Repairing an Acer E5-521 Laptop: A Case Study

The Patient Returns With Unrelated Complications

I let the laptop boot to its log-in screen, tested the trackpad, hit a few keys in the password box to test the keyboard, plugged in devices to test the USB ports, and sound, then sent a message to my friend telling him that I was done as far as I could tell. The day after he came to pick it up, I received a message from him telling me that the keyboard didn’t work. Of course, this puzzled me and I asked him to bring it back so I could have another look. Upon further inspection, it turned out that the cluster of keys surrounding the ‘I’ key, including ‘I’ itself, were non-functional.

My first thought was that perhaps I had plugged the keyboard’s ribbon in slightly crooked or not far enough into its connector. The thing is situated awkwardly, orientated backwards from the front with its sliding wedge lock that tends to partially insert itself while attempting to push the cable in. Multiple re-insertion and cleaning attempts later, the keyboard got worse, acting as if the ‘ENTER’ key was intermittently stuck down. No amount of twisting or bending the keyboard to either get a stuck key unstuck or break an intermittent short had any effect on its behavior. Time to dig in again.

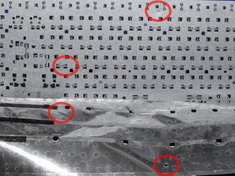

A dozen tiny screws fasten the keyboard to the laptop’s cover frame. While the keyboard’s face may not reveal any particular signs of abuse in the gaps between keys normally occupied by the top cover, the aluminum sheet glued to the bottom the keyboard’s plate features two distinct circular screw tip marks, one from the battery latch landing under the F7 key and the other from the optical bay retaining screw near the semi-column key. The area between these two keys corresponds to where most of the dead keys are located, which may not be a coincidence. Whatever impact hit hard enough to create these circular dents in the metal sheet could have hit hard enough to pinch the membrane traces, breaking them or shorting the layers together.

The only way to investigate is to pop off enough keys and clear one area of interest, then pry the membrane off of the keyboard’s steel substrate. Peeling off the glued metal sheet reveals that the screw near the F7 key (right) punched a hole through the sheet and made a significant dent in the steel plate underneath, while the other hole on the left lines up with a key hook-up hole and therefore didn’t leave any visible mark on the plate.

To gain access to the membrane and have a look at what may have happened, some key pulling is necessary to clear the way for prying the membrane off of the steel plate. On a typical desktop keyboard, the key caps’ stems and retention snaps guide the key along its travel path up and down. On a low-profile keyboard with short travel distance, a more compact (and complex) arrangement is necessary. Behind each key, you find a scissor lift mechanism retaining the keys while providing stabilization to make the keys press and depress evenly regardless of where pressure is applied. Over-sized keys also feature stabilizer bars to offset their extra leverage and keep most of the force aligned with the membrane switch. If keys were merely pressed on top of the membrane nipples, off-center pressure would cause them to tilt, resulting in many more missed keys, horrible keyboard feel, and much unnecessary frustration.

After prying a bunch of keys from the first two rows, I could finally coerce enough of the membrane away from the steel base to access the back of the area where the screw mark was. What did I find there? Nothing obvious. The membrane construction consists of a tough black plastic (like polyethylene) covering the gaps between switches to protect the membrane layers from objects that may poke between key caps, silicone rubber for the contact domes, and more plastic or silicone layers underneath to support the silver ink signal traces. Crush damage either breaking the silver ink traces or shorting them between layers is still my best guess, but there isn’t anything I can do about it without ruining the keyboard worse than it already is. How could it be worse? As-is, it still has the benefits of looking and feeling normal. If I hacked away at the membrane until all intermittent contacts are removed, the keyboard would still be unusable due to multiple dead keys, possibly turning into a mangled mess with 90 keys to manually put back in if I didn't want 90 open holes in the cover. Since the laptop would end up needing an external keyboard either way, I chose to spare myself the hassle and cosmetic damage by simply leaving the built-in keyboard unplugged to eliminate its spurious input.

