Intel Shows How A CPU Is Made

Intel released a press kit that visually explains how a CPU is made and reveals all the major steps in a process that normally takes hundreds of stages to complete. Check out the engineering magic!

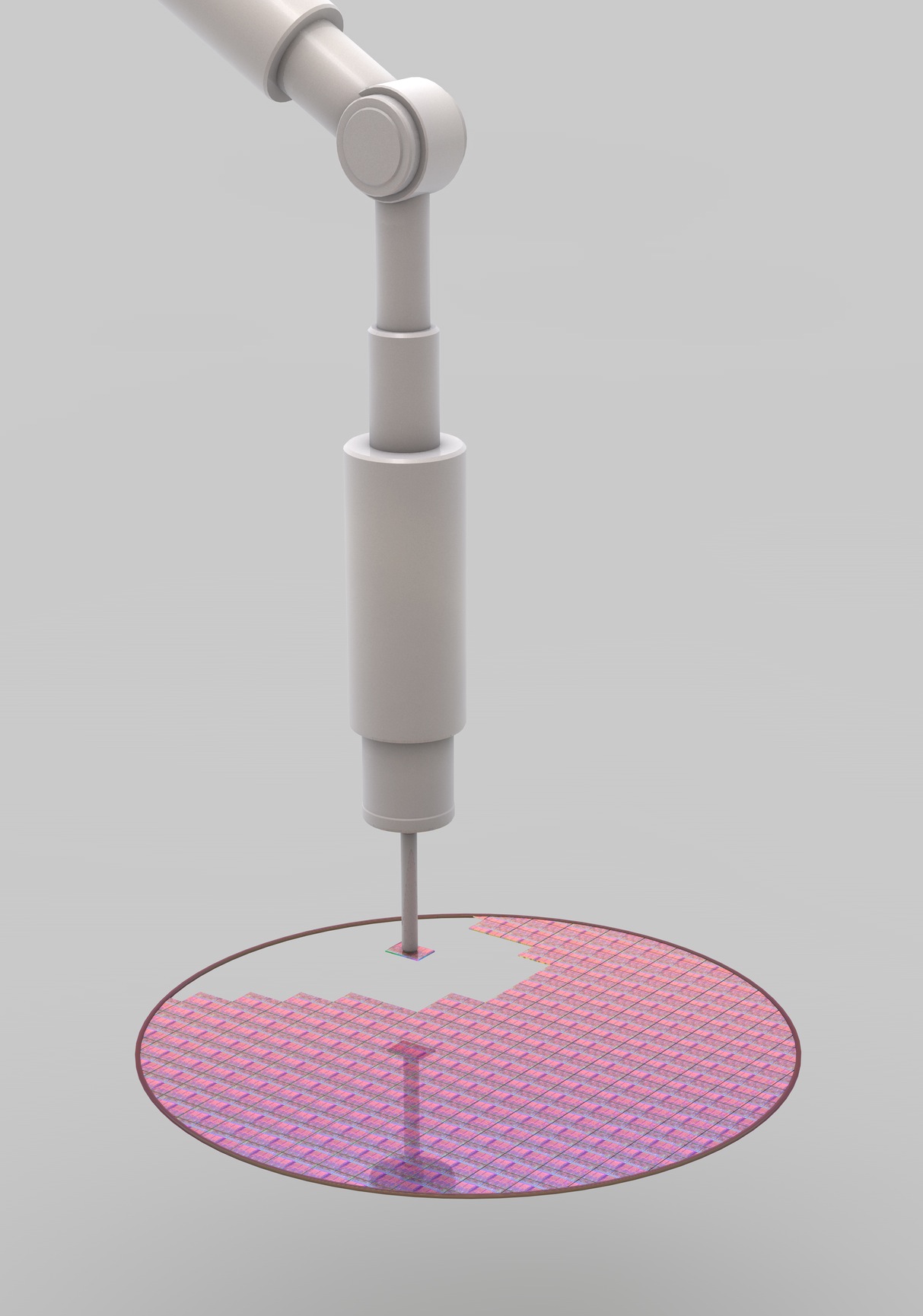

The Good, The Bad, The Ugly

The dies that responded with the right answer to the test pattern will be put forward for the next step (packaging). Bad dies are discarded. Several years ago, Intel made key chains out of bad CPU dies.

