Tom's Hardware Verdict

With a built-in air filter, easy build platform leveling, and a .05mm XY resolution, the Mars 2 Pro sets the benchmark for MSLA resin 3D printers in the sub-$300 price range.

Pros

- +

Spring-loaded self-leveling build platform

- +

Integrated air filtration system

- +

Solid metal construction

Cons

- -

Build volume can feel limited

- -

Preloaded test print isn’t up to par

Why you can trust Tom's Hardware

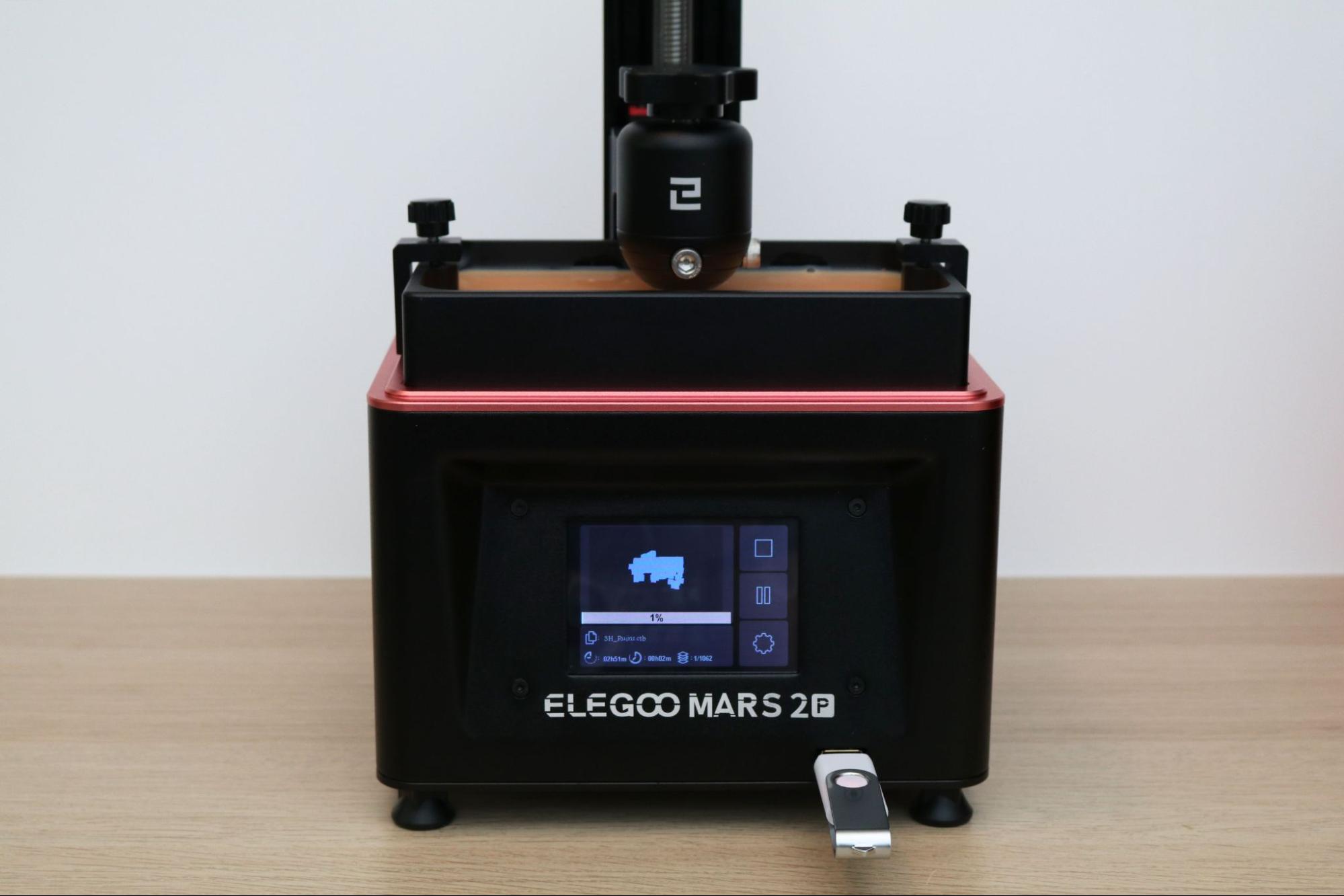

The current flagship of the Mars series, the Elegoo Mars 2 Pro offers rock-solid CNC machined aluminum construction, a 2K resolution mono LCD with a per-layer cure time of 2.5 seconds and an integrated air filtration unit. From initial unboxing to the first finished print, the Mars 2 Pro impressed me with its strong build quality and ease of setup and use.. The build volume on the Mars 2 Pro is on par with other machines in this price range like the Anycubic Photon, but it may be limiting if you’re hoping to make larger creations.

The Mars 2 Pro is currently on sale through Elegoo directly and Amazon for $259.99, which makes it one of the best 3D printers you can buy for under $300, and a great choice for those who want the quality of resin on the cheap.

Elegoo Mars 2 Pro Specifications

| Machine Footprint | 7.87" x 7.87" x 16.14" (20cm x 20cm x 41cm) |

| Build Volume | 5.08" x 3.15" x 6.3" (129mm x 80mm x 160mm) |

| Resin | DLP Photopolymer Resin |

| UV Light | 405nm UV LED |

| Masking LCD Resolution | 1620 x 2560 px |

| Masking LCD Size | 6.08-inch |

| Interface | 3.5-inch LCD Touchscreen |

| XY Axis Resolution | .05mm |

Included in the Box of Elegoo Mars 2 Pro

Unboxing the Elegoo Mars 2 Pro feels a bit like opening a nesting doll; inside the box is the printer, and inside the printer is all of the accessories. I like how Elegoo has efficiently packed the Mars 2 Pro, and this densely-packed box contains almost everything you need to get started printing as soon as you pop it open. Face masks, rubber gloves, paper filters for filtering resin, a pair of scrapers and a measuring cup are all common consumables that you’ll be using with this machine and Elegoo has included enough to get you started in the box. The USB drive contains a digital version of the user manual, a test print, and the Chitubox slicing software used by the machine.