MORE: Best Gaming Laptops

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

MORE: Gaming Laptop Previews

MORE: All Laptop Content

Current page: The Patient Returns With Unrelated Complications

Prev Page Synchronous Rectification Buck Regulator 101 (And A Cure) Next Page Postmortem-

Roland Of Gilead Ha, that was interesting!Reply

At first I thought, 'what the heck is this about?'. Thought the title alone was very random. Anyway, I read the article and it's changed my mind. Not only is it well written, but also informative. I've had maybe, three laptops that I've either thrown away or given away, some with minor issues that I couldn't have been bothered to try and troubleshoot. Screens failing, other unusual behaviour with power issues etc. I guess Ill brush up on some basic engineering skills, and give future dead devices a chance for redemption.

Thanks Daniel, I enjoyed that of a Sunday morning :) -

farberj Nice and informative article, nice to see the logical train of thought that a true problem solver uses.Reply -

Danny Leiva Thanks for the very informative piece! About 6 months ago I repaired my wife's macbook air after there was a spill accident that occurred. With resources online, I figured out and was able to diagnose that the connector on the board with the ribbon cable to LCD had a few pins that had disintegrated. Was able to buy the replacement connector online and, after learning to get much better with tiny-piece soldering, was able to replace the connector successfully! Felt really good!Reply -

AnimeMania The real question is how much information was retrievable from the hard drive. Name, address, phone number, SSN#, (amazon, facebook, twitter and banking access), personal photos (some of a very private nature (nude)), tax returns, emails, etc. What are your legal rights to this information, is it similar to when someone buys one of those abandoned storage lockers contents? Anyone with minimal computer skills could probably remove the hard drive and revue its contents.Reply -

Allen_B Great article, thanks! I've got some electronics knowledge but this is inspiration to learn more. It's such a shame to see electronics end up in the trash, and friends having to shell out for new stuff they didn't really need.Reply -

Daniel Sauvageau Reply20251438 said:Ha, that was interesting!

Thanks Daniel, I enjoyed that of a Sunday morning :)

Glad you liked it!20251813 said:Nice and informative article, nice to see the logical train of thought that a true problem solver uses.

Liquid damage can get pretty nasty when power stays on long enough to let electrolysis eat the pads. Congrats on managing to replace the connector!20251834 said:Thanks for the very informative piece! About 6 months ago I repaired my wife's macbook air after there was a spill accident that occurred.

The HDD is fully operational, whatever information on it that wasn't encrypted would have been easy picking. When my friend told me that I could keep the laptop when I couldn't repair the keyboard, I did a factory reset to get rid of the password instead of poking around for ways to crack it.20251991 said:The real question is how much information was retrievable from the hard drive. -

mikewinddale "support your 'Right to Repair' and similar bills"Reply

But that just means that devices will be more expensive. Presumably, devices are being constructed with more proprietary parts that are difficult to repair, because this makes the final product less expensive for the consumer. (After all, manufacturers compete with each other, and it is difficult to imagine them deliberately making their products more expensive than necessary.)

Furthermore, as standards-of-living increase, wages tend to increase relative to raw material and other manufacturing costs. This rise in relative wages means that it is economically less sensible to repair broken devices. When wages are low and manufacturing costs are high, it makes sense to pay a repairman to avoid purchasing a replacement. But when wages are high and manufacturing costs are low, it makes more sense to trash the device and buy a new one.

So a "right to repair" would essentially mean increasing manufacturing costs without any benefit. The device would cost more to purchase, and in the end, high labor costs mean it wouldn't be worth it to repair it anyway, so you'd still end up buying a new device when it breaks. So you're paying more to purchase a repairable device, and even then, it still isn't worth it to repair. -

IInuyasha74 Certainly was an interesting read. Must feel like a big waste of time for a beat up old laptop with an AMD E2 processor in it, but excellent for the fun of seeing a notebook taken apart and parts soldered on and off of it.Reply