APC BR1000G Tear-Down

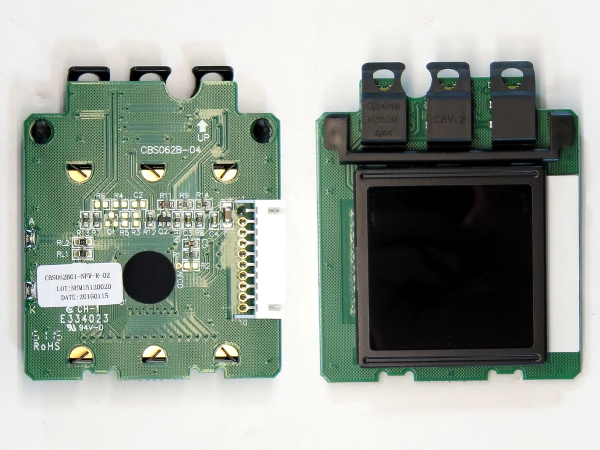

Control Panel

The BR1000G, like many modern mid-range UPSes, sports a custom LCD displaying basic status information. Key-hold combinations of the mute, power, and display buttons also grants access to a limited number of internal parameters like transfer voltage limits and "master" detection threshold calibration. The three buttons are back-lit, and their LEDs are quite bright with the cover off. With the cover and rubber/silicon button caps in place, their brightness is drastically reduced.

Mezzanine Board

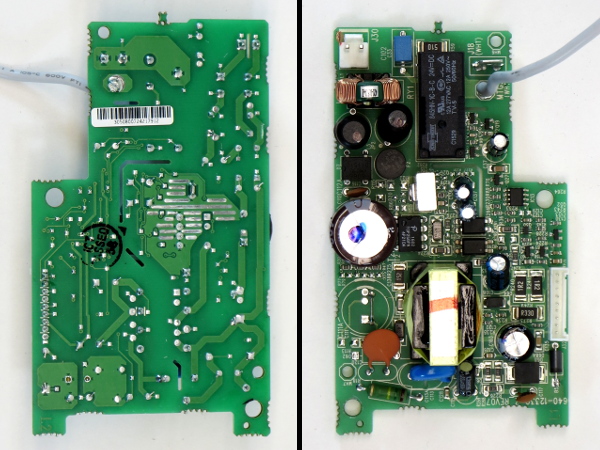

What does that mezzanine board actually host? The UPS’ single power supply based on a TOP285 monolithic off-line switching regulator right next to a heat sink slug, similar to APC's BE550G. This one has a complete input noise suppression network including the Y-class capacitor at the transformer, filter inductors after the common-mode choke, a 47 µF/400 V Chemi-Con input capacitor, and APC’s signature mix of Jamicon, JiangHai, and Cheng capacitors for the rest. Will this design match the BE550G for standby efficiency?

This board also hosts a relay that closes the neutral connection to the AVR/inverter transformer’s neutral wire.

MORE: APC BN650M1-CA Tear-Down

MORE: APC BGE90M-CA Tear-Down

MORE: APC BE550G Tear-Down

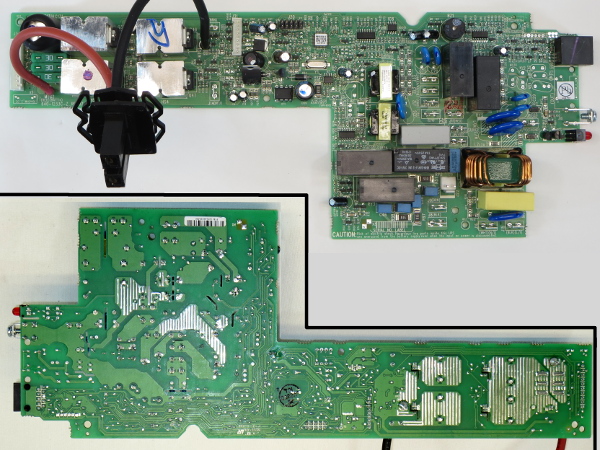

Main Board

Starting from the left edge on the top side, we have the control panel connector; three 30 A battery fuses; a tall capacitor wrapped in heat-shrink tubing; the high- and low-side switching FETs; a cluster of support electronics including the UPS’ micro-controller, a pair of current-sensing transformers, and five relays; the input filter; USB port; and wiring fault indicator circuit.

Input-Outputs

Power routing on the board begins in the bottom-right corner with an Epcos S20K230 MOV across live-neutral, a yellow X-capacitor, a chunky common-mode choke, two more S20K230s to ground, and a smaller film capacitor before the mezzanine’s power connector. From there, five relays switch power around as necessary.

