16-Pin Power Connector Gets A Much-Needed Revision, Meet The New 12V-2x6 Connector

Graphics card owners with the 16-pin (12VHPWR) power connector no longer have to live in fear. According to a new report from the German publication Igor's Lab, PCI-SIG is revising the specification in an attempt to save the 12VHPWR power connector. It's about time that PCI-SIG took action on the matter amidst multiple user reports of the 16-pin connector melting on Nvidia's GeForce RTX 4090, one of the best graphics cards for gamers.

Innovation is a great thing because it drives companies to release novel products. However, too much innovation can also be a bad thing. The feedback was mixed when word got out that Nvidia would put the 16-pin power connector on some of its consumer GeForce RTX 40-series (Ada Lovelace) graphics cards. Some were happy that we could finally ditch the cable clutter and use a single 16-pin power cable instead of three 8-pin PCIe power cables. However, others had reservations about Nvidia's decision. The 12VHPWR was a new connector, and there's always a bit of fear for early adopters. Furthermore, what worried many users was that large amounts of power were going through that tiny 16-pin power connector.

Unfortunately, it took a lot of GeForce RTX 4090 casualties to get to a point where the big guys up top realize that the 12VHPWR power connector deserves a revision. Igor's Lab shared a small excerpt from a draft engineering change notice of the forthcoming CEM 5.1 specification that will serve as the basis for the ATX 3.1 standard. The 12V-2x6 power connector will replace the 12VHPWR power connector. The draft reportedly goes under the "PCIe Base 6.0" moniker and explicitly defines the measurement guidelines for the maximum and sustained power for the connector. Nonetheless, the 12V-2x6 power connector has backward compatibility with the 12VHPWR connector. It's not a good look since Nvidia had attributed the 12VHPWR connector meltdowns to user error. The fact that PCI-SIG is revising the connector implies that maybe not all the reported cases were due to user error.

