Intel Shows How A CPU Is Made

Intel released a press kit that visually explains how a CPU is made and reveals all the major steps in a process that normally takes hundreds of stages to complete. Check out the engineering magic!

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Your CPU Came From Sand

Sand. Made up of 25 percent silicon, is, after oxygen, the second most abundant chemical element that's in the earth's crust. Sand, especially quartz, has high percentages of silicon in the form of silicon dioxide (SiO2) and is the base ingredient for semiconductor manufacturing.

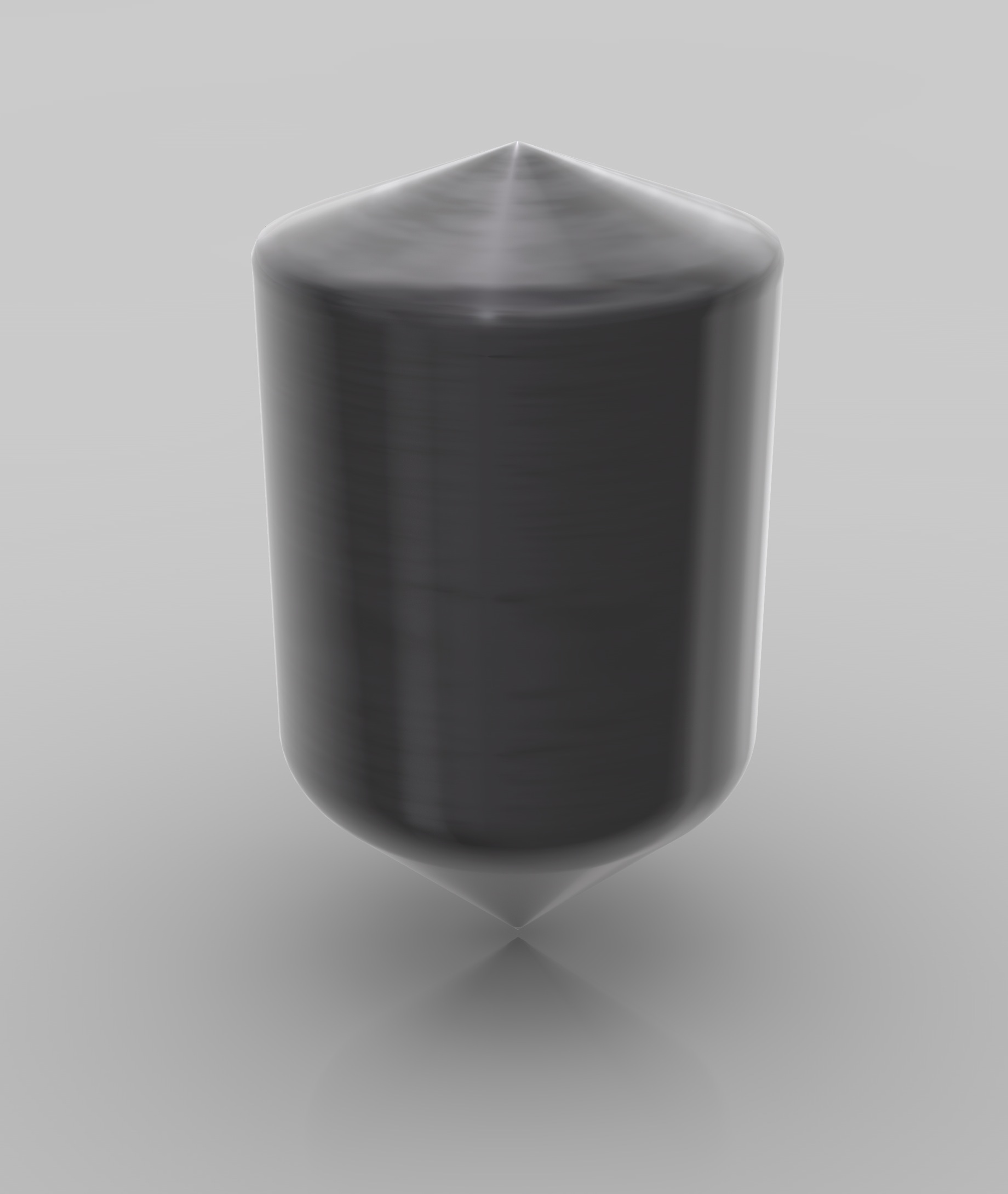

Purification and Growing

After procuring raw sand and separating the silicon, the excess material is disposed of and the silicon is purified in multiple steps to finally reach semiconductor manufacturing quality which is called electronic grade silicon. The resulting purity is so great that electronic grade silicon may only have one alien atom for every one billion silicon atoms. After the purification process, the silicon enters the melting phase. In this picture you can see how one big crystal is grown from the purified silicon melt. The resulting mono-crystal is called an ingot.

A Big Ingot

A mono-crystal ingot is produced from electronic grade silicon. One ingot weighs approximately 100 kilograms (or 220 pounds) and has a silicon purity of 99.9999 percent.

