LCD Juggernaut: Tom's Hardware Looks Into Samsung's Seoul

Panelpalooza!

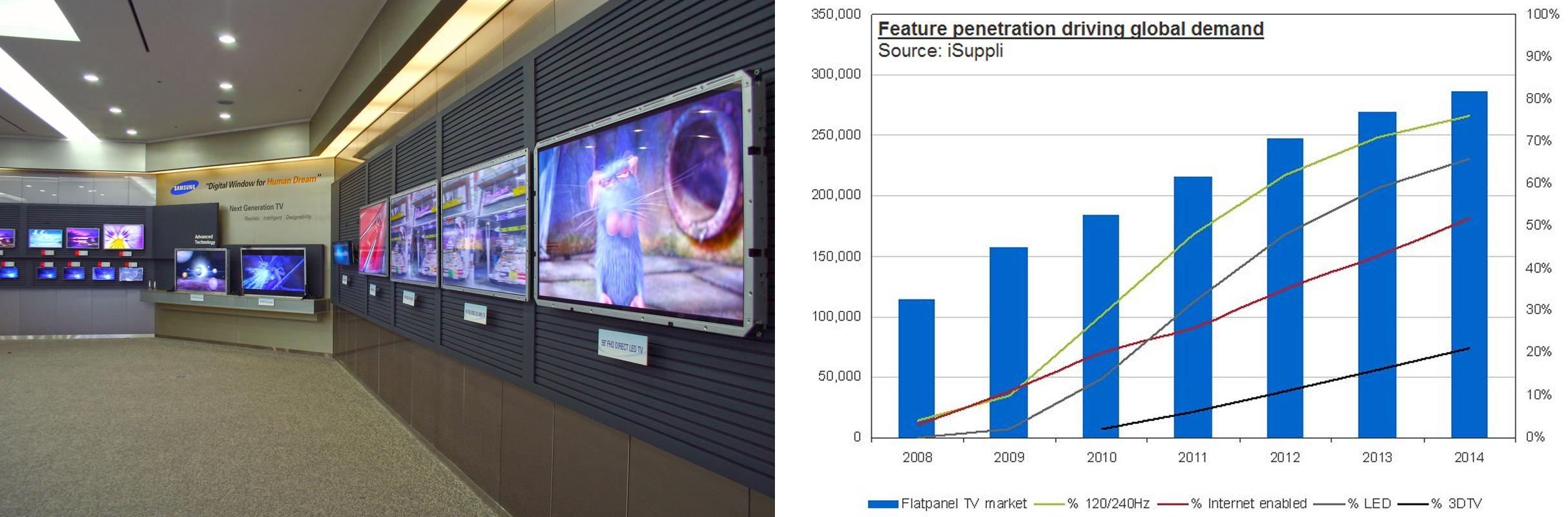

Stepping inside the fab building (I think it was L8-1), we took a hard left into the LCD business’s showroom. If you dig displays, this is like being a 10-year-old walking into a candy store. Aligned along the walls are the state-of-the-art in every type of display Samsung produces. For all of the rampant hullabaloo being made about 3D displays now, 3D is only one of the eye-catching technologies shown here. This graph from iSuppli shows the real story. As a feature, Internet connectivity is expected to reach more than double 3D’s penetration in the next few years. LED backlighting and 120/240 Hz refresh should be even more common.

We didn’t have much time to stop and bask in the backlit magnificence here, but I’ll try to show you some of the highlights. For instance, the 55" 1080p direct LED screen you see in the foreground, featuring Remy from Ratatouille, looked to my eyes to be only marginally better than the cold cathode fluorescent lamp (CCFL)-lit screens around it. However, making comparisons when different content is used and there are so many other variables between screens is virtually impossible. Regardless, I know that LED backlighting uses substantially less power, which is enough of a selling point for me.

Down the line, you can see another two 55" panels side by side, one interpolating at 120 Hz and the other at 240 Hz, both running the same quickly panning street scene. While I couldn’t capture the difference on-camera under indoor lighting conditions, the 240 Hz panel was obviously superior at keeping moving text details clear.

