Strip Out The Fans, Add 8 Gallons of Cooking Oil

Sealing The Plexiglas Case

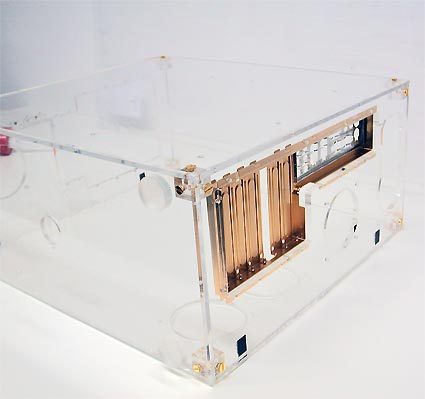

We struck gold by finding a transparent case to show off our DIY oil PC masterwork.

The underlying thought behind this project was to design a system that cooled the components by total submersion in a liquid-filled case. The lab engineers immediately set two conditions: The system should run silently and only choice hardware should be used. We also sought out an attractive container or case. Using an aquarium was excluded from the very beginning - cables and connections couldn't be cleanly brought from the inside to the outside. The system had to look good, too. In the end, we decided on a transparent PC case made of Plexiglas, which however meant an immense labor expense. All contact surfaces of the individual edges had to be glued and made airtight. The sealing of boreholes and openings on the individual slabs meant additional effort. Step by step, first special glue and then silicone were used. The latter particularly needs time to cure, making the use of a dryer recommended.

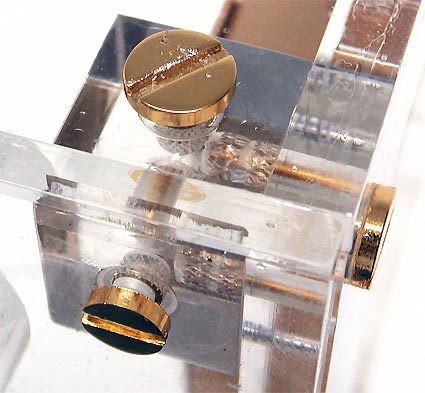

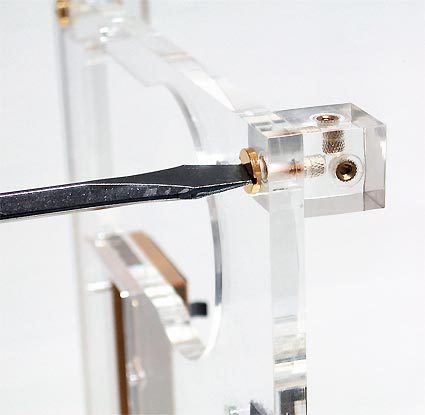

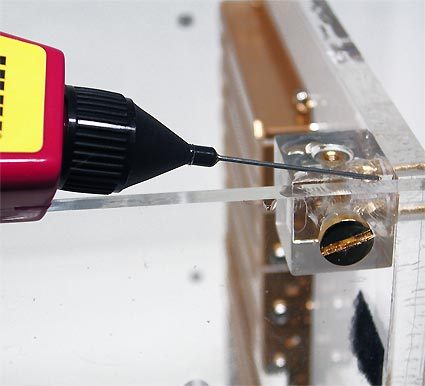

All screw joints in the case have to be loosened, followed by wetting with special glue.

To seal the openings, we got Plexiglas slabs that we cut accordingly. If you expect the oil smell to be a problem, then you should plan for a top cover right away. However, the heat exchange between the oil liquid and the environment will then be altered.

