Nvidia products could be made using humanoid robots for the first time ever — company in talks with Foxconn to deploy them in Houston factory building GB300 AI servers

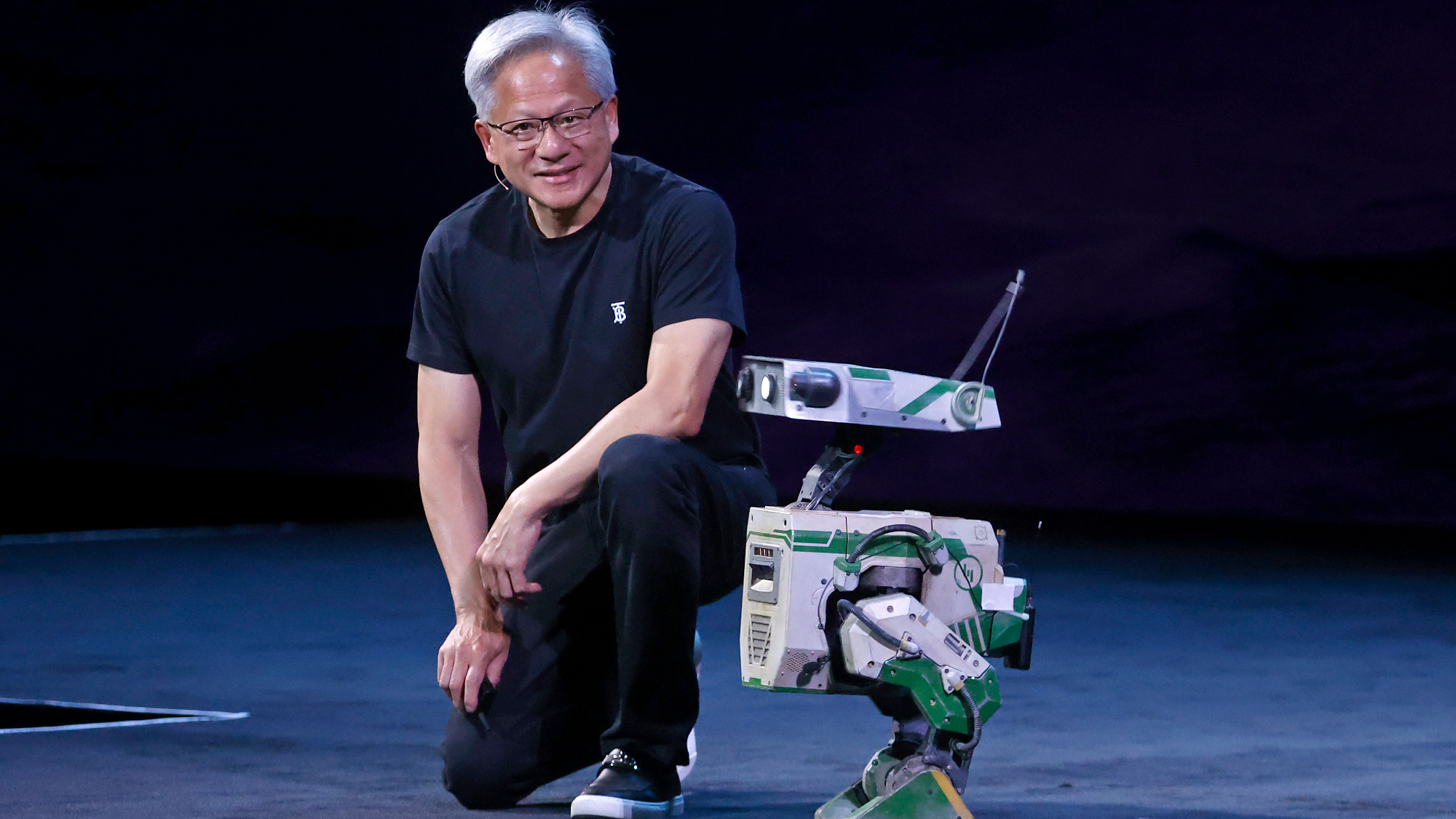

RTX2-D2

A new report indicates that Taiwan manufacturing giant Foxconn and Nvidia are in talks over the prospect of deploying humanoid robots at a new Foxconn facility in Houston. It is purported the bots would be used in the construction of Nvidia's new GB300 AI servers, which will go into production of at the plant next year, according to Reuters.

As the report notes, the milestone would mark the first time an Nvidia product has been made using humanoid robots, and would mark the first Foxconn AI server factory to deploy the tech on its production lines.

If deployment gets the go ahead, the report claims the rollout will be finalized in the coming months, promising to transform the manufacturing process.

Both Foxconn and Nvidia are reportedly trialling humanoid robots, the latter using China's UBTech. However, according to the report, it is unclear at this stage what type of robots would be used in the Houston factory, what they would look like, or how many would be used.

A more specific timeframe suggests the companies are targeting the first quarter of 2026 to begin the project, which would coincide with the start-up of Nvidia GB300 AI servers at the plant.