Design of Elegoo Mars 2 Pro

The Elegoo Mars 2 Pro looks like a typical resin 3D printer from the outside: tinted acrylic UV-resistant lid, front-facing LCD screen, and a build platform suspended from a linear rail on the Z axis. Unlike similar printers in this price range (like the Anycubic Photon) which use a plastic base, the base of the Mars 2 Pro is made of metal, which gives the Mars 2 Pro a solid, bottom-heavy feel.

Both the resin vat and the masking LCD ship with protective stickers applied to them, and removing them is as easy as grabbing the red tab and peeling. The base of the Mars 2 Pro has a groove in it, which lets the resin vat self-locate and sit flush with the masking LCD.

Unfortunately, the bottom of the vat is flush with the FEP film, which makes it awkward to lay the vat down without putting pressure on the film. I prefer the solution Elegoo came up with on the Saturn; by adding four screws to the edges of the vat it sits slightly raised when placed on a surface which keeps the delicate vat away from anything that could potentially damage it.

The included drip bracket is a surprisingly useful tool that I found myself looking for after every print. After a model prints, resin typically pools on the top of the build platform and in the part, and it drips when the platform is removed from the printer. The drip bracket lets you mount the build platform at an angle after printing, which drains the resin back into the vat and makes scraping the rest off easy. I really like this style of bracket, and I hope to see it included as a standard accessory in other MSLA 3D printers going forward.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The Mars 2 Pro uses a front-facing USB port for transferring files via thumb drive, just like the original Mars Pro. The 3.5-inch color touchscreen LCD is bright and allows for easy navigation to all of the various settings of the Mars 2 Pro. The LCD is the only interface between you and the printer, so the responsiveness of the screen is important when calibrating the build platform and selecting a part to print.

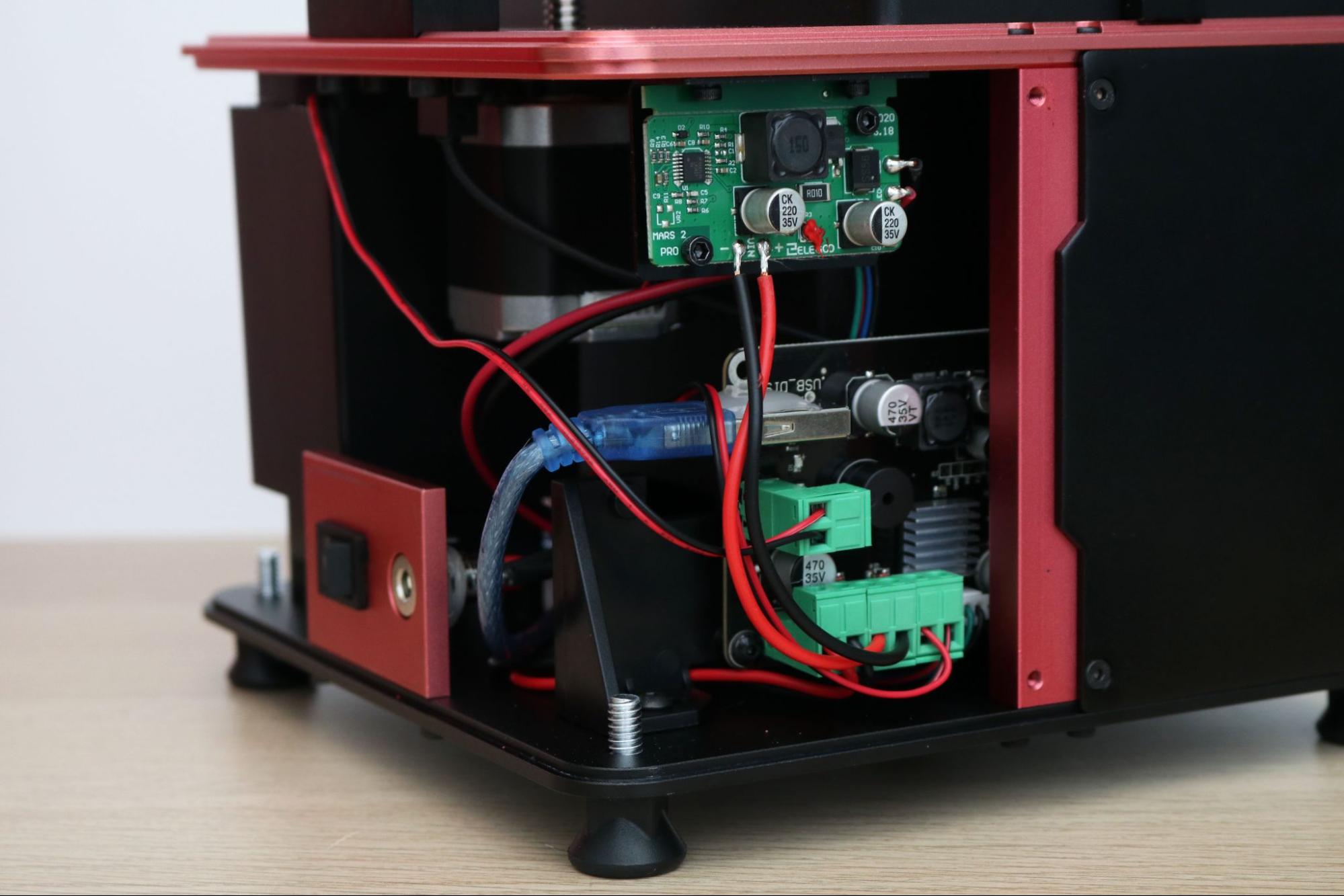

The wiring job on the inside of the Mars 2 Pro looks clean and professional, with all terminal blocks securely fastened and additional adhesive added to the USB terminal that runs to the front of the machine. One of my favorite additions to the Mars 2 Pro is the built-in air filter, visible to the left of the power switch in the above picture. This filter pulls air from the inside of the lid when it’s placed over the printer and filters it before exhausting out of the machine. This is a small feature, but it’s a big benefit for anyone who is sensitive to the smell of resin while it’s printing.

