Intel Foundry Services Wins US Defense Contract for Chips with 18A Node

Bolstering US production

The U.S. Department of Defense has inked a deal with Intel for the company to provide commercial foundry services for the Rapid Assured Microelectronics Prototypes - Commercial (RAMP-C) program.

Intel Foundry Services (IFS), a new Intel division that offers the company's chip manufacturing services to chip designers, will work with the Department of Defense to create a foundry ecosystem to produce leading-edge "custom and integrated circuits and commercial products" for DoD systems, with the initial test chips being fabbed on Intel's 18A node. The dollar value of the contract is currently unknown, but we've reached out to Intel for details.

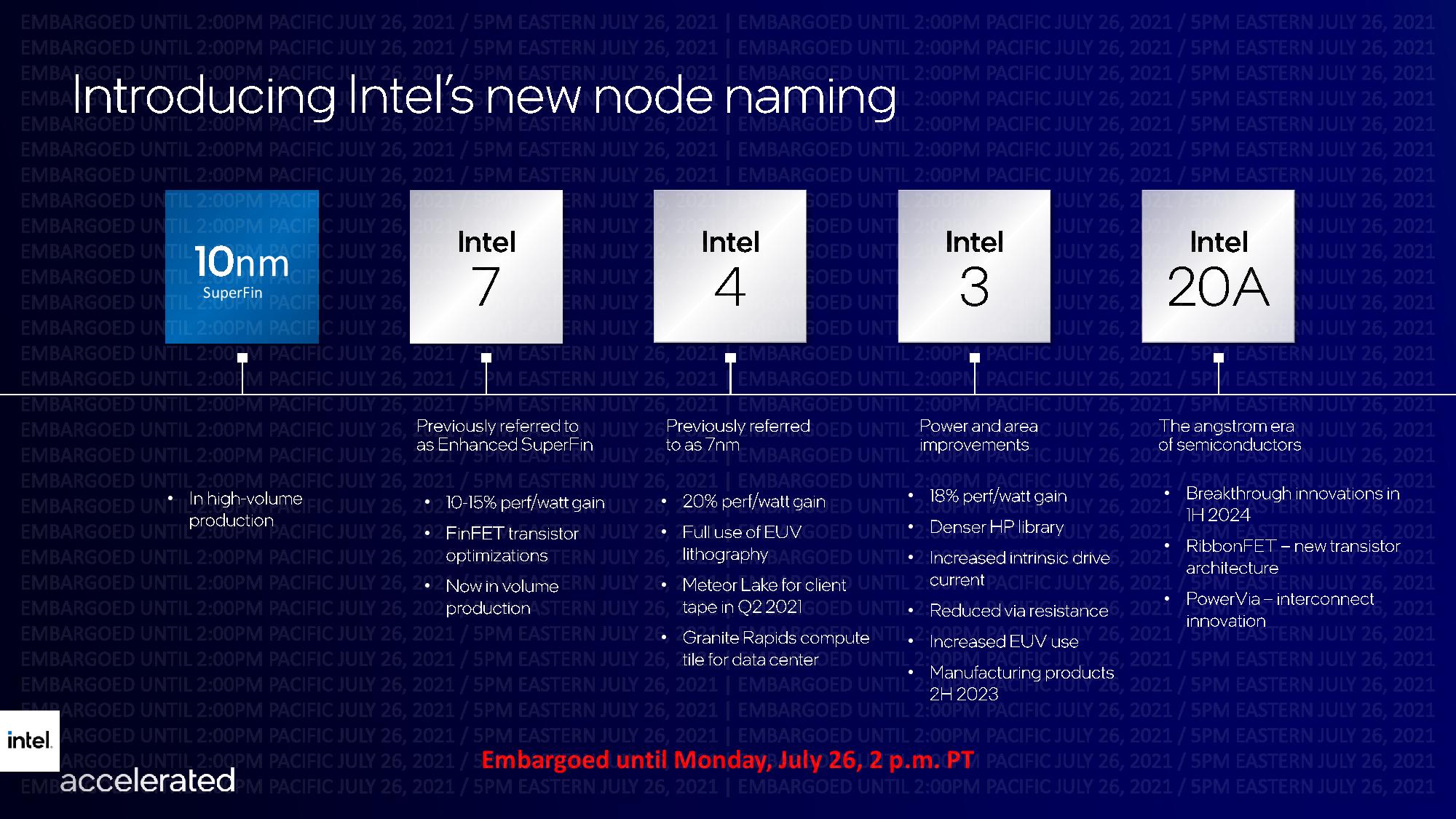

Intel will work with other industry stalwarts, like IBM, Cadence, and Synopsys, among others, to develop a semiconductor IP system that supports designing and manufacturing chips, with the first test chips using Intel's 18A process, which Intel cites as its most advanced node. However, Intel's 18A will be the company's second-gen Angrstrom-class process node and won't be available until early 2025, signaling this is a long-term contract. Intel will not ship the first generation of its Angstrom-class chips, 20A, until 2024.

