Tom's Hardware Verdict

The Elegoo Saturn 2 produces stunning quality prints and is well worth the price.

Pros

- +

Super high resolution

- +

Included air purification module

- +

Hardened scratch-resistant LCD

- +

Built-in port for external ventilation

Cons

- -

Air Purification Module only reduces odor

Why you can trust Tom's Hardware

Resin-based 3D printers have been around for a few years now and are available in all sizes, ranging from units small enough to fit on your desktop to larger printers that have a volume that exceeds some popular FDM printers. As manufacturers develop these printers, they are rapidly adding new features to make them easier to use and more accessible to the average person and the new Saturn 2 is no exception.

Elegoo has been in the resin 3D printer business for the past few years and has produced several different sizes ranging from small printers like the recent Elegoo Mars 3, which has a 4K resolution, all the way up to the new Elegoo Jupiter, with a 6K resolution. Like the number in its name suggests, the new Elegoo Saturn 2 is the latest iteration of their Elegoo Saturn line of resin 3D printers and comes with quite a few improvements. The Saturn 2, which is designed to compete with the Best Resin 3D Printers, normally has a retail price of $600, but will be available for pre-order with an early bird price of only $500 for the first 1000 units and $550 for the next 5000 units.

For the prints in this review, I used some of Elegoo’s water washable resin because it was thinner than the low odor resin I had used previously with other resin printers and I wanted to bring out the details so the prints would come out better. I was very impressed with the new resin and using it did seem to make a difference in both the ease of cleanup as well as an improvement in the quality of the prints.

According to Elegoo, they should have an 8K resin available very soon, but it was not available for purchase at the time of this review.

Elegoo Saturn 2 8K Specifications

| Machine Footprint | 12" x 10.8" x 22.3" (306mm x 273mm x 567mm) |

| Build Volume | 8.62" x 4.84" x 9.84" (219mm x 123mm x 250mm) |

| Resin | DLP Photopolymer Resin? |

| UV Light | 405nm UV LED? |

| Masking LCD Resolution | 7680 x 4320 px |

| Masking LCD Size | 10-inch |

| Interface | 4.3-inch Capacitive LCD Touchscreen |

| XY Axis Resolution | 28.5 microns |

Included in the Box with Elegoo Saturn 2 8K

The Elegoo Saturn 2 came well packaged with plenty of foam around all sides along with some cardboard reinforcements along the edges to help prevent any damage occurring during shipping.

Like many of Elegoo’s other printers, it came packaged in a nesting doll style with the tools packaged inside of a smaller box. The smaller box is inside of the printer itself along with the build platform, which is placed inside a large block of foam.

The Elegoo Saturn 2 includes a pretty standard array of accessories that many other Elegoo resin printers ship with including tools such as the diagonal cutters for support removal as well as the metal and plastic spatulas.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The metal spatula is for helping to remove your prints from the build plate and you want to be careful while doing so, as it can potentially gouge or scuff the metal surface. The soft spatula is used more as a tool for cleanup such as assisting with removing any residual resin out of the resin tank when emptying.

It also comes with a set of hex key wrenches and some spare screws in case any servicing or repairs need to be performed during the printer’s lifetime. There are two pairs of latex gloves and two surgical style masks for personal protection, but you will probably want to get some higher quality masks and additional gloves for working with resin.

Additionally, it comes with a set of paper filtering funnels, the power brick, an air purifier module, a user manual, and a USB memory stick with a copy of the manual, Chitubox Basic (the recommended slider for the Elegoo Saturn 2) and some test prints on it.

