UK company shoots a 1000-degree furnace into space to study off-world chip manufacturing — semiconductors made in space could be 'up to 4,000 times purer' than Earthly equivalents

One small step for chips, one giant leap for a lack of impurities.

A team from Cardiff, Wales, is experimenting with the feasibility of building semiconductors in space, and its most recent success is another step forward towards its goal. According to the BBC, Space Forge’s microwave-sized furnace has been switched on in space and has reached 1,000°C (1,832°F) — one of the most important parts of the manufacturing process that the company needs to validate in space.

“This is so important because it’s one of the core ingredients that we need for our in-space manufacturing process,” Payload Operations Lead Veronica Vera told the BBC. “So being able to demonstrate this is amazing.” Semiconductor manufacturing is a costly and labor-intensive endeavor on Earth, and while putting it in orbit might seem far more complicated, making chips in space offers some theoretical advantages. For example, microgravity conditions would help the atoms in semiconductors line up perfectly, while the lack of an atmosphere would also reduce the chance of contaminants affecting the wafer.

These two things would help reduce imperfections in the final wafer output, resulting in a much more efficient fab. “The work that we’re doing now is allowing us to create semiconductors up to 4,000 times purer in space than we can currently make here today,” Space Forge CEO Josh Western told the publication. “This sort of semiconductor would go on to be in the 5G tower in which you get your mobile phone signal, it’s going to be in the car charger you plug an EV into, it’s going to be in the latest planes.”

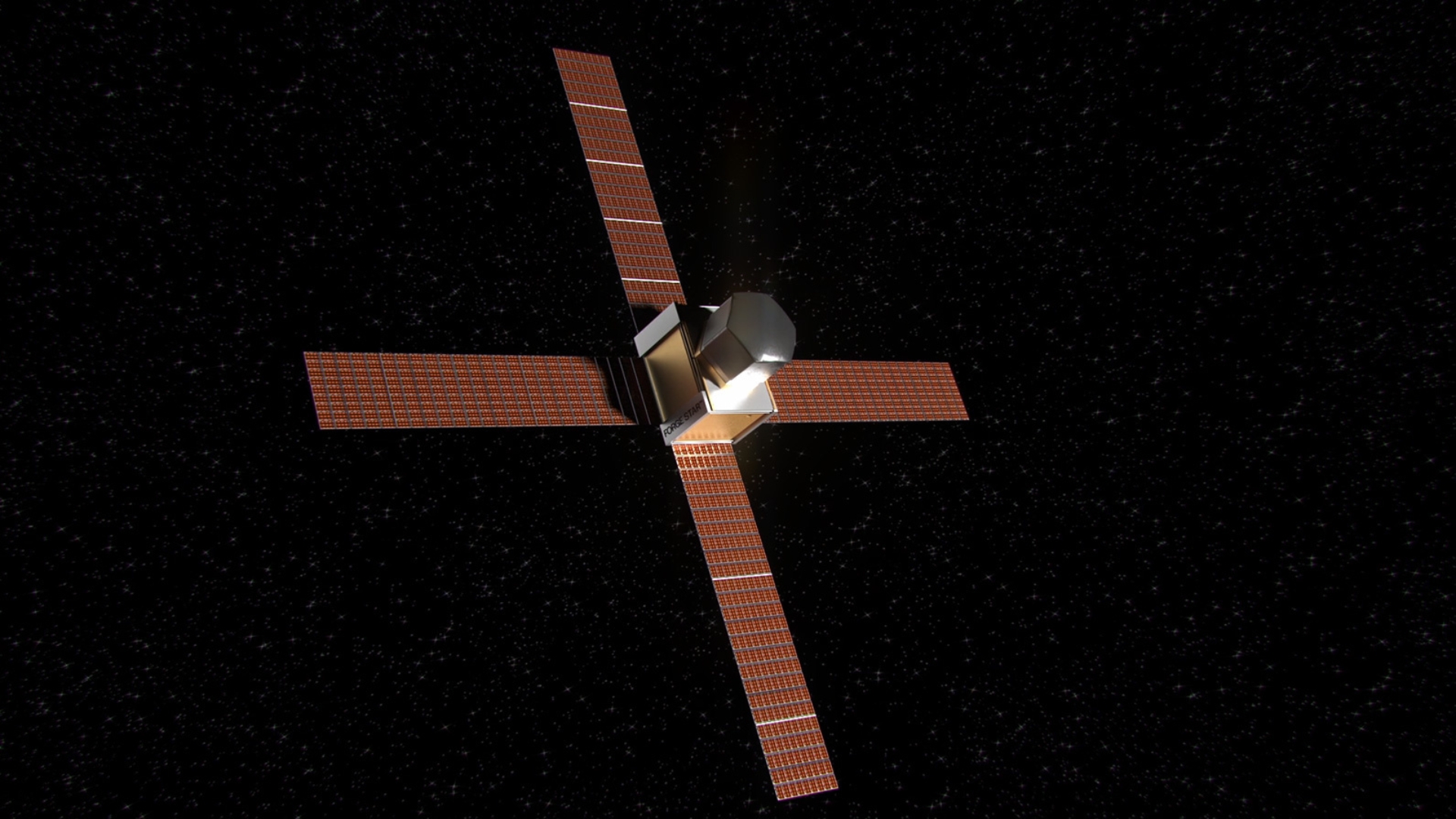

Space Forge launched its first satellite in June 2025, hitching a ride on the SpaceX Transporter-14 rideshare mission. However, it still took the company several months before it finally succeeded in turning on its furnace, showing how complicated this project can get. Nevertheless, this advancement is quite promising, with Space Forge planning to build a bigger space factory with the capacity to output 10,000 chips. Aside from that, it also needs to work on a way to bring the finished products back to the surface. Other companies are also experimenting with orbital fabs, with U.S. startup Besxar planning to send “Fabships” into space on Falcon 9 booster rockets.

Putting semiconductor manufacturing in space could help reduce the massive amounts of power and water that these processes require from our resources while also outputting more wafers with fewer impurities. However, we also have to consider the huge environmental impact of launching multiple rockets per day just to deliver the raw materials and pick up the finished products from orbit.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Jowi Morales is a tech enthusiast with years of experience working in the industry. He’s been writing with several tech publications since 2021, where he’s been interested in tech hardware and consumer electronics.

-

cyrusfox Sounds wildly optimistic. Even if the physics checks out, how do you realistically supply the tools, materials, power, and maintenance in orbit at any scale that matters economically?Reply