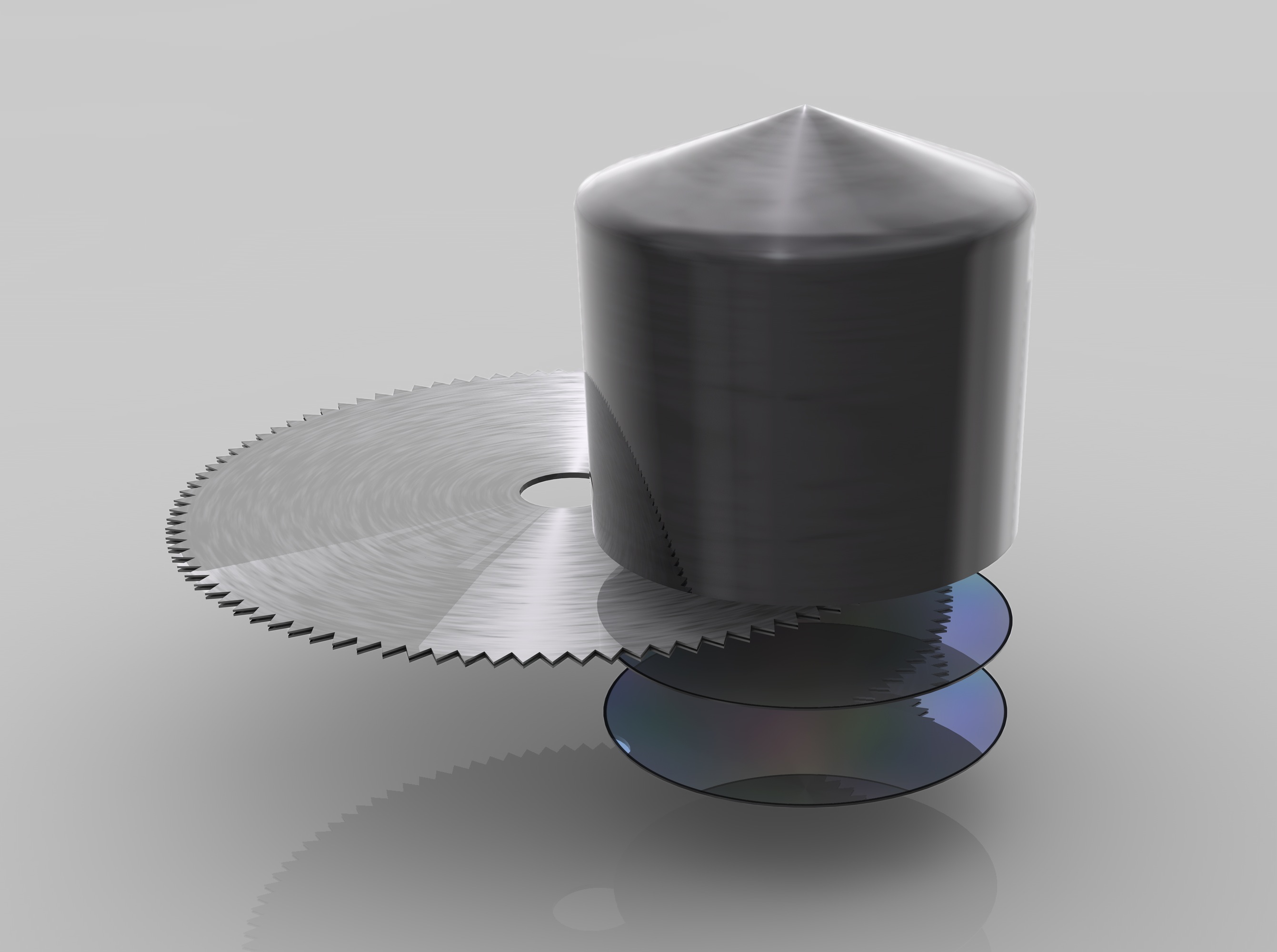

Ingot Slicing

The ingot is then moved onto the slicing phase where individual silicon discs, called wafers, are sliced thin. Some ingots can stand higher than five feet. Several different diameters of ingots exist depending on the required wafer size. Today, CPUs are commonly made on 300 mm wafers.