All parts of the case must have airtight contacts.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Current page: Sealing The Plexiglas Case

Prev Page DIY Step By Step: Tools And Aids Next Page Sealing The Plexiglas Case, Continued-

jayh619 does anyone no how long a computercan lst doing this? like after six months of being submerged and the oil was rinsed out. would the computer still work without the oil? or would the oil would decrease the computer's components life spans? Or increase it?Reply -

ive seen some run for a year at 80 degrees C with out anything cooling the oil but with a zalman water cooler hooked into it to cool the oil it will run at 30c for as long as the cpu lifespanReply

-

logicmoo "On the motherboard http://en.wikipedia.org/wiki/Motherboard in the area of the CPU base, the oil is responsible for increasing the capacitive resistance between the individual wiring. In short, the oil acts as a dielectric material. Since very high frequencies occur on the motherboard, the capacitive resistance goes down. Accordingly, this then influences (or tampers with) the digital signals, particularly in the area of the CPU base. After all, 939 pins are located there in a very tight space."Reply

This is the first article I've seen mentioning the sealling of he base of the CPU. Other's some in the forums are concerned that there is not enough cooling flow under sockets.. since liquid is thicker than air it tends to want to create hotspots here. Air will swell and vent heat more. This article notes that they "had" to seal the base for stability. I understand the dielectic effect. But anyways for a socket 775 anyone know for sure what we should do? -

creepster Why not use mineral oil, or better yet, transformer oil? It would have better electrical properties than cooking oil, and probably better thermal properties, too.Reply -

davea0511 I can't imagine those leads are long enough to cause any kind of capacitance issues. Furthermore, I can't imagine that silicone is going to keep oil out of there for very long. Dozens of others have done this without sealing off the CPU with no ill effects. Pugetsystems oil computer for example.Reply

Anyway, I'm curious about the long term effects. This project was started a couple years ago. Is the computer still running, or did they decided to can it. Seems like everyone that does this ends up draining it before it get's a chance to fail from oil-related reasons. Pity - It would be nice to have some data to see whether it really could be a viable solution for a silent PC that would last literally for as long as the cpu transistors normally last. -

OnyxxOr Another note on the silicone... I noticed the only long term oil setups use seemless tanks (i.e. no silicon sealing in the actual submerged part of the tank). I've done some research on silicone and the "service" temperature range is listed at -50 to 150 celsius. However, one can understand normal silicone usage is for applications that experience far lower in use and/or continued temperatures (Fish tanks, showers etc).Reply

Before considering that I purchased a tiny (15 litre) fishtank for a low end setup that was built/sealed with silicone, so I guess I'll soon know xD (hopefully not by it falling apart and spilling oil all over my carpets lol).

I have an existing 3 foot tank which I intended using for my 'production' system which will be more than double the power in every sense :D - and big enough for a whole bunch extra cold cathode's and led fans (for the looks of course ^^). I may reconsider that after some testing.

I'll do my best to pop back and post on this new consideration to let you know how the silicone behaves under extreme usage.

Oh and another thing, on the mineral oil... in all experiments the folks mentioned difficulty in getting hold of mineral oil. I initially thought the majour problem would be in the fact that it's classed as a known laxative and any distributor would be hesitant handing over that much of it for legal or safety reasons. Turns out most people don't even know what it is xD!! That got me onto some research into it's common consumers, and in so doing found a bunch of alternative names for it, which I DID see at some stores.

I'll list them here for acedemic interest but please keep in mind that common or trading names may differ from region to region so ask the right questions (Low viscosity, high flash point, no electrical conductance) AND test it in a controlled outdoor enviroment on smaller (cheaper) components before going the whole way :) That said, mineral oil also goes by the following names:

White oil

Nujol

Paraffin oil (Not normal paraffin, like for lanterns, far as I know)

Baby oil xD (Yep, though I'm suspecting the fragrance additives may have some unwanted properties, probably mildly corrosive)

Anyways, happy modding for now

l8r,

OnyxxOr

-

now i can overclock the living daylights out of my machine, and use the heat to deep fry some fish. Increasing my enjoyment (and that of my computer), as well as shortening my life (as well as my computer).Reply

-

Cooking oil will turn rancid rapidly when exposed to air and heat. It will stink.Reply

Don't use a food-based oil if you do this. -

why not use synthetic motor oil?, miniral oil has trace minerals that can stick to surface (non-conductive but it looks ugly)Reply