The GPU 16-pin melting fiasco is getting ridiculous — now this entire Nvidia RTX turns into a red ring of death when it is incorrectly plugged in

Galax’s Hall of Fame graphics cards use ARGB lighting to warn of 16-pin issues

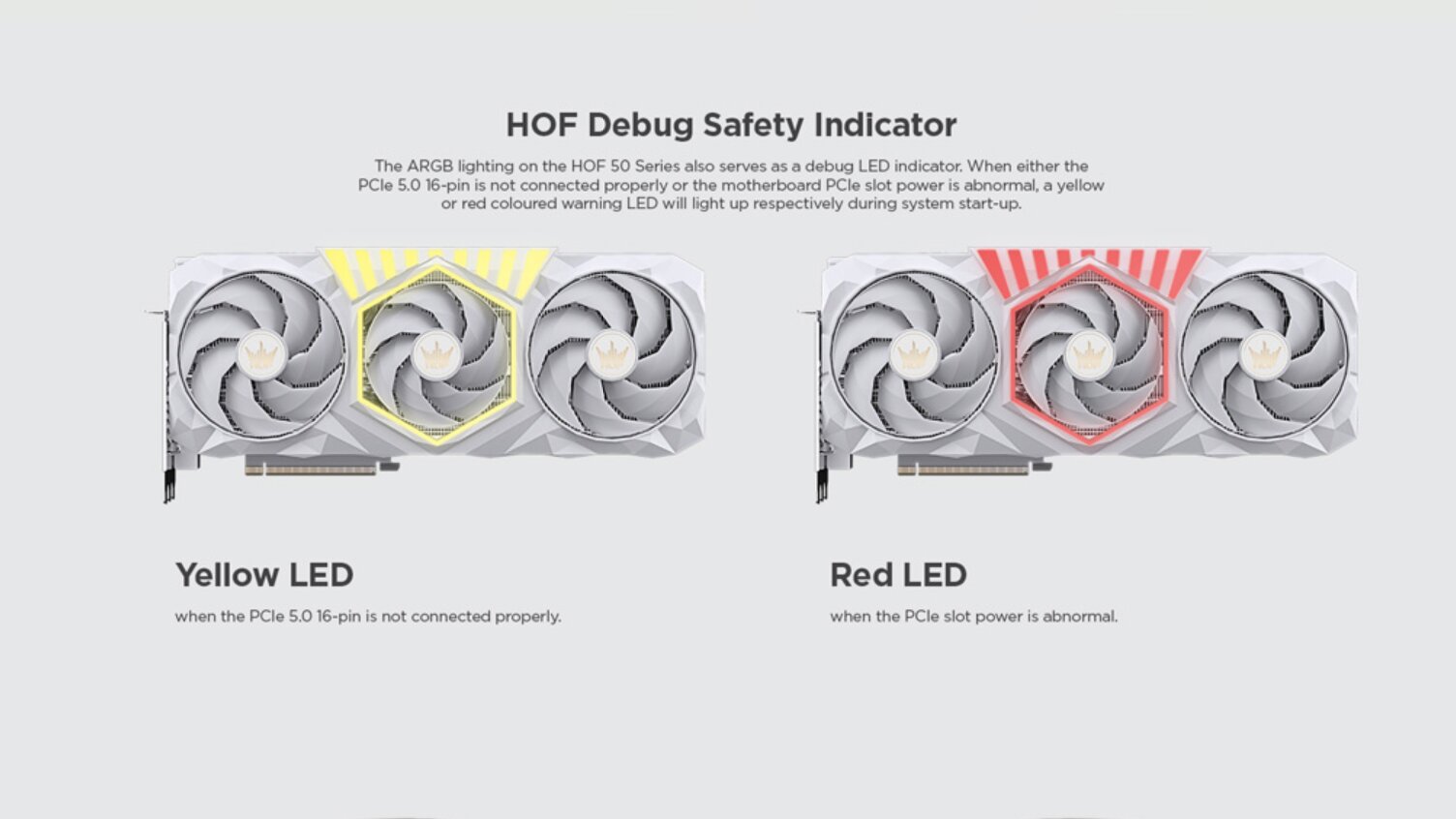

The 16-pin power connector, used in many of today’s best graphics cards, continues to be a headache with multiple reports of melting connectors on both the GPU and PSU ends. To address the ongoing issue, graphics card maker Galax has introduced a new solution aimed at warning users of potential failure. Its latest Hall of Fame (HOF) series GPUs, including the RTX 5080 and RTX 5070 Ti variants, feature ARGB lighting that also functions as a debug LED.