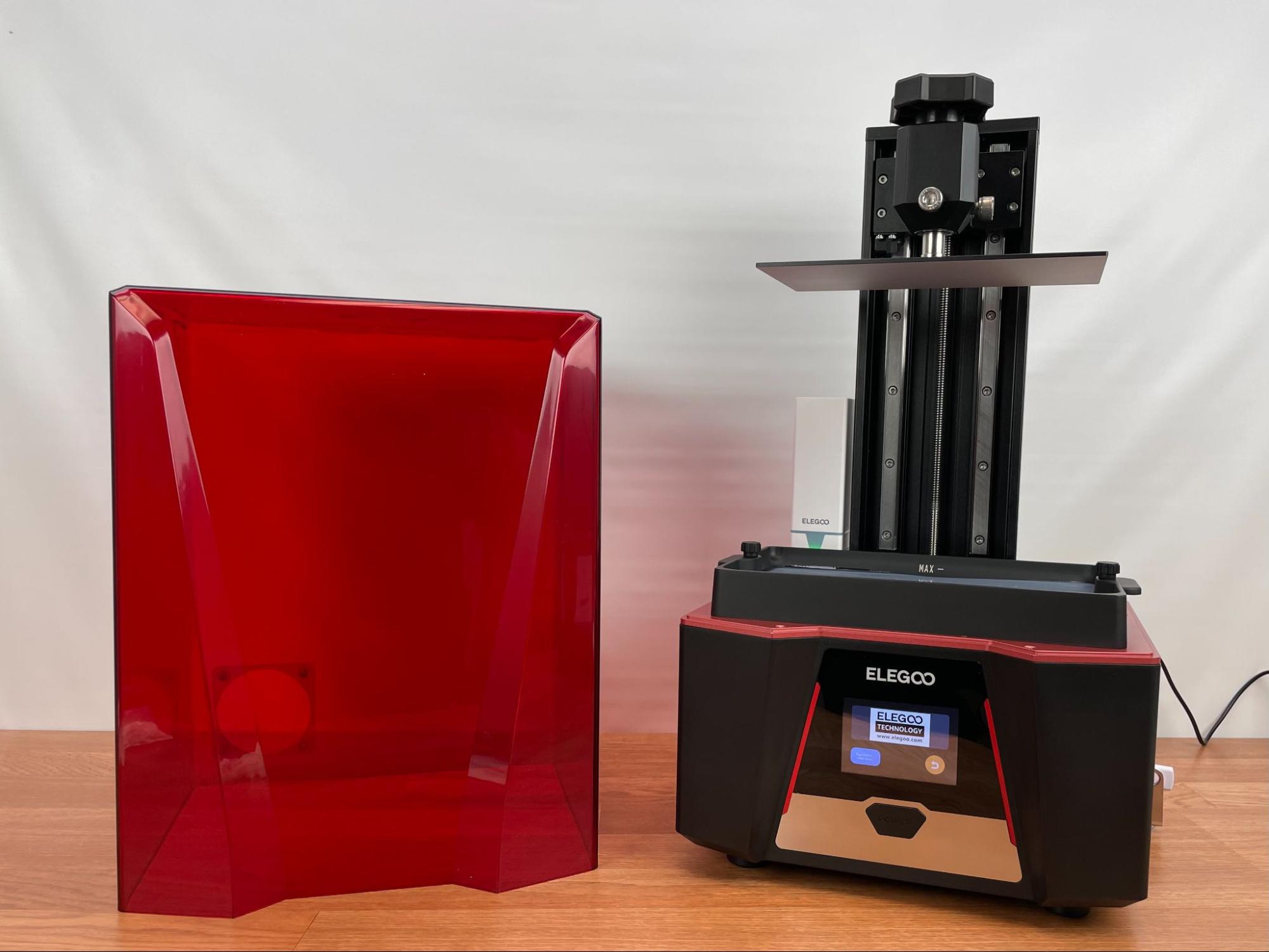

Design of Elegoo Saturn 2 8K

Right away, you can tell the design of the Saturn 2 is different from the previous models. While not being as curvy as the Mars 3, the aesthetic is appealing in its own right. With regard to the features, the Elegoo Saturn 2 is closest in design to the Saturn S of any other of Elegoo’s offerings, which is to be expected as that was the previous model.

One of the most obvious improvements of the Elegoo Saturn 2 is the 8K high resolution screen. The screen is 10 inches, which is a noticeable improvement over the 8.9-inch screen on the original Saturn and the 9.1 inch display that came on the Saturn S.

In addition to having a larger screen, it is also a significantly higher resolution then either of its two predecessors. The higher resolution means you can produce more detailed models than ever before. Underneath the 8K LCD is a Fresnel Lens that is able to distribute the UV light very evenly.

The Elegoo Saturn 2 is driven by a pair of linear rails along with a nice thick lead screw for a very sturdy build platform, which is necessary to produce detailed prints at such a high resolution.

One of the more interesting design features is a removable panel in the rear of the UV cover that can be used to connect to an exhaust ventilation system to help further reduce odors for people who operate in small spaces and are concerned with fumes.

Like Elegoo’s Saturn S and Jupiter printers, the Saturn 2 8K comes with a replaceable air purifier module that is powered by a port underneath the UV cover. Even though the port is shaped like a standard USB port, it has a warning next to it that the output voltage is 24 volts instead of the usual 5 volts produced by USB ports, so you wouldn’t want to plug your USB memory stick into it. During testing, I noticed that there was still a lingering resin odor that wasn’t completely eliminated.

Another feature that I’m really happy to see on this model is that the power switch that is on the rear of the Saturn S has now been replaced with a power button on the front of the Saturn 2, making it very convenient to turn on and off.

Leveling the Build Platform on the Elegoo Saturn 2 8K

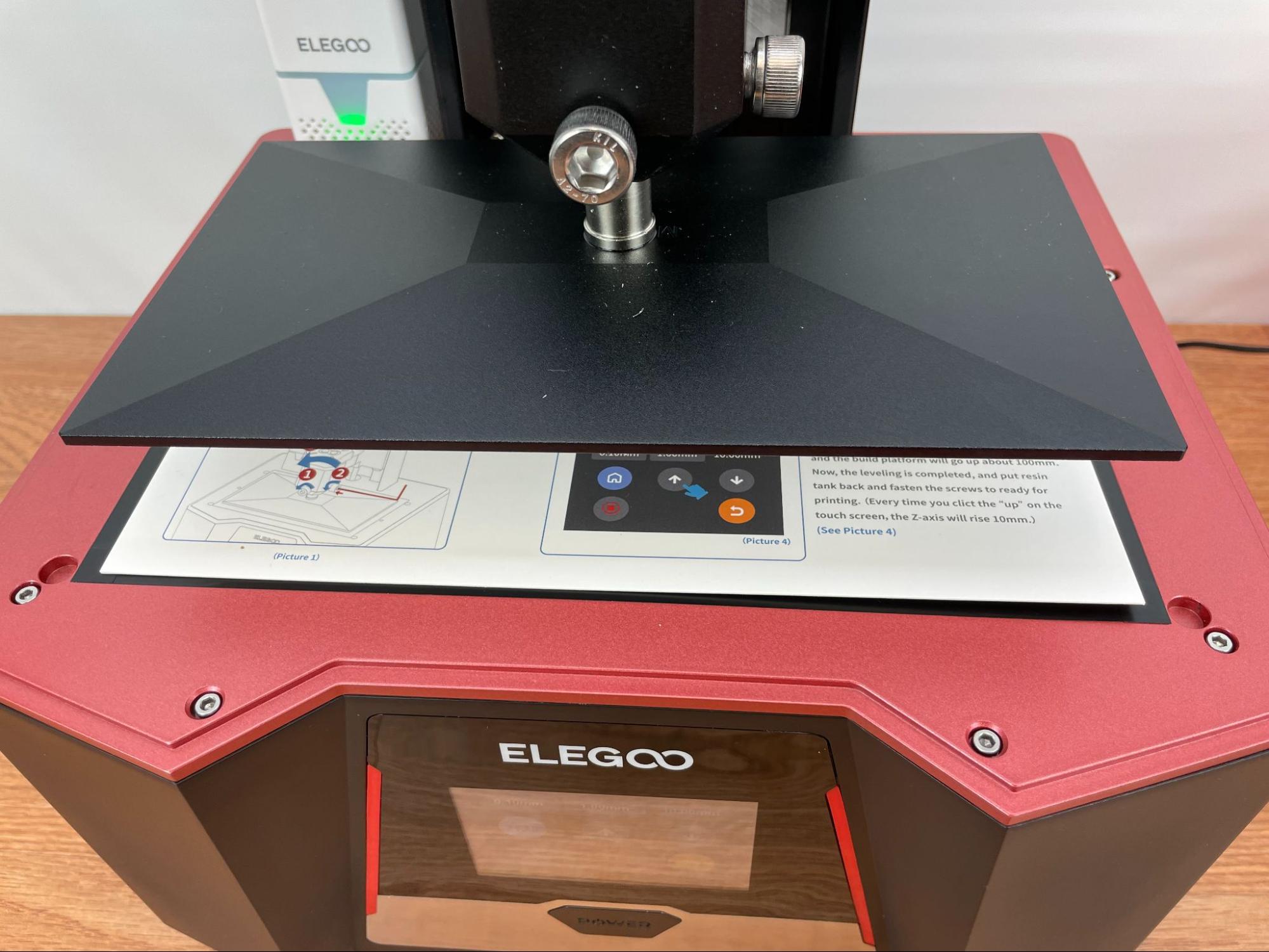

Leveling the printer was pretty straightforward. The first step is to loosen the two bolts on the sides of the resin tank. Then using the control panel on the front of the printer, you want to raise the build platform to a sufficient height that the resin tank can be removed.