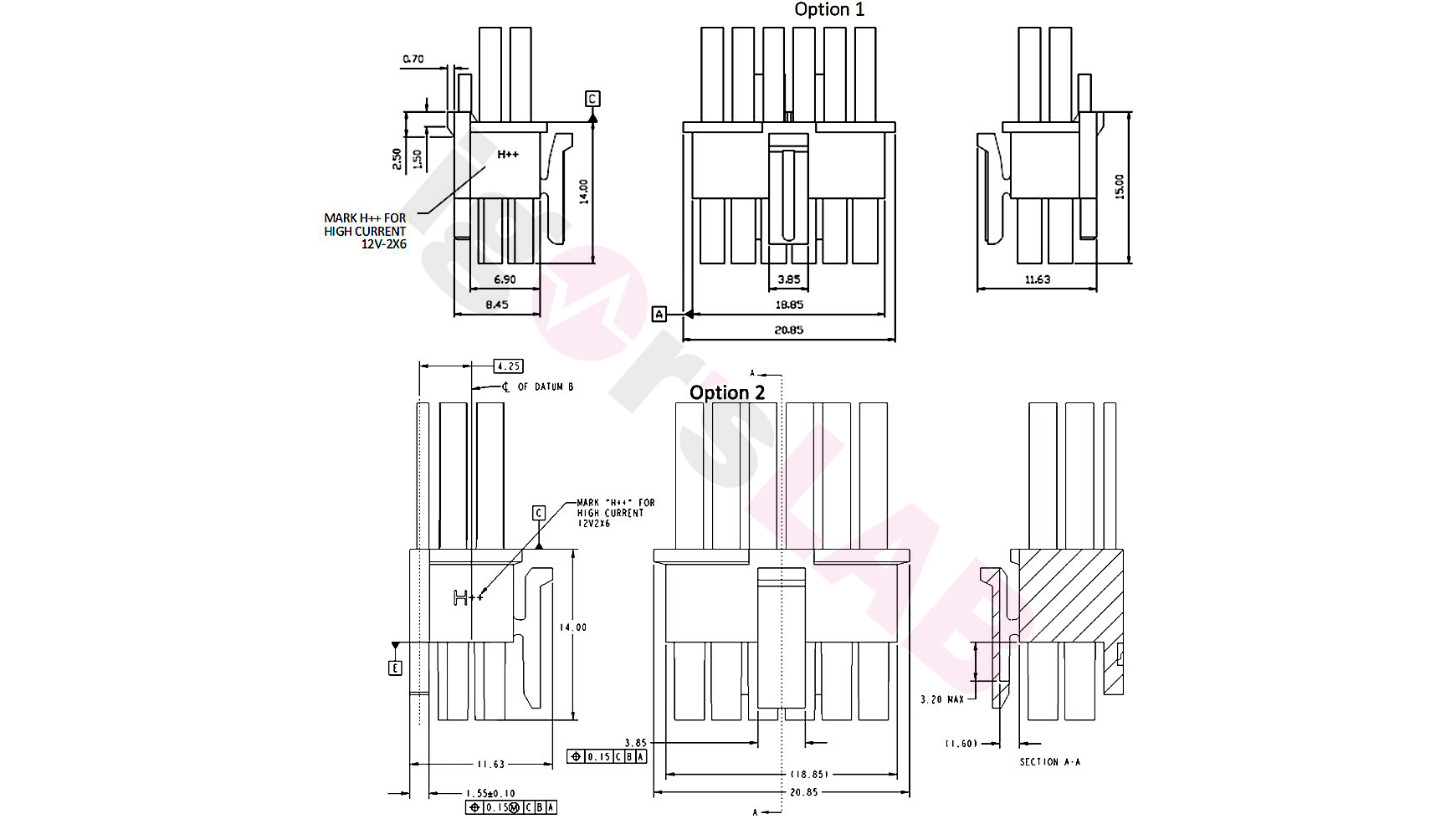

With the previous 12VHPWR power connector, the maximum power was 600W, 525W from the connector, and 75W from the expansion slot. On the other hand, the new limit on the 12V-2x6 power connector peaks at 675W, 600W for the connector along, and 75W from the expansion slot. The two power connectors are obviously different. However, PCI-SIG has made efforts to help less-experienced users differentiate one from the other by using unique identifiers. The old 12VHPWR power connectors will have the H+ marking, whereas the new 12V-2x6 power connector will have the H++ identifier.

The 12V-2x6 power connector delivers up to 55A of power to feed graphics cards for up to 600W on a 12V aux rail. The guidance states that the minimum rating for the current pins is 9.2A per pin with a ceiling of 30 degrees Celsius T-rise over the ambient temperature at 12V DC with 12 contacts activated. The connector must carry the H identifier to denote that it supports up to 9.2A per pin or higher.

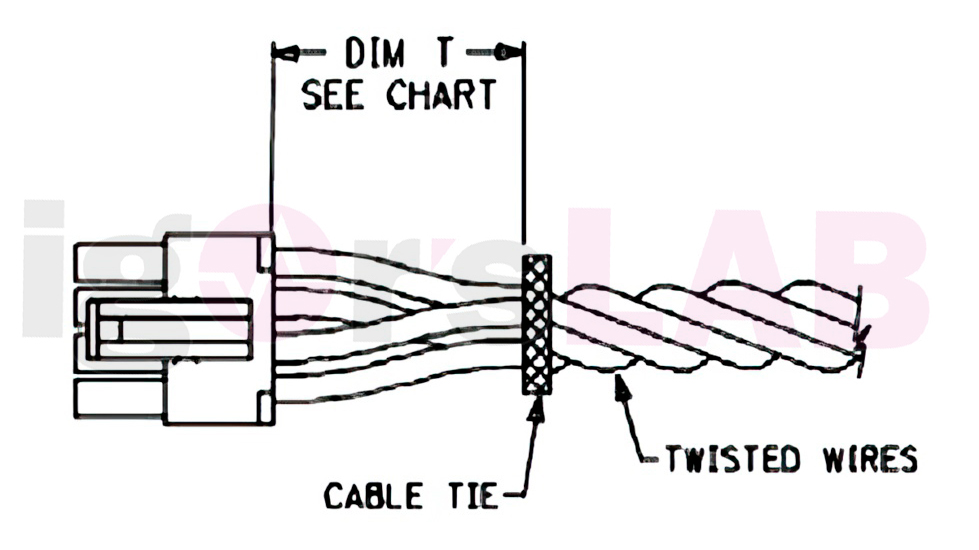

It's plausible that a pin may exhibit a current higher than 9.2A due to uneven cable contact resistance. Nonetheless, the total current should not surpass 55A RMS in either direction. Manufacturers must ensure that their connector's assembly, including the 16 AWG wires and pins, meets the minimum current requirement and maximum temperature. The document also specifies the locked connector retention force, emphasizing a minimum of 45N when you pull the connector axially.