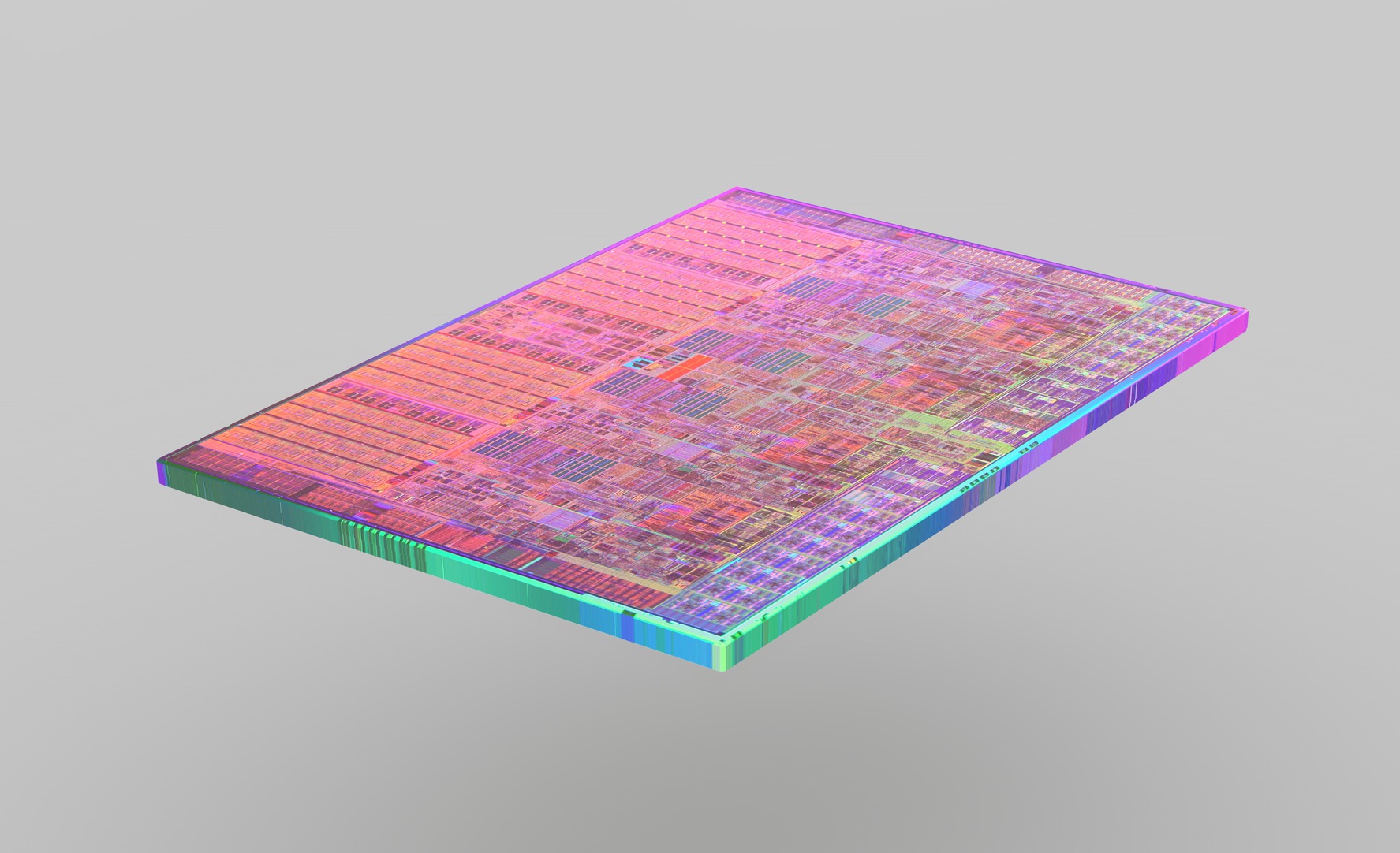

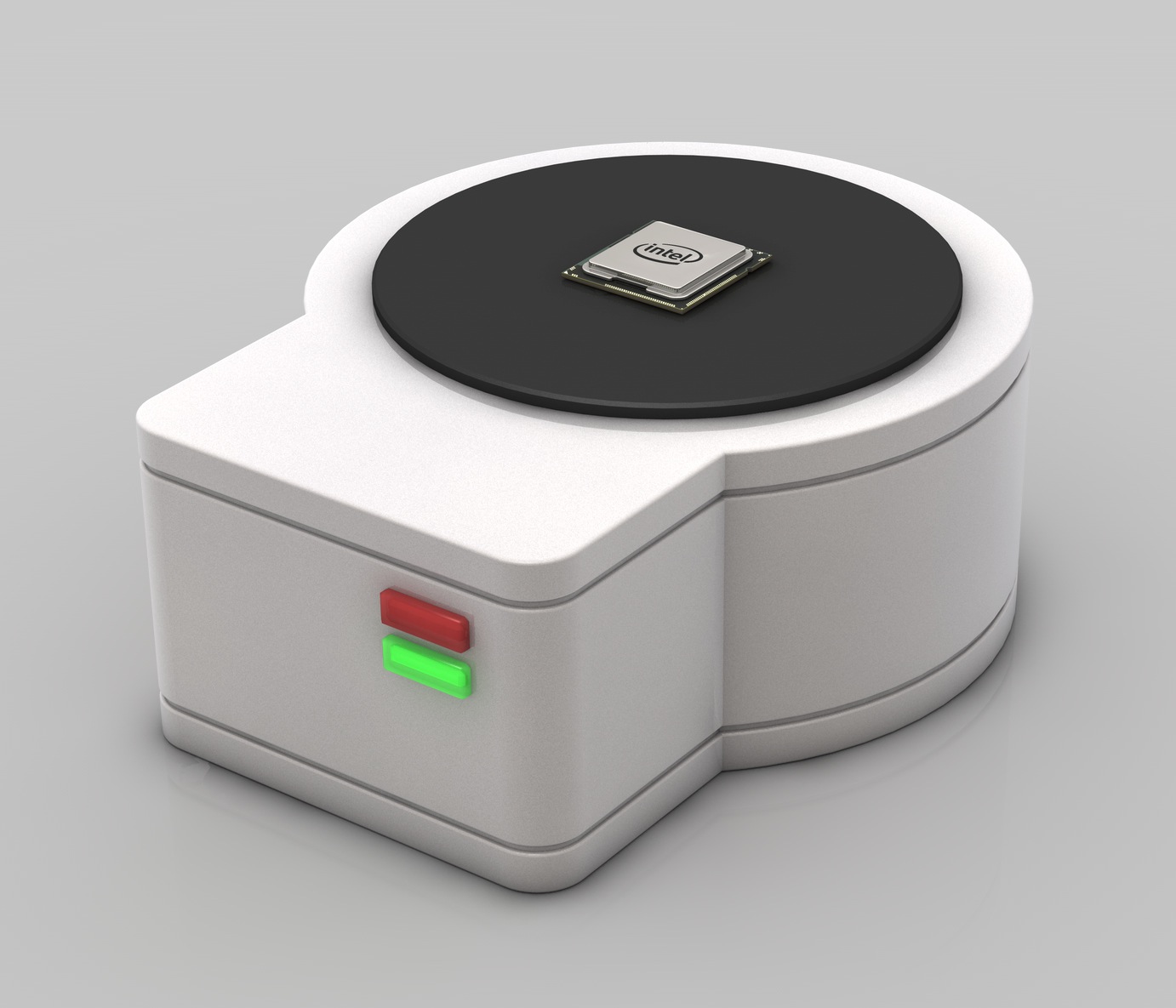

Individual Die

This is an individual die, which has been cut out in the previous step (slicing). The die shown here is a die of an Intel Core i7 processor.