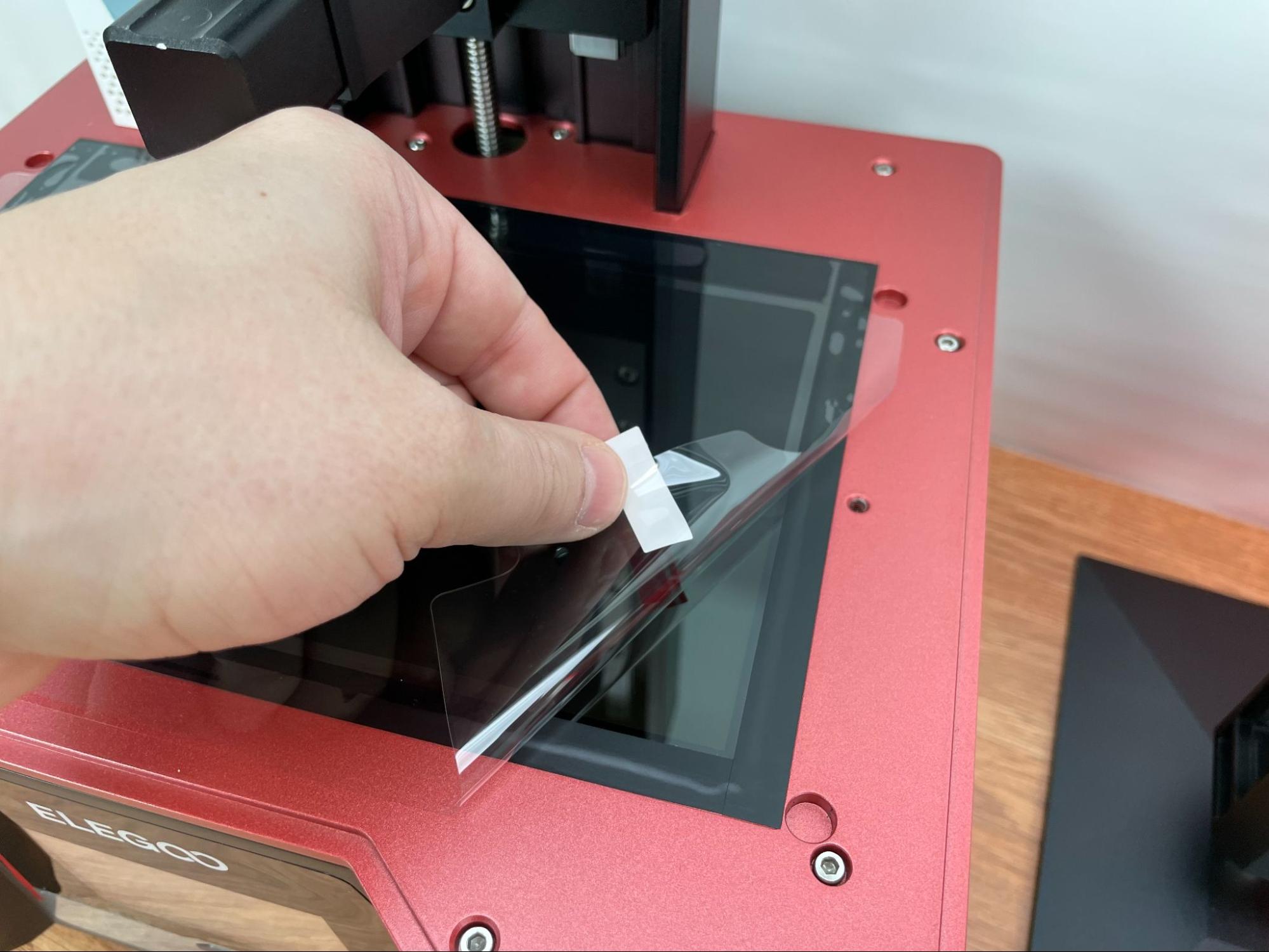

Then after making sure the large knob that holds the build platform onto the printer is tightened, use the largest hex key to loosen the bolts on the front and side just below the knob. Make sure to remove the screen protector from the LCD if you haven’t already.

There is a card that comes with the printer that is about the thickness of cardstock. You will want to place that directly on top of the LCD screen. On the earlier generations of printers, a regular piece of paper was used to compensate for the thickness of the FEP film, but a thicker card is now used because the new FEP 2.0 film is thicker and more durable.

Next, you will want to press the home button to lower the build platform until it rests squarely on the card. You can press the home button to readjust the card if necessary. Once you are happy with the position, hold the build platform with some pressure against the LCD while you tighten first the front bolt, and then the side bolt.

You can then press the up button until the build platform is high enough to reinstall the resin tank. The platform should now be properly leveled. If you are having trouble with prints sticking to the platform or you notice a flat spot on your printed model after removing it, you may want to try re-leveling the platform.

Printing Safety with Elegoo Saturn 2 8K

With resin printing, you will want to print in a well ventilated area that’s still out of the way of any UV radiation such as direct or indirect sunlight. Even with the low odor resins, the fumes can still be toxic. You will also want to make sure you are wearing gloves to avoid directly contacting the resin with your skin.

One thing that you hear discussed a bit less often is exposure to UV light. With the Elegoo Saturn 2, I tested whether removing the cover would turn off the UV light source and unfortunately found it continues to emit UV light. Although it’s likely not any stronger than sunlight, it is best to avoid looking directly at a UV light source with your eyes if you can help it, and it is a good idea to avoid direct exposure to your skin as well. Most of the time the resin will be covering up the UV light source, so this isn’t really much of an issue, but it is something to be aware of.

