Who's Who In Power Supplies: Brands, Labels, And OEMs

Did you think all power supplies were manufactured by the brand selling them? We show you what makes a good PSU and reveal who actually builds PSUs. You can actually find lots of quality, instead of just scrap metal, behind some of the budget labels.

Firecracker Or Power Plant?

How do you identify a bad power supply before buying it?

- Extremely high wattage claims at a comparatively very low price are suspicious. There are simply no decent 750 W power supplies for $50. For every product class based on performance and features, there must be a minimum price. When a product is significantly below that price, be cautious. You can get a "400 W PSU" for $20, and such fire hazards are installed in budget PCs every day by unscrupulous companies that know exactly the risk they're handing off to buyers.

- Check the specifications. For example, if a PSU claims high performance on the 3.3 and 5 V rails while the 12 V rail numbers are low, then you know something is wrong.

- The manufacturer does not specify any combined maximum performance, but instead only shows the maximum load for each rail separately. This is done without specifying how much real power would be available if all rails are used at the same time. Avoid PSUs without this information.

- Be careful with juicy marketing expressions and commercial lingo: Super, Extreme, Gaming, Combat, etc. Using superlatives to describe something quite normal should arouse suspicion and have you double-check specification details.

- Passive rather than active Power Factor Correction (PFC) leads to lower power efficiency.

- Very few or short power connectors and cables might be an issue. A 750 W PSU usually has four PCIe connectors for graphics cards (2 x 6-pin and 2 x 6+2-pin), so think twice if a model only offers two (or at least consider your upgrade options).

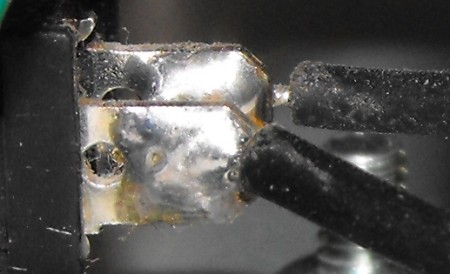

- With cheap PSUs, the quality of the cable insulation may be poor, or the cables may not be insulated at all. The power cable grommet may also be insufficiently padded.

- Be careful if there are few or no indications of protection circuitry. If the PSU specification only says OPP (overload protection) or perhaps SCP (short circuit protection), this points towards a normal fuse. If the specification also says OVP (overvoltage protection), this probably means that it is equipped with a simple metal oxide variable resistor. These security measures by themselves are absolutely insufficient and cannot replace any kind of digital safety chip.

Unfortunately, you can't always tell at first glance whether you're dealing with a high-quality PSU or whether there's nothing but disappointment waiting behind the pleasant facade. Therefore, we decided to open up two budget PSUs representative of what you can find in many of today’s OEM PCs and illustrate the points and features you should be examining.

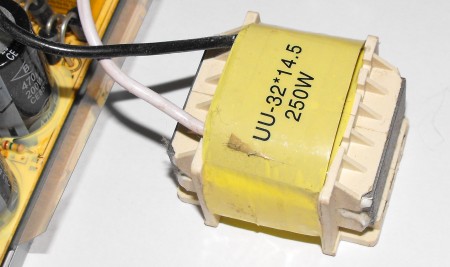

A First Look At the Inside: Primary Capacitor and PFC

First, look at the storage capacitors in the primary circuit. These act as buffers and help protect the PSU and computer from voltage fluctuations. The electrolyte used in them is key, because it evaporates or dries out through a combination of heat and time. As a general rule, capacitor lifetime is halved for each 10 degrees Centigrade increase in temperature over the specified normal load. Using higher-quality capacitors that can handle 105 degrees instead of 85 degrees (C) should almost double their lifetime, greatly contributing to the PSU's durability.

A PSU equipped with chokes (a kind of inductor) is a clear indicator of passive Power Factor Correction (PFC). Passive PFC plays a significant role in the efficiency of the PSU. Only active circuitry allows for factors close to the optimum value of 1, while passive components can reach 0.7 to 0.8 at best, meaning they only achieve 70% to 80% efficiency. PSUs with a passive PFC may be cheaper to buy in the short run, but poor efficiency can swallow savings over time in the form of higher electricity costs.