Leveling the Build Platform on Elegoo Mars 2 Pro

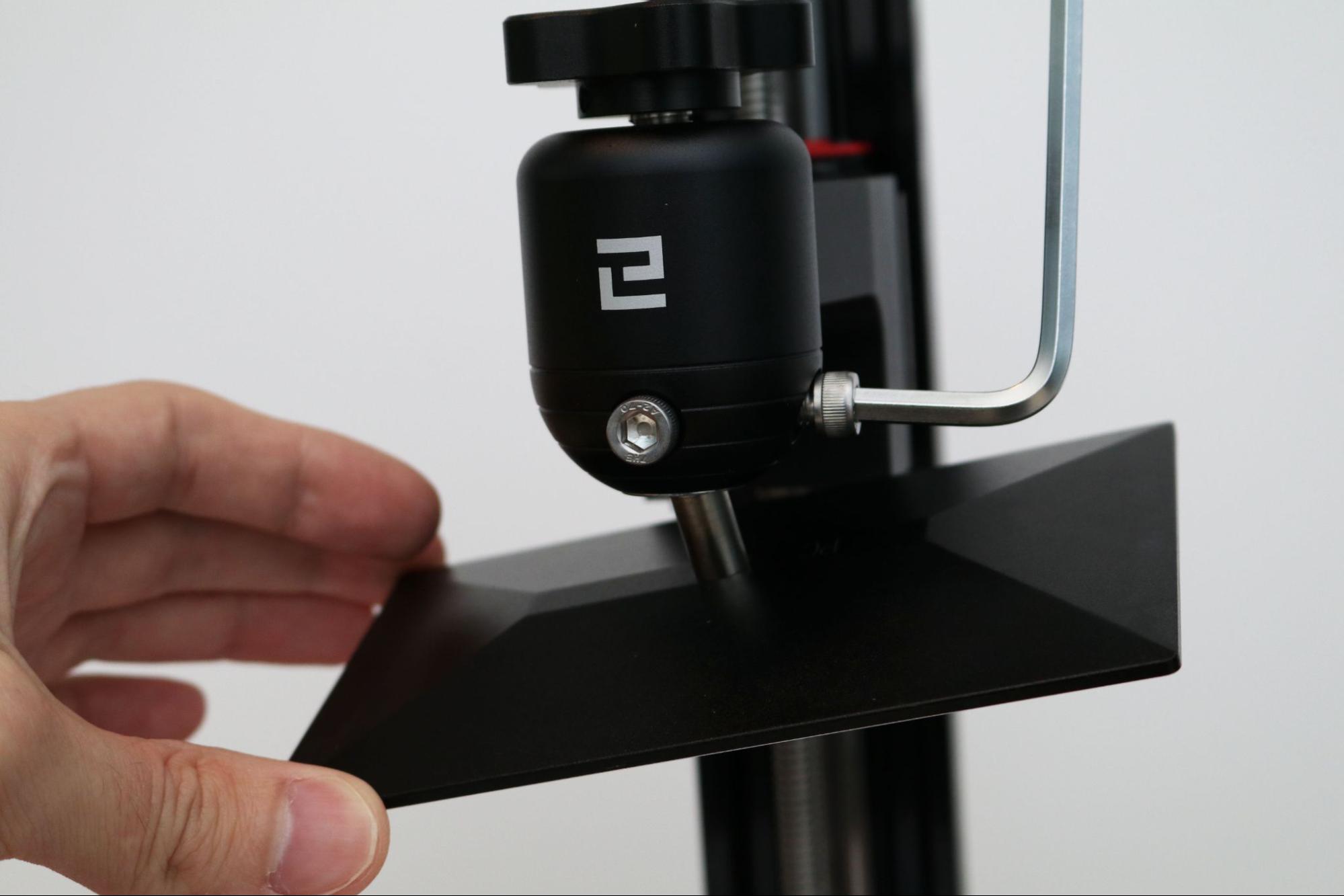

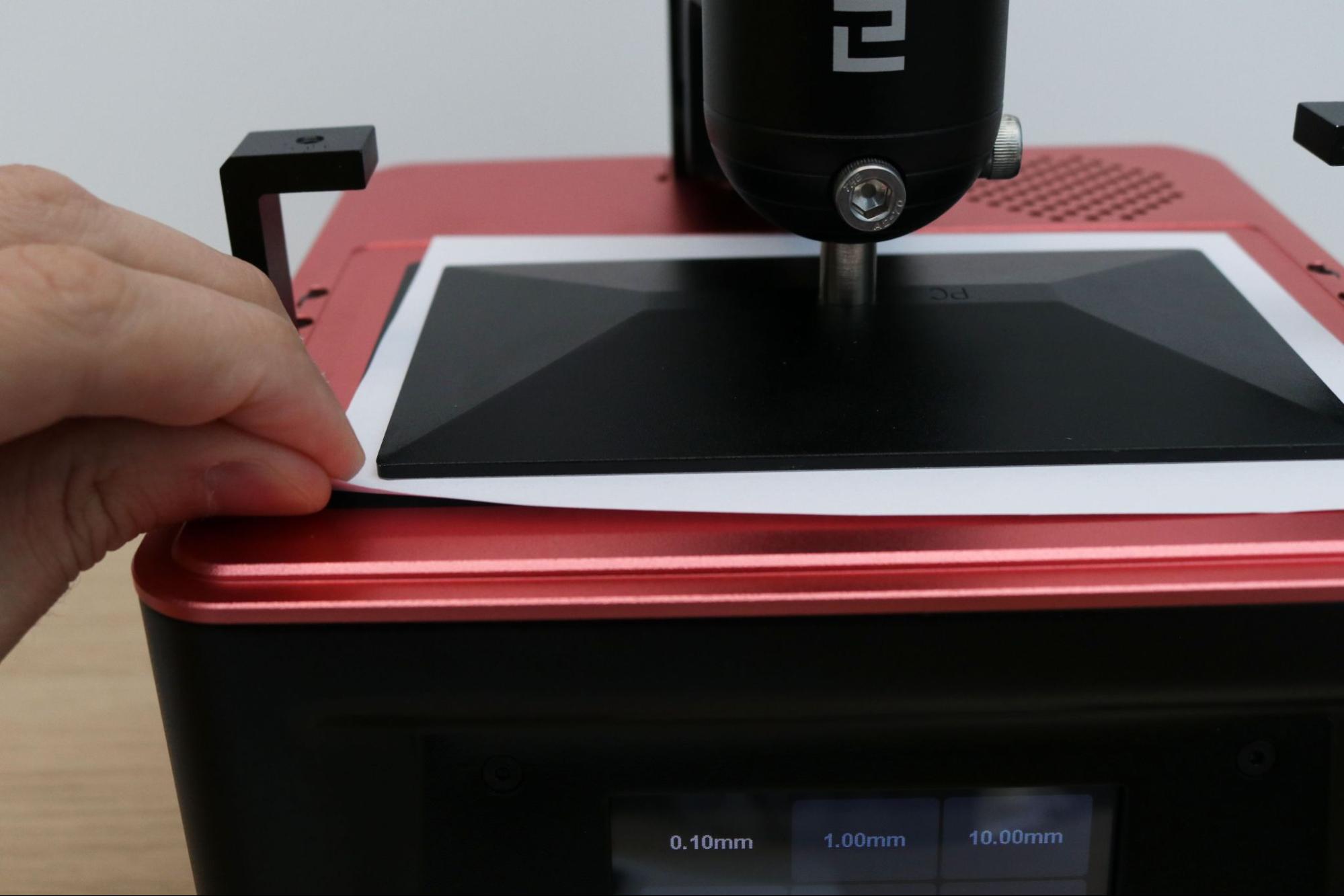

The calibration of a 3D printer is one of most important factors in the success of a print, and Elegoo has taken steps to make sure this process is as simple, accurate, and repeatable as possible. The build platform on the Mars 2 Pro uses a spring-loaded ball-and-socket design that allows the platform to make contact with the masking LCD without pushing into it and damaging the LCD. Elegoo has standardized this type of build platform across their line-up (including the Elegoo Saturn, one of the best resin 3D printers we’ve reviewed), so it’s no surprise that the Mars 2 Pro is just as easy to calibrate.

Following the instructions in the manual, I placed a piece of paper over the masking LCD to protect it, loosened the two bolts on the build platform and lowered it until the build plate self-leveled on top of the LCD. It would be hard for me to overstate how easy this is; the printer practically levels itself and only requires the two bolts be tightened back up after it has self-leveled. This is a welcome change from the four-bolt process on the Longer Orange 10, which can cause the build platform to move as the bolts are tightened.

Printing Safety with Elegoo Mars 2 Pro

The Elegoo Mars 2 Pro uses 405nm UV resin, a material that you need to handle safely when in an uncured state to avoid injury. The resin can be harmful when making contact with skin, so make sure to wear gloves when pouring, cleaning up, or handling uncured resin. I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