Printing Included Test Prints on the Elegoo Saturn 2 8K

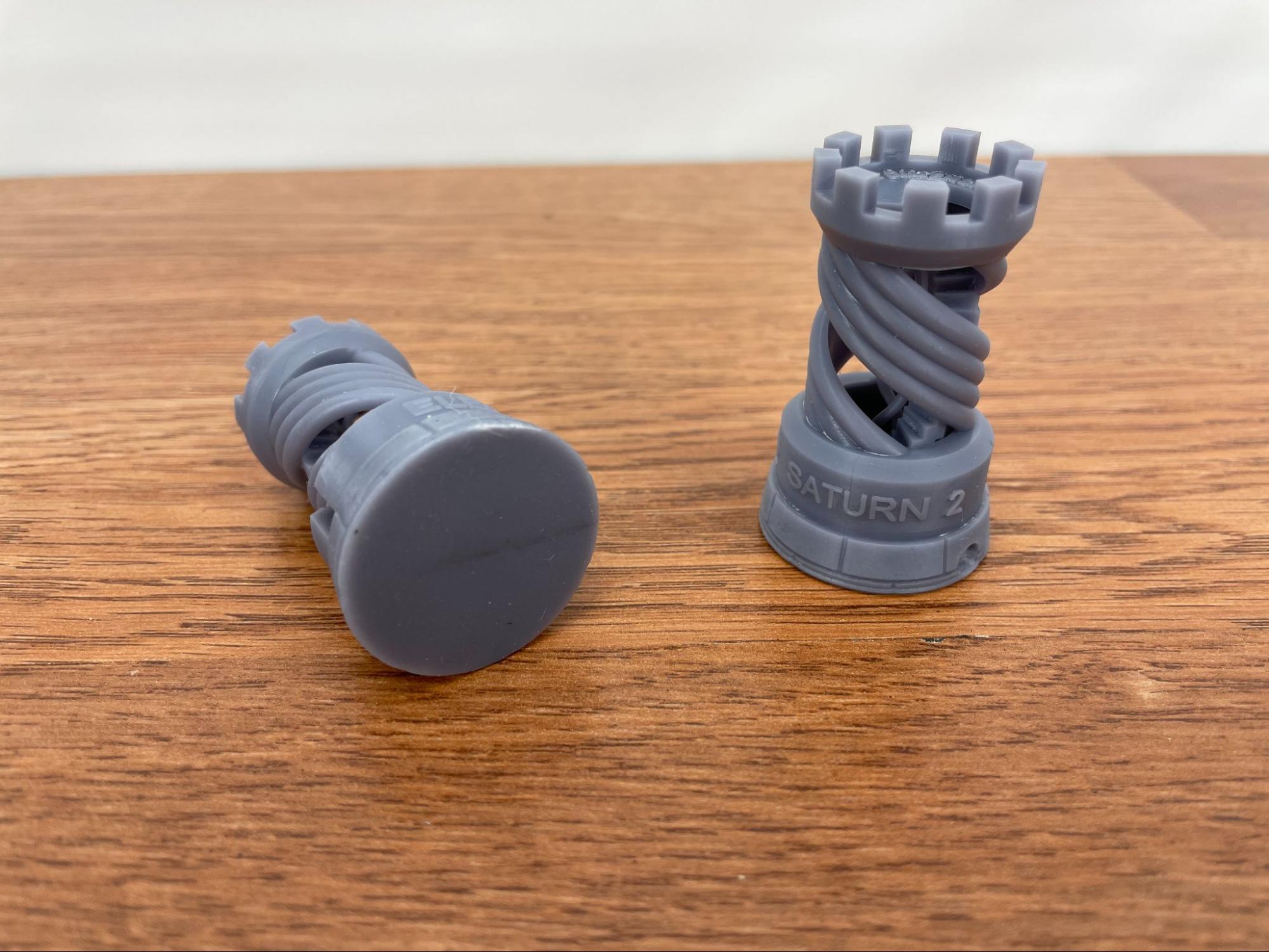

Test prints allow 3D printer manufacturers to demonstrate the printer’s strengths. Having the prints pre-sliced is a bit of a double-edged sword. On one hand, the manufacturer can choose the best settings for the printer, but on the other hand, the manufacturer is making a guess about the specific resin that new users will be using to produce the test prints. In typical Elegoo fashion, the test print that comes with the Saturn 2 is a pair of rooks.

With some of Elegoo’s earlier printers, this guessing has yielded softer prints that were often gouged with the spatula upon removal. It appears that the company has increased the exposure time with the latest test prints, so it takes a bit longer, but the model is less likely to be damaged.

Printing the test prints is pretty simple. Just insert the USB memory stick into the USB port on the right side of the printer, select the Print option from the main menu, open the “ELEGOO SATURN 2 Rook Model for Printing Test” folder, and select the Rook Test Print Model. There is also an STL of the model if you would like to try slicing it yourself with Chitubox.

Preparing Files for Printing with Chitubox

The first thing you’ll want to do once you have Chitubox Basic installed is to add a new printer in the software. The current version at the time of this writing already has the Saturn 2 as an option, making setup a breeze. One thing you will want to check is the exposure times on the resin you will be using. I ended up needing to increase the exposure time quite a bit for the water washable resin because the default values left the resin a little too soft.

After you have your printer all set up, you can load a model to slice. Slicing with a resin printer is quite a bit different from slicing for a traditional FDM printer. Since the model is printed upside down and is printed used liquid resin, there are additional things you need to take into account such as drainage holes, the weight of the item you are printing so it doesn’t fall off the build plate, and even where the supports attach so that when they are removed, you don’t remove delicate details.