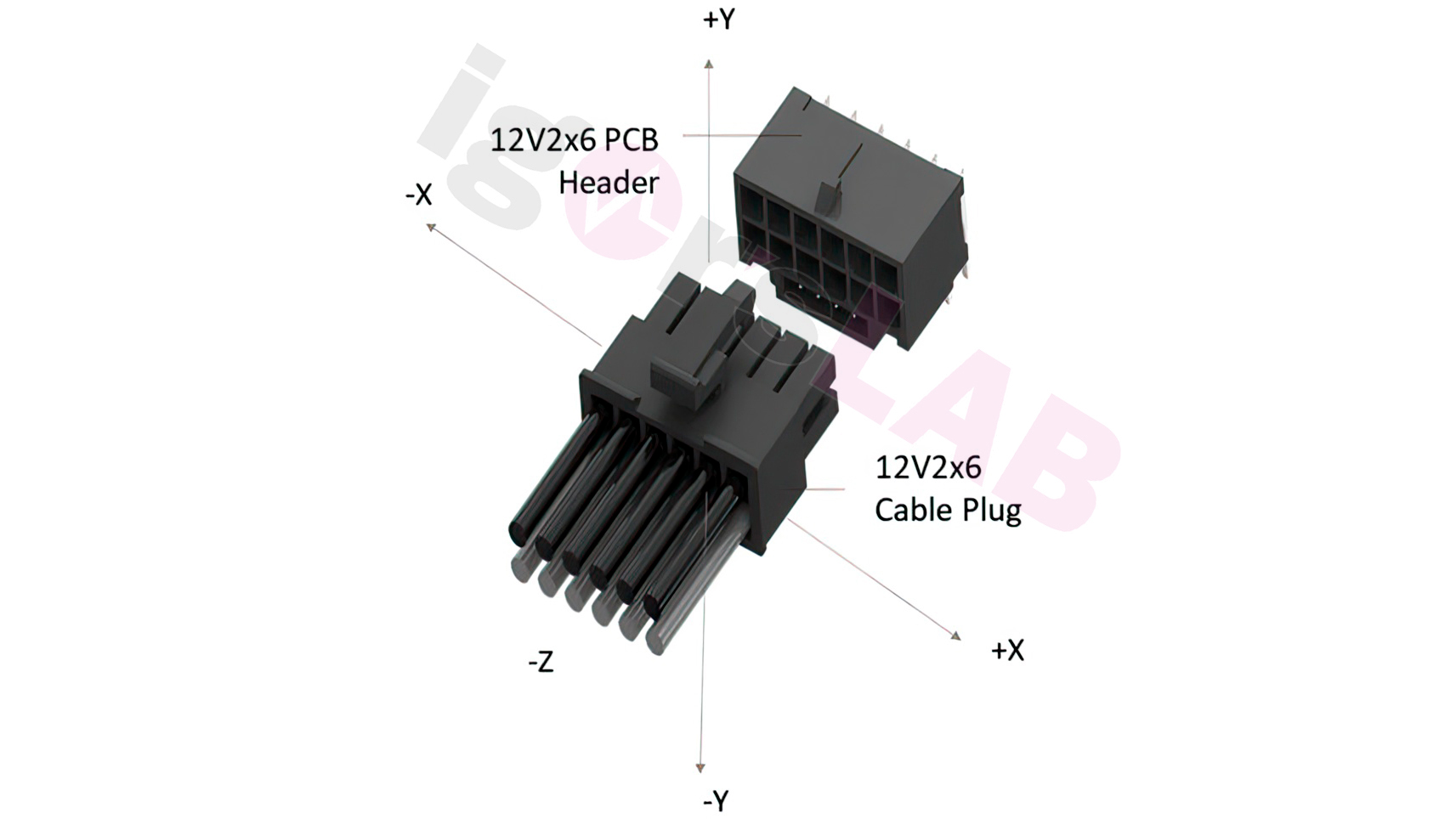

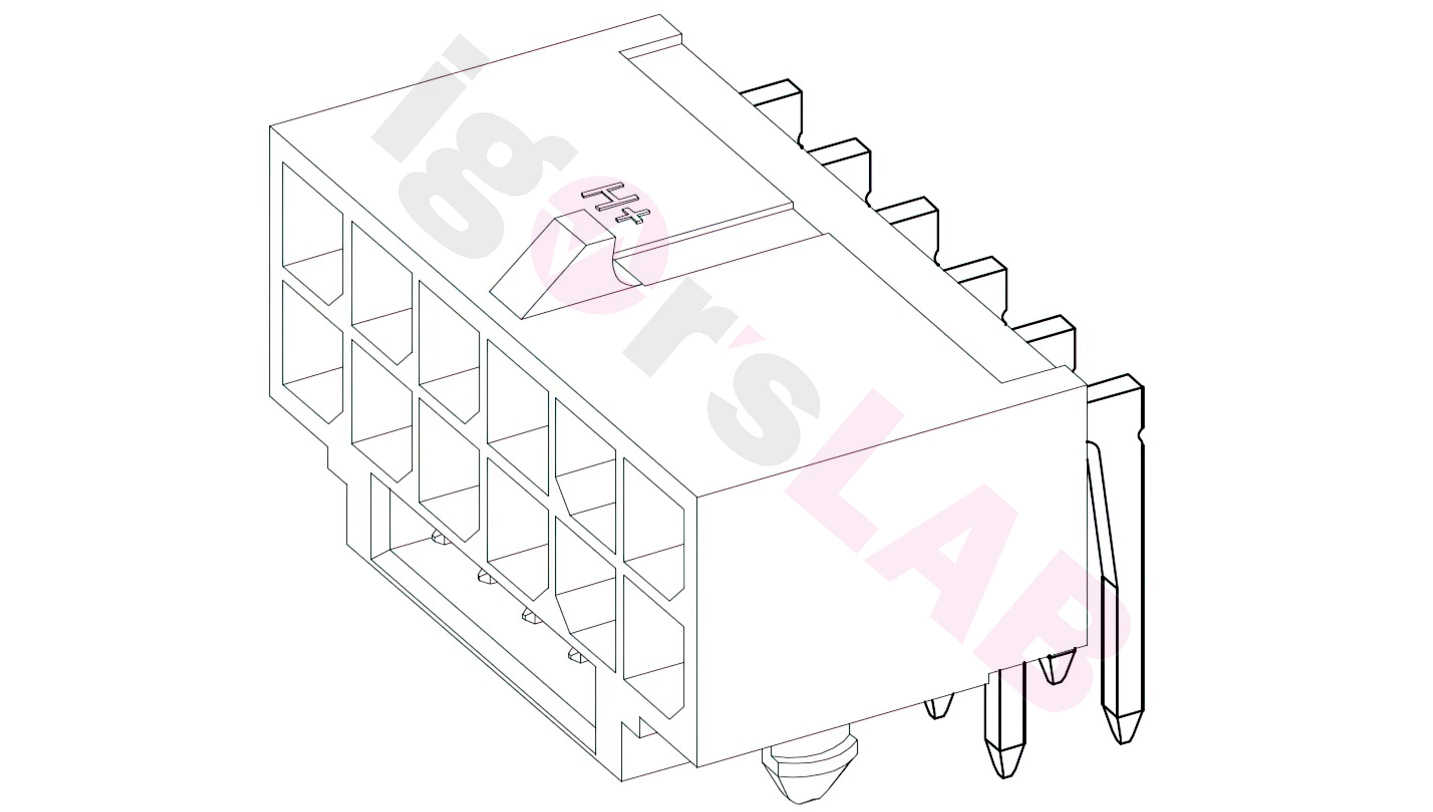

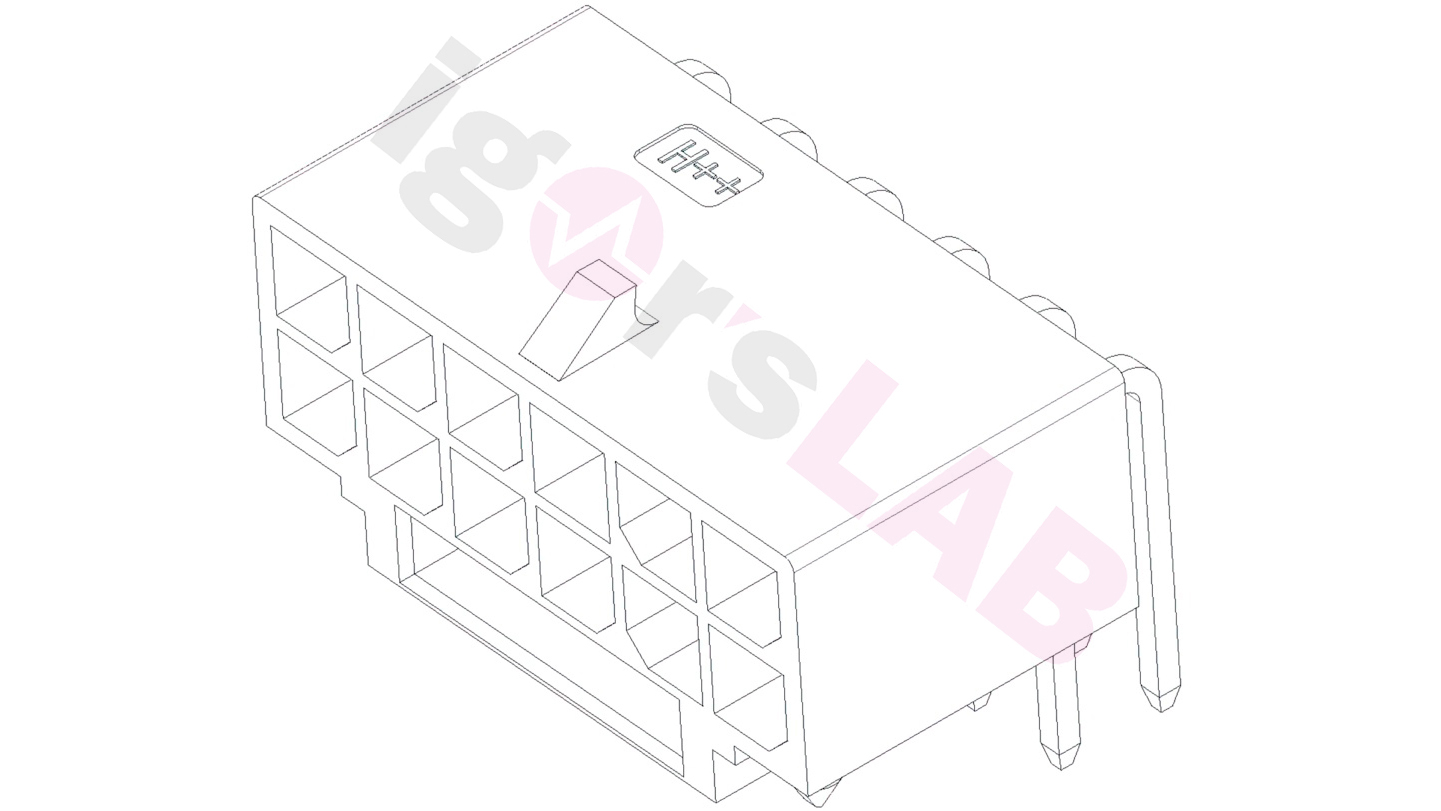

The 12V-2x6 power connector retains the same number of contacts as the 12VHPWR power connector. The 12 larger contacts carry the power, while the four smaller contacts are the sense pins for the sideband signals. However, PCI-SIG made significant changes to the 12V-2x6 header (socket) and connector (plug).

