Frore's new LiquidJet coldplates are designed to handle up to 4,400W of power from Nvidia's Feynman AI GPUs — new design uses semiconductor manufacturing techniques to create 3D jet-channel microstructures

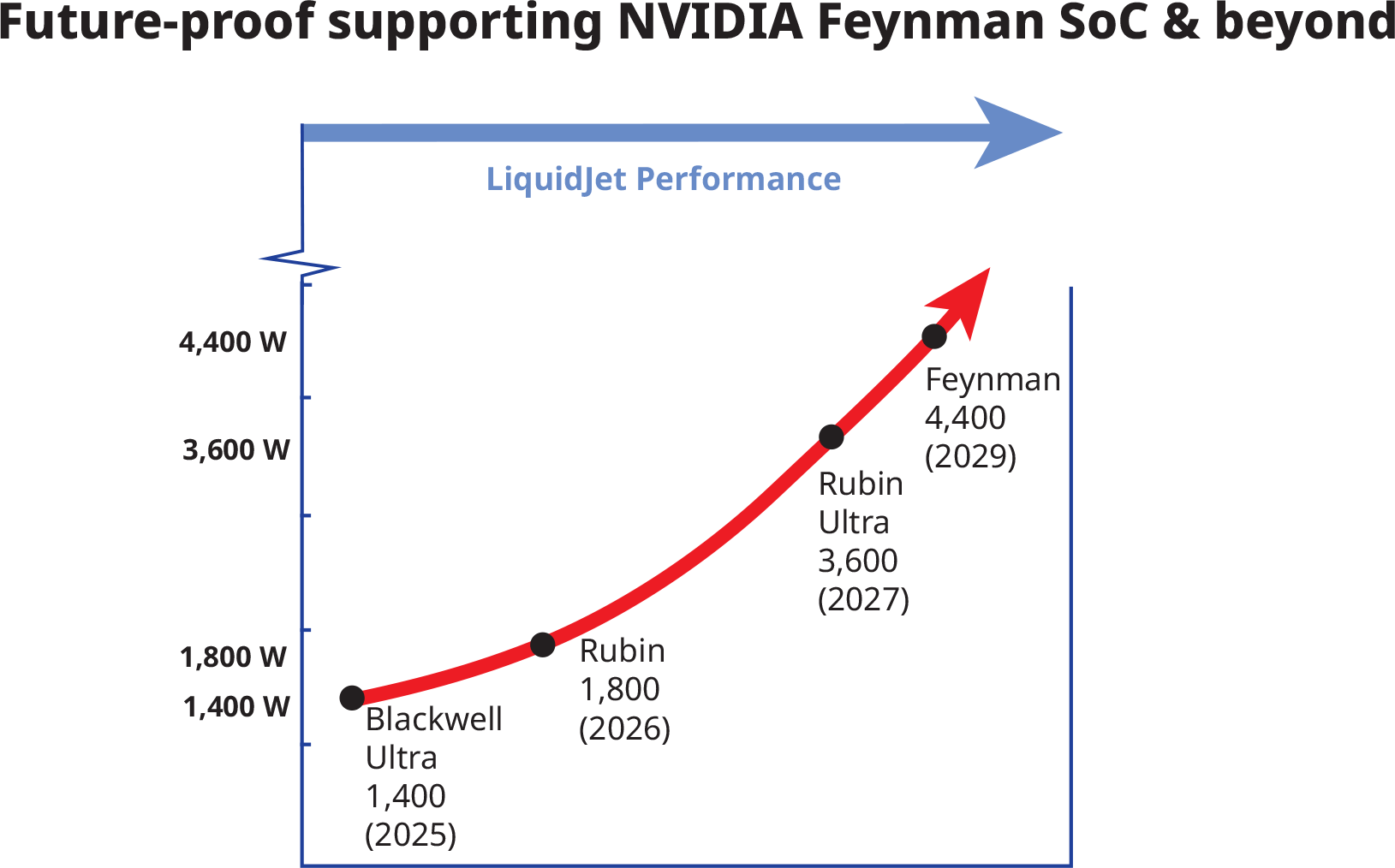

Drop in compatible with Blackwell Ultra today, ready for Feynman tomorrow.