According to the company’s global website, the HOF series GPUs feature a triple-fan configuration, with the central 92mm fan surrounded by LEDs that extend to the edge of the shroud. In addition to delivering dazzling ARGB lighting effects, these LEDs serve a functional purpose. When powering up your system, these may turn yellow to indicate an improperly installed power connector or red to signal abnormal power delivery to the GPU.

What makes this development absurd is that it reflects just how far GPU makers are going to compensate for a design flaw that should’ve been solved by Nvidia long ago. The fact that an entire graphics card now needs to act as a warning beacon with a red ring of death (reminiscent of Xbox's famed 360 flaw) when something goes wrong speaks volumes about the 16-pin connector’s reliability issues. Despite updates like the revised 12V-2x6 standard, real-world problems persist, raising the question: at what point do GPU makers and power supply vendors stop treating the symptoms and actually fix the root cause?

If you recall, Zotac introduced a somewhat similar solution earlier this year with its RTX 50 series GPUs, which feature an LED indicator near the power connector. While it serves the same purpose of alerting users when the power cable isn’t properly connected, Galax’s HOF graphics cards take it a step further. In their case, the entire GPU glows, providing a more prominent visual warning.

MSI also introduced its own solution by adding yellow-colored tips for its 16-pin connector on cables and adapters supplied with its GPUs and power supply units. The idea was to make it easier for users to see whether the cable is completely inserted or not, potentially preventing meltdowns. Despite the company’s efforts, though, the issue persists as a user reported thermal damage using MSI's preventive yellow-tipped 12V-2x6 power cables.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Kunal Khullar is a contributing writer at Tom’s Hardware. He is a long time technology journalist and reviewer specializing in PC components and peripherals, and welcomes any and every question around building a PC.

-

Kindaian Prominent warning only if you use a glass box. So the design failure continues.Reply

me -> grabbing popcorn while waiting for Nvidia class action... or should that be glass action?

-> I know the joke is bad... leaving now! -

chaz_music I have commented on this so many times:Reply

"If they are Hell bent on sticking with this configuration on the GPUs, they should be using interleaved PWM switching stages, with one power stage used per pin. In other words, do not tie the PSU pins together in parallel: Treat each pin as its own supply with its own Buck converter causing equal current draw. This allows the PWM controller to force each pin to draw a balanced load and not rely on uncontrolled parallel path resistances."

Since they are probably using interleaved Buck converters anyway for this high of a power rating, this would not incur much of a price increase for the GPU. It might require some added input filter capacitance on each Buck converter due to conducted EMI back toward the main PSU. The nutting thing here is that these interleaved Buck converters are having to create equal currents in their power stages inherently. But their inputs are getting tied together and accepting the input power from a paralleled wiring system.

This is why companies should have a seasoned consultant come in and review their designs. In this case, a power electronics guy.

Mercy, this is such as obvious and simple fix. And I mean bonehead simple. -

-Fran- This made me cringe a bit: "when it is incorrectly plugged in" in the title feels like you're already blaming the user when these lights tell you "there's an issue".Reply

Come on, is it that hard to take the consumer side on this one?

Regards. -

chaz_music And some suggestions to use these in the meantime (from a previous post of mine):Reply

1. Do not use cabling that has a wiring loom wrapped around it, which acts as to reduce and constrict the airflow. The connector datasheets are expecting decent wire cooling to draw heat away from the connector housing at rated current. So no "pretty" nylon shroud covering the wiring. This allows for reasonable convection cooling of the wire. If this loom exists, remove it and allow the wire insulation to convection cool better. If you really want the wiring looms, consider current/power derating if you want to use them (like only below ~300W).