Back To Basics

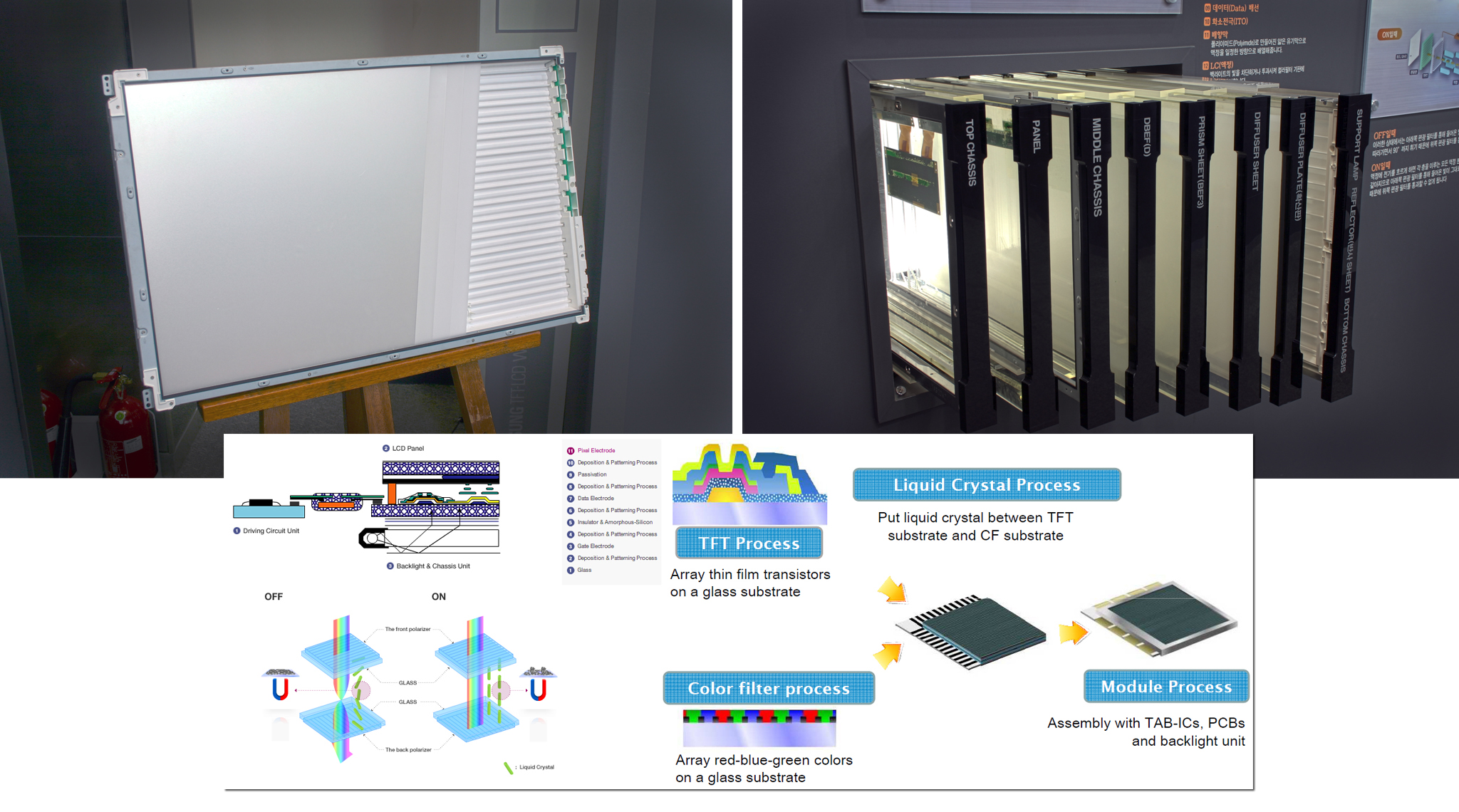

Samsung had a couple of displays in the showroom illustrating how LCD screens operate and are built. Many Tom’s Hardware readers will likely know these concepts already, so I won’t divert us with a discussion of them here. Still, if you’ve never dissected a CCFL LCD panel before, it’s interesting to zoom in and examine the many layers that comprise these devices. For a 32" TV, Samsung uses 16 CCFL lamps, but fewer than ten are needed for a 30" monitor. Samsung doesn’t make the backlight units itself but it does reserve special models from its backlight suppliers made specifically for Samsung displays.

I would encourage you to go back and look at the glass sizes image on page nine and that cheesy shot on page one of yours truly illustrating just how big that LCD panel is behind me. That black bar running vertically behind me isn’t separating two screens. It was a sliding arm that held up the smaller LCD display used for playing a promotional video. That’s one huge L8 sheet turned into a single LCD monitor. So when you hear companies like AMD saying that we’re now a step closer to having holodecks in our houses, it’s easy to think of screens like this, not being mounted on our walls, but rather being the walls themselves.