Make sure you use the Mars 2 Pro in a well-ventilated room to minimize the danger from inhaling fumes. Any spills or uncured resin stuck to a surface should be cleaned using 99% Isopropyl Alcohol and the container for the resin should be kept closed and secured when not actively pouring material.

The build plate on the Mars 2 Pro has a slight taper to it, which allows resin to drip off the edges while printing. The build platform is fully submerged during the initial portion of printing, so preventing the resin from pooling makes cleaning easier and allows you to reclaim more of the resin after printing. Between this taper and the included tilt bracket, cleaning the build platform on the Mars 2 Pro is easier than most other resin 3D printers.

Don’t Print the Included Test Print on the Elegoo Mars 2 Pro

So far, everything about the Mars 2 Pro shows a great deal of attention has been put into the design of the machine and supporting documentation. Unfortunately, the test print included with the Mars 2 Pro is the first (and only) major stumbling block I ran across. If you’ve already read our review of the Elegoo Saturn, you already know what’s coming. If you haven’t, let me tell you why you should skip the included test print with the Mars 2 Pro.

Resin 3D printers like the Elegoo Mars 2 Pro work by progressively hardening layers of liquid resin using UV light as a catalyst. This is a simple concept, but the execution requires a few considerations to ensure success. The hardened thermoset resin is solid, and isn’t pliable or malleable like a thermoplastic, like the PLA printed by the Anycubic Vyper. A solid block of this material, printed onto a solid metal platform, is very difficult to remove and usually results in damage to the build plate or the printed part.

