SurgeX SA-1810 Tear-Down

Spicing Things Up

Of course, for that first question, simulation may offer a worthy alternative to hands-on measurements. Here, I reproduced the SA-1810's circuitry in LTSpice with some help from Harford's patents to fill in blanks. Robert from ESP kindly providedparameters for the EMI filter magnetics and actual waveforms so I could sanity check my simulation model against them.

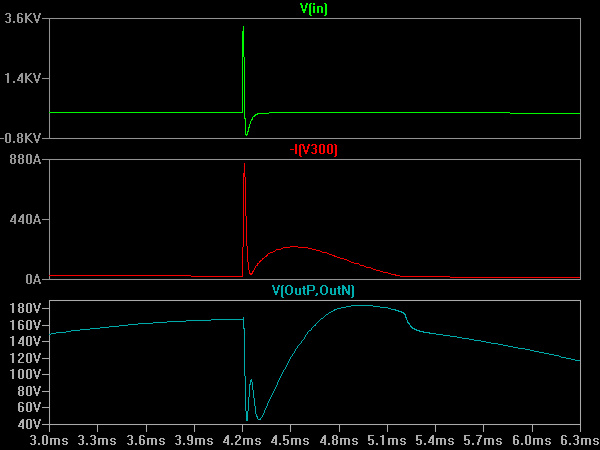

Vin is the input voltage with a standard B-class (1.2x50/8x20) surge applied to it, I(V300) is the current passing through the simulated source and finally, Vout(P-N) is the voltage across output live and neutral. After the EMI filter, there is effectively nothing left of the surge and the output voltage peaks at a completely benign 184V, merely 14V above nominal for 120VAC.

What is the lazy hump after the initial surge? Simply the shunt capacitors (C4/C6) finishing to charge since normal SCRs cannot turn off until their anode current drops near zero.

For Comparison's Sake

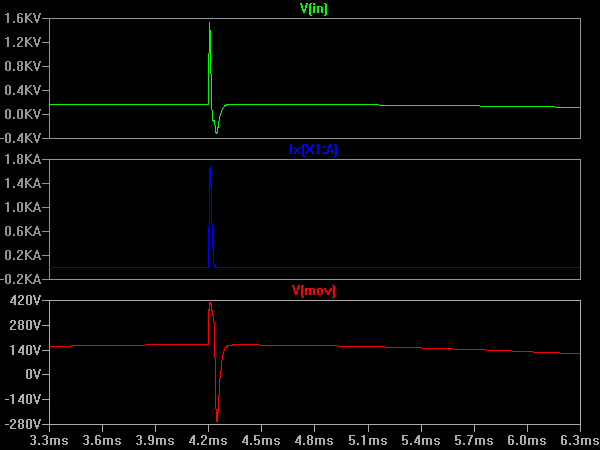

Since I went through the trouble of modeling a combination wave surge generator, I thought I may as well pick up a MOV spice model (Epcos S20K130 here), whack it in and see what happens. After much fiddling with circuit and spice parameters to get around “time step too small” errors, I managed to get these waveforms.

As before, Vin is the input, Ix is the current through the MOV and Vmov is the voltage across the MOV, which also counts as the output voltage. The MOV peaks at 420V and 1700A, 250V above peak AC voltage.

Why don't the voltage input and current waveforms peak at 6kV and 3kA? The first reason is because the specifications are 6kV 1.2x50µs open-circuit and 3kA 8/20µs short-circuit, so the two conditions are intrinsically mutually exclusive since you cannot have 6kV across a short-circuit. The second is that as-modeled, my combination wave pulse shaper only went up to 4.5kV/2.5kA, so not quite up to full spec.