2. The wire is expected to act as a heatsink for the connector pins and sockets. Again this is simple physics used in ALL connector systems. The pin and socket contact points are tiny and much smaller than the wire cross-sectional area bring current to the pins & sockets. For this reason, suppliers should find a way to use larger wire than is presently being used. Even tool up a larger pin that fits the housing.

3. Since the pin and socket contact points have gone through oxidation and corrosion before you even install them, you should plug and unplug them several time to knock this oxidation off. Don't get excessive with it because you don't want to create fretting failure by scrapping off too much tin plating. About 3-5 time is great. One post I read stated that these pins are only rated for 50 insertions for their entire lifetime. Make sure the last insertion is seated well. Think about how long the GPU took to get to you, sat in a transport ship with high humidity to get to you, was even assembled in a factory with high humidity when it was soldered together.

4. You want to get the heat out of the cabling ends. So mount a fast fan by the GPU connector, as well as at the PSU connector. The imbalance can be caused by both ends of the cable! The fans should be mounted close by the connectors so that the airflow is "impingement".

I hope these suggestions help people while the industry addresses these shortcomings. -

dipique Reply

Exactly this. It's understandable that they made this error when the connector was first introduced. Historically this kind of fault prevention wasn't valuable enough to justify the cost/complexity (particularly on the design side). This is just because these are pretty low-margin products for the most part (for the manufacturer).chaz_music said:"If they are Hell bent on sticking with this configuration on the GPUs, they should be using interleaved PWM switching stages, with one power stage used per pin.

Now, the fact that they're low-margin products dictate the opposite. They can easily eat through most of their ROI with warranty replacements and bad press. And since this has been a known issues for several years, they can't exactly plead ignorance.

Nvidia guidance was initially rather vague, but it has since gotten quite specific; it's confusing to me why manufacturers are so slow to address the issue.

Not that Nvidia is blameless. The standard should probably work more like USB C such that the pins are independently and separately verified; however, anything sophisticated enough to truly verify (e.g. PSUs measuring resistance on test loads through each pin) would require a lot of added cost/complexity to PSUs, already a component famous for cutting corners on low end products. But if USB-PD can solve this problem with low-cost commodity chips, I suspect that this is a solvable problem that only Nvidia is in a position to solve. -

uplink-svk Deaign and shunt configuration on side of VGA's 12VHPWR and 12V2x6 is a disaster by all metrics and means, though, I've installed up to a hundred of RTX 4070/4080/Super/Ti/4090 and 5080 and 5090 cards, some had bad values on particular rails and I've had 0 issues so far. Yes, some cables went up to 10A/rail so I replaced whole cable, but so far so good. I'm well asare that ~100 units is a small sample and has anecdotal information and experience value at best, but still...🤷♂️Reply -

warptek I've got an even better solution though AIB aren't going to like it. The GPU should be an add on chip to a dedicated motherboard socket surrounded by VRAM sockets. You pick your GPU, you pick your VRAM configuration. You want to start out with a 4060 and upgrade down the road? You got it. You want to start with 8 GB and go to 16GB later? You got it. All on a minimum 256 bit bus.Reply -

Papusan What is this new news? From the artcicle... #To address the ongoing issue, graphics card maker Galax has introduced a new solution aimed at warning users of potential failure. Its latest Hall of Fame (HOF) series GPUs, including the RTX 5080 and RTX 5070 Ti variants, feature ARGB lighting that also functions as a debug LED.Reply

Galax introduced this feature with 4000 series or better say 4090 HOF. For over two years ago. So thanks for yesterdays news packed in as todays news :) -

DingusDog I have a dedicated 10,000btu air conditioner duct blowing directly on my 12V-2x6 power cables. I also have a live broadcast thermal camera monitoring the temperature of said cable that I can check from anywhere even when out of town. This way I can assure that my $3k GPU which could easily have had built in precautions and fail safes doesn't self immolate and take my whole house with it.Reply

/s

I'm still running a 4080 super and will probably keep it until it dies. 50 series is beyond a joke.