing 3.5-inch infrastructure. In fact, in some cases it may even make more sense for HDD makers to lower their areal density a bit and increase the number of platters if that improves yields, reliability, or both. According to Coughlin Associates, areal density of HDDs has been fluctuating in the recent years.

Still, fewer platters is preferable from a cost point of view, which is why Seagate and Western Digital have been gradually re-introducing their mid-range parts (8TB~12TB) with new high-capacity platters and using TMDR and other innovations.

EAMR Needed

In the recent quarters, Seagate and Toshiba promised to introduce their next-generation heat-assisted magnetic recording (HAMR) and microwave-assisted magnetic recording (MAMR) HDDs. Those technologies would help increase capacity to get to 50TB by the middle of this decade. In both cases, usage of new recording technologies is pivotal for the capacity gain.

Toshiba is shipping its MAMR-based HDDs and Western Digital offers its energy-assisted PMR (ePMR) drives, but Seagate so far only supplies its first-generation HAMR HDDs inside its own Lyve storage systems, or to select clients. Furthermore, the capacity of these EAMR drives does not exceed 20TB, which means that their areal density is barely higher when compared to regular PMR+TDMR offerings, so we continue to stagnate at 1.1–1.2 Tbit/inch^2.

Seagate once said that its HAMR technology can support areal densities of 1.5–2.6 Tb/inch^2 with a path to grow to 6 Tb/inch^2 by 2030 to enable 100TB 3.5-inch HDDs. However, we are not even close to that, and before Seagate starts shipping of its HAMR drives for the mass market, it does not look like we are going to see any breakthroughs with HDD development.

HAMR requires all-new glass platters with a brand-new magnetic layer, all-new heads, and numerous changes to the internal design of HDDs, which is why it's taking Seagate so much time for this technology. By contrast, Toshiba and Western Digital are taking a considerably more conservative approach with their MAMR and ePMR technologies that do not require so many changes at once, allowing a very gradual and less risky development . They also come at the cost of lower capacity increases and a and slower transition to HAMR, naturally.

Ultimately, while 10-platter HDDs are here and it is possible to increase the number of platters within a drive to offer a yet another capacity step, more is needed. If companies are to restart the rapid growth in HDD areal density and capacity, EAMR technologies are needed.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

Alvar "Miles" Udell Have to wonder if the 5.25" form factor could make a comeback. Given advances in computer machining tolerances as well as higher density, platter count, multiple read actuators, and RAID allowing for lower RPM while retaining throughput, I think it could work in the enterprise market.Reply -

USAFRet "density growth slows"Reply

Well, yeah.

1TB to 2TB is 100% growth.

16TB to 20TB is 25% growth. -

InvalidError Reply

3.5" HDDs are the go-to size because it is the optimal choice between density and reliability. If you make platters larger, they also need to be thicker to maintain the necessary stiffness all the way to the edge. Since the moment of inertia scales with the fourth power of radius, making the platters 50% larger by diameter would require making them ~4X as strong unless you lower the RPMs. The performance and density would take a substantial hit. Everything being 50% bigger and 70-150% heavier will put that much extra strain on motors, drivers, bearings, etc. too.Alvar Miles Udell said:Have to wonder if the 5.25" form factor could make a comeback. Given advances in computer machining tolerances as well as higher density, platter count, multiple read actuators, and RAID allowing for lower RPM while retaining throughput, I think it could work in the enterprise market.

The biggest problem with 8+TB drives is the time it takes to rebuild an array: if you average 100MB/s, you are looking at 22+h in downgraded status, possibly several times more depending on how much usage still needs to be served while the rebuild is in progress. The very concept of 20+TB spinning drives sounds almost like data genocide. You need some serious redundancy to use these with any degree of confidence. -

hasten CPU Manufacturers arent advertising clock speed you say?Reply

"Core i9-12900KS World Record: How I Hit 7.8 GHz on 8 Cores"

"Intel Alder Lake-HX Leak: 16 Cores, 5 GHz Boost Clock"

Must be better for clicks than selling cpus ;)! -

pug_s ReplyAlvar Miles Udell said:Have to wonder if the 5.25" form factor could make a comeback. Given advances in computer machining tolerances as well as higher density, platter count, multiple read actuators, and RAID allowing for lower RPM while retaining throughput, I think it could work in the enterprise market.

I doubt it. I recall the last company which made 5.25 factor of hard drives was Quantum bigfoot drives. They are extremely slow which ran 3600 rpm while 3.5 drives ran 5400 rpm.