Early Verdict

Those looking for liquid cooling in the $140 - $160 range will be hard-pressed to find a better performer or better cooling value.

Pros

- +

Least expensive custom loop cooling kit we’ve seen to date

- +

Incredible cooling performance for the money

- +

Close to premium full copper loops

Cons

- -

Must use aluminum only parts for upgrades and expansions

Why you can trust Tom's Hardware

Features & Specifications

Aluminum. It's a dirty word in liquid cooling. Enthusiasts have been told for years that buying an aluminum radiator is as bad as dunking your GPU in a bucket of ice water, right? So what do we think when EK claims its next great product is made of aluminum? Really, that EK? The company that prides itself on selling only premium copper loop components? Yes, really that EK. Don't worry, this isn't a disaster of biblical proportions; dogs and cats aren't sleeping together.

Specifications

Chemistry 101. For those who don’t want to read a wall-o-text (and my editor who doesn’t want to proof-read it), I’ll try to keep it relatively brief. In short, aluminum in cooling loops often leads to galvanic corrosion. You can read EK’s own post if you want full detail.

For those who never took (or paid attention in) chemistry class, galvanic corrosion happens when two dissimilar metals are connected by an electrically conductive fluid. This creates a battery, even if it's a weak one. The metal that is more resistant to oxidation and corrosive chemical reactions (called the cathode or more noble metal) will remain while the other (the anode) will eventually dissolve.

Listing metals in order of their relative nobility and reactivity to each other is known as an anodic index. The more dissimilar the metals and the farther apart they are on the anodic index, the higher the voltage difference between them and the more aggressive the corrosion will be. Sometimes this reaction is intentional and beneficial, such as in batteries. Sometimes it’s not, such as the corrosion between the copper skin and iron supports in the Statue Of Liberty.

In chemical terms, aluminum is very high on the anodic index and is a very reactive metal. In contrast, copper is quite noble. When using them both in the same cooling loop, the coolant bridges the two metals, enabling galvanic corrosion. Even though pure distilled and deionized water are not electrolytic when you first pour them into a loop, they slowly become ionized as they flow through the loop and rub along the metals. When this happens, the aluminum parts will start to dissolve, eventually leading to leaks in the loop (and aluminum-oxide "gunk" in the passages). Many coolant mixes include corrosion inhibitors that slow down the process, but it’s always preferable to not mix copper and aluminum in the first place.

That's not to say copper is the only metal safe for use in liquid cooling. Brass and bronze are both alloys of copper, and all three metals are right next to each other on the anodic index. Indeed, EK's regular radiators use brass for the end caps. Some manufacturers even use brass in their radiator cores. Nickel is another metal very close to copper on the anodic index and has a higher corrosion resistance than copper. This makes it a common electroplate on copper water blocks. All of these metals can be used simultaneously in a loop without risk of corrosion and subsequent leaks.

But the mantra of “don’t use aluminum in liquid cooling” is actually wrong. A more correct version would be “don’t mix aluminum and other metals in liquid cooling.” Using aluminum on its own won’t induce corrosion. It actually has a few advantages over copper, namely lower cost and weight. Copper may not be a precious metal by everyone's definition, but it's still pricey. Copper does have the advantage of being nearly twice as thermally conductive as aluminum. Intel’s old stock cooler with the copper slug was a much more efficient cooling solution than its solid aluminum alternative. But liquid cooling loops have much different dynamics than air coolers, so let’s find out how much difference it makes in application.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

EKWB Fluid Gaming A240 Kit Feature Overview

The A240 kit is nearly identical to the Slim 240 we just reviewed. The major change is that all metal used in the kit is aluminum. The water block cold plate is aluminum. The radiator is completely aluminum. Even the compression fittings are aluminum. The pump and fans are the same as the Slim 240, and the radiator is still a dual 120mm fan model. Material change aside, these kits are practically the same design, so this should be an excellent comparison of copper versus aluminum. Because the A240 and Slim 240 share many of the same features, we won’t waste time and space covering them all again. You can read the original Slim 240 review for additional detail as necessary.