Totally Tiled

Speaking of big displays, check out this bad boy. That’s four ultra-thin bezel 46" panels melded into a single “digital information display” (DID), which I believe is a fancier way of saying “signage.” Samsung called DID “the next momentum for the LCD industry.” A normal LCD panel’s bezel is two to three centimeters thick, which leads to the endless grumbling you hear from gamers in Eyefinity forums.

In a signage setting, bezels are just as annoying—perhaps even more so given the exorbitant price tags common in signage products. However, these Super Narrow Bezel 46" panels yield only a 7.3 mm division between screens. That’s not the bezel-free ideal, but it gets us a lot closer. Better yet, these DID configs can be built in much larger arrays. Here you see a 2x2 array, but Samsung noted possibilities spanning up to 4x5.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

3D x 2 = 1 Good Question

I was particularly interested in comparing Samsung’s two 3D technologies side by side. On the right, you see a 55" LED LCD panel that uses active glasses technology with a 240 Hz refresh rate. The screen supports 1080p and allegedly offers a sub-4 ms response time to help eliminate interference between the left and right images. Of course, the Holy Grail of 3D is to get rid of the glasses, which takes us to the screen on the left.

On the showroom floor, ten feet or so in front of the screen, Samung had laid down strips of black tape marking the “sweet spots” in which the 3D effect would be most visible. Sure enough, when I stood with my toes on the tape, on-screen objects popped right out. A half-step to either side killed the effect. Samsung notes that it’s targeting this non-glasses approach at signage applications, and that’s fine. I’ve said all along that I feel 3D is premature for living room environments, but these displays show that Samsung is still working hard to evolve the field.

One question, though: As long as we’re still saddled with using glasses, how hard would it be to make the glasses auto-sensing such that when the user sets them down their associated screen(s) automatically revert to 2D mode?

Once You’ve Seen Black...

Getting a proper exposure on this shot was tricky, but just know that when Samsung describes this 43" super-widescreen as being “true black,” it’s really black. It can be tough to see the difference between the screen and the bezel. Unlike conventional 4:3 or 16:9 panels, this display is 4:1, offering a 1920 x 480 resolution. With this, you could fit three VGA images onto one screen concurrently. Perhaps we’ll see future, higher-res iterations used for gaming someday. For now, Samsung is targeting signage environments, such as subway stations, shopping malls, and schools. The company expects to be able to cut 12 super-wide substrates from a single sheet of L7 mother glass.

The Tiger Bites

Now comes the embarrassing part. Rather than get flamed about it in the comments section, let’s just be up front. While Samsung was very generous to invite my group on this trip, I was completely vexed by the company’s policies on guarding information. Those two outside shots you see on page 11? I snapped those from the window in the back of our tour bus because I was warned that having my camera out on company grounds could and probably would lead to it being confiscated. I could shoot anything in the showroom, but not the LCD screen on the wall displaying animated artwork between the two lobby elevators.

At one point, Jenny showed us a clear window looking into another room. With the press of a button, the LCD window turned impenetrably opaque and gray, as if it had been magically painted. I begged to take a quick video of it with my phone but was told no. We were shown several long technology presentations, including one brilliant session on Samsung’s cutting edge AMOLED technology. I recorded the whole thing on my voice recorder, and no one objected. Then I asked for a copy of the PowerPoint slides we’d just been shown so I could turn the session into an article...and was denied. Repeatedly.

I don’t understand this mindset, but my understanding obviously isn’t necessary from Samsung’s perspective. Perhaps this fevered level of secrecy stems from the background psychology of being in a country that could very literally go to war any day. Maybe it’s just good business: inspire buzz while giving away nothing. I don’t know. But the end result was that I wasn’t allowed to bring my camera past the showroom doors. Jenny supplied me with a few images from the manufacturing operations, and I captured a few more from a video she was able to pry loose for me. But that’s it. For the following images, she was merely able to say the following:

“The fabrication process consists of the thin film transistor array fabrication process, color filter array fabrication process, liquid crystal injection process, and module assembly process. If you want detailed information of every [following] photo, I have to apologize that I am not allowed to give information about equipment and process technology. Sorry.”

If the following content feels a bit sparse, now you know why. The PR team did the best that it could, but its hands were bound...tightly.