What are all of those small metal film capacitors and 510 Ω resistors near every relay for? They are snubbers across relay contact points to mitigate arcing wear.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

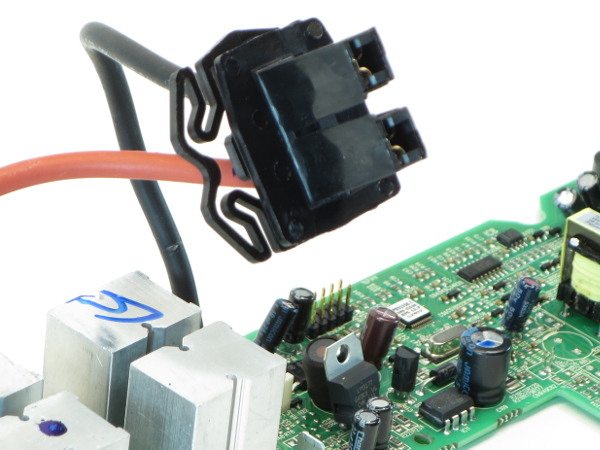

Battery Connector

The battery connections ride in a slot at the top of the battery compartment, and its springy wings provide what little freedom of movement it requires to align itself with the battery as it gets pushed in.

Below it, you may be able to distinguish a few Cheng and Jamicon capacitors. Illinois makes an appearance as the manufacturer of the brown capacitor, next to an LM317 linear regulator in loose TO-220 format. At a glance, the LM317 appears to be fed by an MC34063 switching regulator (the DIP-8 chip next to the fat Jamicon capacitor near the bottom-right corner).

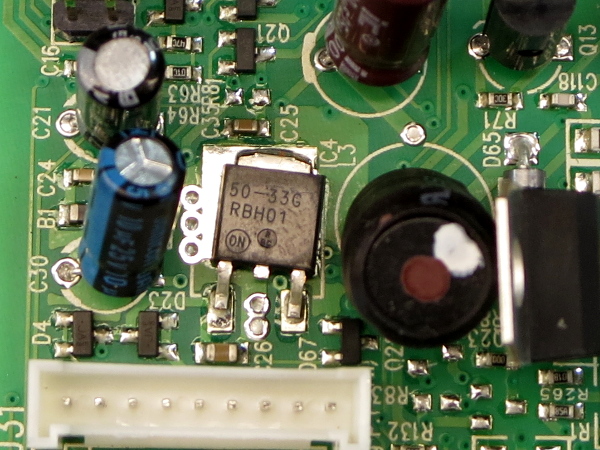

Something Needs An Alignment

Something in this picture does not look straight. I’m not talking about those electrolytics on long leads being slightly bent over or the LM317 on the right. Either the pick-and-place machine has issues with DPAK components or the vias’ thermal capacity caused solder to reflow on the right side first, yanking the 100 mA/3.3 V linear regulator to the pad’s edge. Don’t stack all of your thermal vias on one side.

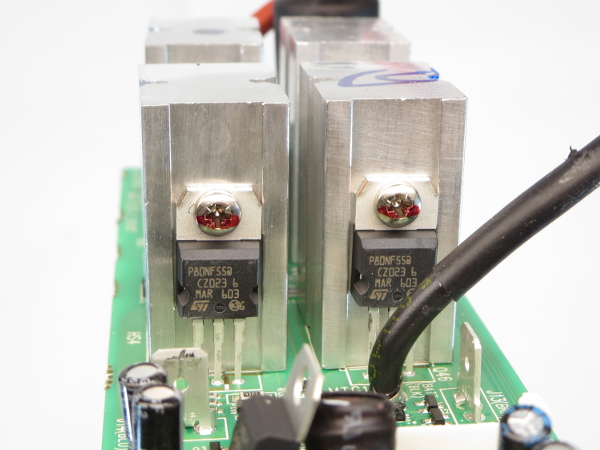

Output Bridge

The task of driving the transformer’s low voltage primary is handled by a quartet of STP80NF55 FETs in a full bridge arrangement, which, as you may have guessed from the model number, are rated for 80 A and 55 V. That might sound weak considering the 3x30 A battery fuses, but at 24 V you only need 42 A to deliver 1000 W. It looks to me like APC fused the 1000 VA unit as if it was a 1500 VA one and put one too many on there.

In unrelated news, check out the blue and red squiggles. QA isn't taking chances with heat sinks or screws going AWOL.