Water Block

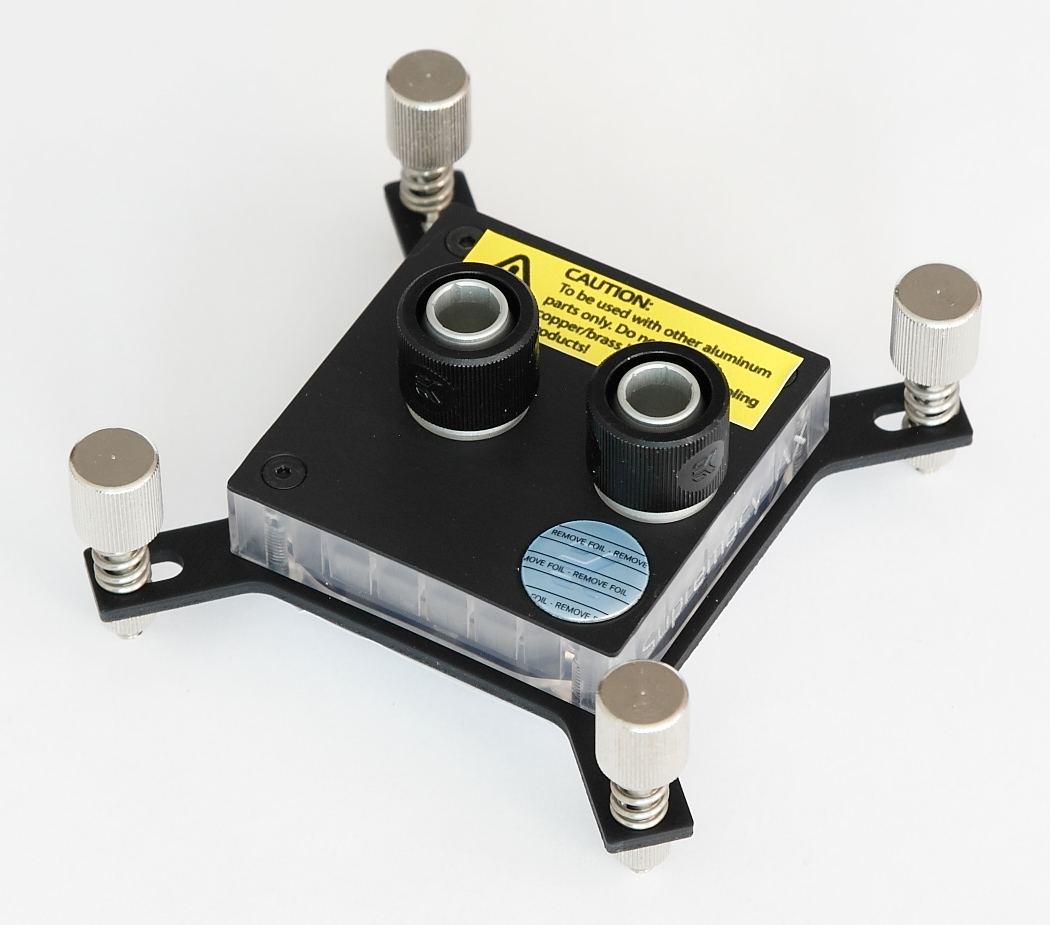

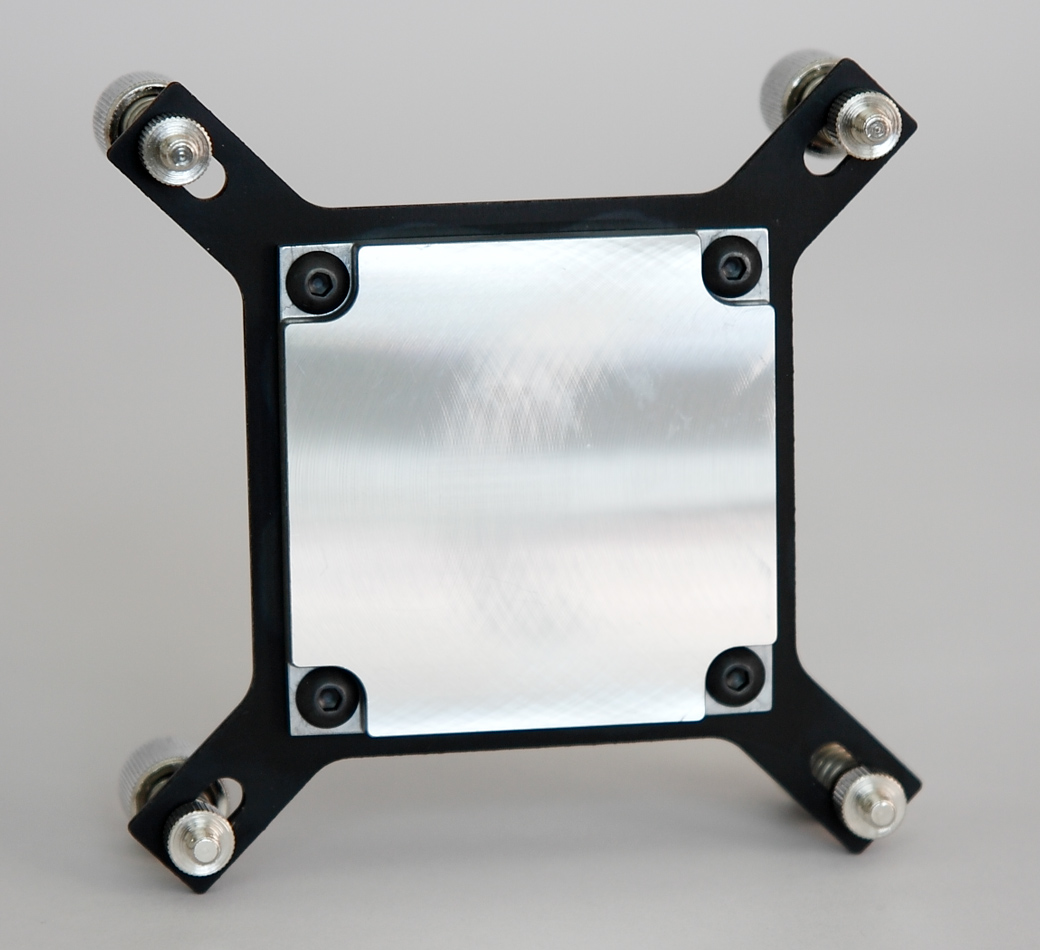

The Fluid Gaming kits introduce EK's Supremacy AX water block. This block uses the exact same parts (top, insert, and jet plates) as the regular Supremacy MX except the cold plate is aluminum instead of copper. Even the microfin pattern on the plate is the same. The plate bottom isn’t polished like its copper cousin and does show machining marks. The AX still uses two G1/4 fittings on top and the same mounting mechanism as the MX. The mounting bracket in the block itself is now aluminum as well. Socket compatibility is the same as the Slim 240, meaning LGA 115X, 2011(-3), 2066, AM3, and AM4 sockets are all supported.

Radiator

The radiator in the A240 is a completely new affair, although the dimensions and overall design are very similar to the copper SE 240. The core still uses 22 fins per inch and is only 25mm thick. The exterior frame now leaves the end chambers exposed instead of completely enclosed like on the SE 240. Our testing showed a small gap between the radiator edges and the fan frame, even when the fans are securely bolted on. That’s something you don’t see on the regular SE 240.

Fans

Fans don’t come into contact with the coolant, of course, so there’s no reason to change out the Vardars. These are the same 1800 RPM, seven-blade F3-120 fans as last time.