Robots (By Samsung, Of Course)

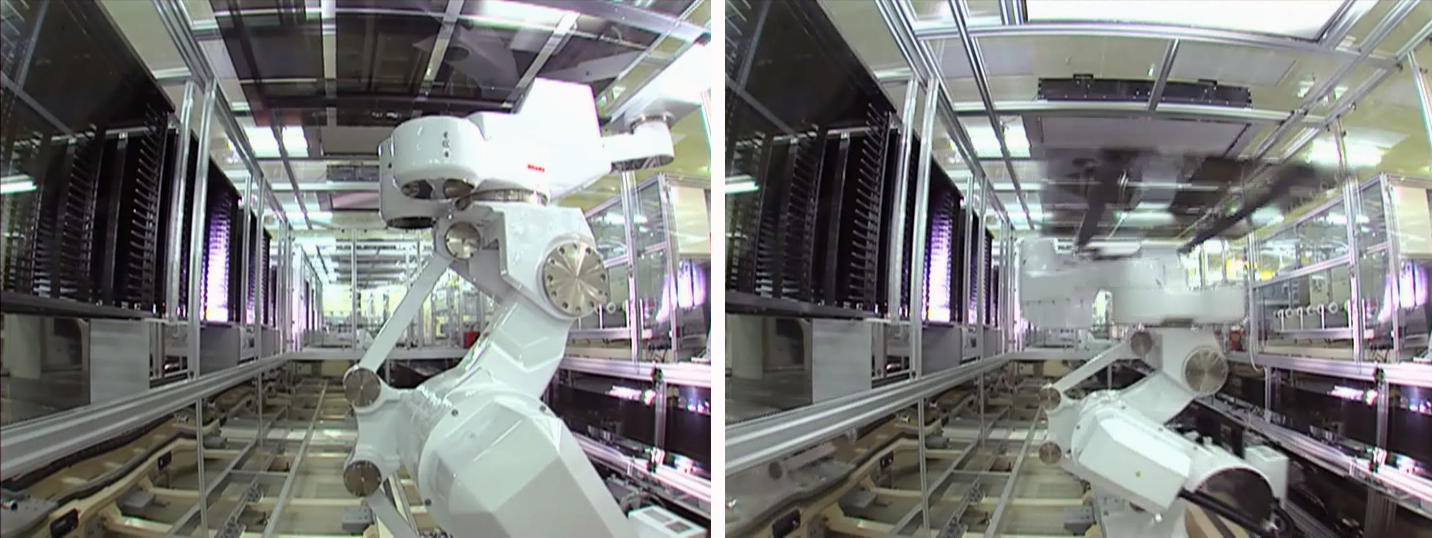

The rule in fabs is that the fewer humans you have in the mix, the better. Robots never sneeze, trip, throw out their backs, or anything else that might lead to thousands of dollars of glass shattered on the floor and hundreds of thousands of dollars in production setbacks. Having felt a pane of mother glass, I can’t imagine humans actually attempting to carry it. Instead, these robots do the job, looking like a cross between a Transformer and a pallette jack. The speed with which these things whip around inside their sealed hallways, shuttling panes through various processes, is a marvel to behold.

Loading And Shuffling

Here you can see a robot loading glass into a sort of exit airlock out of its chamber. Between such chambers there are sometimes wide hallways. Special laser-guided forklifts run in prescribed paths, shuttling the glass slowly from one location to the next. Each of these forklifts sports very bright LED readerboards on their fronts, presumably showing their ID code and/or function. These were actually one of my favorite aspects of the fab window tour (no, the bunny suit part of the trip got canned early in the planning stages). I stood there watching the lifters, imagining their drivers flashing funny LED messages at each other and then busting out in a snail’s pace game of bumper cars in the cavernous facility.

Samsung’s Spin

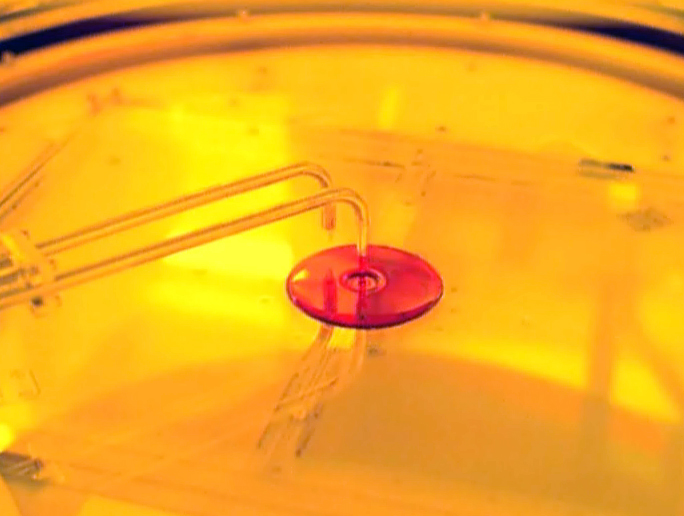

You may have noticed the red-tinted glass on the prior page. I wish I had confirmation of exactly what this image is and when in the manufacturing process it happens, but I suspect it might show one method of creating a color filter on the front glass. The three primary methods of creating color filters are applying foils, using a doctor blade system, or spinning a dye or pigment filter onto the glass. I think this shows the dye being deposited before being spun. However, dye spinning yields more waste than the other methods, so I have to wonder if perhaps this image comes from an older Samsung process.