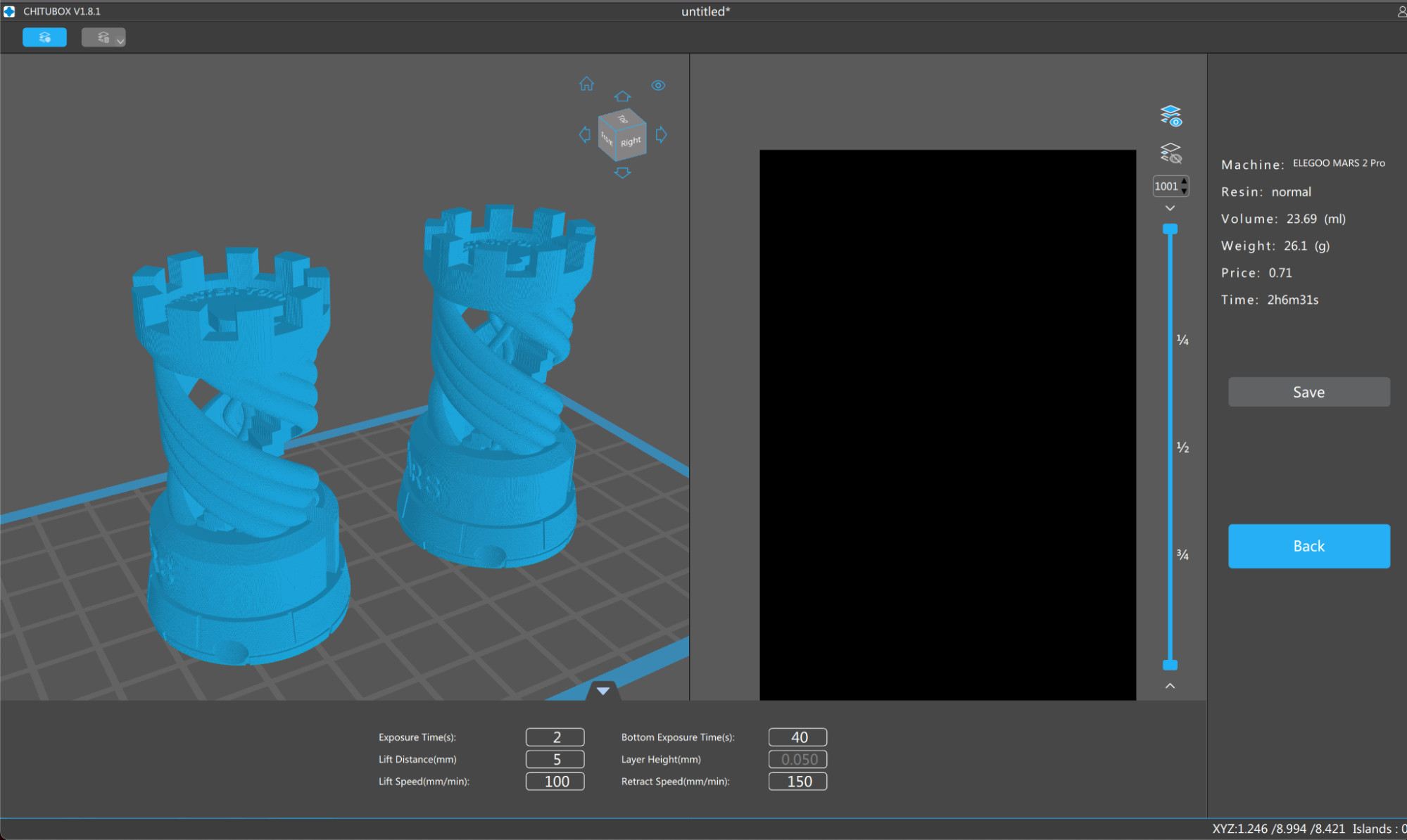

The test print included with the Elegoo Mars 2 Pro is the same model that’s included with the Saturn; a pair of rooks with fine features inside and outside of the model. Both of these rooks are solid on the bottom, which results in a part that is extremely difficult to remove from the build platform. Without a flexible or pliable thin raft to use as a removal aid, these parts can be frustrating at best, and lead to damage to the machine (or user) at worst. I would recommend skipping this test print, as the difficulty in removing it from the build platform far outweighs the benefit of verifying the printer’s functionality.