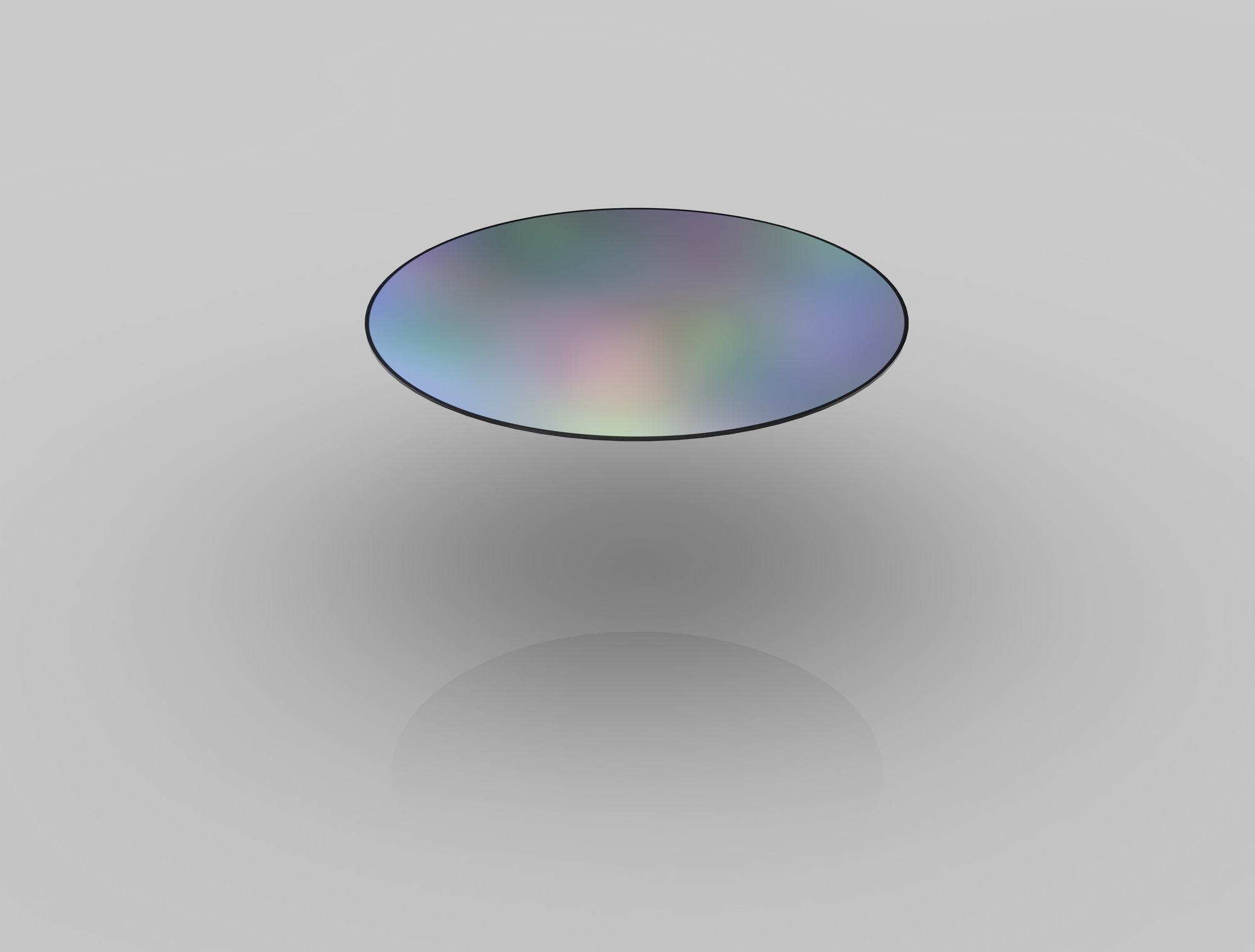

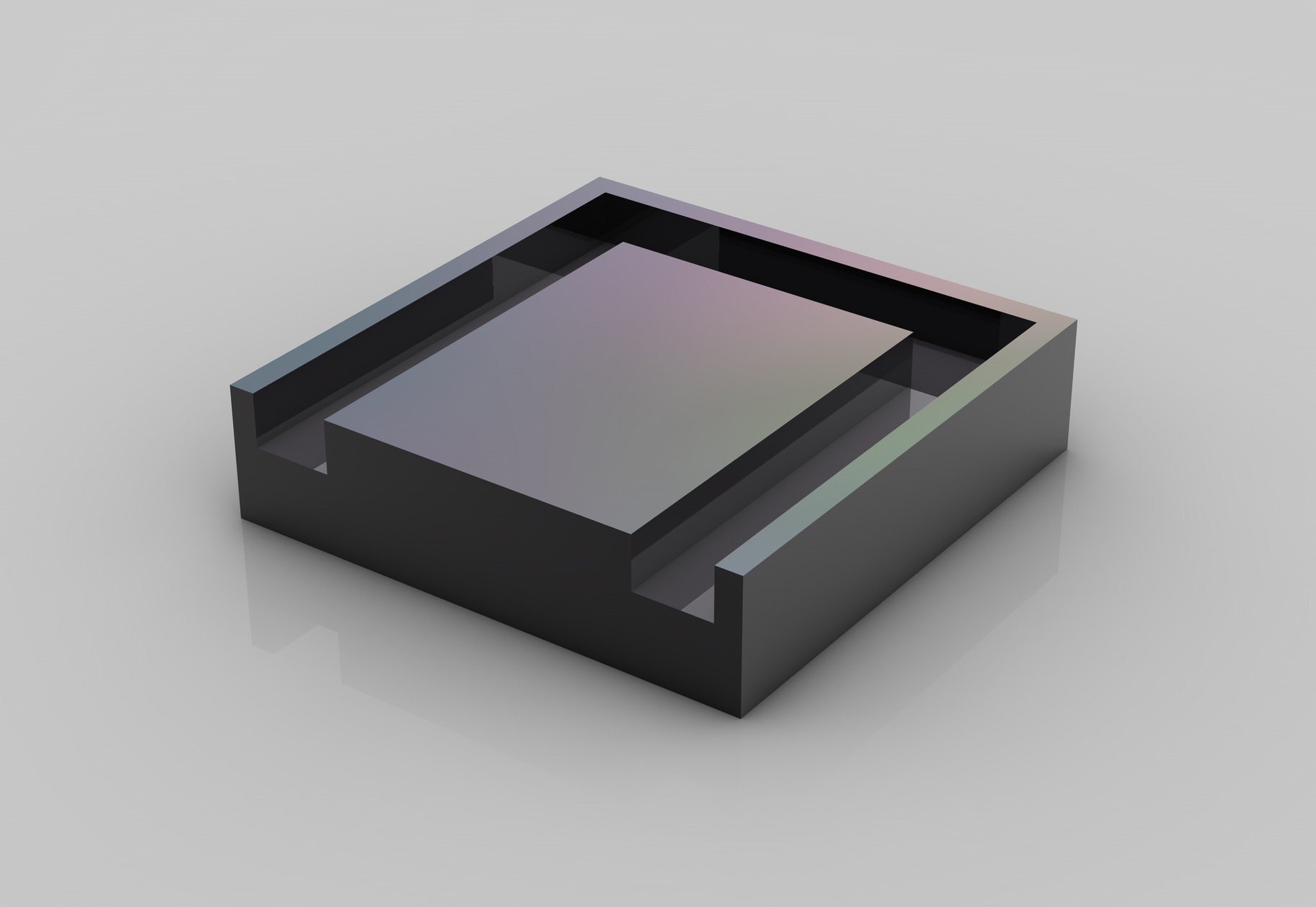

Wafer Polishing

Once cut, the wafers are polished until they have flawless, mirror-smooth surfaces. Intel doesn't produce its own ingots and wafers, and instead purchases manufacturing-ready wafers from third-party companies. Intel’s advanced 45 nm High-K/Metal Gate process uses wafers with a diameter of 300 mm (or 12-inches). When Intel first began making chips, it printed circuits on 50 mm (2-inches) wafers. These days, Intel uses 300 mm wafers, resulting in decreased costs per chip.