As part of its IDM 2.0 initiative, Intel recently invested $20 billion of its own money to build two fabs that it will use for both its IFS services and its own internal production. But the company has also been on a full-court press seeking government investments for more fabs, both at home in the US and abroad, leveraging the fact that it is the only American company that designs and manufacturers chips on US soil. These efforts come as the US and EU countries look to reduce their reliance on chip production from foreign countries.

Intel's 18A will come with all of the bleeding-edge tech of the company's 20A process, like RibbonFET transistors and backside PowerVia power delivery, but adds in High NA EUV manufacturing. This is a new ultra-precise version of EUV production that can etch designs at smaller (<8nm) resolutions than current machines. New machines from ASML will be required to do single-patterning EUV at such fine geometries because existing EUV tools would require less desirable multi-patterning EUV manufacturing techniques. Intel will be the first company to receive a High NA EUV machine from ASML.

Intel recently announced in its IDM 2.0 announcement that it would collaborate with IBM on future logic and packaging technologies, and the company will also work with IBM as part of the RAMP-C program. Intel hasn't shared too many fine-grained details of its Angstrom-class chips, but they bear a striking resemblance to IBM's recently announced GAA/nanosheet tech that it fabbed on a 2nm test wafer. This partnership is important for Intel as it looks to recover from years of stagnation with its process technologies. During our briefings with IBM about its nanosheet tech, the company was quite clear that its new 2nm IP will benefit all of its partners, including Intel. You can read more about IBM's similar tech here.

"One of the most profound lessons of the past year is the strategic importance of semiconductors, and the value to the United States of having a strong domestic semiconductor industry. Intel is the sole American company both designing and manufacturing logic semiconductors at the leading edge of technology. When we launched Intel Foundry Services earlier this year, we were excited to have the opportunity to make our capabilities available to a wider range of partners, including in the U.S. government, and it is great to see that potential being fulfilled through programs like RAMP-C.”– Pat Gelsinger, Intel CEO

Intel's press release doesn't outline the size of the US government investment or a timeline for the contract, which comes after Intel won another DoD project last year to develop packaging solutions for the US government. We've reached out for details about the RAMP-C project and will update as necessary.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Paul Alcorn is the Editor-in-Chief for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.

-

InvalidError The burning question given Intel's recent slip-up history: how many years late is it going to be? Even if we accept Intels process renaming to reset the clock on how far behind its own calendar it has fallen, it is still about two years behind competition process-wise.Reply -

Giroro If Intel is out there saying their node naming has nothing whatsoever to do with transistor size, then we should not be pretending that 18A is going to be "Angstrom class".Reply

Although, I'm curious which misleading branding Intel switches to when their investors learn that the made-up numbers are smaller than silicon's Van der Waals radius.

Intel Quantum? -

Historical Fidelity Reply

Intel infinitesimal? HahahaGiroro said:If Intel is out there saying their node naming has nothing whatsoever to do with transistor size, then we should not be pretending that 18A is going to be "Angstrom class".

Although, I'm curious which misleading branding Intel switches to when their investors learn that the made-up numbers are smaller than silicon's Van der Waals radius.

Intel Quantum? -

InvalidError Reply

The renaming was done primarily for marketing purposes to align Intel's branding with other foundries based on process density.Giroro said:If Intel is out there saying their node naming has nothing whatsoever to do with transistor size

Neither TSMC nor Samsung 'nm' numbers have any direct relation to physical sizes either. These numbers are nothing more than relative densities between the fabs' processes based on the company's own internal rules which they may change at any time. -

Groveling_Wyrm ReplyInvalidError said:The burning question given Intel's recent slip-up history: how many years late is it going to be? Even if we accept Intels process renaming to reset the clock on how far behind its own calendar it has fallen, it is still about two years behind competition process-wise.