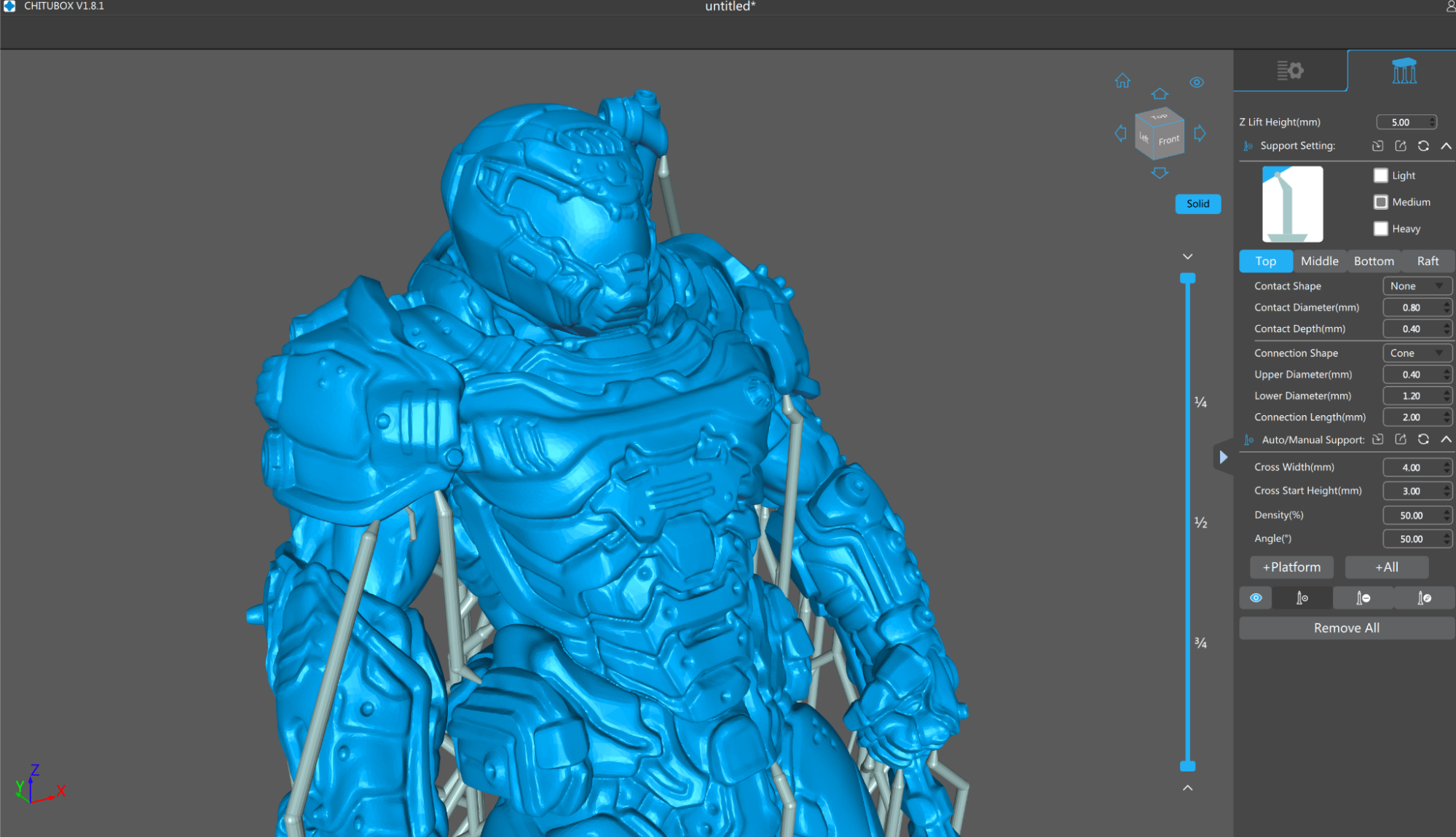

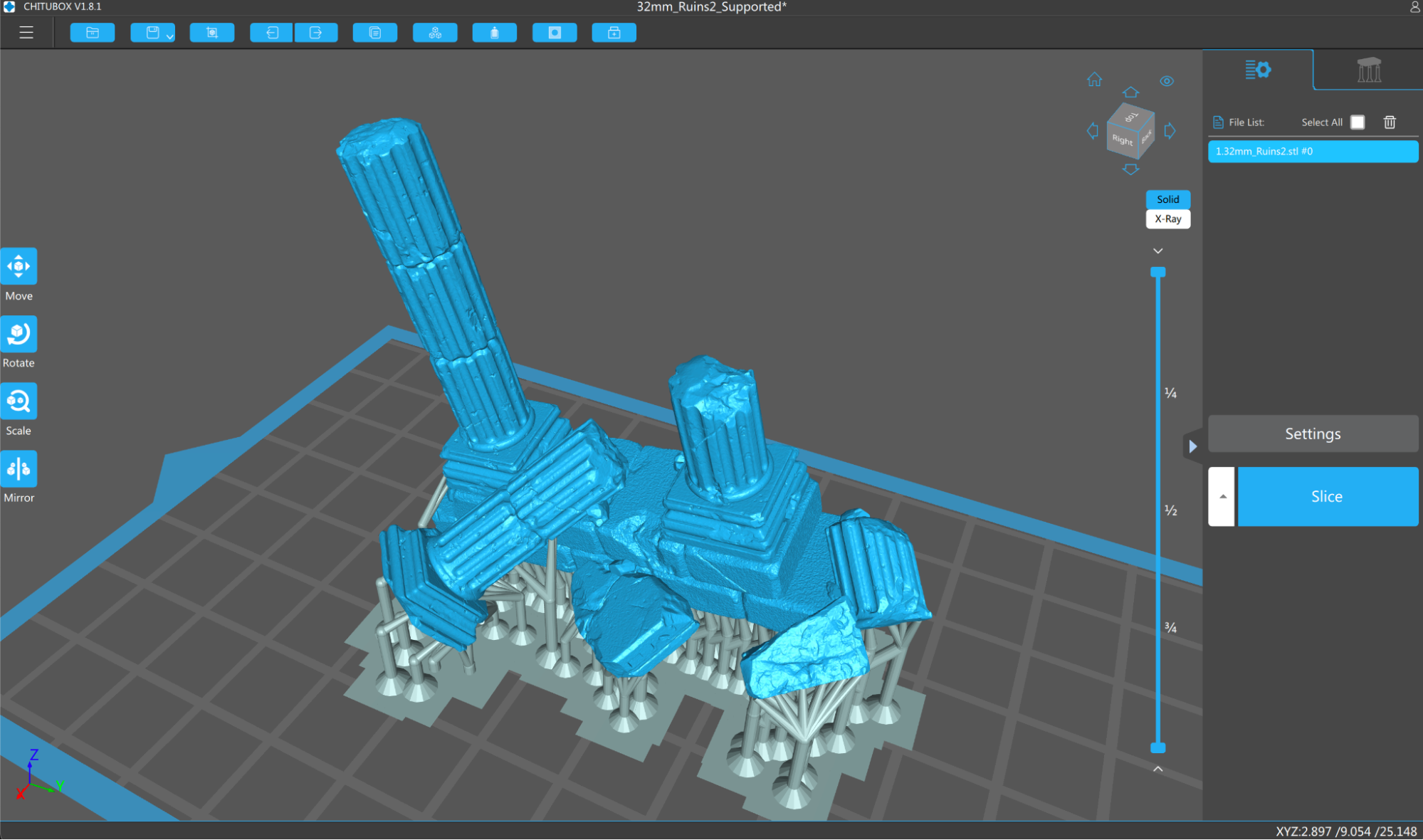

Preparing Files for Printing with Chitubox

The Elegoo Mars 2 Pro uses the included Chitubox software for preparing models for 3D printing. Chitubox uses a simplified interface that is friendly to first-time users but also offers enough features to satisfy the requirements of advanced users looking for more granular control. Chitubox is designed to be an all-in-one solution for resin 3D printing, with features like model hollowing, support generation, and drain hole creation all included in the base software.