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

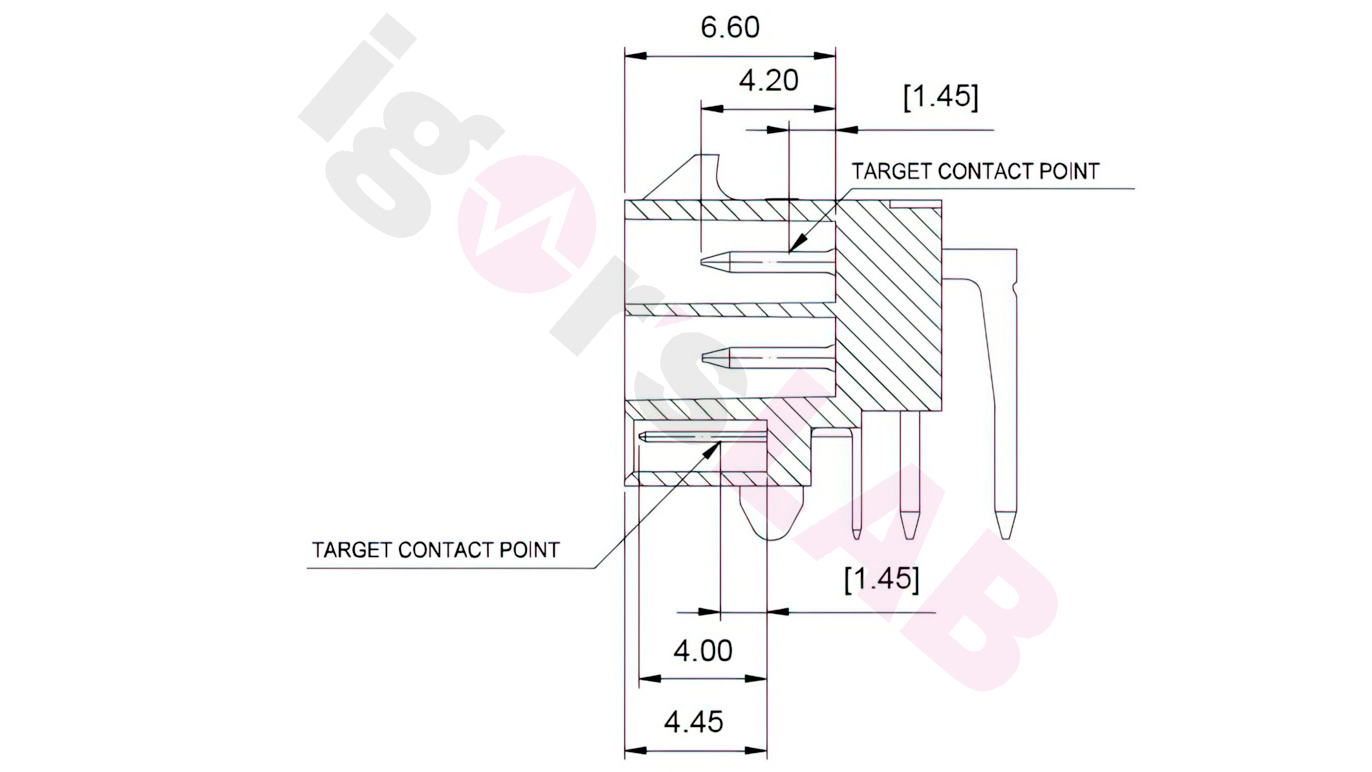

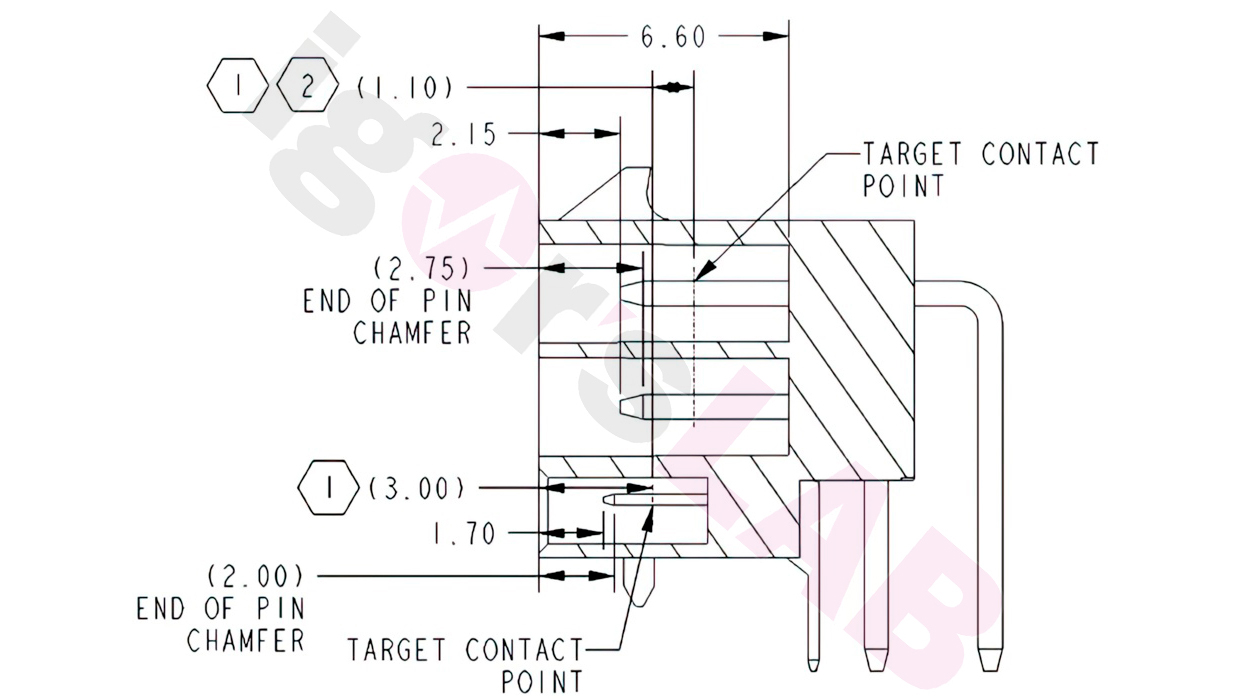

With the 12VHPWR header, the sense pins were 4mm long, with a space of 0.45m from the edge. The target contact point is 3mm behind the edge of the opening—the 12V-2x6 header shares similar outer dimensions as the 12VHPWR header. Even the target contact point for the sense pins is the same (3mm) to maintain compatibility. For safety reasons, PCI-SIG extended the spacing between the tip of the sense pins to the edge to 1.7mm on the 12V-2x6 header, a 1.25mm improvement. As a result, the pin behind the tip is 2mm behind the outer edge.

The Sense0 and Sense1 contacts are important for properly operating the 12V-2x6 power connector. If Sense0 and Sense1 remain open, no power will go to the graphics card. Grounding Sense0 and leaving Sense1 open will allow up to 300W or grounding both contacts for 600W. Meanwhile, the 150W mode implies connecting Sense0 and Sense1 directly without grounding, or in other words, shorting them. Igor's Lab believes the 150W design will require new power cables or a special power supply.

Shortening the sense pins seems like something that PCI-SIG should have done from the start with the 12VHPWR power connector. If the connector isn't fully inserted into the header, the graphics card will not turn on, or if the connector accidentally falls out, the graphics card will power down. In a way, pins being further recessed in the pin chamber should ensure the connector is completely plugged in.

