EKWB Factory Tour

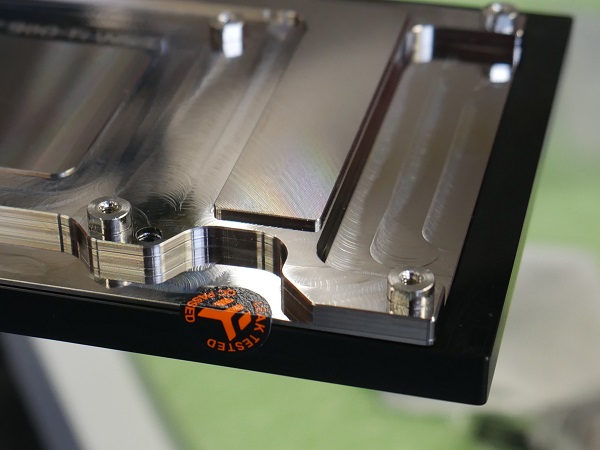

Pressure Testing

EKWB has an automatic pressure-testing machine. The only interaction required is for an employee to place each block in the tester. The machine does the rest of the work by itself.

Seal Of Approval

The machine works by sealing around the block's inlet and outlet, forcing air into it. If the block can take EKWB's specified pressure, it passes the test. The machine was set to 0.207 megapascals, which is equivalent to about 30 PSI. That's roughly what's in most car tires.

Next, an employee places a "Leak Tested" sticker on the block, and sends it off to packaging. Should you ever dismantle the block, you'll have to go through that sticker first.

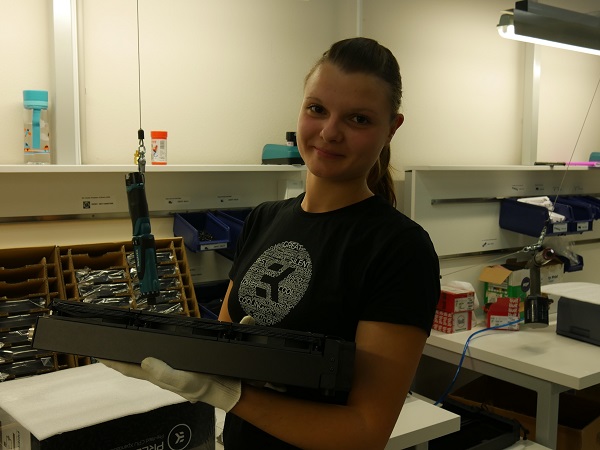

Packaging

There isn't much to be said about packaging, except that the folks running this department are extremely efficient. At first, I told one of the workers to just do what she normally does as I took pictures. Right away, though, I had to ask her to slow down. The process consists of cleaning the block, bagging it, putting it in the right box with its bundled accessories, closing it up and labeling the box. For that last step, the team has a label printer.

Distribution

There are two teams that handle distribution. One takes care of customer orders, and another handles shipments that go to EKWB's distributors around the world.

The End

Perhaps the biggest surprise was how efficiently everything runs in EKWB's factory, and how good the working conditions appear to be. You're never really sure what to expect when visiting a company's headquarters, but I was allowed to browse freely. After spending just over a day talking to the employees and figuring out how everything works, it became clear to me why nobody was nervous about my presence -- they had nothing to hide.

MORE: Best Cooling

MORE: Cooling in the Forums

MORE: All Cooling Content

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Niels Broekhuijsen is a Contributing Writer for Tom's Hardware US. He reviews cases, water cooling and pc builds.