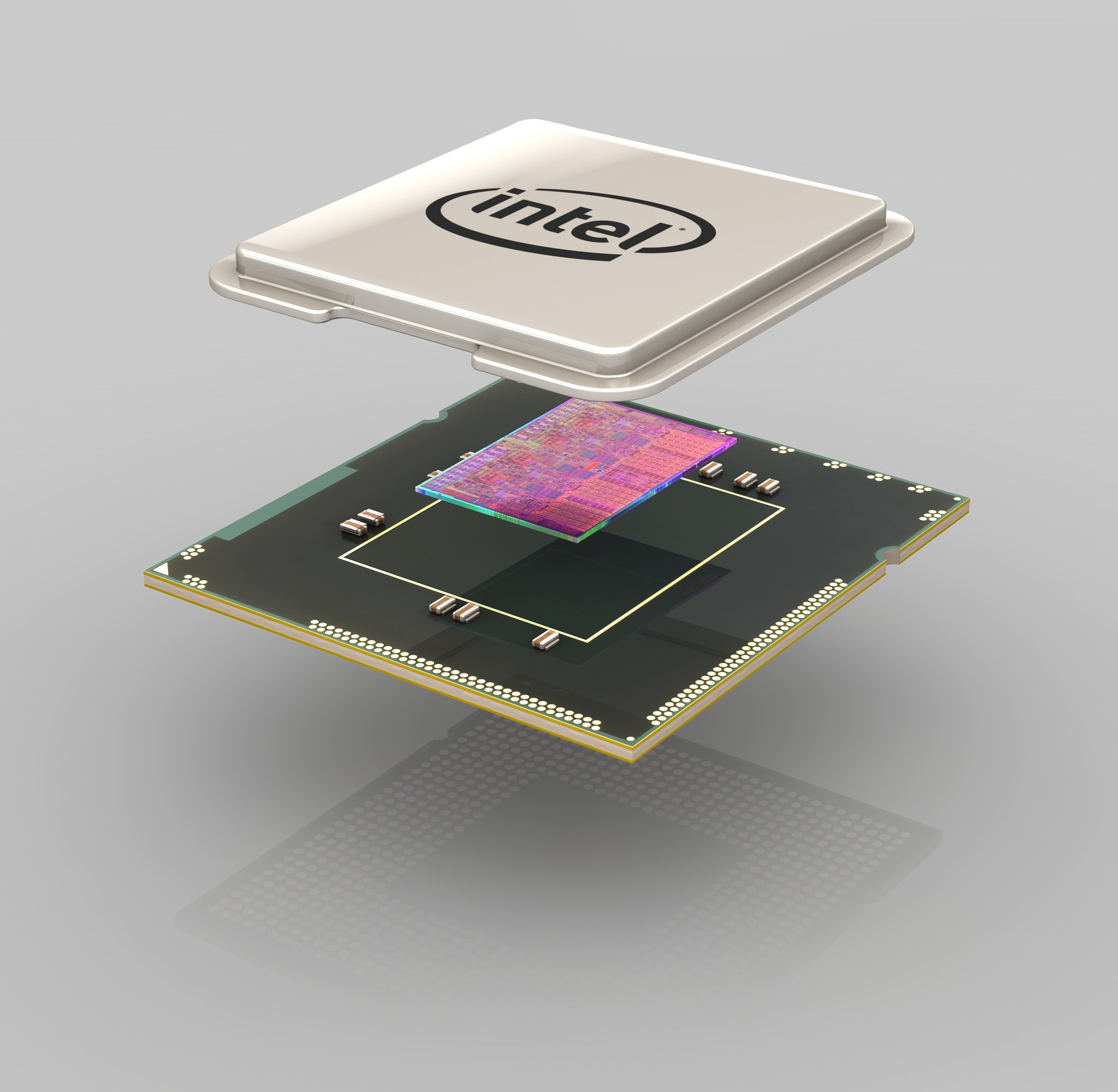

CPU Packaging

The substrate, the die, and the heatspreader are put together to form a completed processor. The green substrate builds the electrical and mechanical interface for the processor to interact with the rest of the PC system. The silver heatspreader is a thermal interface where a cooling solution will be applied. This will keep the processor cool during operation.

