Corsair RM750i Power Supply Review

Corsair is revamping its RM line, adding the letter "i" to highlight a more advanced digital interface — today we check out the RM750i.

Why you can trust Tom's Hardware

A Look Inside And Component Analysis

Parts Description

Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station and a Hakko 808 desoldering gun.

| Primary Side | |

|---|---|

| Transient Filter | 6x Y caps, 3x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | NTC Thermistor |

| Bridge Rectifier(s) | 1x GBJ25L06 (600V, 25A @ 113 °C) |

| APFC MOSFETs | 2x Vishay SiHG22N60E (650V, 13A @ 100 °C, 0.18 ohm ) |

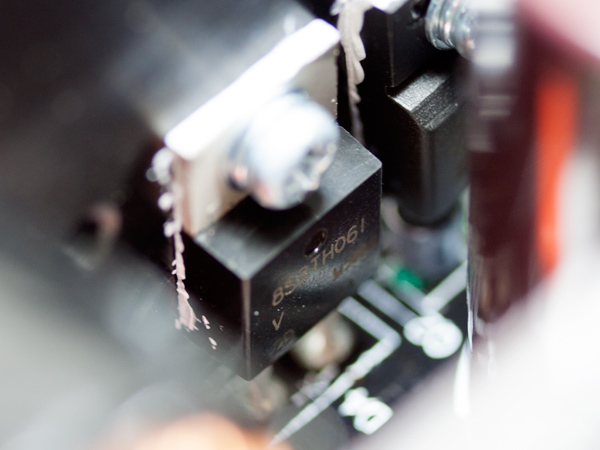

| APFC Boost Diode | 1x Vishay 8S2TH061 (600V, 8A @ 120 °C) |

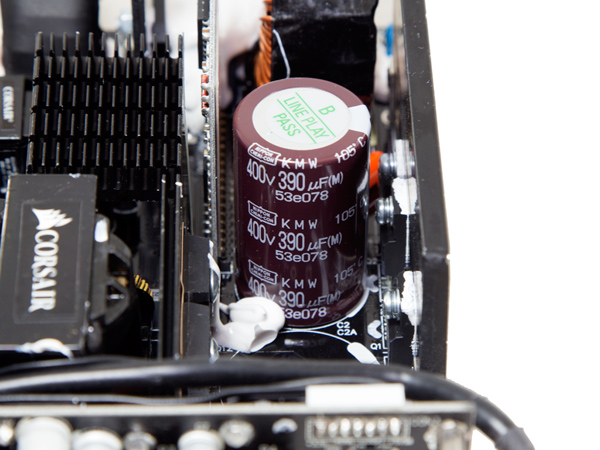

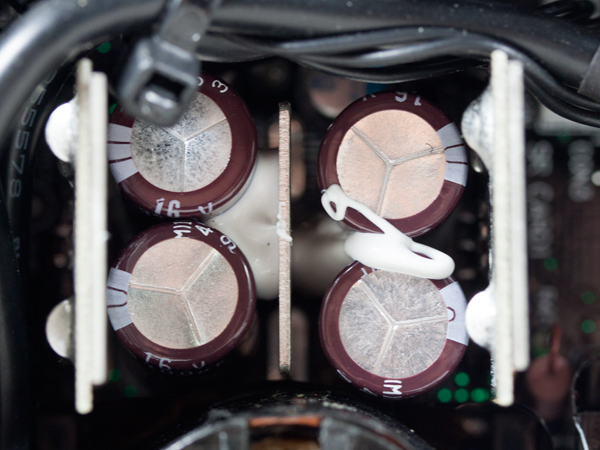

| Hold-up Cap(s) | 2x Nippon Chemi-Con (400V, 390uF & 470uF or 860uF combined, 2000h @ 105 °C, KMW - KMR) |