Wrapping Up

If you were starting to grow tired of power strips that all seemed to look mostly the same inside, the SA-1810 is definitely something different. Through clever use of magnetics, semiconductors and large capacitors, it achieves power line surge suppression that MOVs cannot match. Even after tweaking my surge generator model some more to get closer to 6kV/3kA, the peak output remained under 200V, well within even the most sensitive electronics' comfort zone.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

I really liked the overall construction except for the use of RTV to secure the reactor instead of nuts, in equal parts because the RTV failed in my unit and if it had stuck, I would have had to pry it off for the tear-down. This would have likely involved mangling the reactor's sticker, scratching the reactor housing and bottom tray.

Despite its great surge elimination performance and build quality, I cannot help feeling like the $400 street price is still too steep for what it is and does. If you have a large collection of sensitive electronics to protect, though, it should be worth considering.

Thanks go to Nicholas from Caster Communications for having the unit shipped to me, Robert from ESP for sharing his engineering insight, and readers like you whose on-going interest in these stories drive the manufacturers' interest in participating.

-

Evil_Overlord Thank you for this write-up. In my eyes, this article is a shining example of what (technical) journalism should be. It is both worthy of being used as a product review, and reference guide. If I were going shopping for a series-mode surge suppressor, or if I knew someone who was shopping for a power protection solution for power-sensitive equipment, I would -without pause- recommend using this article as a launching pad for any/all research.Reply

Two things in this article stand out and gave me a reason to write this comment. First: You didn't give up. When faced with equipment that could not perform all the tests you desired, you switched to a simulated circuit. That takes time, research, and effort. Second: You openly admitted the transition from real-world to simulation. Lesser authors might skipped that disclaimer.

Well done. -

mortsmi7 They go to all the trouble of making such a beefy product and then they back-stab the outlets. The cross-section of a stab connection is very low compared to a screw-type. A space heater, which applies a constant high amperage, will kill a back-stabbed outlet in no time.Reply -

Daniel Sauvageau Reply

They make models for just about every country, you just need to go through surgexinternational.com to pick your country. All they need to do is put the appropriate cord and transformer/reactor in, increase the bleeder resistors' value for 220-240V countries and that's probably it*.16422851 said:Interesting , do they have a European version of this ?

Edit: *and put 400-450V electrolytic input caps in instead of 250V since 240V crests near 350V.

Thanks.16423853 said:Thank you for this write-up.

Two things in this article stand out and gave me a reason to write this comment. First: You didn't give up. When faced with equipment that could not perform all the tests you desired, you switched to a simulated circuit. That takes time, research, and effort. Second: You openly admitted the transition from real-world to simulation. Lesser authors might skipped that disclaimer.

Well done.

I had already done a fair chunk of the simulation research almost a year ago after getting into an argument with some readers about SurgeX and similar products, so I was basically biting my time to do something with the results and what I learned during that process.

As for admitting to using simulated results, this simply requires a lot less effort than producing convincing fake results. The main reason I do it though is as a shout-out to test equipment manufacturers: "if you had sponsored me with test equipment relevant to this story, your gear would have probably been shown or at least mentioned here." -

Daniel Sauvageau Reply

These are not "stab" connection with the crappy leaf-springs snaring wires. They are captive nut connections: the wire gets secured between the captive nut (a piece of cast metal with a tapped hole the terminal screw screws into and grooves to guide the solid copper wires) and screw/terminal by tightening the screw.16424079 said:The cross-section of a stab connection is very low compared to a screw-type. A space heater, which applies a constant high amperage, will kill a back-stabbed outlet in no time.

As far as current-passing capacity, those captive slab types should be every bit as good as plain screw terminals: they are basically the same except that instead of the wire being squeezed directly between the screw and outlet metal strip where you need to wrap the wire around the screw just so it does not slip out from under the screw while tightening, the wire is squeezed between the captive slug and the metal strip with the groove guiding the wire in place, eliminating the need to wrap the wire around the screw. These same grooves might actually provide more total contact area with the wire than the screw head does. -

blackmagnum Thanks Daniel for the tips. When using $1k plus computer equipment at work or home, it has been proven that you should play safe with reputable power delivery than be cheap and sorry.Reply