Pump

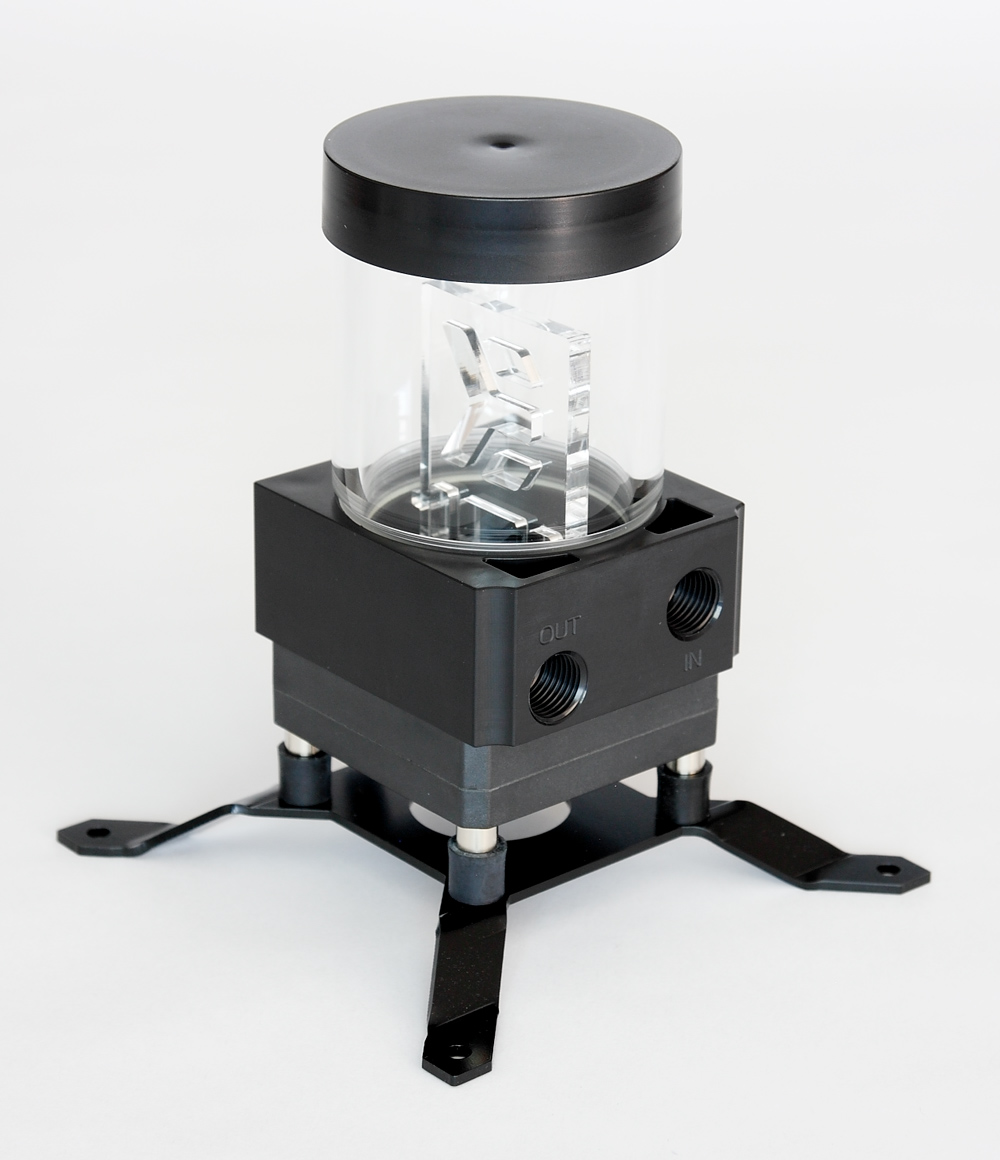

Like the fans, the pump remains the same SPC 60A combo model found in the Slim 240. All internal sections of the pump and reservoir that come in contact with the coolant are nonmetallic, meaning no risk of corrosion.

Tubing & Fittings

The Fluid Gaming kits still get two meters of EK’s DuraClear 13/10 PVC tubing. The six compression fittings are now aluminum instead of brass, both rings and barbs. The rings this time are black anodized rather than nickel plated. They still use the same hex wrench to secure them in place.

Extras

The rest of the extras are also the same. The pump still has a mounting bracket and rubber dampening feet. The same Cryofuel concentrate bottle is included, as well as PSU bridge plug, SATA-to-4-pin adapter cable, splitter cable for fans, and 4-pin extension cable.

Installation

The first thing you see when opening the A240 box is a huge sign warning against using any copper components with the kit. Further warning stickers and labels can be found throughout the box and on the components. Even the most unobservant consumers can’t miss them.

Installation with the A240 is no different than other open loop setups. The individual components still need to be fully rinsed with distilled water prior to final assembly. Planning and placing the components in your case allows you to measure the exact length of tubing needed between the water block, radiator, and pump. It’s still critical to run the tubes in sweeping curves instead of sharp bends where possible to avoid crimping them.

One important installation note on the A240 compared to the Slim 240 and other copper-based loops is the fittings: as we mentioned, the barbs, rings, and machined ports are aluminum, which is much softer than copper and brass. The fittings aren’t fragile by any means, but the difference is noticeable. Be careful when tightening the barbs with the included hex wrench, because they’re easier to bend and damage than you might think. Similarly, over-tightening the compression rings can strip the threads.

MORE: Best CPU Cooling

MORE: How To Choose A CPU Cooler

MORE: All Cooling Content

-

Malik 722 what about the regular all-in-one solutions from the other brands which use cooper plate for heat transfer are they safe.Reply -

WyomingKnott Yes they are safe. They just have to be made with all copper parts. Heck, you could make one with silver for all the metal parts and it would be "safe," but it would be a waste of money.Reply -

lightofhonor I have the A240R for Vega cards. Works great, though can't cool both if both are OC and full load.Reply -

Lutfij It might be a cheaper alternative to get your feet wet for custom level watercooling but expansion options can and will be limited since not everyone makes aluminum waterblocks for every card on the market. Even EKWB have shut down their thinkcell programme since they couldn't keep track of the immense level of suggestions for various request/demands with a vast sea of SKU's for CPU's, motherboard's chipsets as well as monoblocks and lastly GPU's.Reply

FYI, corrosion inhibitors only slow down the process of galvanic corrosion or the liquid inside an AIO aren't actually water based but a special fluid concocted at Asetek's factory. -

Olle P The initial part about galvanic corrosion is somewhat flawed:1. To get galvanic corrosion there must be a direct metallic path between the two different metals in contact with the fluid. An aluminium radiator paired with a copper water block is no problem unless they're in direct electrical contact through the mountings.Reply

2. Galvanic corrosion is typically a very slow process. The only clear example of galvanic corrosion I've been able to find in water cooling is the CPU block provided with Zalman Reserator 1. It had a gold plated base mated to an aluminium housing, doubling the galvanic potential compared to copper.

Over the last few months I've been running a test to see the effects of galvanic corrosion. A piece of aluminium and a piece of brass in a plastic cup with mineral water (the top notch local tap water). The metal pieces are connected by a wire and I add more water every few days due to evaporation.

This far there's absolutely no sign of corrosion!

It would be horrible to use in a cooling loop though, because there's a lot of calcium being produced that would clog any cooling block. In fact: Most of the pictures found of what users seem to think is the result of galvanic corrosion in water cooling seems to be other substances (from the fluid) causing deposits.