Semiconductor Production 101

Doping, Diffusion

I already mentioned doping, which is done at the time the mono crystal is grown. Doping, however, can also be done with the final wafer, and during the photolithography process later on. This allows for the alteration of the electrical properties of specific areas and specific layers instead of the entire crystal structure (partial doping).

Adding a doping material can be done via diffusion. The doping material fills empty spaces within the crystal lattice, while it comes between the silicon compounds. In some cases, it even switch positions with silicon compounds. Diffusion can be achieved via gases (nitrogen and argon) or solid materials, or other doping sources.

Another doping approach is ion implantation, which is very useful to alter a wafer that has already been doped, because ion implantation is performed at ambient temperature. This prevents existing dopings to diffuse. It is possible to mask certain areas of the wafer to treat only very specific areas. There is much more to say about ion implantation, such as the depth of penetration, activation of the doping additive at high temperatures, channeling, diffusing oxide layers, etc.- but this would go into far too much detail for the scope of this article. This process can be repeated multiple times during the process.

Mask Making

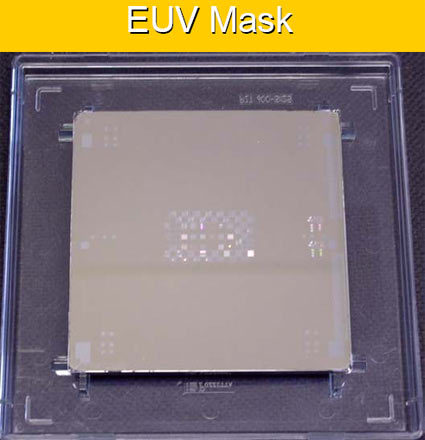

To create the fine patters of an integrated circuit, photographic processes are also applied. Since you don't want to expose the whole wafer to high intensity light or energy sources, it is important to work with so-called masks, which allow light to pass only through specific regions. Masks can be compared to b/w film negatives. Integrated circuits have multiple layers (20 and more); as a consequence, there are masks for each individual layer.

A thin film of chromium is patterned onto a plate of quartz glass to create the so-called reticles. Expensive tools, using either electron beams or lasers, fetch the necessary IC data and form the chromium-plated quartz plates. Here it is important to know that each modification in an IC design requires new masks to be produced, which makes the whole affair pretty expensive. Especially complex circuit designs take longer time for mask creation.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Tom's Hardware is the leading destination for hardcore computer enthusiasts. We cover everything from processors to 3D printers, single-board computers, SSDs and high-end gaming rigs, empowering readers to make the most of the tech they love, keep up on the latest developments and buy the right gear. Our staff has more than 100 years of combined experience covering news, solving tech problems and reviewing components and systems.