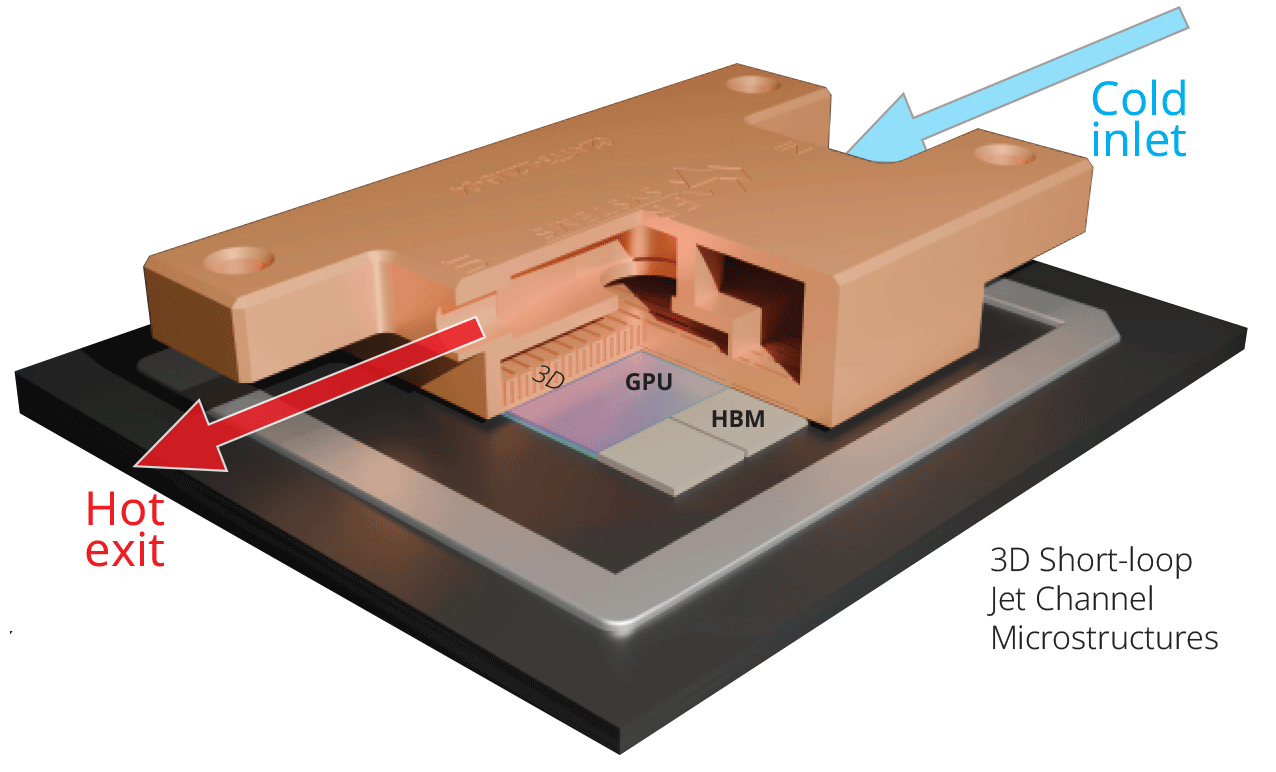

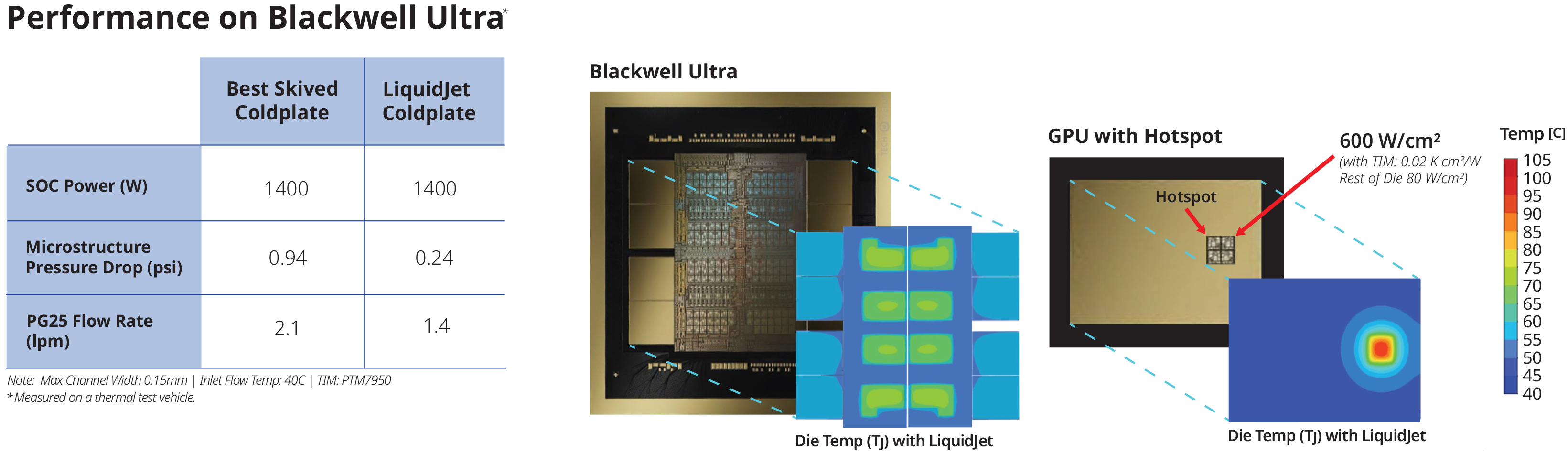

Frore Systems has introduced LiquidJet, a coldplate that supports existing AI GPUs, such as Nvidia's Blackwell, with a 1,400W thermal design power. It can scale its performance for next-generation processors, such as Nvidia's Feynman, which will feature a total power of 4,400W. The new coldplates feature 3D short-loop jet-channel microstructures that increase hotspot power density of a whopping 600 W/cm^2 and reduce pressure loss by four times compared to conventional coldplates. In the end, Frore's LiquidJet is ready for multi-kilowatt AI GPUs set to arrive in the coming years.