Logically, the 12V-2x6 power connectors or adapters will feature a slightly different design than the existing 12VHPWR power connectors. According to the draft, two variants of the 12V-2x6 power connector could exist. Option 1 has a 0.7mm thick shoulder below the sense pins, while there is no shoulder on Option 2. Regardless of the design, both variants have the same dimensions. However, there's no explanation behind the reasoning for the two proposed options.

PCI-SIG recommended NTK's contact design over Astron in the CEM 5.0 specification. The recommendation should still be the same as the 12V-2x6 power connector, but we should wait for official confirmation before passing judgment.

The guidance to not bend the cable too close to the connector still stands with the 12V-2x6 power connector. With the previous 12VHPWR power connector, the recommended spacing was at least 35mm from the connector before bending, although some power supply vendors suggested up to 40mm for good measure. However, the distance for the 12V-2x6 power connector is unknown as Igor's Lab didn't provide the specific measurement in the report. The 12V-2x6 document also delves into more technical aspects, such as testing methodologies.

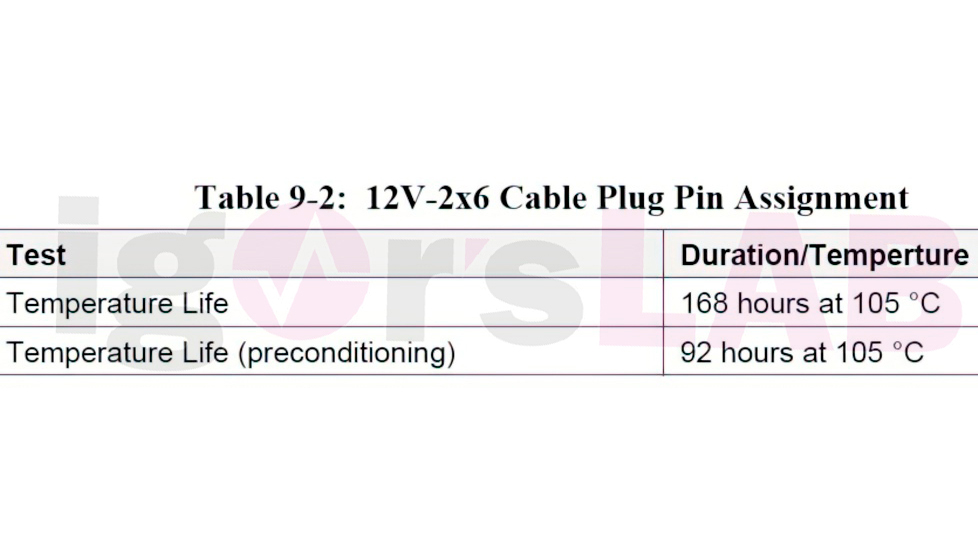

Another interesting bit of information from the draft concerns temperatures on the 12V-2x6 power connector's pins. The temperature life is 168 hours at 105 degrees Celsius, while the expectancy is 92 hours at 105 degrees Celsius with preconditioning. Therefore, manufacturers must consider temperature limits when designing their graphics cards to ensure that other components, such as the shunts, VRM, or coils, don't add unnecessary heat to the header.