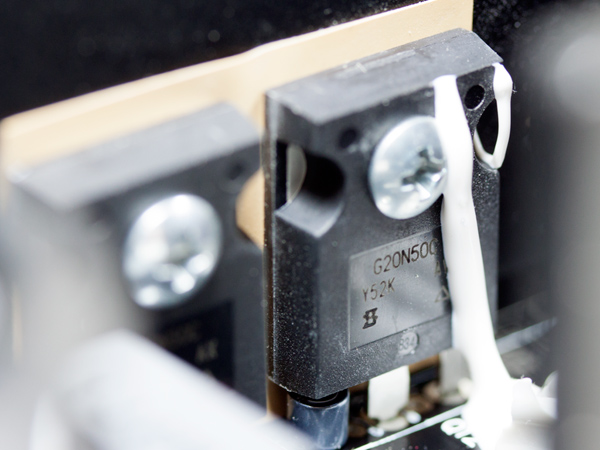

| Main Switchers | 2x Vishay SiHG20N50C (560V, 11A @ 100 °C, 0.27 ohm) |

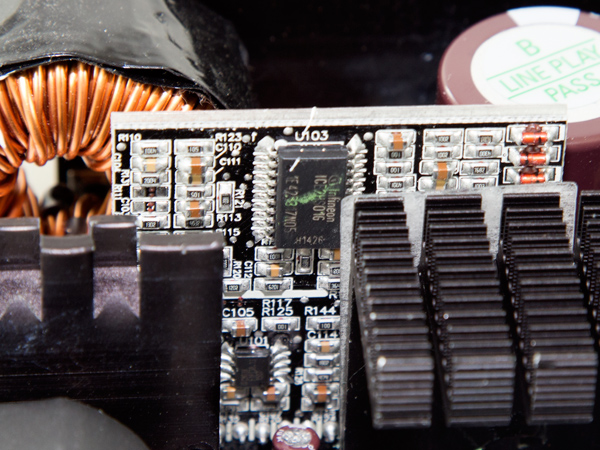

| APFC Controller | Infineon ICE3PCS01G - CM03X |

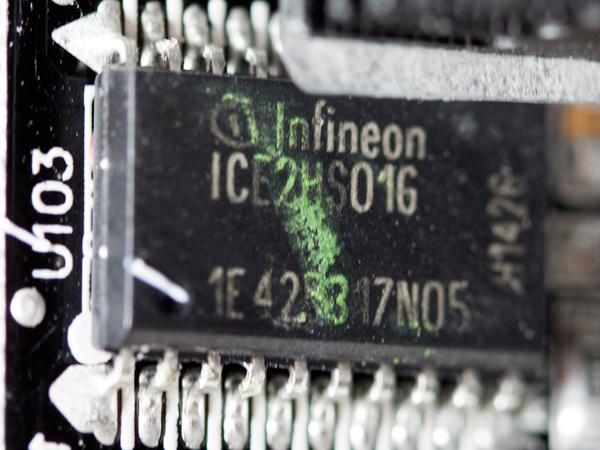

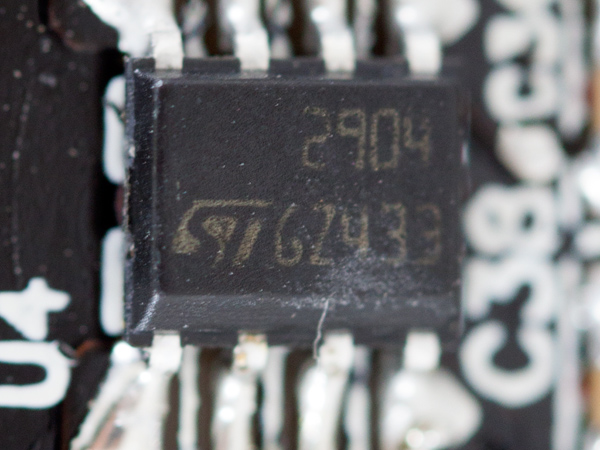

| Switching Controller | Infineon ICE2HS01G |

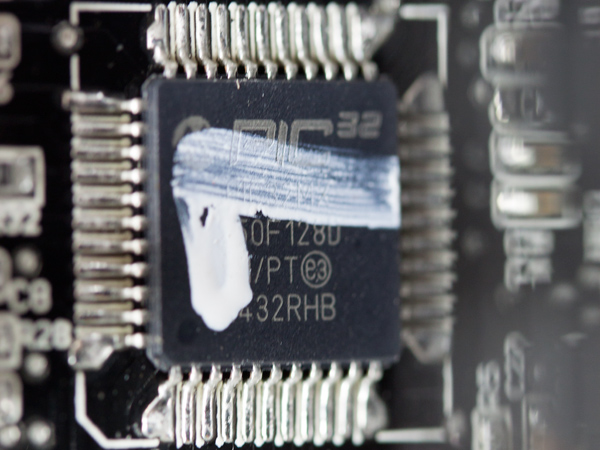

| MCU | PIC32MX |

| Topology | Primary side: Half-Bridge & LLC Resonant Converter Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 6x Sinopower SM4021NAKP (40V, 100A @ 100 °C, 2.7 ohm ) @ VGS=6V) |

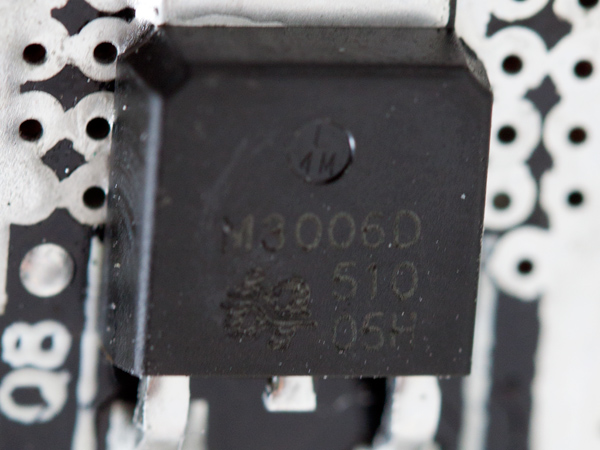

| 5V & 3.3V | DC-DC Converters: 4x M3006D & 2x M3004D FETs PWM Controller: APW7159 |

| Filtering Capacitors | Electrolytics: Chemi-Con (105 °C, KZE series) Polymers: Nippon Chemi-Con |