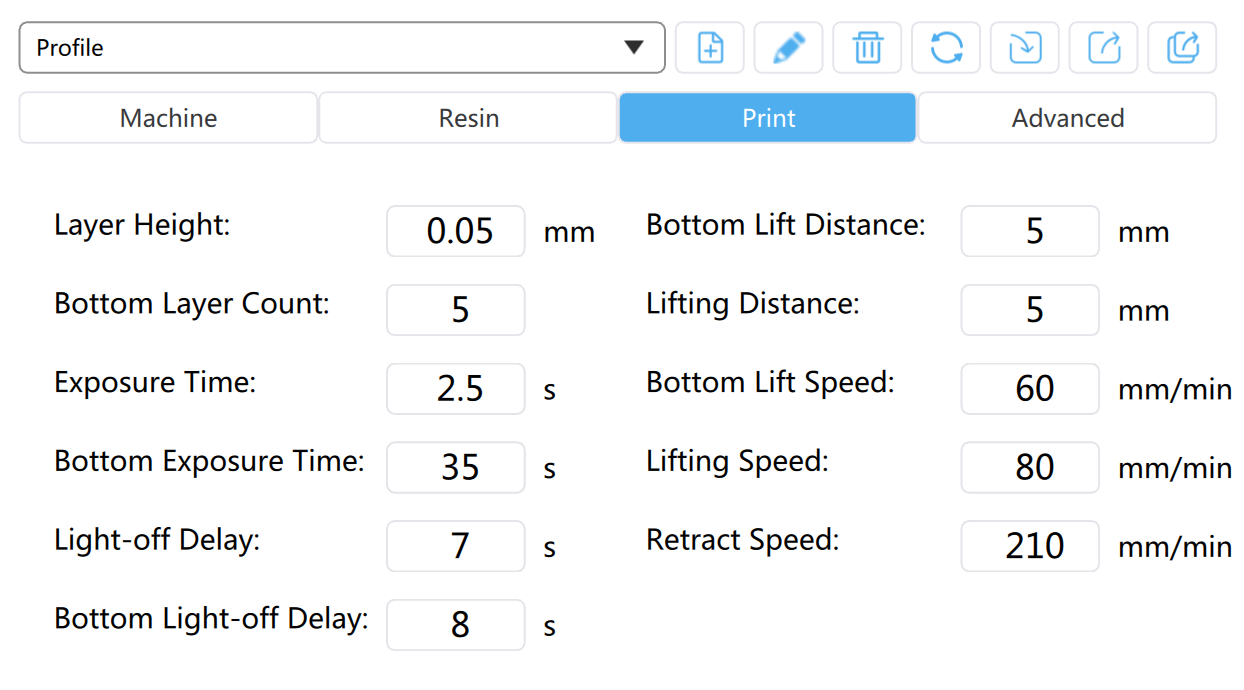

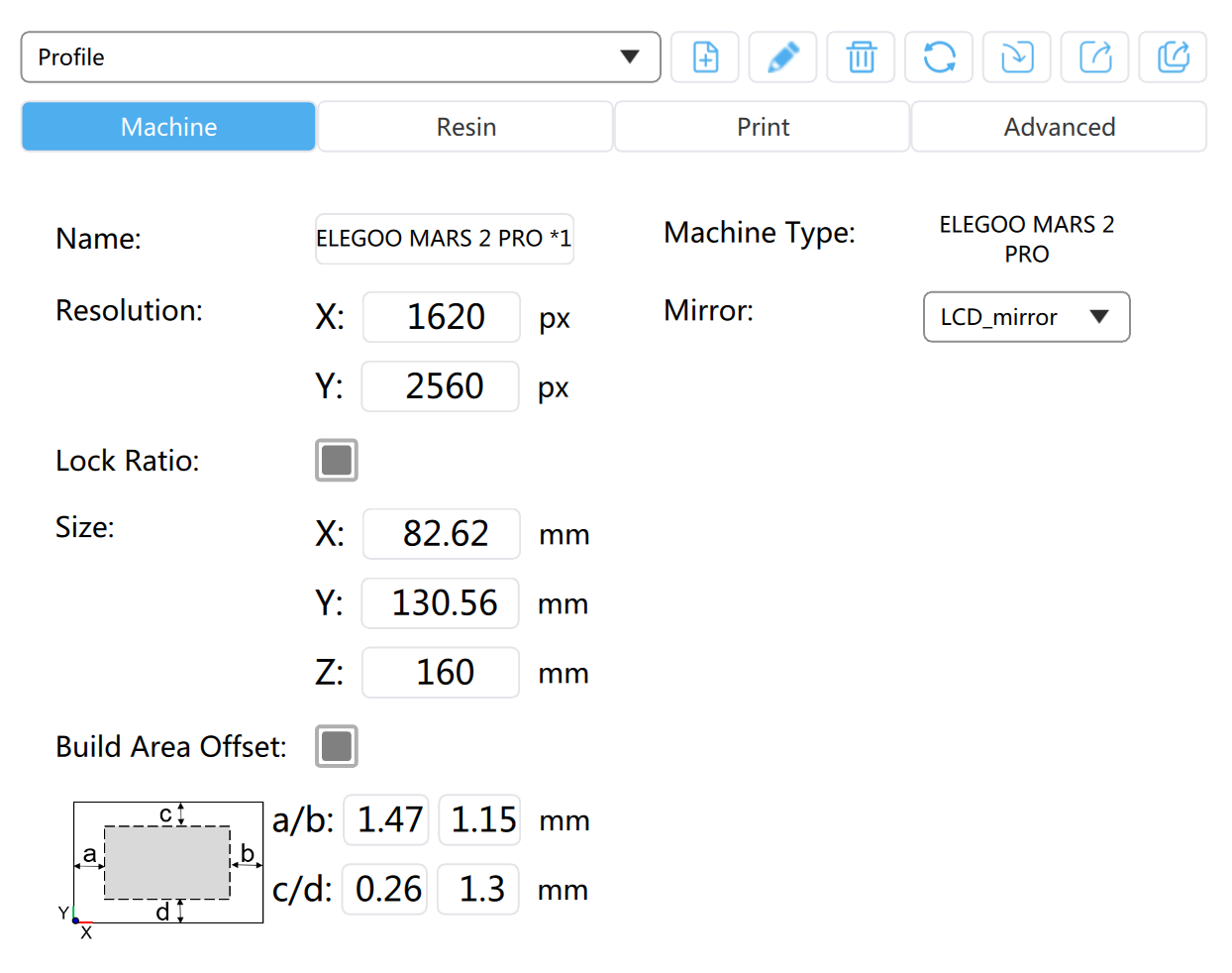

Chitubox includes a profile designed for the Mars 2 Pro, and the settings are worth examining more closely. With a per-layer exposure time of 2.5 seconds made possible by the mono LCD, the Mars 2 Pro rockets ahead of resin 3D printers with traditional LCD screens like the Creality LD-002R which can take up to 9 seconds per layer to cure. When printing models that have thousands of layers, that extra per-layer cure time can add up quickly.

