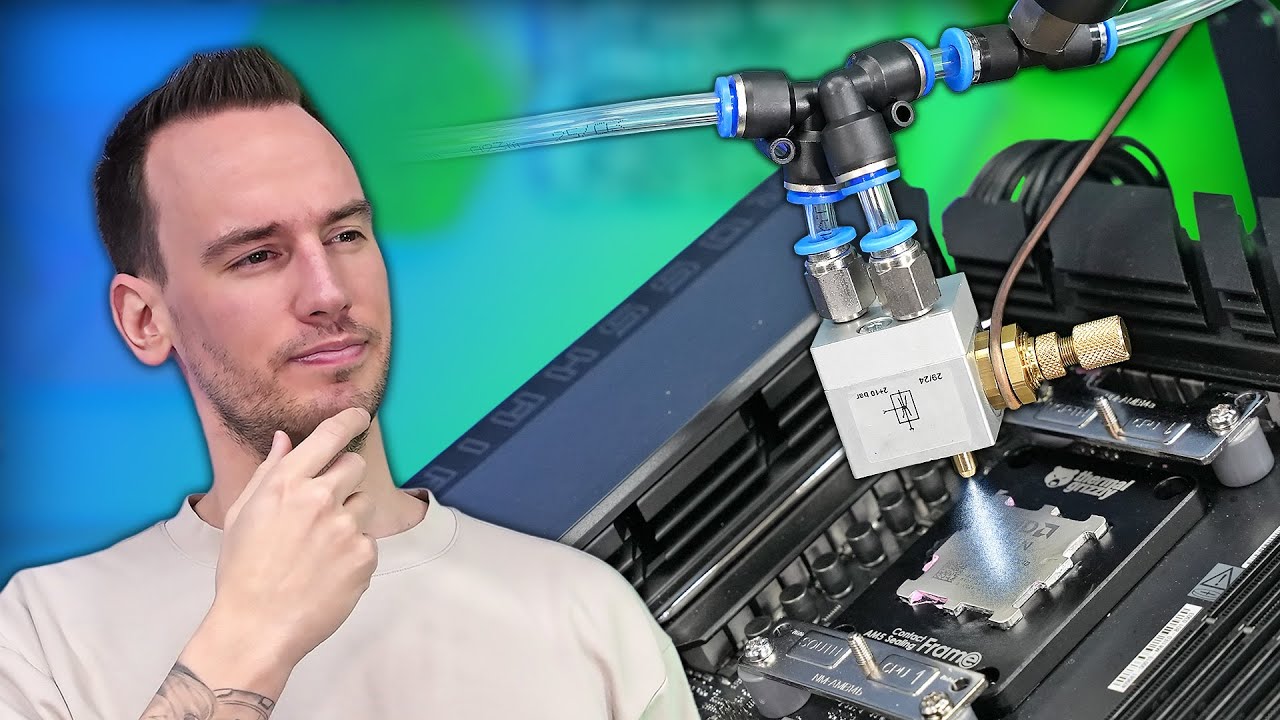

Der8auer rigs up exotic spray cooling for Ryzen 7 9800X3D, but don't get excited just yet — supercomputer cooling method underperforms due to partial IHS coverage

Only a select few supercomputers utilize the exotic cooling method.

There are many exotic forms of chip cooling in the wild, such as immersion cooling and liquid nitrogen cooling. But one cooling paradigm you might not have heard of is spray cooling, used by some supercomputers. Famous German overclocker Der8auer showed off the capabilities of spray cooling in a recent video, cooling a Ryzen 7 9800X3D CPU by spraying a non-conductive mist right on top of the IHS.

Spray cooling functions just as it sounds; nozzles are placed above a CPU or GPU that sprays mist right on top of the chip itself. Depending on the coolant used, the mist will evaporate after hitting the chip (while the chip is active and running warm/hot) and returns to the cooling loop, where the vapor cools off, turns back into a liquid, and cycles back toward the CPU. If this sounds familiar, vapor chamber coolers use the same phase change principle.

To demonstrate what a CPU looks like that is tailor-made for spray cooling, Der8auer showcased a Cray X1 supercomputer processor from 2003, designed from the ground up for spray cooling. Compared to a regular CPU that has an IHS, the Cray X1 is pre-packaged in a stainless-steel clamshell that features some of the components needed for spray cooling baked into the clamshell.

On the inside of the clamshell are a plethora of tiny nozzles that aim at the chip's eight dies. Der8auer notes that the direction of each nozzle and the pressure at which the fluid is flowing are all critical elements to ensuring each die is fully covered in liquid. If even a small portion of one of the dies is not covered in liquid, it could lead to overheating in that particular spot.

Furthermore, Der8auer states that the coolant itself is critical to ensuring that any chip cooled by spray cooling stays at the right temperature. Primarily, the coolant needs to be non-conductive, with a low boiling point, so that the fluid can phase change at the right temperature. If the boiling point is too high, the fluid won't change into a vapour, trapping heat inside the chip.

To test spray cooling, Der8auer jerry-rigged a cooling setup comprised of a Ryzen 7 9800X3D with a custom-loop cooling system modified to support a vaporizer. The system is comprised of two separate loops, one supplies coolant to the vaporrizer, and the other pushes high-pressure air, which mixes with the coolant to form the mist.

Despite not covering the whole IHS, the jerry-rigged spray cooling system was able to successfully cool the 9800X3D. It wasn't able to cool it as well as a traditional CPU cooler, but it was enough for Der8auer to run through a single Cinebench R23 test without overheating. Achieving 18,164 points at around 95C. (To contrast, the 9800X3D normally hits around 23,000 points in R23 with a proper cooler.)

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Der8auer's test might seem underwhelming, but its worth pointing out again that the vaporizer was only cooling a small portion of the IHS. If the IHS were fully enveloped, with a properly tuned vapor cooling setup, it's possible that the results could have been different.

Vapor cooling is one of the most potent cooling solutions for semiconductor chips. Its cooling potential is directly connected to the flow rate of the coolant, making it exceptionally effective at cooling CPUs.

Despite its capabilities, spray cooling is not widely used and is almost exclusive to the supercomputing space. But even then, only a handful of supercomputers ever used spray cooling (including the Cray-2).

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Aaron Klotz is a contributing writer for Tom’s Hardware, covering news related to computer hardware such as CPUs, and graphics cards.

-

edzieba I think most using low boiling point cooling setups have shifted to full immersion (device to be cooled in immersed in fluid with a simpler nozzle directing cooled return flow to the heat load) with mixed-phase return, rather than direct impingement spray with gas phase return. Surrounding components today are far less vulnerable to solvent attack from the inert coolants we have available now, so the extra complexity is not really necessary, and handling phase separation is not that big of a deal.Reply

The real problem with atmospheric pressure LBP phase-change for today's loads is that packing >kW loads into a few hundred square mm is just not enough area - at low enough flow rates that the fluid can boil the heat transferred is not sufficient, at high low rates the phase change does not occur over the load so you may as well just stick with a single-phase system and use water to cool (and gain the benefit of its much specific heat capacity and thermal conductivity). Sub-ambient phase-change using water is the sweet spot, where you get water's heat capacity and conductivity but with a boiling point below 100C: that's that heat pipes and vapour chambers use. Thus you end up with high power density cooling setups using a vapour chamber 'heat spreader' to get heat from the die to a larger coldplate on a liquid loop system.