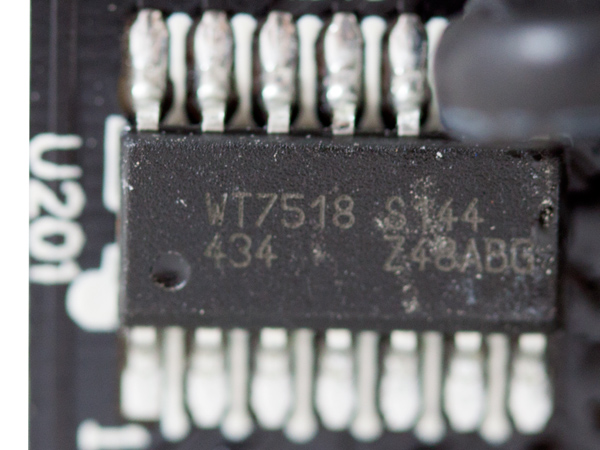

| Supervisor IC | Weltrend WT7502 & Weltrend WT7518 |

| Fan Model | NR135P (12V, 0.22A, fluid dynamic bearing) |

| 5VSB Circuit | |

| Rectifier | PFR20V45CT (45V, 20A, VF: 0.42V max @ 125 °C) |

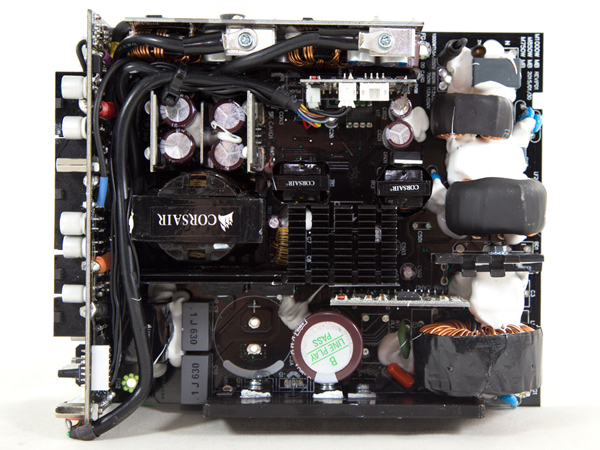

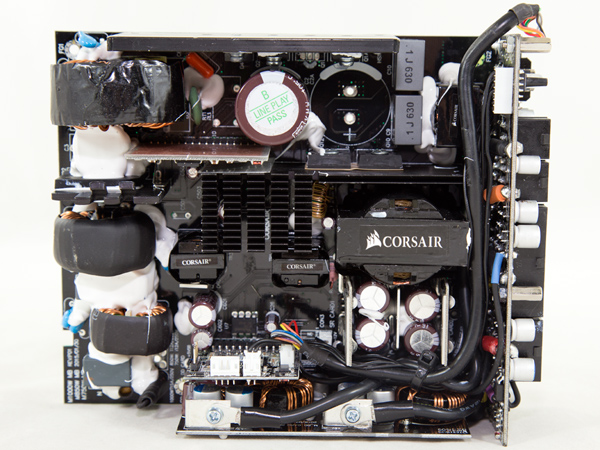

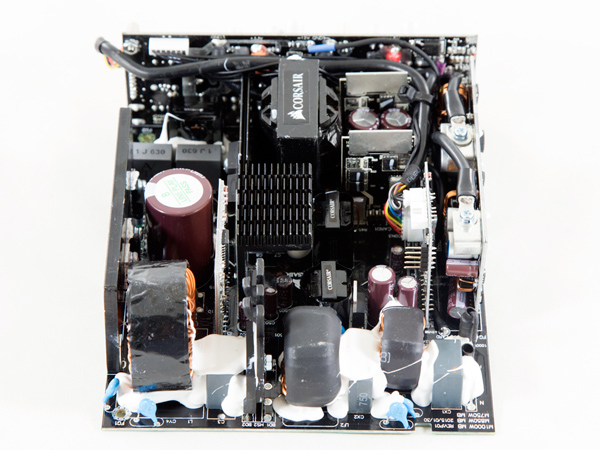

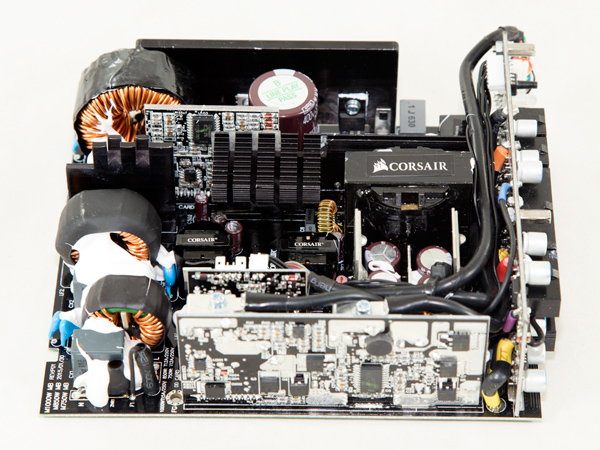

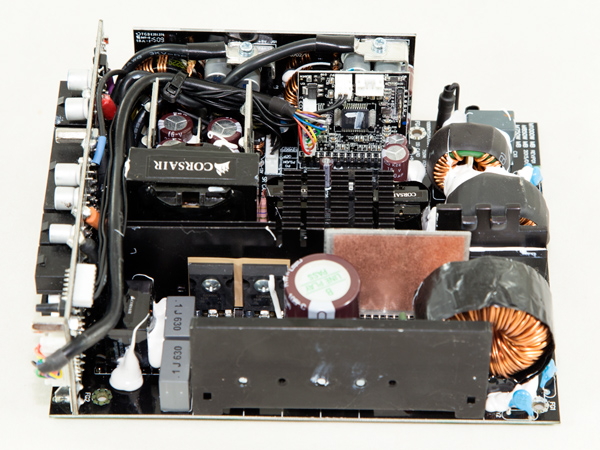

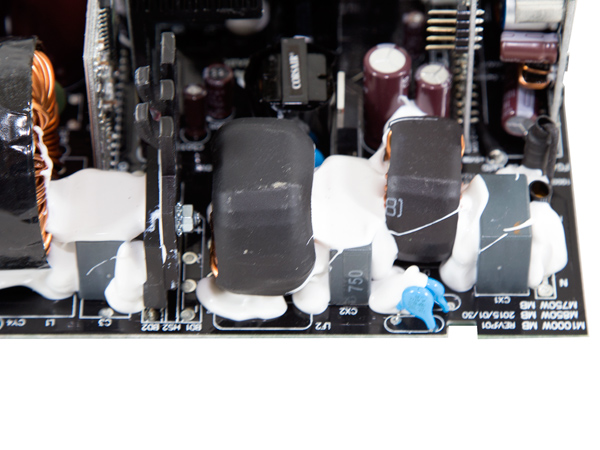

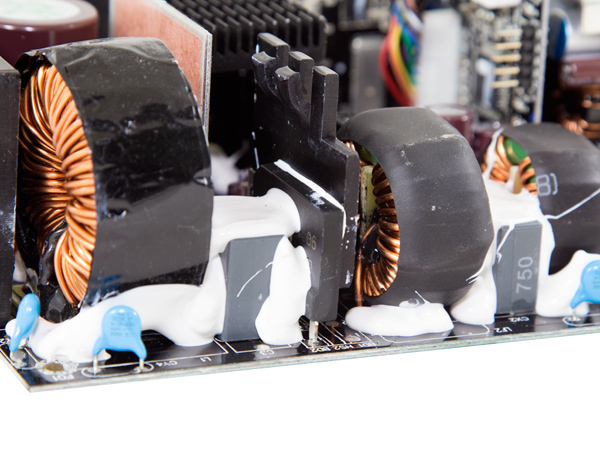

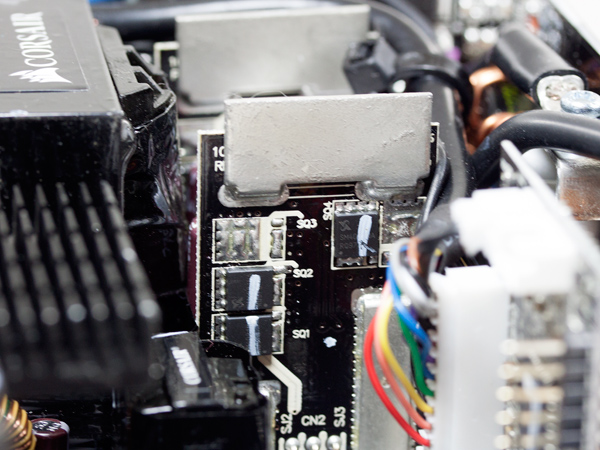

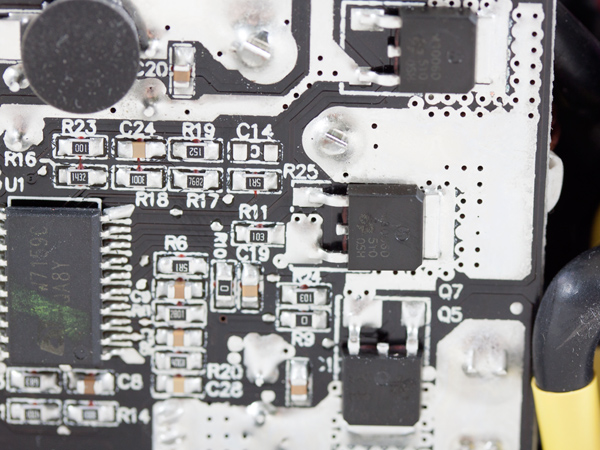

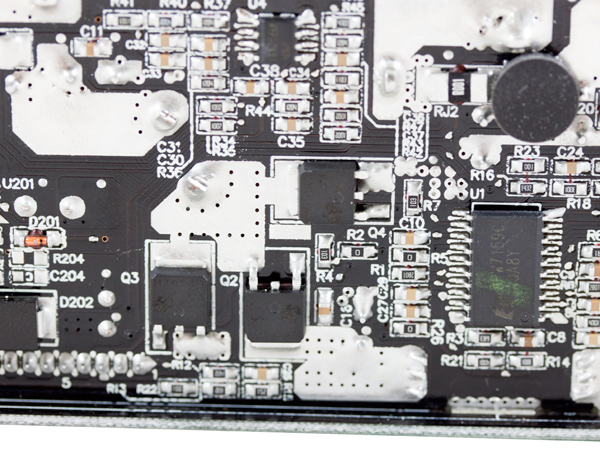