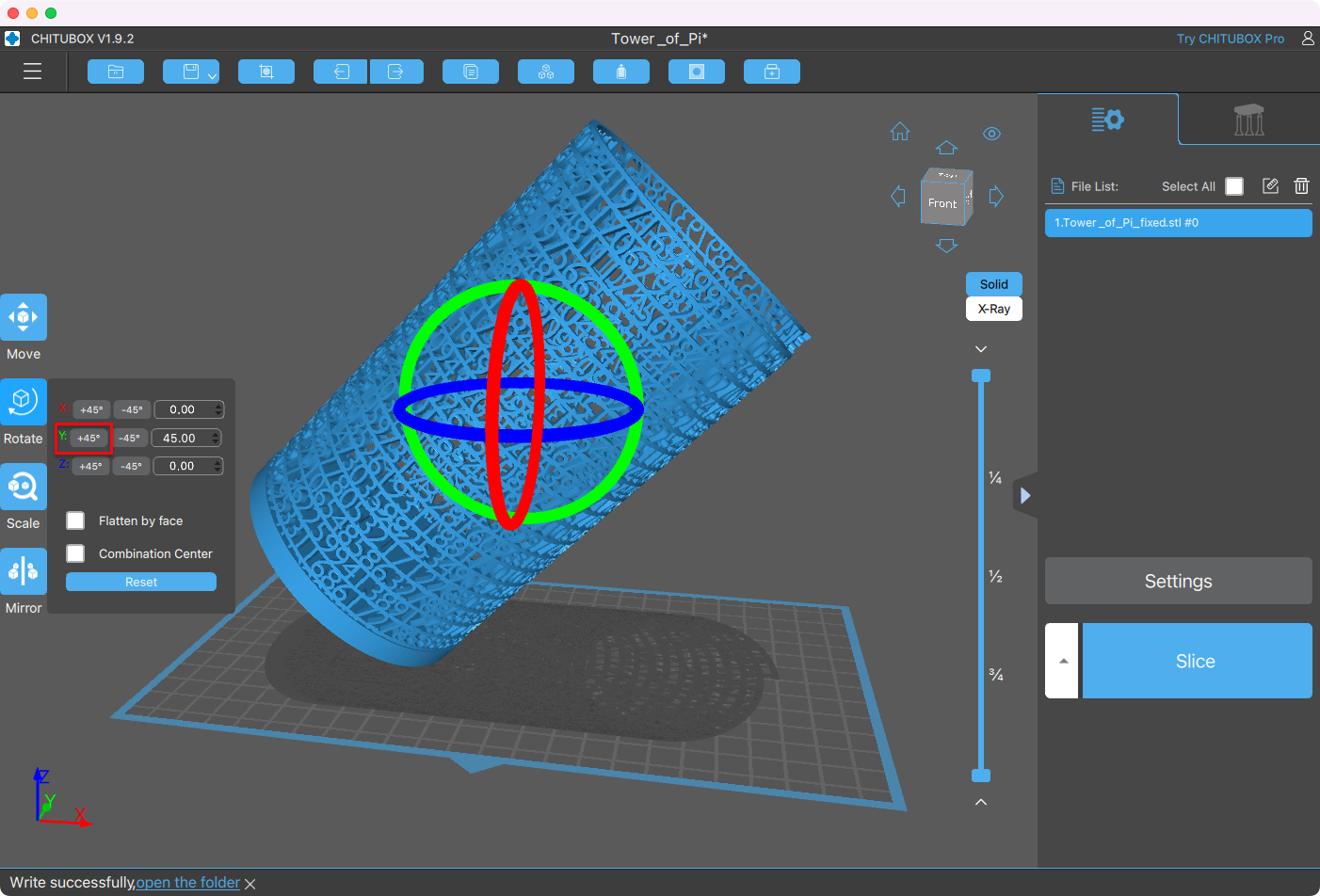

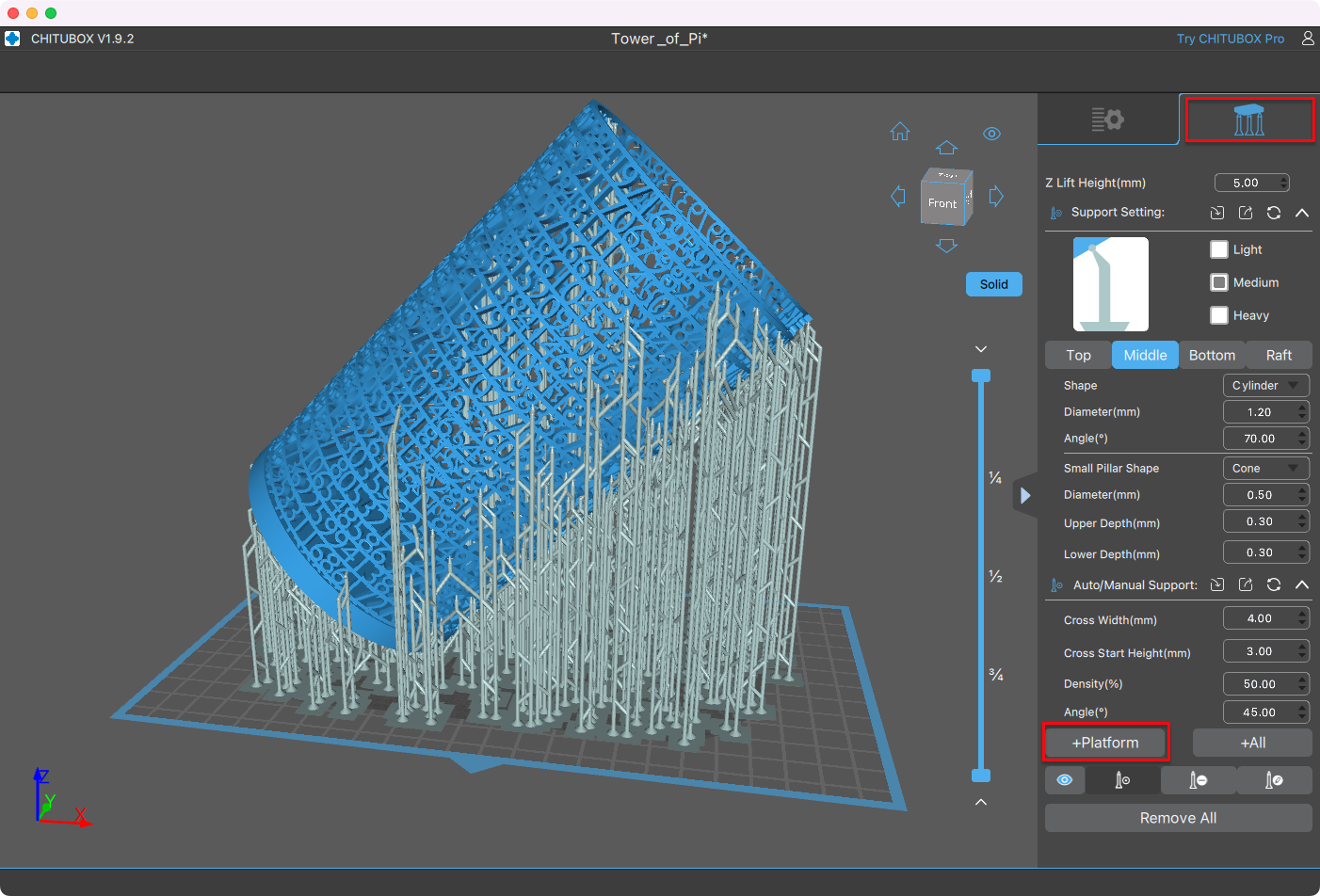

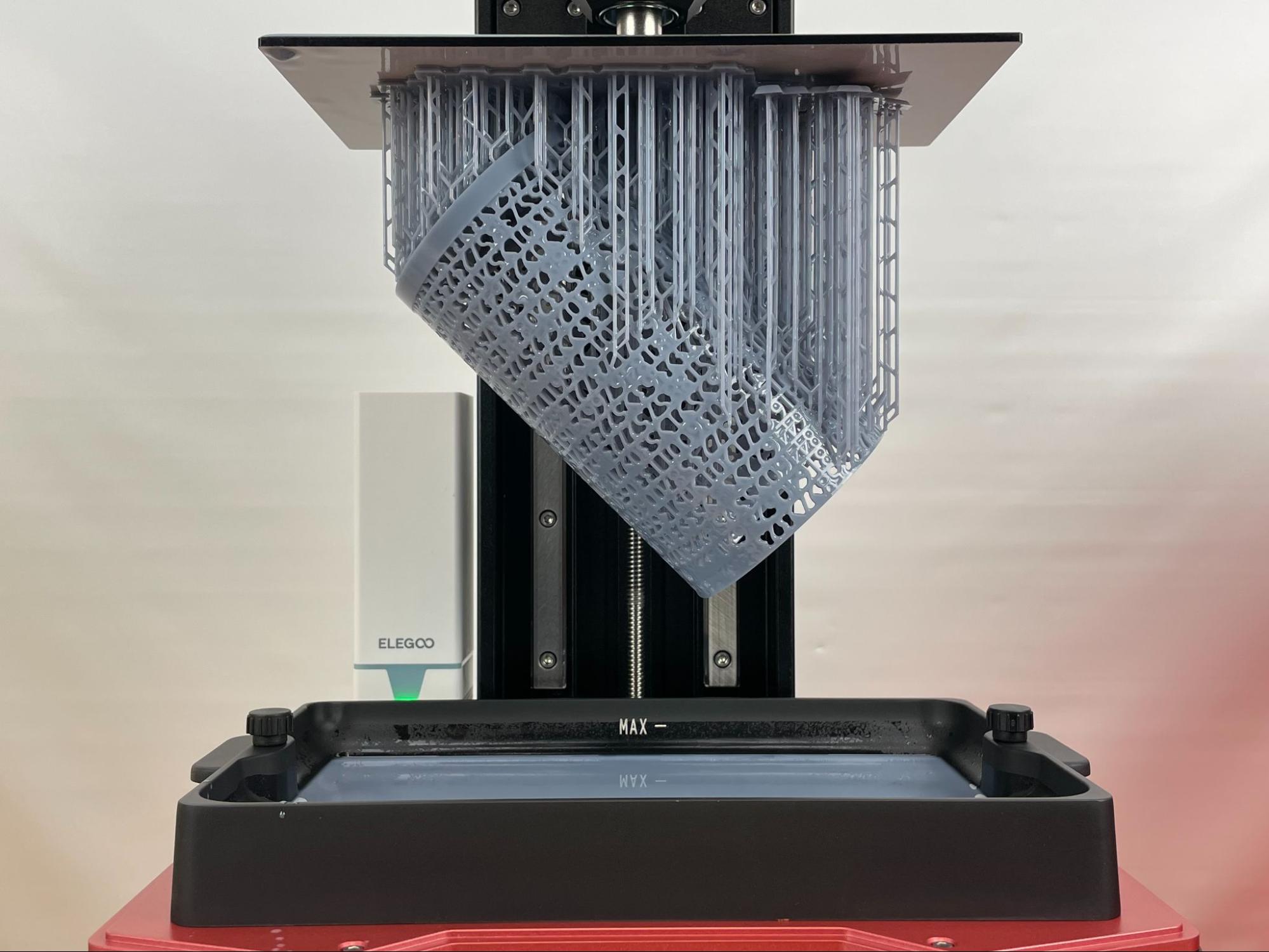

For the first model, I went with the Tower of Pi to show basic slicing. This one is fairly straightforward since it doesn’t have any large solid sections, but it also has a lot of detail making it a great demonstration of a resin printer.

To get your model prepared, you will want to place the model at an angle. Placing models at an angle makes it much easier to remove them from the build platform without damage in the process. It also gives more surface area for supports to hold on so the model is less likely to fall during printing.

Start by opening up the file that you would like to print. You can open the Rotate panel on the left side by clicking the Rotate button. If your model is not upright, you can first get it oriented correctly using the controls. Once it is upright, find the axis that corresponds to the longer side of the build platform and click +45° or -45° to place it at a 45 degree tilt so that you can add supports. You can always adjust this angle to your liking, but I found the tilt buttons were pretty convenient.

Under the Supports tab on the right side of the screen, you can have Chitubox automatically generate supports. For this model, I found the default settings to be sufficient and added supports only for items above the build platform by clicking on the +Platform button. After pressing the button, it will take about 10 seconds or so for the supports to be generated.

Once the build supports are in place, you can go back to the Settings tab and click on the Slice button. This will slice the model. Once it is sliced, a Save button will appear, which will allow you to save the sliced file onto the USB stick that came with the printer.

Once it is saved, you can eject the memory stick from your computer and plug it into the printer. On the printer, just go to the Print option from the menu and choose the model. It should show up just as it looked in Chitubox.