As to the role of the robots, Foxconn has allegedly trained them to pick up and put down objects, insert cables, and do assembly work. The Houston factory is tipped as a great proving ground because it's newer and larger, with more space than Foxconn's existing facilities.

Later this year, Foxconn is expected to showcase two new robots, one a humanoid model with legs, and the other a wheeled autonomous robot base.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

At a recent June keynote at GTC Paris, Nvidia CEO Jensen Huang touted the company's enormous efforts to help develop robots for all manner of applications. Huang even invited AI robot Grek onto the stage for an adorable segment as he showcased the power of the Nvidia, DeepMind, and Disney project Newton. Nvidia's mechanized aspirations also seem to extend to its own supply chain.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Stephen is Tom's Hardware's News Editor with almost a decade of industry experience covering technology, having worked at TechRadar, iMore, and even Apple over the years. He has covered the world of consumer tech from nearly every angle, including supply chain rumors, patents, and litigation, and more. When he's not at work, he loves reading about history and playing video games.

-

chaz_music Exactly what I have been saying for nearly 25 years. No need to outsource manufacturing to global locations. Just change the design to minimize manual labor and then you can manufacture anywhere you want. And not only does the cost go down from lower manufacturing costs, your warranty costs go down because you get consistent low-defect assembly and higher MFG yields. And robots don't require OSHA restrictions and other high cost overhead. This is how the US can produce locally again products such as cellphones, computers, TVs, and other products that are presently seen as high labor products. They don't have to be that way.Reply

With manufacturing being done locally, the problem feedback loop is much faster and tighter, allowing for faster responses and less production loss/cost when a real problem occurs (assembly errors, material errors, infant mortality problems). Making this kind of change and commitment requires companies not use lazy and poor engineering like so many do now.

It is unfortunate that US colleges have touted outsourcing for so long that nearly all US companies do it to "keep up with the Jones". This is exactly how the US caused the mortgage meltdown - everyone jumped on the same ship without checking the validity of the concepts they were following. I call this kind of poor group thinking "Lemming herding".

The concepts of Lean Design/Manufacturing/6 Sigma are how the Japanese car manufacturers leaped ahead of the rest of the world. These world class concepts push the importance of not outsourcing what should be a company's core competency. And in high tech, manufacturing is a core competency. This is how ultra-successful companies have made their mark, such as GE, HP, Toyota, Honda, Westinghouse, and even Motorola (before their newer management bought into the outsourcing Koolaid). And the awesome footnote: all of these concepts were developed here in the US and are hardly being taught in business schools. These **should** be central in their syllabus.

Lean Design/MFG:

https://en.wikipedia.org/wiki/Design_for_lean_manufacturing

Wikipedia on Deming (came up with 6 Sigma concept in 1970-80s):

https://en.wikipedia.org/wiki/W._Edwards_Deming -

Notton As a tech demonstration, sure.Reply

As a practical product? Why does it need to be humanoid?

If it's going to work in a factory, it should have >4 arms with flexibility beyond what the human arm is capable of, >6 baby-sized fingers per arm with super human dexterity and gorilla-like strength, and a multi-angle camera/sensor array for full 3D vision not limited by a single head and a pair of eyes. Bonus points for having 2 thumbs per hand.

It doesn't need a torso or legs because it's working in a factory, and if it's an assembly line, the arms can be placed on a rotating pedestal with power coming off of the floor or ceiling. -

jlake3 As a former engineer for an industrial automation company, why are they humanoid? What does being humanoid do that existing industrial robots could not?Reply

And no, "delicate tasks"or "irregular positioning" does not count. You can have a 6-axis robot arm with force control and machine vision that detects rotation and non-matching components. The thing that we ran into, however, was that if a product only has a 4-7 year lifecycle, ROI between an expensive automation solution plus engineers on-call at all times just in case an error takes the line down at an odd time versus a minimum-wage employee gets messy, and the fact that the automation cost is larger up front makes decision makers antsy. (And that's at US wages; expensive automation versus cheap outsourcing is an even more difficult sell)

I'm not sure "more flexible" counts either? I suppose you can move programming between robots without needing new tooling, but companies refurbish robot arms and stick new end-of-arm tooling on them all the time, or even modify the existing tooling on the robot. Some companies run automatic tool changers where it places the end-of-arm tooling to a stand and picks up another tool on it's own, both for automated changeovers between production lots and from cycle-to-cycle to handle mixed products coming down the same line.

If they need to work safely in proximity to humans, they've already got product lines for that.

...and if they're not hardwired, now you've got batteries and charging to manage.

And yeah, you can have a custom-shaped tool with more points of grip than a 2-handed, 10-fingered human, plus precise locator pins and all manner of sensors, and then have all that move around in ergonomically-impossible ways...

I'm sure there's use cases where a humanoid robot makes sense, but I really need to hear why existing robots don't work and what's so game-changing about humanoid robots in a particular application before I can see it as more than a gimmick.