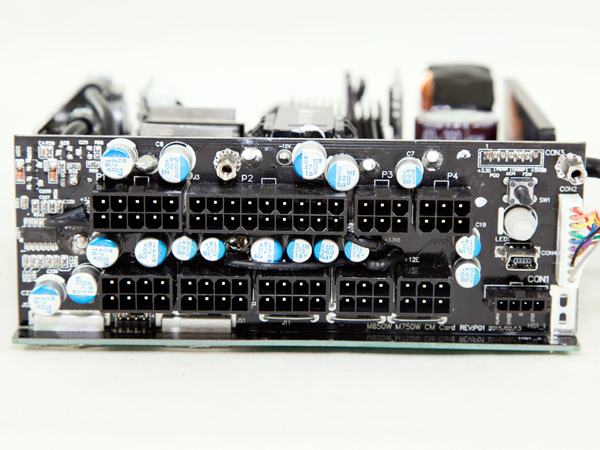

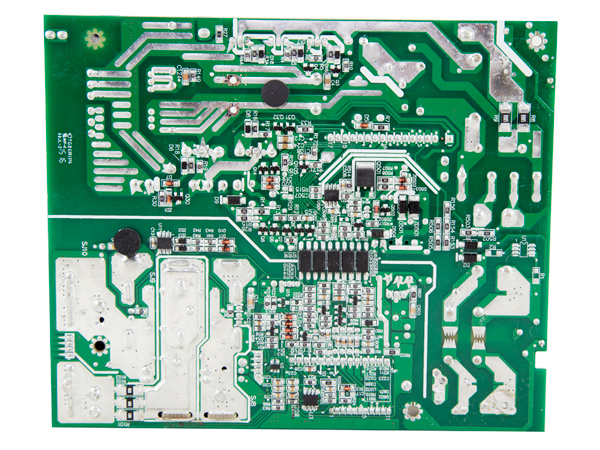

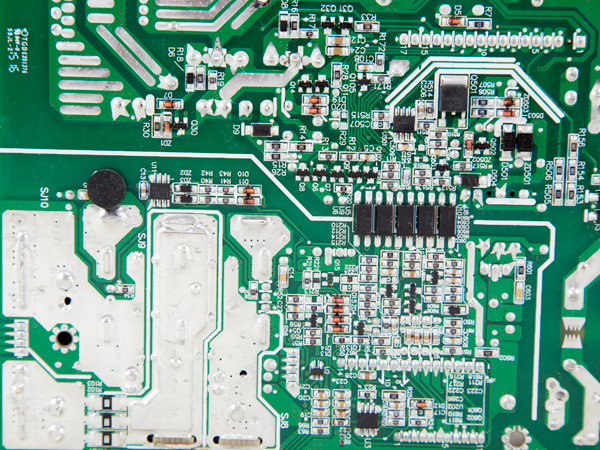

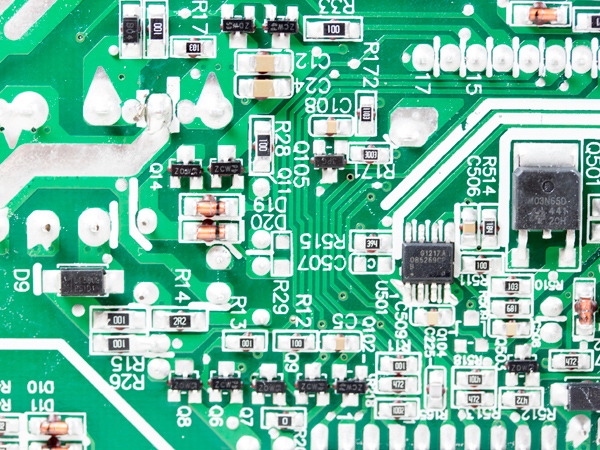

The platform, made by Channel Well Technology (CWT), is the same as the one used in the Corsair HX750i unit, with only some component changes that lead to a lower efficiency. A digital interface allows the monitoring of the PSU's status and control of the fan along with the selection between single +12V and multi +12V modes. Analog circuits, however, control the main functions in both the primary and the secondary sides. In the primary side, a half-bridge topology is used along with an LLC resonant converter for increased efficiency; in the secondary side, a synchronous design is used along with a couple of DC-DC converters for the generation of the minor rails. In addition, Corsair used only Japanese capacitors in order to increase reliability and ensure good performance over time. (Chinese caps tend to age faster than the higher-quality Japanese ones.) This specific CWT platform doesn't use any proper heat sinks in the secondary side, which looks weird, especially in a semi-passive unit equipped with a low-speed fan. Later in this review we will take some thermal shots of the internals to check on the temperature levels in the secondary side.