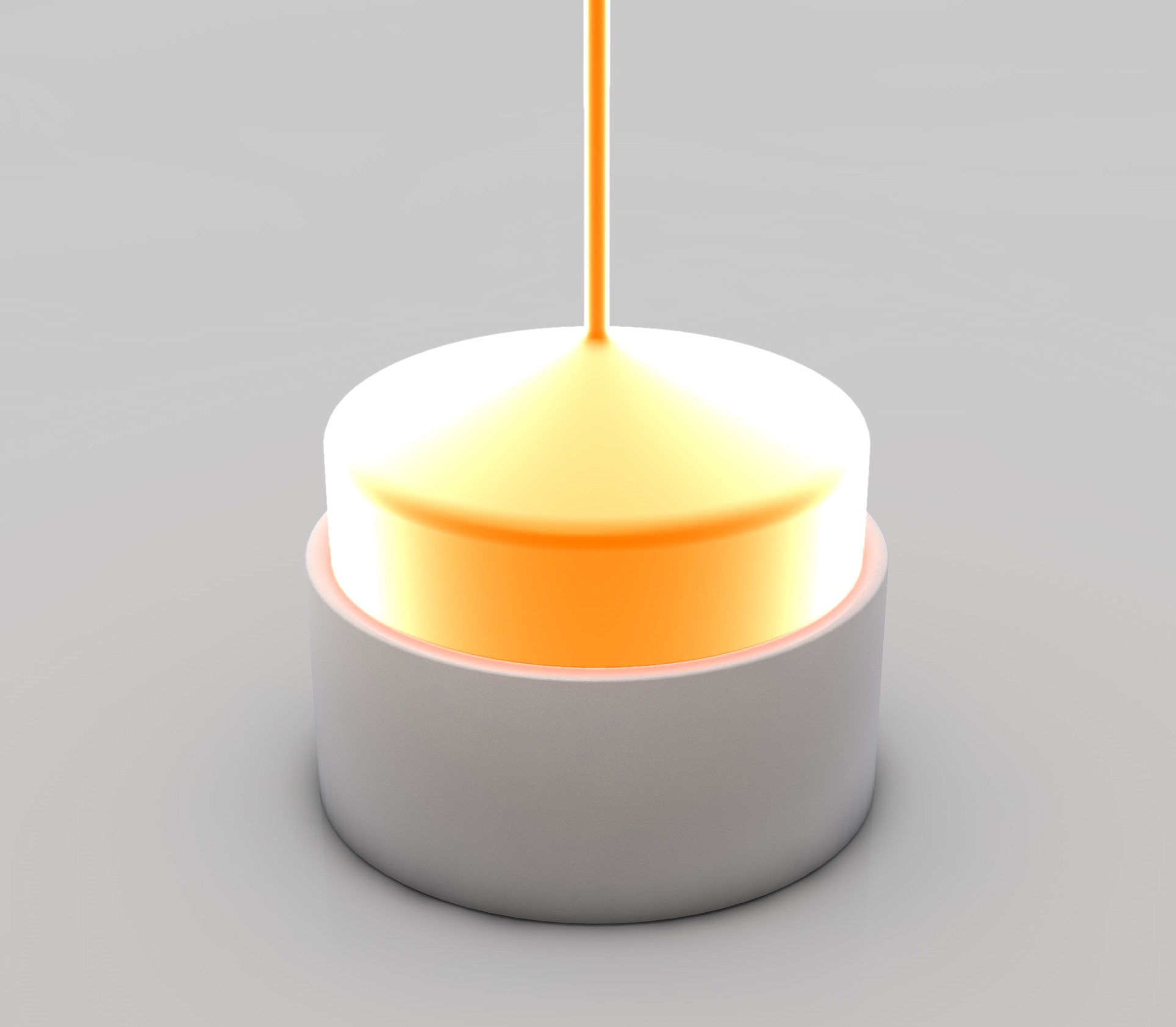

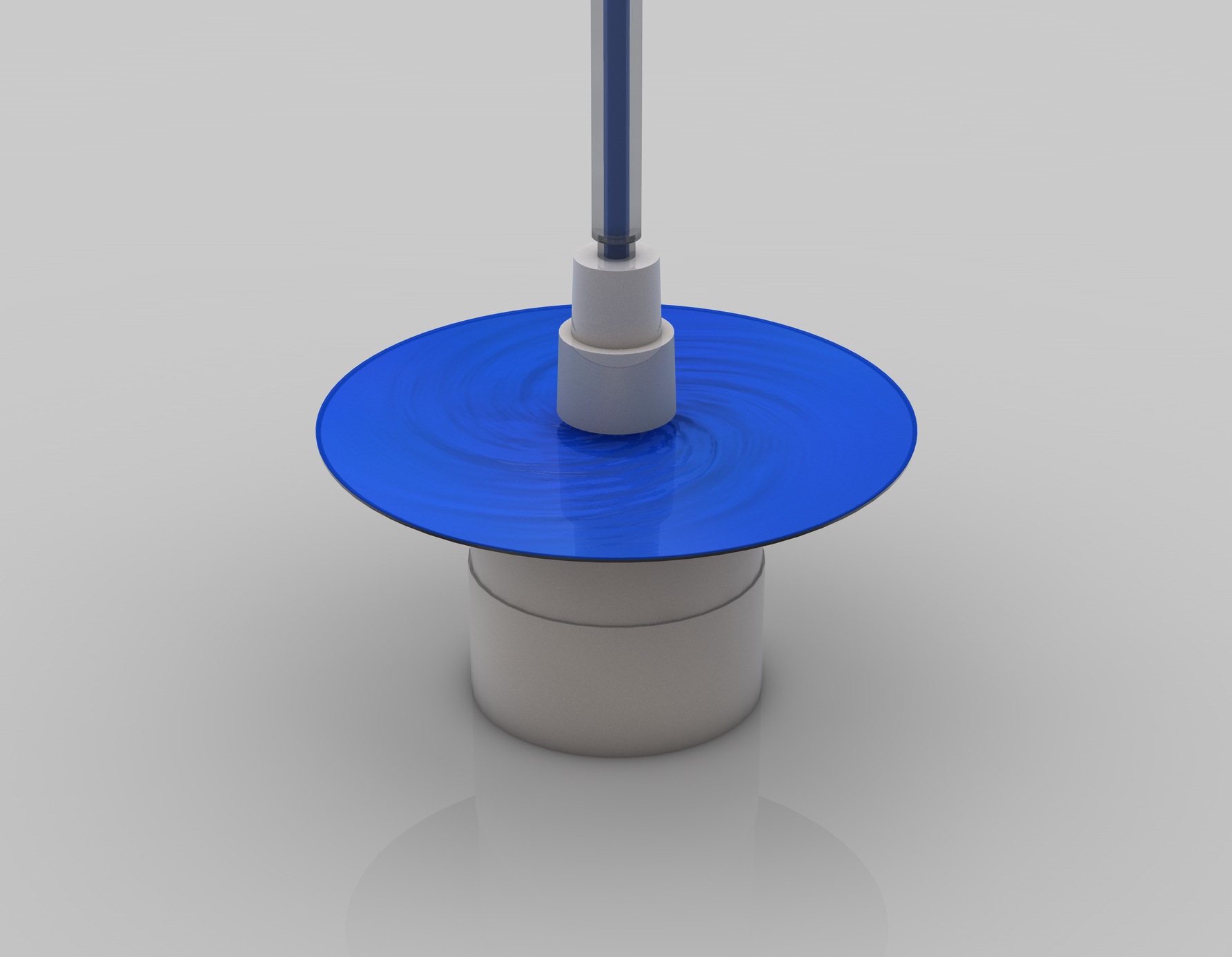

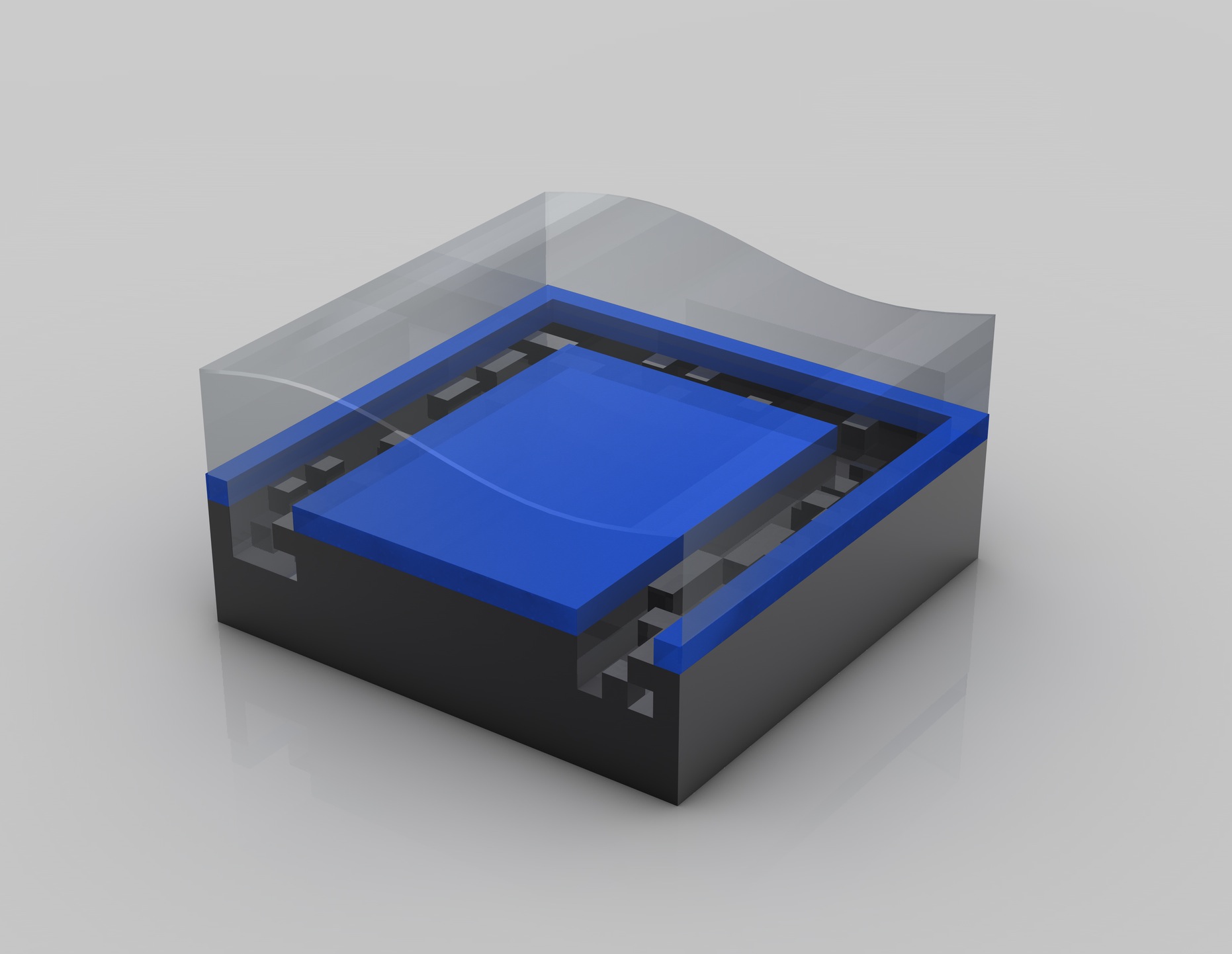

Photo Resist Application

The blue liquid, depicted above, is a photo resist finish similar to those used in film for photography. The wafer spins during this step to allow an evenly-distributed coating that's smooth and also very thin.