Robots On The Edge

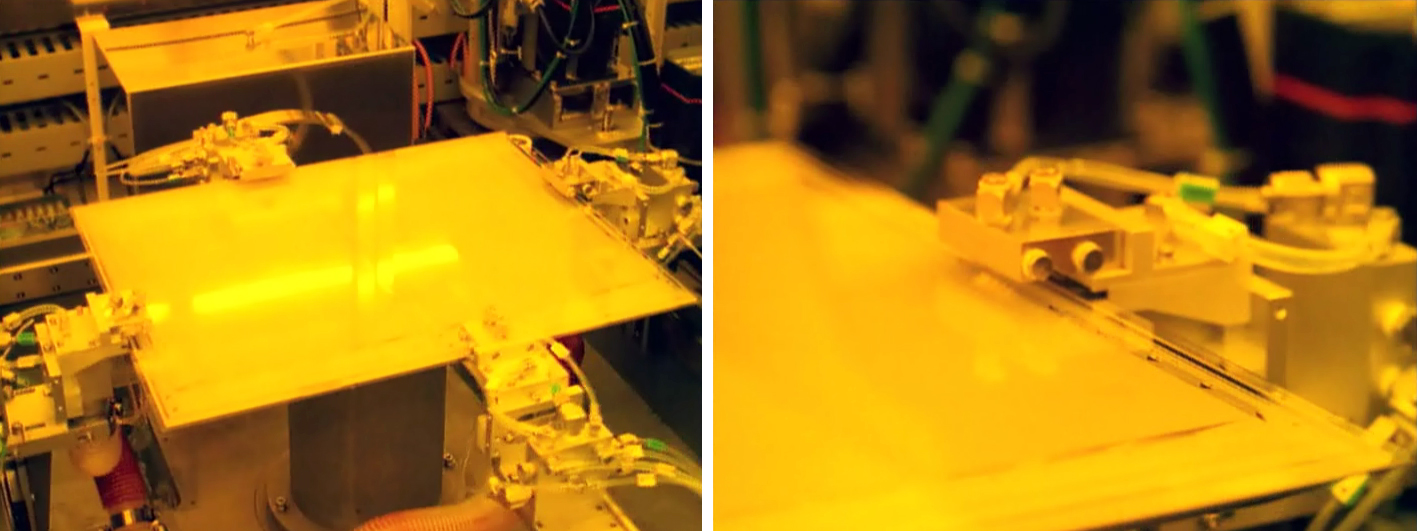

TFT displays rely on electric signals activating individual cells within the display matrix. I believe these shots show robots preparing the control module assemblies that line the edges of LCD screens. You can get a peek of such a module in the top-right image on page 13.

-

p1n3apqlexpr3ss Wow... south korea from nothing to one of the most technologically advanced countries in the world some could argue in just over 50 years, with plants like these and also with the fastest broadband connections...Reply

Nice article as usual as well, pity bout the actual manufacturing floor and filming stuff though :( -

one-shot Wow.....Reply

It's amazing what goes into a factory of this enormous scale.

Did anyone notice the garage doors in the side of the Fabs in the larger pics? It looked like garage doors in the sides several stories up. Good thing this isn't a Foxconn factory. -

rohitbaran Picture 6 shows how fast Koreans can develop a region. Magnificent facility. I admire their dedication as much as I can perceive from this virtual tour.Reply -

rohitbaran So, Sony working with Samsung (7th picture)! Well, maybe it would be useless to compare LCDs then!Reply -

amnotanoobie rohitbaranSo, Sony working with Samsung (7th picture)! Well, maybe it would be useless to compare LCDs then!Reply

It's not unusual for them to outsource some of their production to the largest producer of LCD's. Probably though, some of their higher-end or newer models may still be made by Sony itself. -

rohitbaran ReplyI recall passing one normally illuminated area in which test patterns were examined by lines of technical staff, with the control systems running Windows XP.

Ha ha. Proves something about XPs popularity, an OS that refuses to die despite its creator's sincere efforts. -

rohitbaran BTW, the title of the article should have been "LCD Juggernaut: Tom's Hardware Looks Into Samsung's S(e)oul"Reply