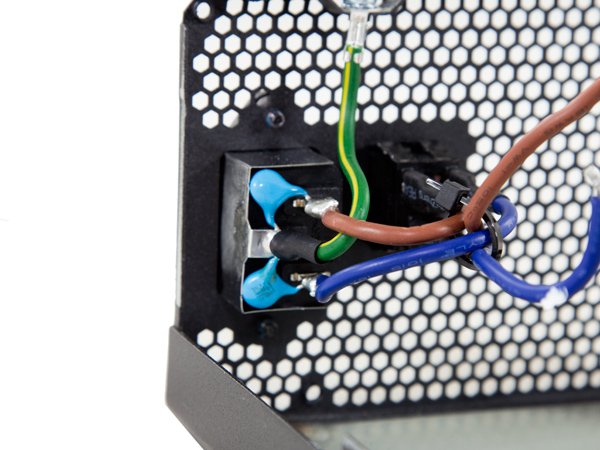

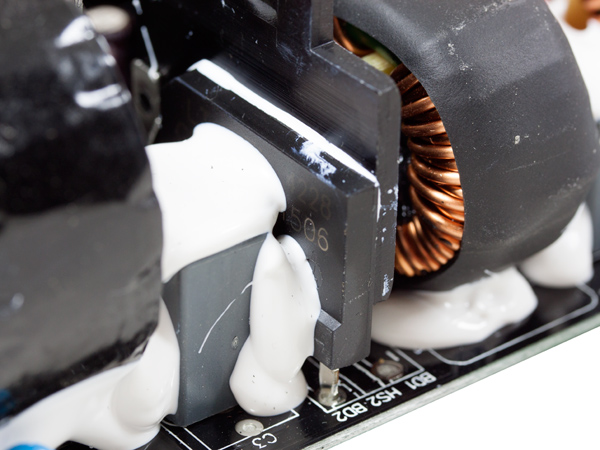

In the AC receptacle we found a couple of Y caps. The second part of the transient-filtering stage continues on the main PCB with another four Y caps, three X caps, two CM chokes and an MOV. There is also an NTC thermistor providing protection against large inrush currents. Unfortunately, Corsair didn't use a relay to isolate this thermistor once the startup phase finishes, hence a small amount of energy will be lost. But most important, during a hot start the thermistor won't be able to protect the PSU efficiently in case the bulk caps are discharged, since its resistance will be low.

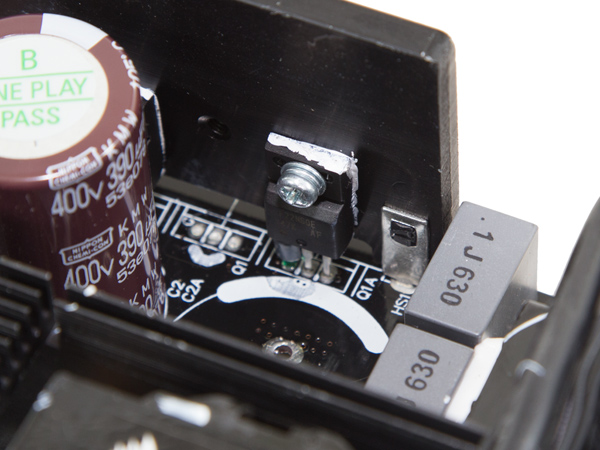

A single GBJ25L06 bridge rectifier is bolted onto a dedicated heat sink. It can rectify up to 25 A so it will easily handle this PSU.

In the APFC converter two Vishay SiHG22N60E FETs are used along with a single Vishay 8S2TH061 boost diode. The smoothing caps are provided by Chemi-Con (400V, 390uF & 470uF or 860uF combined, 105C, KMW & KMR series) and their combined capacity is adequate for this PSU's capacity, so we expect a pretty long hold-up time.

A vertical PCB hosts the APFC controller, an Infineon ICE3PCS01G, along with a CM03X Green PFC controller. On the same board there is the LLC resonant controller and an Infineon ICE2HS01G.

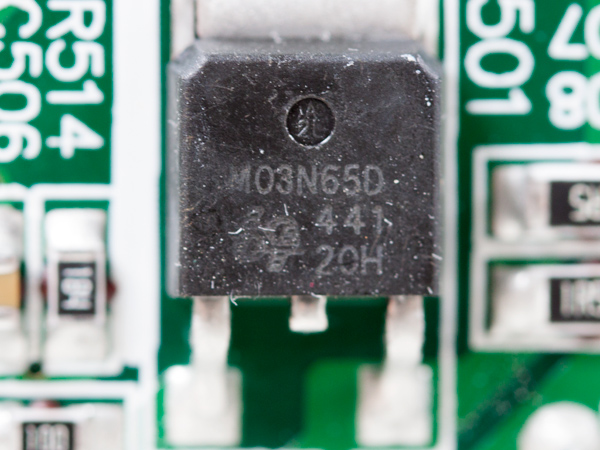

The primary switchers are two Vishay SiHG20N50C FETs arranged into a half-bridge topology.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