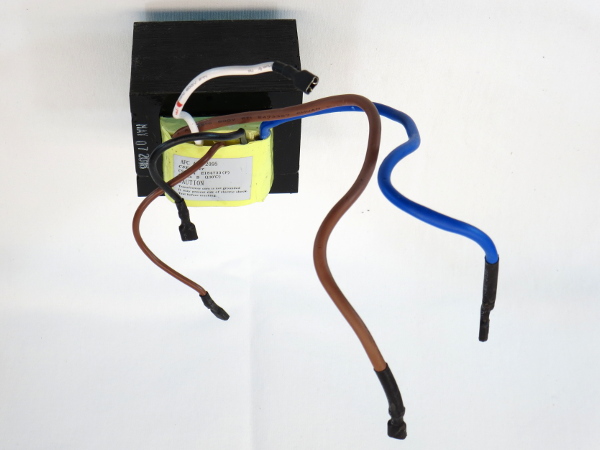

CAUTION HEAVY

Remember that 400-gram difference I mentioned earlier? With the BR1000G lacking the BX1000’s many large aluminum plate sinks, HVDC transformer, and Falco choke, the missing weight had to reappear somewhere else. This is where it went: the BR1000G’s transformer core has twice the lamination stack thickness, enabling it to achieve the same inductance using fewer turns, in turn freeing enough room to fit the heavy-gauge low-voltage winding without increasing the winding area’s cross-section. What does this mean in terms of actual weight? Between the longer iron core and extra copper going through it, we have 1700 grams for the BX1000 versus 2950 grams for the BR1000G, a 74% increase. For non-metric folks, this is a whopping 2.75-pound difference.

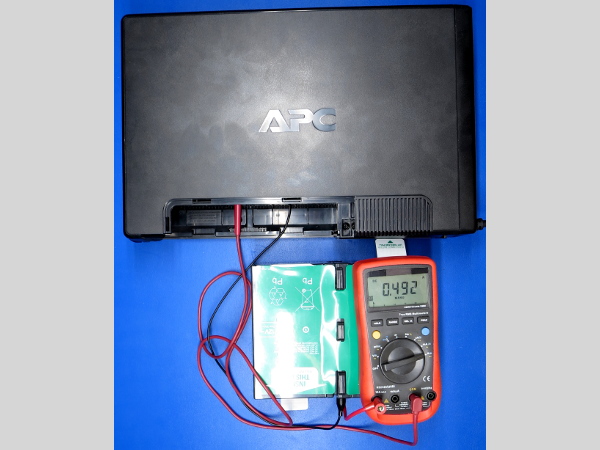

Baseline Battery Draw

How about baseline power draw from the batteries? With the inverter running under no-load condition, this iron lump-based design draws less than 500 mA from its 24 V pack. Although that's 50% more than the BX1000’s ~330 mA, it is also only half as much power as CyberPower’s 1000PFCLCD, which drew 2 A from its single 12 V battery. If you want to see when and where I did those other measurements, they can be found in my APC BGE90M-CA tear-down.

When I ordered the BR1000G, I was hoping to find a more efficient implementation of the BX1000’s electronic inverter. On the bright side, 500 mA means that its 7 Ah battery pack should still be able to run under very light loads for roughly 10 hours.

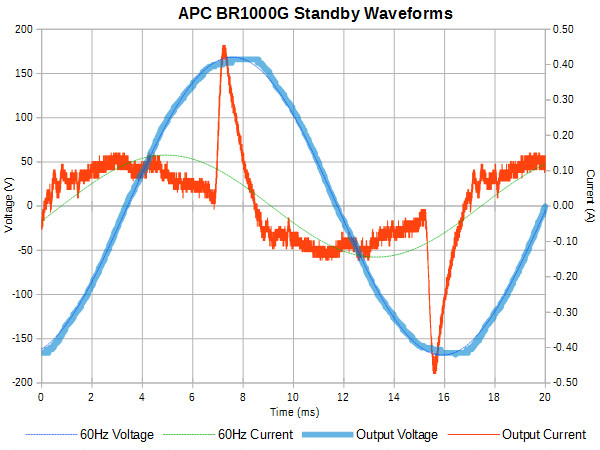

Standby Waveform

In an off state with a charged battery, the BR1000G draws an apparent power of 9.67 VA and a real power of 3.67 W. In no-load standby, those figures increase to 12.14 VA and 6.64 W. Off the top of my head, these are the worst measurements we've seen from an APC UPS over the past year. Additionally, we observe surprisingly sharp peaks, which may explain the faint 120 Hz buzzing I hear while the unit is plugged in. And by faint I mean that my ear is almost touching the UPS by the time I can clearly hear it.

Out of curiosity, I repeated the measurements with the battery removed. While the on-state power remained practically unchanged, the off-state result dropped to 2.17 W, suggesting either a 50 mA float-charge when off or a very long (10+ hours) end-of-charge phase.