Protection Circuits

Even without opening the PSU, a data sheet can reveal some of the safety measures taken (or not) by manufacturers. A decent PSU should contain the following safety measures:

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

- OCP (Over Current Protection): protection against power spikes

- OVP (Over Voltage Protection)

- OPP (Over Power Protection): overload protection, sometimes called OLP

- OTP (Over Temperature Protection): protection from overheating

- UVP (Under Voltage Protection)

- SCP (Short Circuit Protection)

- NLO (No Load Operation): this isn’t exactly protection in the same sense as the other features, but it allows the PSU to power up and function normally, even with no load.

Without this information, you have to look inside the PSU to find out what you need to know.

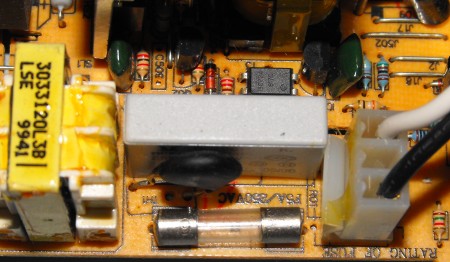

We found no protection at all on this unit, except for a simple fuse. Sadly, this PSU is still available on the market under a couple of different labels.

Passive components do not guarantee sufficient protection. Without a digital security chip, the computer hardware is severely exposed to risks.

The security chip PS223 from Silicon Touch is popular, and you should avoid PSUs not using it or similar products, such as the PS332S.

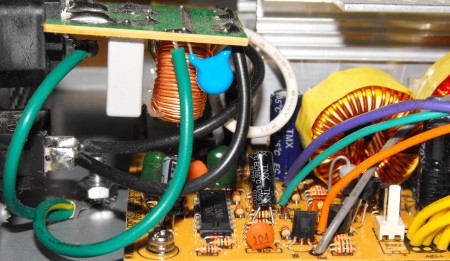

Cables and Short Circuits

You can tell a lot about your PSU by looking at its internal wiring. A lack of heat shrink tubing, carelessly exposed solder joints, and components fastened with a glue gun are symptomatic of cheap and hazardous manufacturing. If unprotected cables are placed next to hot components, a PSU failure is nearly assured.

Boards

A final quality indicator is the circuit board material. Impregnated laminated paper (like the yellow boards in the pictures) is a sure sign of cost cutting. Fiber materials are much more durable and, perhaps more importantly, non-flammable.

Current page: Firecracker Or Power Plant?

Prev Page Manufacturers, Designers, And Labels Next Page How Do You Recognize The Manufacturer?

Igor Wallossek wrote a wide variety of hardware articles for Tom's Hardware, with a strong focus on technical analysis and in-depth reviews. His contributions have spanned a broad spectrum of PC components, including GPUs, CPUs, workstations, and PC builds. His insightful articles provide readers with detailed knowledge to make informed decisions in the ever-evolving tech landscape

-

siliconchampion My favorite brands for power supplies are PC P&C, Antec, and Corsair. The common denominator between them all? SeaSonic. That is a testament to Seasonic's manufacturing. I have never had a Seasonic PSU die on me. I cannot say the same for countless numbers of stock OEM PSU's and Apevia branded PSU's... and now I have an idea why.Reply

The Apevia story. Purchased an Apevia case bundled with a 450 Watt PSU. Set aside the PSU in favor of an Antec EA650, left the Apevia on a shelf for a few months. I was building an extreme low budget computer for my cousin, and decided to take a gamble in the name of free PSU's using the Apevia to drive the low power Athlon X3 system (total peak consumption under 350 watts). 10 days later I was shelling out $45 for an Antec EA430 and spending a few hours of my time driving and installing the new PSU. Epic Fail. -

ira176 I've put together three computers in the last 8 years with Seasonic PSU's. Never a failure, always reliable.Reply -

chaz_music Great article with lots of data! Thanks for the comprehensive list.Reply

I had a few comments to share that can help some. I am a power electronic engineer who designs switching supplies (PSUs) and inverter systems, so I see these technologies every day. One misconception is that PFC correction improves efficiency. It CAN improve efficiency if implemented right, but often it is not. PFC is needed to keep the current draw from the utility low in harmonics (only sinusoidal current) and in phase (phase angle power factor). This helps keep the utility system efficiency highest - but does not guarantee anything about the end power supply efficiency. That is depended upon the PSU design itself and how thorough it is done. Often, the simple passive diode-bridge and cap bank front end PSU is very efficient versus its PFC counterpart.