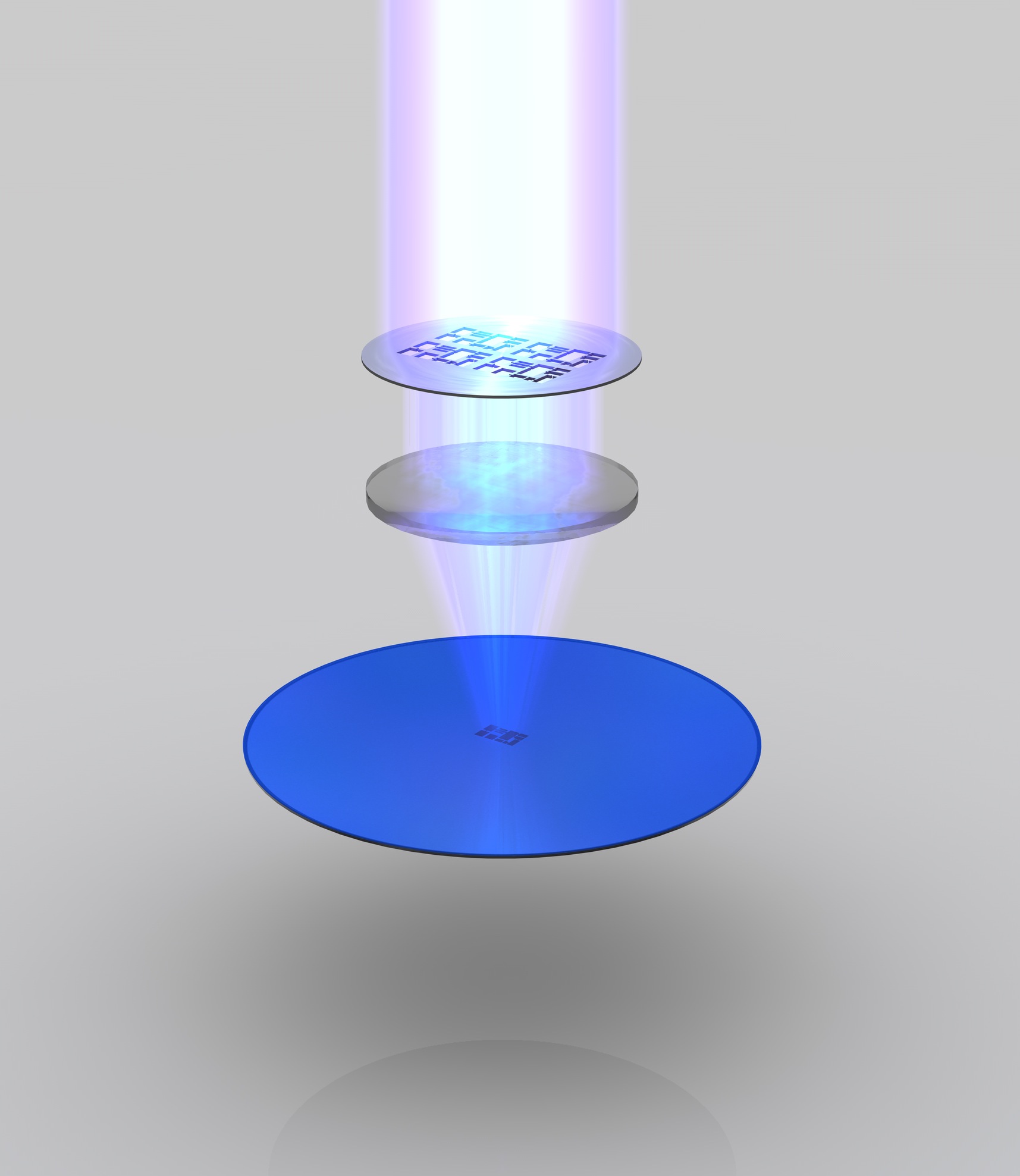

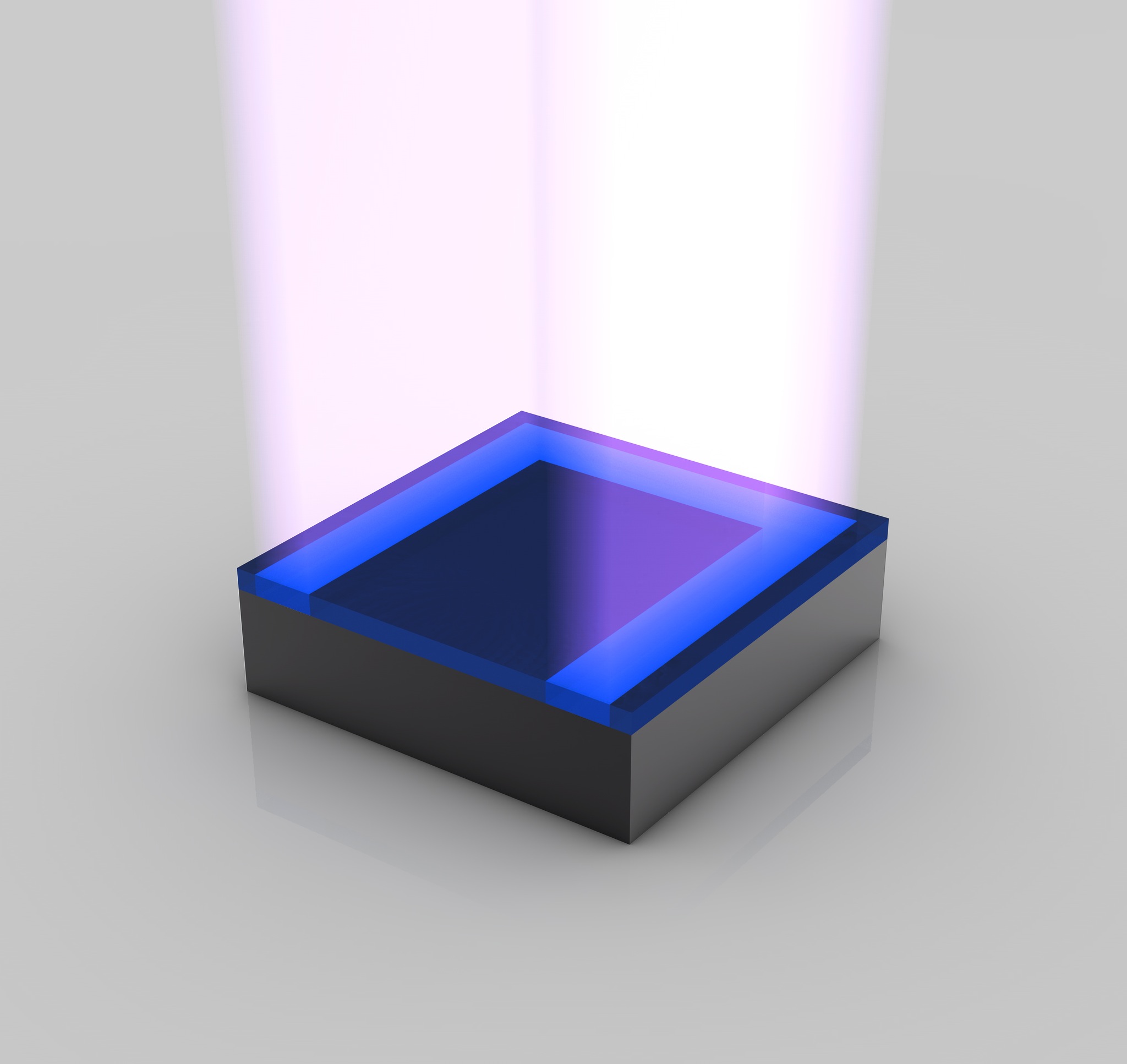

UV Light Exposure

At this stage, the photo-resistant finish is exposed to ultra violet (UV) light. The chemical reaction triggered by the UV light is similar to what happens to film material in a camera the moment you press the shutter button.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Areas of the resist on the wafer that have been exposed to UV light will become soluble. The exposure is done using masks that act like stencils. When used with UV light, masks create the various circuit patterns. The building of a CPU essentially repeats this process over and over until multiple layers are stacked on top of each other.

A lens (middle) reduces the mask's image to a small focal point. The resulting "print" on the wafer is typically four times smaller, linearly, than the mask's pattern.

More Exposing

In the picture we have a representation of what a single transistor would appear like if we could see it with the naked eye. A transistor acts as a switch, controlling the flow of electrical current in a computer chip. Intel researchers have developed transistors so small that they claim roughly 30 million of them could fit on the head of a pin.