The specifications for the 12V-2x6 power connector aren't final; however, Igor's Lab believes they're unlikely to change. For example, MSI has already launched new ATX 3.0 power supplies with the 12V2x6 connector. The fact that the vendors can spec the 12V-2x6 power connector for 150W or 300W might mean that we could potentially find the new power connector on lower-end graphics cards as well.

Everything looks good on the drawing board until it hits the market, and issues start popping up left and right. That was the case with the 12VHPWR power connector. Only time will tell whether PCI-SIG's mechanical modifications will yield positive results.

Zhiye Liu is a news editor, memory reviewer, and SSD tester at Tom’s Hardware. Although he loves everything that’s hardware, he has a soft spot for CPUs, GPUs, and RAM.

-

bit_user I think they had to at least appear to do something, after all the reputational damage the 12VHPWR took, regardless of whether or not it was all entirely deserved.Reply

And let's hope it doesn't really take until PCIe 6.0 to roll out, though backwards compatibility probably means it won't. -

-Fran- Any improvements to safety are welcome in any high powered part!Reply

I wonder if AMD will adopt this connector now for the next gen and if nVidia will update the connector for the refresh (if there is one) or next gen.

Given the cycles, maybe for the next next gen?

Regards. -

torbjorn.lindgren Whether the root cause for the melting connectors is/was "user error" or not doesn't really matter, at best they messed up by making the specification too loose and/or too hard to use properly/safely.Reply

The retention clip on them are clearly not good enough for example, on many it's possible to wiggle the connector far too much with it inserted fully and latched, and the latch also lacks a "positive feedback" which the previous connector had. Arguably they should probably have gone to two latches for this wider connector but it was likely hard to do and stay compatible.

In short, it may well be that technically all the melted connectors ARE user errors, but that doesn't mean the PCI-SIG is blameless here or that they shouldn't improve it so that it's no longer a "gotcha" connector. -

Rdslw Reply

The amount of juice we push through such tiny cables is already concerning. I double down on that, revision of those cables was long overdue.-Fran- said:Any improvements to safety are welcome in any high powered part! -

RodroX Good news for those few who were able to upgrade the GPU. Bad news is you may have to upgrade again, if you want the piece of mind. And of course pay nvidia once again.Reply

Most peple in my country are still rocking pre-GTX 1060 era GPUs, so we are ok here (y) !!! -

vinay2070 I have a feeling there will still be burned connectors despite this change, tho they may be few. That is too much power for such a small package. Why not just use 16 or even 20 wires.Reply -

InvalidError 168h connector lifespan at 105C... time for everyone who freaked out when they found out that PCIe slots and most other internal PC connectors are only rated for 10 cycles to freak out again!Reply

GPUs should just have a thermistor or two to monitor connector pins temperature (put a ground and power polygon just below the thermistors on the top or bottom layer to conduct pin heat, then do some modelling to map thermistor temperature to actual connector temperature) and throttle as necessary. Doesn't do anything for the PSU-side connector though, that would require adding a control pin to let the PSU tell the GPU to hold back if you don't want the PSU to outright shut off. -

bit_user Reply

Or use 48V at 1/4th the current, but that would require a new PSU.vinay2070 said:Why not just use 16 or even 20 wires. -

kiniku We have to idiot proof a connector. No problem whatsoever with my 16 pin ATX 3.0 connector to my MSI 4090 Supreme. Just connect it snugly. Jeez.Reply -

foxrox To make this new connection totally right they would be wise to include thumb screws on each side of the connection like an old VGA or DVI video, or serial port, cable. With that change there would be no reliance on a chintzy clip and no way the cable could come loose or not be firmly seated. You would simply tighten the thumb screws until the cable housing was bottomed out into the cable socket and enjoy never having to check on it again.Reply