This is the normal for the U.S. defense industry. Look at a lot of their contracts. Missed deadlines, cost overruns, unexplainable price changing and gouging. Happens all the time. I would say that this won't even be reported when the deadline hits. -

PapaCrazy ReplyInvalidError said:The burning question given Intel's recent slip-up history: how many years late is it going to be? Even if we accept Intels process renaming to reset the clock on how far behind its own calendar it has fallen, it is still about two years behind competition process-wise.

It's been frustrating as a gamer to have seen such little innovation from Intel the last few years. Then the chip shortage started happening, and I'm seeing the whole world become dependent on 3rd party fabs in parts of the world that have become security concerns, I'm seeing the car market fluctuate in ways it never has, delays of new product releases, cuts in production, and losses of jobs across the entire economy. This whole situation has gotten way out of hand, and my humble little PC concerns are the least of the global problem now.

It may seem unfair to lay the entire chip shortage and corresponding market disruption, the massive inflation and booming of the scalper market, squarely on Intel's shoulder. Yet, had they had enough foresight (or atleast as much as the Asian fabs did), and took time to stop spending their executive bonuses, they should have seen this rabid need for silicon coming. And their responsibility wasn't just to fill their greedy corporate pockets, but provide a secure, reliable, and plentiful North American source for silicon.

So this contract, and whatever flawed attempts Intel makes to catch up, are both pitiful and also absolutely necessary. I have been taking every verbal or written shot I could at Intel the last few years. But for the sake of economic stability and security we should all be rooting for their fabs. -

Findecanor BTW. The unit Ångström is spelled Å, as in 18Å, but hey, this section of the computing industry hasn't yet figured out how to type \00d7 or µ either ... :rolleyes:Reply -

Co BIY ReplyPapaCrazy said:It's been frustrating as a gamer to have seen such little innovation from Intel the last few years. Then the chip shortage started happening, and I'm seeing the whole world become dependent on 3rd party fabs in parts of the world that have become security concerns, I'm seeing the car market fluctuate in ways it never has, delays of new product releases, cuts in production, and losses of jobs across the entire economy. This whole situation has gotten way out of hand, and my humble little PC concerns are the least of the global problem now.

It may seem unfair to lay the entire chip shortage and corresponding market disruption, the massive inflation and booming of the scalper market, squarely on Intel's shoulder. Yet, had they had enough foresight (or atleast as much as the Asian fabs did), and took time to stop spending their executive bonuses, they should have seen this rabid need for silicon coming. And their responsibility wasn't just to fill their greedy corporate pockets, but provide a secure, reliable, and plentiful North American source for silicon.

So this contract, and whatever flawed attempts Intel makes to catch up, are both pitiful and also absolutely necessary. I have been taking every verbal or written shot I could at Intel the last few years. But for the sake of economic stability and security we should all be rooting for their fabs.

I think you give Intel too little credit. With competitive pressure they have produced very competitive chips at reasonable prices, produced some very solid SSD storage products and plenty of cutting edge advancements like optane that cost them money. They also took large risks in keeping their fab capability when others cut and ran from that side of the business. I would say they did so because they had the foresight for demand that you claim they lack.

Are they running as well as TSMC on the engineering side for the last two years - NO but they have been selling everything they can make, and that's a lot. Their products are available and not vaporware.

Inflation has nothing to do with Intel or the Semi-conductor market as a whole. In fact it is a leading sector that makes better things cheaper continuously.

Governments throwing Billions and Trillions around like a rapper throwing cash in a music video is behind inflation.

Their "Greedy Corporate Pockets" are actually the stockholders who are much more likely to be large retirement plans investing to fund the retirements of average people than just a few "fat cats". -

Joseph_138 I wonder how long it will be before a group of Intel employees files a letter of protest with their bosses about the government contract, like they did at other tech companies, and the cancel culture swoops down on them.Reply -

escksu ReplyGiroro said:If Intel is out there saying their node naming has nothing whatsoever to do with transistor size, then we should not be pretending that 18A is going to be "Angstrom class".

Although, I'm curious which misleading branding Intel switches to when their investors learn that the made-up numbers are smaller than silicon's Van der Waals radius.

Intel Quantum?

Transistor size is only applicable during planar transistor days. After the introduction of finfet, process nodes has nothing to do with transistor size.