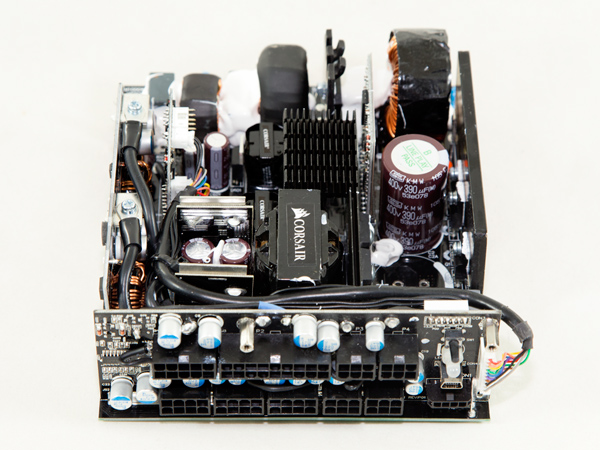

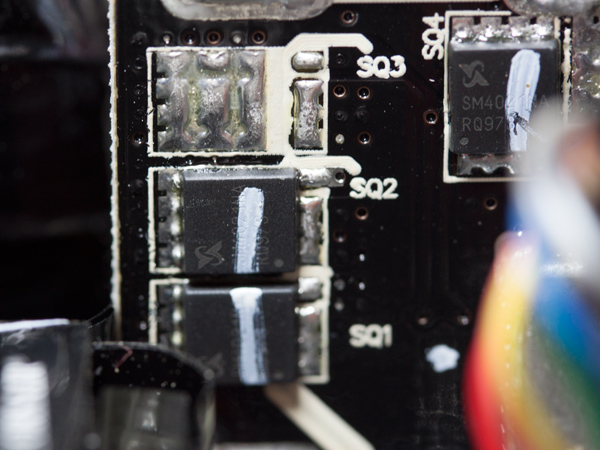

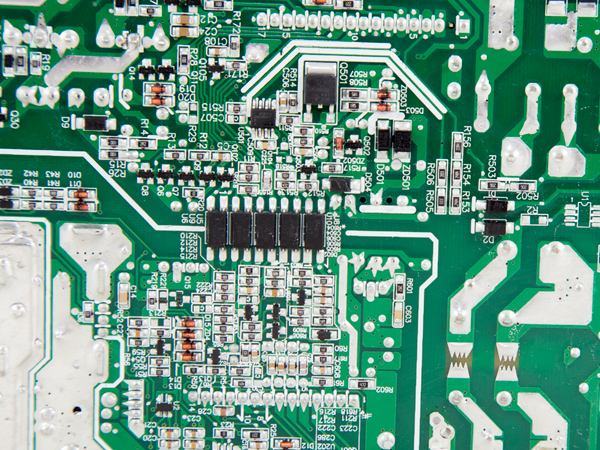

In the secondary side, there isn't a proper heat sink to cool down the +12V FETs, but there are four Sinopower SM4021NAKP, which are installed on two vertical boards. Several bus bars used for power transfer purposes handle cooling of the +12V FETs. They must do a pretty good job, otherwise Corsair wouldn't provide such a long warranty. Finally, all electrolytic caps are provided by Chemi-Con and are rated at 105 degrees Celsius (221 degrees Fahrenheit).

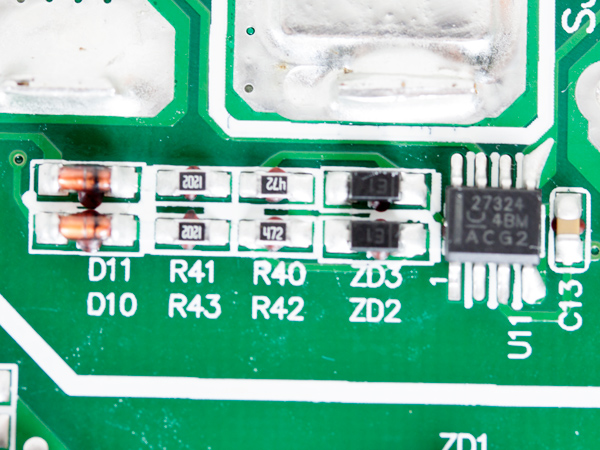

The couple of DC-DC converters that generate the minor rails are installed on a large daughterboard. The common PWM controller is an Anpec APW7159, while on each VRM two M3006D FETs are used along with a single M3004D FET.

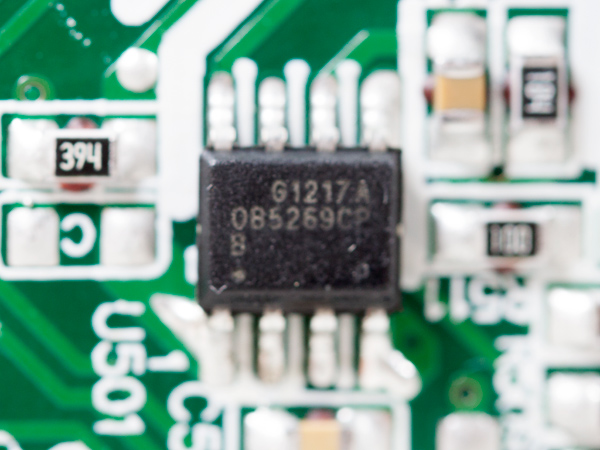

We found a Weltrend WT7502 installed on the main PCB and a Weltrend WT7518 installed on the modular PCB. The WT7518 is engaged when the PSU is in multi +12V rail mode. Finally, a PFR20V45CT SBR regulates the 5VSB rail.