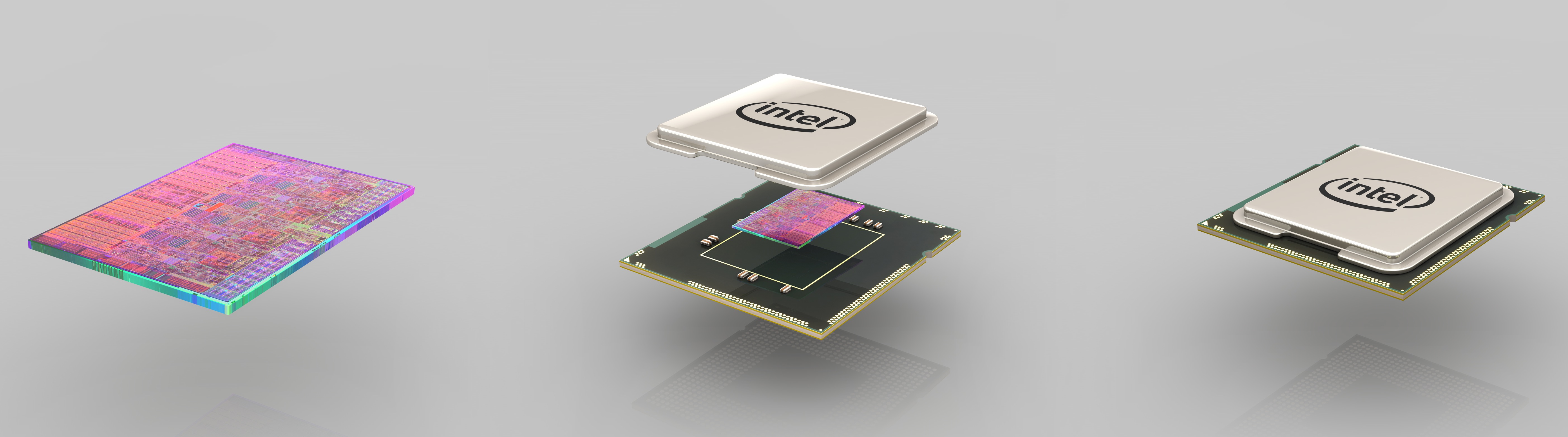

A Finished CPU

A microprocessor is the most complex manufactured product on earth. In fact, it takes hundreds of steps and only the most important ones have been visualized in this picture story.

CPU Testing

During this final test the processors will be tested for their key characteristics (among the tested characteristics are power dissipation and maximum frequency).