Another point - the IC pictured in one of the slides is the control IC, not a security device. There are tons of manufactures of these from Asia, Europe, and the US. The cheapest low efficiency supplies will use hard switching chips. The highest efficiency PSUs will use some form of resonant controller(s) which requires more cost and more parts - which is why higher efficiency costs more.

Last is a comment on what size PSU to use. Too many builders are using huge supplies "just to be safe" and are paying the price on a lower efficiency build when it is all done, not to mention too much cost. A larger PSU will have larger transformers, MOSFETS, diodes, and other parts. Larger parts require more overhead losses, just like having a V8 motor in a car will always have lower mileage than a 6 cylinder motor. The efficiency curve of most PSU designs falls off quickly as you go below 20% load because of losses in the larger parts and other extra overhead. That is why the Plus 80 curves don't go below 20%! It gets ugly below that. So size you PSU closely to the needed load. I have a 10TB server using an AMD 790GX motherboard and IGP graphics. There are a total of 12 WD Green series hardrives in this server. It has an Antec Earthwatts unit rated at 380W, and it only has to work hard during power up - the plus power peaks around 290W. Nominal power is around 115W, which is about 30% rated for this PSU - perfect.

One anecdote - I had a server several years ago that kept killing drives. We thought it was the SATA controller, but got the idea to scope the PSU. We found that the 12V rail was going over 20-21V during power up!! Ah, that's out of spec. Kinda.

- Charles -

chaz_music Great article with lots of data! Thanks for the comprehensive list.Reply

I had a few comments to share that can help some. I am a power electronic engineer who designs switching supplies (PSUs) and inverter systems, so I see these technologies every day. One misconception is that PFC correction improves efficiency. It CAN improve efficiency if implemented right, but often it is not. PFC is needed to keep the current draw from the utility low in harmonics (only sinusoidal current) and in phase (phase angle power factor). This helps keep the utility system efficiency highest - but does not guarantee anything about the end power supply efficiency. That is depended upon the PSU design itself and how thorough it is done. Often, the simple passive diode-bridge and cap bank front end PSU is very efficient versus its PFC counterpart.

Another point - the IC pictured in one of the slides is the control IC, not a security device. There are tons of manufactures of these from Asia, Europe, and the US. The cheapest low efficiency supplies will use hard switching chips. The highest efficiency PSUs will use some form of resonant controller(s) which requires more cost and more parts - which is why higher efficiency costs more.

Last is a comment on what size PSU to use. Too many builders are using huge supplies "just to be safe" and are paying the price on a lower efficiency build when it is all done, not to mention too much cost. A larger PSU will have larger transformers, MOSFETS, diodes, and other parts. Larger parts require more overhead losses, just like having a V8 motor in a car will always have lower mileage than a 6 cylinder motor. The efficiency curve of most PSU designs falls off quickly as you go below 20% load because of losses in the larger parts and other extra overhead. That is why the Plus 80 curves don't go below 20%! It gets ugly below that. So size you PSU closely to the needed load. I have a 10TB server using an AMD 790GX motherboard and IGP graphics. There are a total of 12 WD Green series hardrives in this server. It has an Antec Earthwatts unit rated at 380W, and it only has to work hard during power up - the plus power peaks around 290W. Nominal power is around 115W, which is about 30% rated for this PSU - perfect.

One anecdote - I had a server several years ago that kept killing drives. We thought it was the SATA controller, but got the idea to scope the PSU. We found that the 12V rail was going over 20-21V during power up!! Ah, that's out of spec. Kinda.

- Charles -

duk3 Maybe add something recommending quality PSUs?Reply

Also, you missed XFX and its seasonic PSUs. -

Twoboxer Replacing the psu resolves many more of the hardware issues brought to Tom's than any other part . . . probably more than half.Reply

It isn't possible for the average user to determine whether or not a specific psu is worth using. When we recommend a psu to someone in the forums, it's based on overall corporate reputation (arguably two companies) or specific reviews done by qualified reviewers. That gives us a relatively limited range of safe recommendations.

The more psus are reviewed, the more information that's made available, the better. -

shades_aus Every single SeaSonic PSU I have owned is still running.Reply

I have had Antec and countless others die. Obviously the Antec wasn't the SeaSonic model.

Now I only buy SeaSonic.

Article doesn't have any stats on PSU usage, market share, or failure rates. -

gkay09 Very nice article, though most of the info was available on the net, but not in one place, and this article fixes that...Do update the tables often...Reply