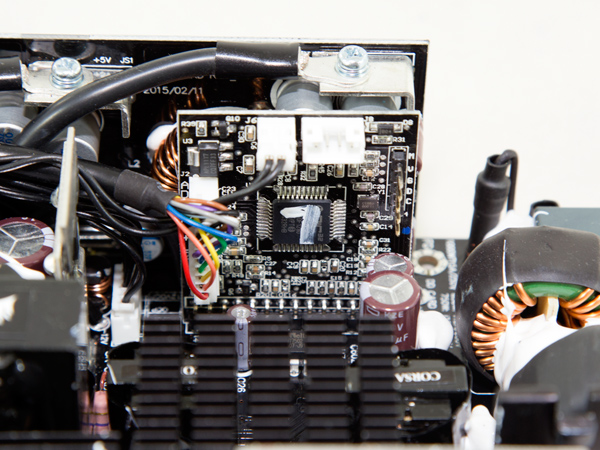

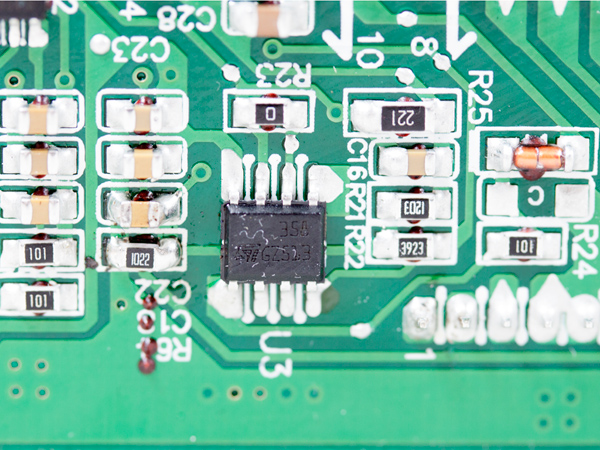

The MCU that supports the digital interface of this PSU is a PIC32MX. This is an analog platform, but it features a digital interface, which allows the monitoring of the PSU's status along with the control of the cooling fan. Through Corsair Link you are able to monitor and log the fan speed along with the voltage and current levels of the +12V, 5V and 3.3V rails. In addition, Corsair Link informs you about the power coming in and out (in Watts), the efficiency, and allows you to enable or disable OCP on the +12V rails. From the factory the PSU comes in multi +12V rail mode.

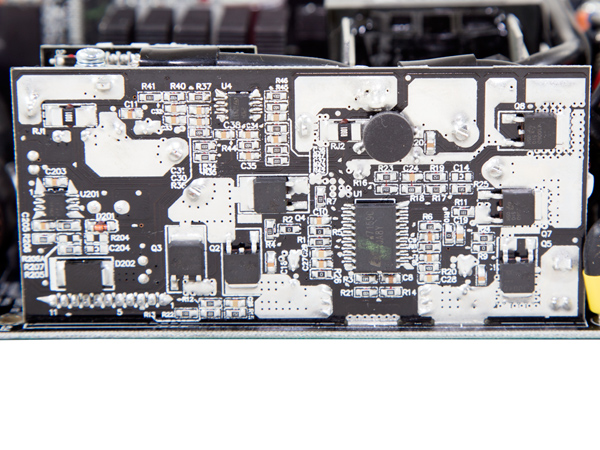

On the front of the modular PCB we found many Chemi-Con polymer caps, which are used for ripple- filtering purposes. On the back side of the board a number of cables transfer power from the regulators to the modular sockets. Soldering quality on the board is quite good overall.

The NR135P FDB fan (12V, 0.22A) is used in many high-end Corsair models besides this one, including the HX750i. It is a low speed, silent fan supported by a very relaxed fan profile and a semi-passive mode. We managed to push it to 1200 RPM speed only during the overload test and with a very high operating temperature.

Current page: A Look Inside And Component Analysis

Prev Page Packaging, Contents, Exterior And Cabling Next Page Load Regulation, Hold-Up Time And Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

Luay ArisReply

Thanks for the thorough review.

The RM750i does beat the G2 750 at $10 more, which is a good trade for a mpore quite operation, and is $20 cheaper than the Snow Silent 750, but how does it compare to the $10 more expensive P2 750? -

Aris_Mp I am sorry but I haven't reviewed the P2 750 model yet. However since it is Platinum it should be compared with the HX750i.Reply -

Luay No I'm comparing it based on price.Reply

Since the gold rated RM750i and the platinum P2 750 are $10 apart, excluding the rebate, and as Jonny (The Jonny??) said, a few %s of efficiency isn't as important to me as something as tangible as emitting noise. -

Dan414 This seems like the droids/PSU I've been looking for. That or maybe the 850i. Also, I like the white lettering - that way it will match my case no matter what lighting I have inside.Reply -

synphul I'm confused, there's no other product that compares to the corsair rm750i except the evga g2 750 and the seasonic snow silent 750 which is a higher category and price. Yet isn't that the ss-750km3 sitting at $10 cheaper?Reply

Cwt may be improving but it's not ss quality. Hard to face the two off when they're so close in price or the seasonic is cheaper. I fail to see how it's a better option than the competition. A better option than their own lineup maybe, but that's not saying a ton.

I suppose it's true it comes with corsair link, though with psu's already this quiet not sure the need is there to control the fan beyond active variable control built in and silent mode at low draw. I've never needed to monitor my psu temp or control the fan speed even on a plain old active fan design. Comes off as a bit gimmicky to try and create added value. Don't get me wrong, this would be nice on an otherwise loud psu with no fan control and no silent operation mode at all but in the face of being quiet and having variable/silent fan operation it's a little redundant.

Idk, like I said it's nice to see they're trying to improve quality in some areas but they don't even come in under the competition. As of right now they're more expensive than the competition. Personally I'll stick with seasonic. -

trifler If any PSU companies read this, I want to see molex discontinued, at least on the non-modular power supplies. At least offer some power supplies that don't have molex.Reply -

fil1p It's good to see that all the caps a Japanese on this one. I like Corsair PSUs, but the last gen RM series had some lower quality caps in there, which quite frankly shouldn't have been in an enthusiast PSU at that price point in the first place.Reply -

jonnyguru Reply16336613 said:Cwt may be improving but it's not ss quality.

How do you know? ;-)

16336613 said:I suppose it's true it comes with corsair link, though with psu's already this quiet not sure the need is there to control the fan beyond active variable control built in and silent mode at low draw. I've never needed to monitor my psu temp or control the fan speed even on a plain old active fan design.

You can also monitor voltages and load and calculate efficiency. So it does a lot more than what you're stating.