XFX unveils Radeon RX 7900 XTX Phoenix Nirvana graphics card with phase-change thermal pad

Another Radeon RX 7900 XTX on the market.

XFX has quietly introduced the Radeon RX 7900 XTX Phoenix Nirvana graphics card that comes with a huge 3.5-wide slot cooling system and an innovative thermal pad made of phase-change (PCM) material (via VideoCardz). The new card — which can well become one of the world's best graphics cards — is available in China, though it is unclear why XFX decided to release a new Radeon RX 7900 XTX graphics board 1.5 years after the launch of the GPU.

The card has a 17-phase digital voltage regulating module and is equipped with three eight-pin auxiliary PCIe power connectors. These connectors are meant to deliver up to 450W of power, a decent amount of power that will be instrumental for overclocking the graphics processor.

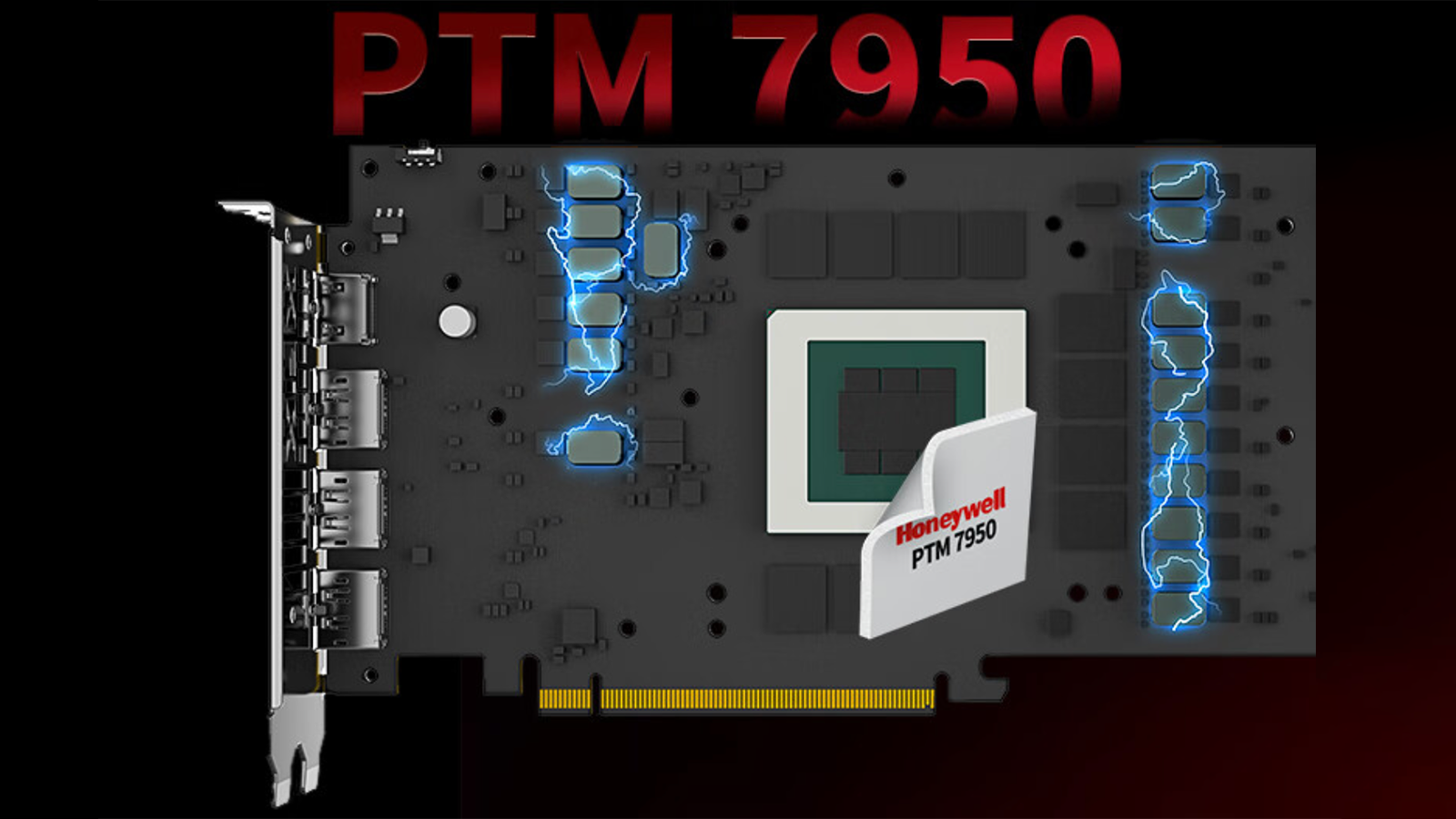

Speaking of overclocking, the XFX Radeon RX 7900 XTX Phoenix Nirvana is outfitted with a huge 3.5-wide cooling system with a vapor chamber, eight 6-mm heat pipes, and 216 aluminum fins. One of the standout features of this cooler is Honeywell's PTM7950 thermal pad, which is made of a phase-change material designed to ensure the best thermal conductivity possible.

This PCM thermal pad from Honeywell could be one of the reasons why XFX decided to launch this graphics card this late in the lifecycle of AMD's Radeon RX 7900 XTX product and Navi 31 graphics processor. By launching this add-in-board, XFX can test how Honeywell's PTM7950 performs and whether it is a good thermal interface for a high-volume product. If XFX is satisfied with the results, it can start using PTM7950 for higher volumes of products and get a competitive advantage over rivals.

Just like other Radeon RX 7900 XTX graphics cards, XFX's Radeon RX 7900 XTX Phoenix Nirvana board is based on AMD's Navi 31 graphics processor with 6144 stream processors and 24 GB of memory. The GPU is clocked at up to 2615 MHz, which isn't the highest frequency in the industry.

As for display outputs, just like many other Radeon RX 7900 XTX graphics boards, XFX's Radeon RX 7900 XTX Phoenix Nirvana has three DisplayPort 2.1 connectors and one HDMI 2.0 connector. The card is now available in China, but it isn't clear when, or if, it will come to Western markets.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

Notton I'm surprised more makers haven't switched over to PTM7950 already.Reply

It'll last the lifetime of the GPU/laptop/etc. It works almost as good as liquid metal, but without any of the risks. -

mac_angel 8.5 W/m.k, that's not that high compared to many other thermal pad makers on the market. What am I missing?Reply -

Notton Reply

W/mk is a useless measurement, because there's no standard.mac_angel said:8.5 W/m.k, that's not that high compared to many other thermal pad makers on the market. What am I missing?

_kzGTOyCYrY -

Alpha_Lyrae Reply

You're missing the pump-out effect of most high W/m.k pastes that inevitably cause high hotspot temperatures, throttling, and/or instability when trying to OC (or UV/OC). This is also phase-change, so it liquefies at high temps and solidifies at low temps. Other pads may still have hotspot issues as well. Graphite pads, for example, can be difficult to place without an adhesive side to affix it. Many don't fill in gaps unless mounting pressure is very high or the pad is very soft. I don't think Navi 31's packaging is compatible with crazy high mounting pressures. Something will probably break. Graphite pads often advertise high W/m.k numbers too, but can see higher operating temps if mating is not 100% correct.mac_angel said:8.5 W/m.k, that's not that high compared to many other thermal pad makers on the market. What am I missing?

PTM7950 (and its usually decent copies) generally solves this issue and also provides a much more stable thermal interface that tends to fill in gaps and any unevenness from cold plate manufacturing to provide better overall temps. This leads to improved stability and can help UV/OC stability as well (due to lower hotspot temps).