Modern AI GPUs like Nvidia's Blackwell AI system-on-chips (SoCs) consume an extreme amount of power and therefore require liquid cooling. Modern copper coldplates feature relatively long 2D microchannels with small cross sections that are CNC-machined or skived from high-purity copper blocks. Because these microchannels are long, liquid must travel farther and rub against more surface area, which increases hydraulic resistance and reduces pressure, which affects performance. Frore says that its LiquidJet coldplates with 3D short-loop jet channel microstructures reduce hydraulic resistance and therefore maintain higher pressure inside to boost performance.

Frore says that it has adapted 'semiconductor manufacturing to metal wafers' (which probably includes metal wafer etching and bonding) and can fabricate 3D short-loop jet channel microstructures that are adjusted to hot spot maps of particular processors, greatly improving performance and efficiency, but at a higher cost compared to traditional production methods. Furthermore, since we are talking about semiconductor fab-style production, LiquidJet may have micron-sized features if needed by a particular application.

The results are pretty staggering, according to Frore. LiquidJet sustains a hotspot density of 600 W/cm^2 at 40°C inlet temperature, twice that of standard coldplates. LiquidJet's heat removal per flow rate rises by 50%, while pressure loss falls by four times, from roughly 0.94 psi to 0.24 psi. As a result, LiquidJet enables lower temperatures and more predictable performance of Nvidia's Blackwell Ultra processor under full load, according to Frore. The unit is drop-in compatible with existing designs.

Meanwhile, LiquidJet's design is scalable and adaptable for Nvidia's upcoming processors, such as Rubin (1,800 W), Rubin Ultra (3,600 W), and Feynman (4,400 W). It can also be adjusted for any other processor, as Frore's production method is particularly flexible in terms of adaptability to a particular hot spot map. In addition to cooling down hotter next-generation GPUs, Frore's LiquidJet will also enable other benefits. For example, better cooling enables steadier frequencies, which means more AI tokens per second at the same power budget. Also, lower pressure requirements reduce pump energy, improving power usage efficiency (PUE) and overall total cost of ownership (TCO).

"LiquidJet's unique 3D architecture, with customized short-loop jet channel microstructures, sets a new bar for coldplate thermal performance," said Seshu Madhavapeddy, CEO and Founder of Frore Systems. "Just as AirJet redefined active cooling for consumer and edge devices, LiquidJet transforms coldplates into a future-ready platform for the AI Factory."

Power consumption and heat dissipation of AI accelerators are expected to increase 10-fold in less than a decade, according to estimates by KAIST, a leading Korean research institute. As a result, these upcoming AI accelerators — consisting of multiple compute chiplets and featuring tens of HBM memory stacks — will require brand-new cooling methods that involve embedded cooling structures both for compute and memory chiplets. This is perhaps when highly optimized coldplates like LiquidJet will become a part of processor packaging rather than a compatible accessory. But this is a completely different story.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button!

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

edzieba Looks a lot like the old IBM Aquasar warm-loop concept, but applied to gain higher deltas at lower temperatures rather than operate at lower deltas at higher temperatures.Reply -

Jame5 So glad not a single company involved in any of this is considering how to do more work per watt, rather than just throwing more watts at the problem.Reply -

bolweval Reply

"You can please some of the people all of the time, you can please all of the people some of the time, but you can't please all of the people all of the time"Jame5 said:So glad not a single company involved in any of this is considering how to do more work per watt, rather than just throwing more watts at the problem.

John Lydgate -

rluker5 Reply

They are all trying to get more per watt, but the node improvements aren't what they used to be, so to increase performance they have to increase watts.Jame5 said:So glad not a single company involved in any of this is considering how to do more work per watt, rather than just throwing more watts at the problem.

There was also just news about Intel making that low power 160GB vram inference card: https://www.tomshardware.com/pc-components/gpus/intel-unveils-crescent-island-an-inference-only-gpu-with-xe3p-architecture-and-160gb-of-memory -

thestryker Reply

They are actually optimizing to get more work per watt, but the fact of AI as it stands today is they want maximum performance. This means that while everyone's happy about perf/watt optimizations delivering that with another 50% power is even better. That is what's different about this AI boom than normal datacenters or supercomputers: power consumption is something to build around rather than target for.Jame5 said:So glad not a single company involved in any of this is considering how to do more work per watt, rather than just throwing more watts at the problem. -

Notton Nvidia can absolutely do more work per watts.Reply

The cost is silicon size, which would be extremely costly for Nvidia.

Just compare the RTX4000 ADA SFF to 4060Ti 16GB

It's like 70W vs 165W for similar performance. -

BoobleKooble Jet flow in water blocks is normally a performance boost, but true jet flow conditions usually require that a system be operated at high pressure. Jets can break up the boundary layerReply