Printing a Bust on the Elegoo Saturn 2 8K

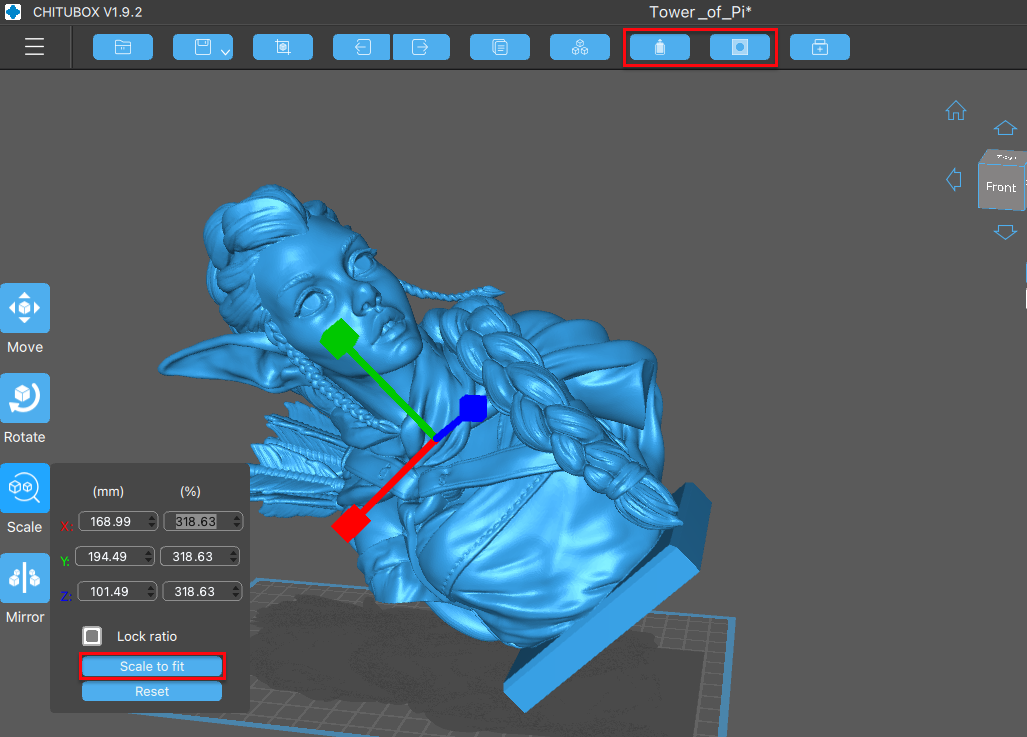

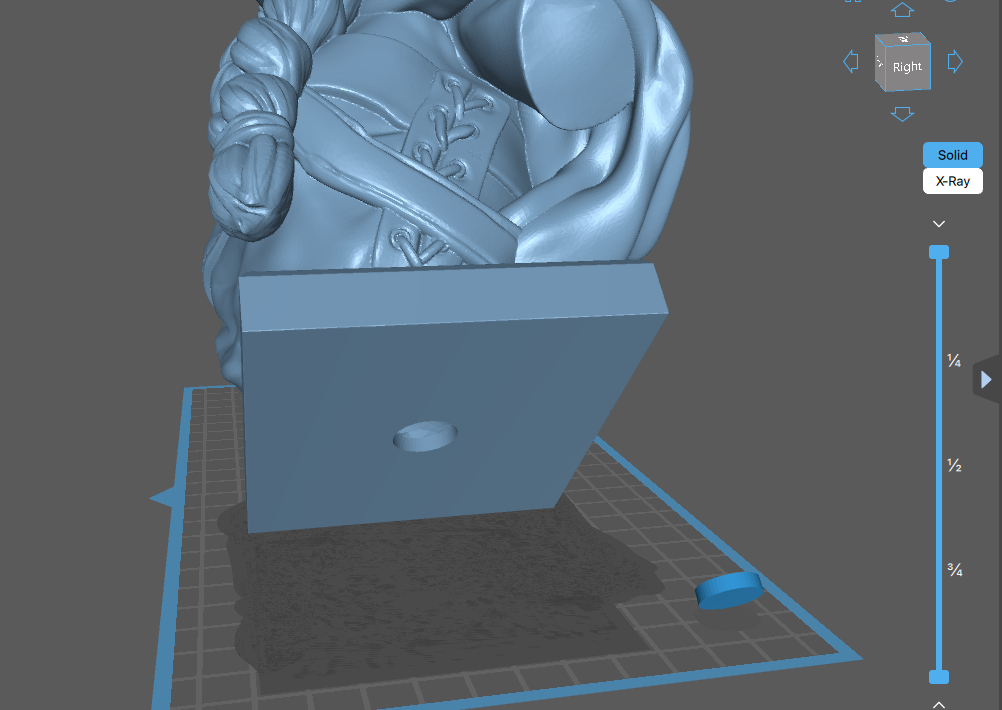

To test printing a bust, I decided to go with a model of an Elf Archer Bust because the dimensions fit well in this printer and I wanted to see how the details came out. Chitubox has a nice feature that allows you to hollow out the model. It also has a feature to allow you to add drain holes so that you can rinse out any excess resin from inside the head.

To start with, I loaded my model into Chitubox Pro just as described above and got it sitting at an angled orientation. I oriented with the face pointing away from the build platform so that there would be fewer supports on the face.

I clicked on the Scale button to get to the scale controls and increased the scale to the maximum using the Scale to fit button. Then I backed it off by about 10% in order to leave room for the supports.

I clicked on the Hollow button at the top, which allows you to set the thickness of the outer shell. I increased the value to 3mm because the defaults are a bit on the thin side. I then added a single large drainage hole on the bottom of the bust using the Dig Hole tool.

The hole will mostly help you out when washing and cleaning your model as most excess resin will leave the model as it is printed. Chitubox will also automatically generate a plug that you can use to fill the hole after washing, though you may choose to just delete this.

After this, it’s just a matter of generating supports like with the first model and printing it out.

Once you have finished printing, you can wash the inside of the model out using the drain hole. I noticed that supports had been generated inside the model through the hole, but I just left them. While cleaning my print, I was a little too eager with removing the supports and ended up breaking the hair and chipping the face, but otherwise the quality of the print turned out very good.

Printing Detailed Models on the Elegoo Saturn 2 8K

For a detailed test print, I went with a model called Red Dragon featuring a winged dragon. This model was a little too large for this printer at the full size, so I chose Scale to fit, which came out to around 75% or the original size. I didn’t bother to hollow the inside as most of the larger features weren’t excessively big and as a result, no drainage holes were necessary. The main thing to watch out for on a detailed model like this is ensuring the supports are in a place where removing them doesn’t cause you to accidentally damage the print.