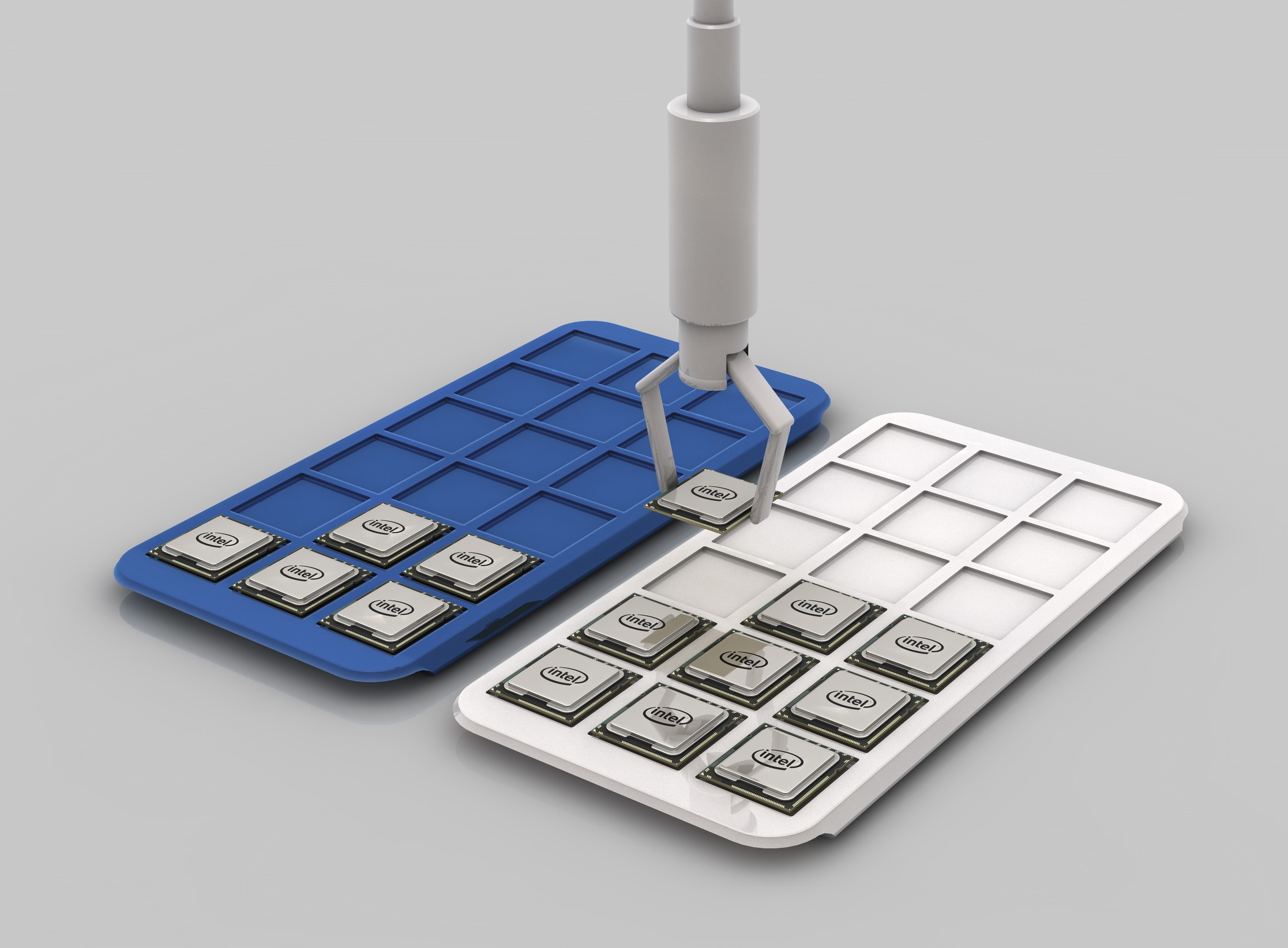

CPU Binning

Based on the test result of class testing processors with the same capabilities are put into the same transporting trays. This process is called "binning," a process with which many Tom's Hardware readers will be familiar. Binning determines the maximum operating frequency of a processor, and batches are divided and sold according to stable specifications.