Photo Resist Washing

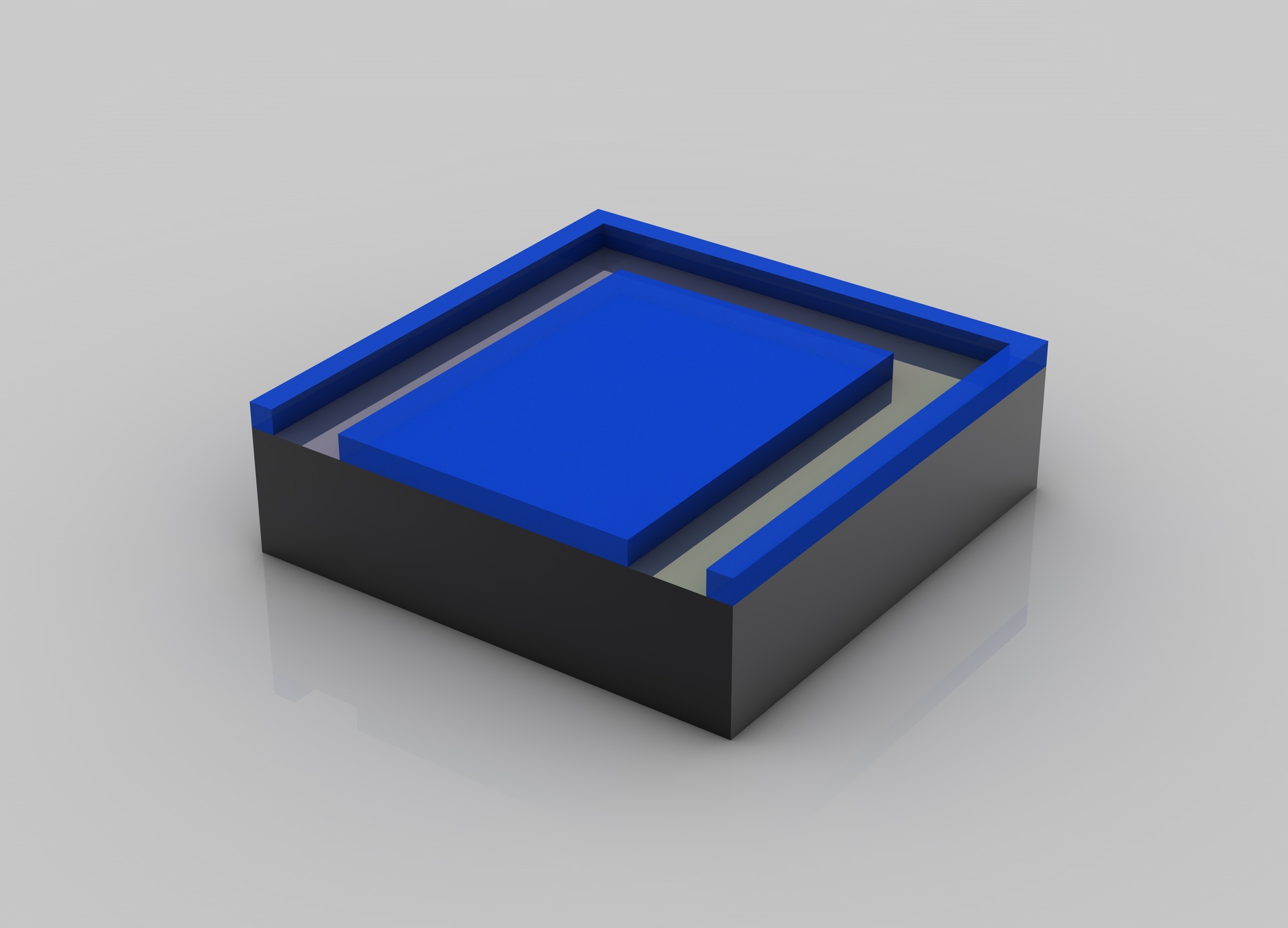

After being exposed to UV light, the exposed blue photo resist areas are completely dissolved by a solvent. This reveals a pattern of photo resist made by the mask. The beginnings of transistors, interconnects, and other electrical contacts begin to grow from this point.

Etching

The photo resist layer protects wafer material that should not be etched away. Areas that were exposed will be etched away with chemicals.

Photo Resist Removal

After the etching, the photo resist is removed and the desired shape becomes visible.

-

tacoslave http://cgi.ebay.com/Collectable-INTEL-Microchip-Keychain-w/-CPU-Steel-rope_W0QQitemZ360155521483QQcmdZViewItemReply

i want one of those keychains!! -

dmv915 tacoslavehttp://cgi.ebay.com/Collectable-IN dZViewItemi want one of those keychains!!Lol, this wouldn't happen to be your auction eh?Reply -

Bloodblender Saw this on APC's website, lol, pretty interesting stuff, but hey, at least Intel and AMD have got plenty of resources (sand) to keep making processors!Reply -

annihilator-x- Instead of 'sand' is the second most frequent chemical element, the article should say 'Silicon' is the second most abundant chemical element.Reply

Abundant is a better word as well as the fact that sand is mostly quartz among impurities and other minerals. Quartz itself is Silicon Dioxide crystals. -

nonamelab A little late Intel :) http://www.globalfoundries.com/multimedia/video/from_sand_to_chipReply -

rickzor I already know that a cpu can die due to overheat deteoration or due to electromigration, but that happens all during use. I always wondered how many years could a cpu or any other chip survive if always turned off!Reply

Maybe if turn off and praticly never used, our descendents could find perfectly working exemplars of our primitive cpus after what...2000 years or more!

Ah sorry about the relatively off topic subject, that's the efect of Life after people series on History Channel! -

Ryun nonamelabA little late Intel http://www.globalfoundries.com/mul nd_to_chipReply

Both of them were great. Thanks for the article, Toms, and thank you for the link.