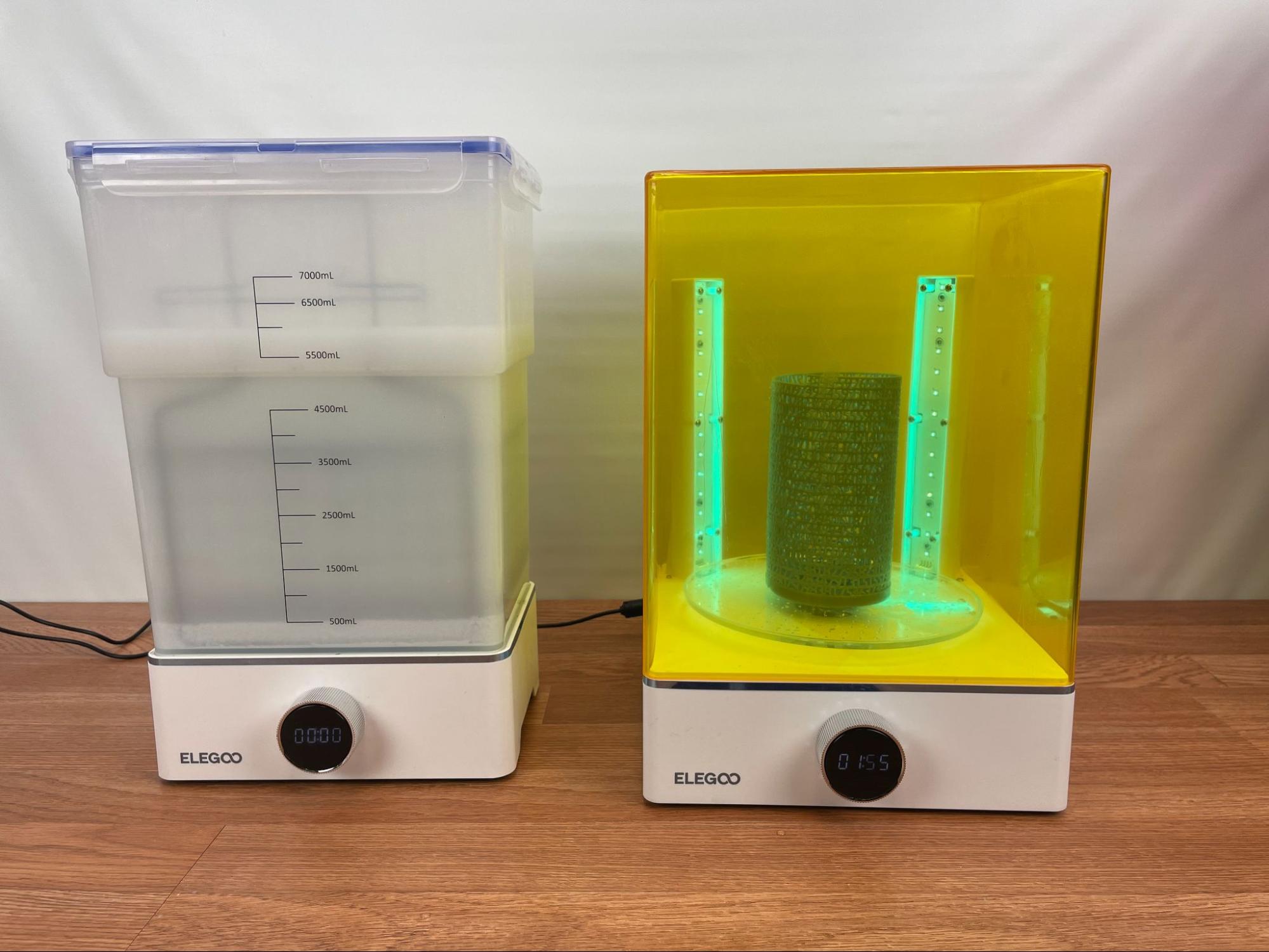

Washing and Curing on the Elegoo Saturn 2 8K

After printing, the model will still likely have some leftover resin on it and, to get a resin print to look its best, you will want to clean it.

To wash the models, I used Elegoo’s largest Wash and Cure station, the Mercury X bundle. Although this was designed with the original Saturn and Saturn S in mind, which have slightly smaller build volumes, I found the build platform still fit into the tank. The only issue I had was with some of the taller prints bottoming out.

Because I used a water washable resin, I emptied the isopropyl alcohol from the rinse tank into a bucket for use at a later time and replaced it with tap water.

What worked well for me was to start off by washing the item in the water first after printing, then remove the supports while they were still soft. After that, I dipped it in water briefly and used the brush included with the water washable resin to loosen up any more resin residue. I gave it another rinse in the rinse tank in hopes that the water would now be able to get into the nooks to help remove any additional resin. After letting the item completely dry, I then cured it and this prevented any white residue from forming on the prints, which can happen even with the water washable resins.

Cleaning Up After a Failed Print on Elegoo Saturn 2 8K

Prints can and eventually do fail even on resin printers, though I did not experience any failed prints on the Saturn 2 myself. Whether it happens due to support structures that are unable to support the mass or any number of other things, you still will have a mess to clean up before you can print again.

It is best to start by removing the model above the resin tank. I found that using the metal spatula on the build plate worked quite well. The reason you want to remove the model first is to avoid dripping any resin onto the LCD screen, which is very difficult, if not impossible to remove once hardened.

After that, run a tank clean cycle through the printer’s menu, which will expose the entire bottom layer of the tray to UV light and create a solid mass of any little pieces that may have broken off of the failed print. You may consider adding a piece of removed support from a previous print to one corner first to make removal of the mass easier.

Once that is complete and you have removed the hardened resin, you should empty the resin tank. The plastic spatula works well to assist with this. Emptying the resin first allows you to inspect the FEP film as well. If it gets too damaged, you may need to replace it before continuing.

You will also want to verify that any stray resin did not get on the outside of the resin tray so that it doesn’t end up getting onto the LCD screen when placed back onto the printer, which could end up curing there. Even though the LCD is scratch resistant, you will still want to be extremely careful if you did have any resin cure there, which is why it is best to avoid it in the first place.

You can use some isopropyl alcohol to help clean any surfaces that resin gets onto and paper towels to wipe it dry. You may want to leave any failed prints outside to dry in the sun and harden or you could place them in a cure chamber if you like.

Bottom Line

This is a very polished machine that produces prints of phenomenal quality. During the entire time I was testing it, I had no failed prints. If you are looking for a mid-sized 3D resin printer or you need to print in a high level of detail, you really can’t go wrong with this printer.

Another printer that is in a similar budget range that you may also want to take a look at is the Phrozen Sonic Mini 8k with an even more impressive resolution of 22 microns, but with the tradeoff being a smaller print volume. If you want something with a smaller footprint and you like Elegoo, you may consider going with the Elegoo Mars 3. If you are looking for a larger build volume, you may want to consider taking a look at the Elegoo Jupiter. However, if you want this level of detail and build volume together, the Saturn 2 8K is hard to beat.

Melissa is a Freelance Reviewer for Tom’s Hardware US covering 3D printers.