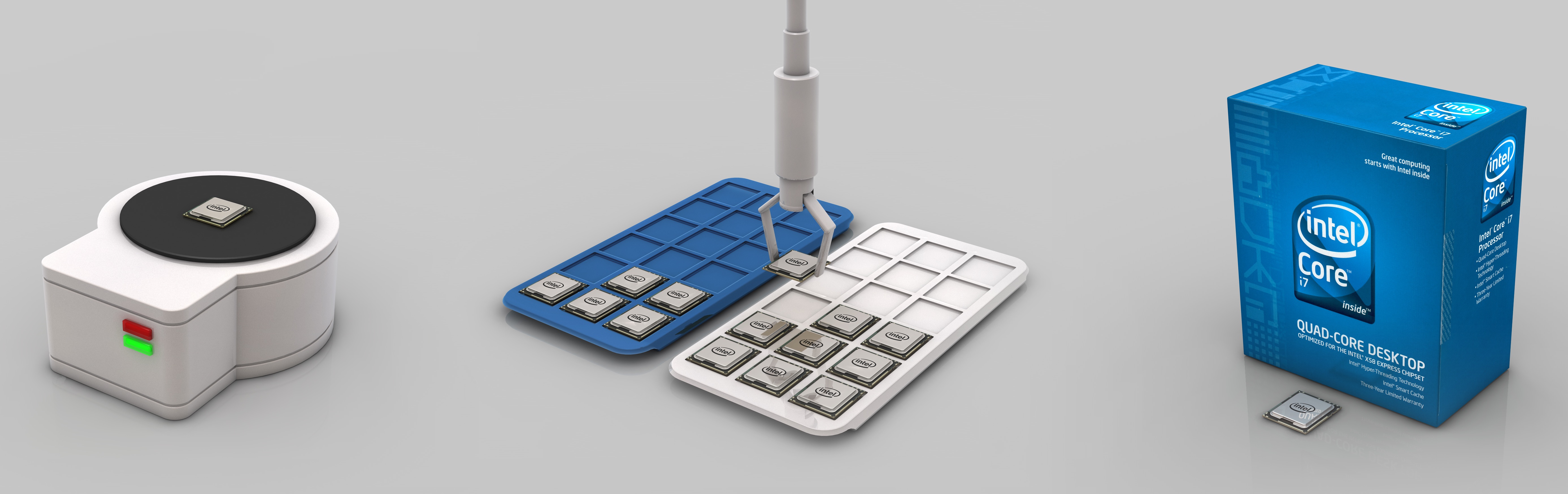

Off To The Stores

The manufactured and tested processors (again Intel Core i7 processor is shown here) either go to system manufacturers in trays or into retail stores in a box.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Many thanks to Intel for supplying the text and photos in this picture story. Check out Intel's site for full size images of this entire process.

-

tacoslave http://cgi.ebay.com/Collectable-INTEL-Microchip-Keychain-w/-CPU-Steel-rope_W0QQitemZ360155521483QQcmdZViewItemReply

i want one of those keychains!! -

dmv915 tacoslavehttp://cgi.ebay.com/Collectable-IN dZViewItemi want one of those keychains!!Lol, this wouldn't happen to be your auction eh?Reply -

Bloodblender Saw this on APC's website, lol, pretty interesting stuff, but hey, at least Intel and AMD have got plenty of resources (sand) to keep making processors!Reply -

annihilator-x- Instead of 'sand' is the second most frequent chemical element, the article should say 'Silicon' is the second most abundant chemical element.Reply

Abundant is a better word as well as the fact that sand is mostly quartz among impurities and other minerals. Quartz itself is Silicon Dioxide crystals. -

nonamelab A little late Intel :) http://www.globalfoundries.com/multimedia/video/from_sand_to_chipReply -

rickzor I already know that a cpu can die due to overheat deteoration or due to electromigration, but that happens all during use. I always wondered how many years could a cpu or any other chip survive if always turned off!Reply

Maybe if turn off and praticly never used, our descendents could find perfectly working exemplars of our primitive cpus after what...2000 years or more!

Ah sorry about the relatively off topic subject, that's the efect of Life after people series on History Channel! -

Ryun nonamelabA little late Intel http://www.globalfoundries.com/mul nd_to_chipReply

Both of them were great. Thanks for the article, Toms, and thank you for the link.