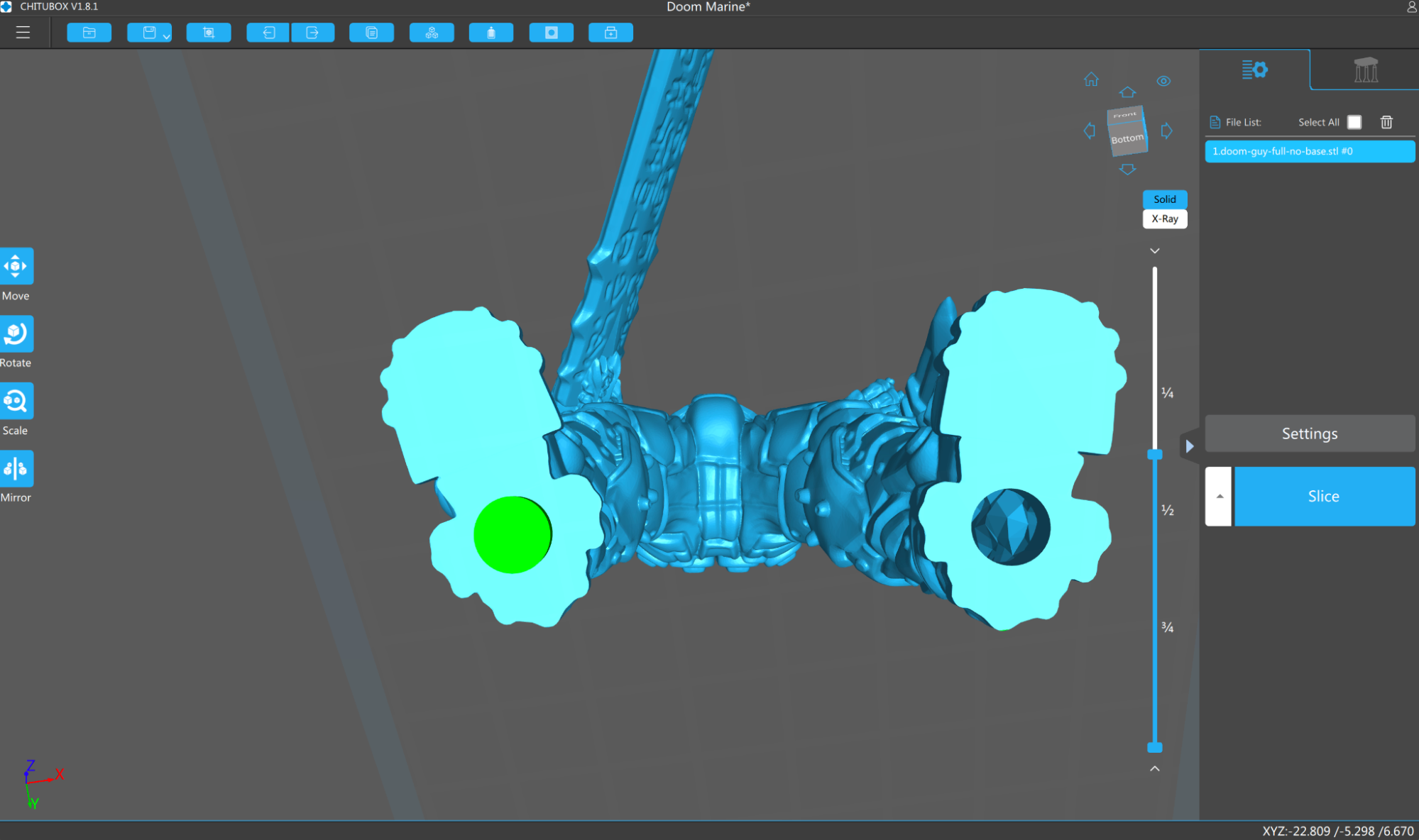

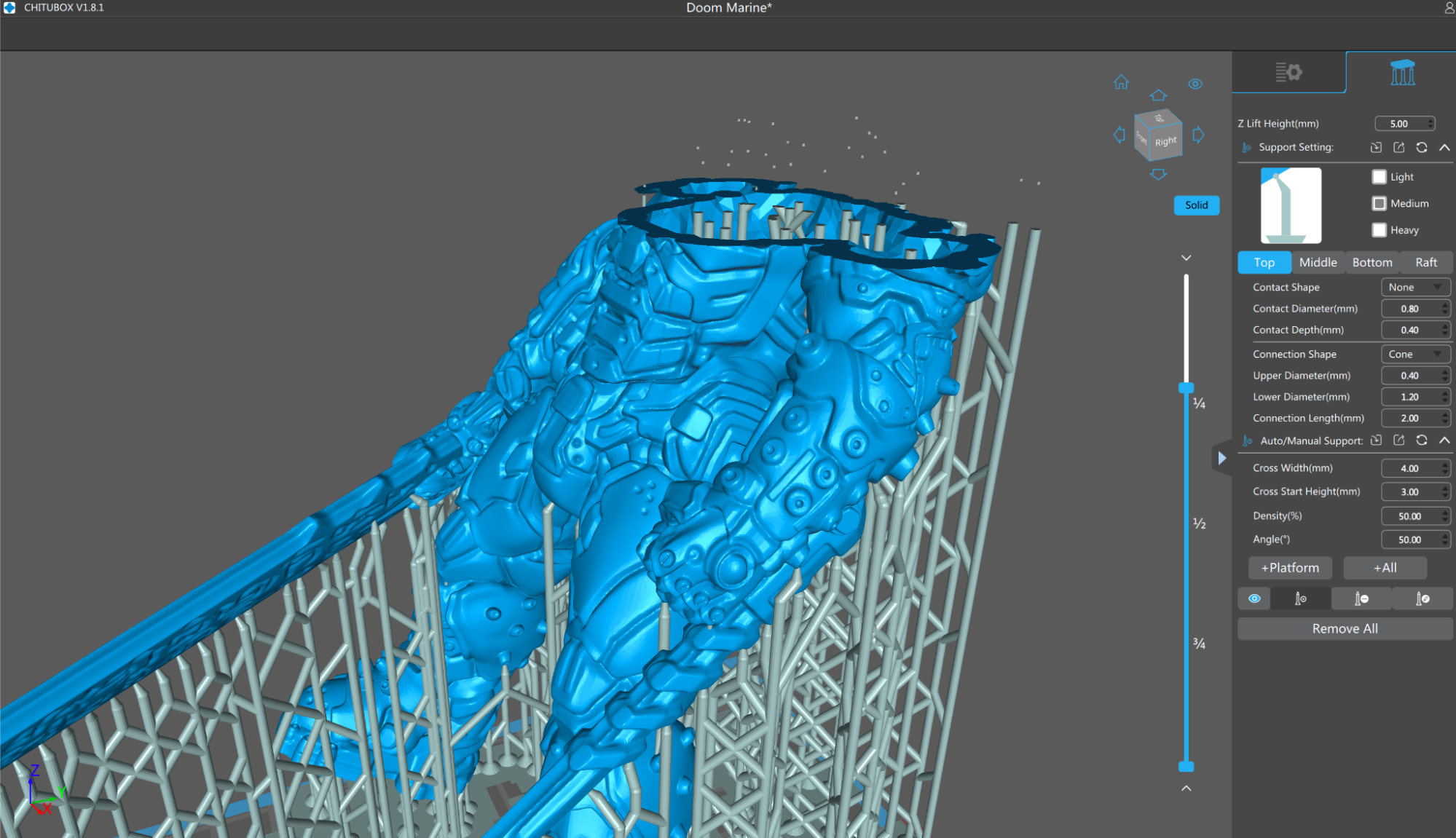

I wanted to test a model with lots of detail that required hollowing, so I used the Doom Guy model by Printed Obsession as a demo print. This model was designed as a solid mesh, so I used Chitubox to hollow it out, add drain holes, and add automatically-generated support structure. Chitubox made this entire process quick and simple, and I spent about 10 minutes total on the processing of the model. While you can’t run Doom on the built-in processor on the Mars 2 Pro (yet), printing this model is a close second.

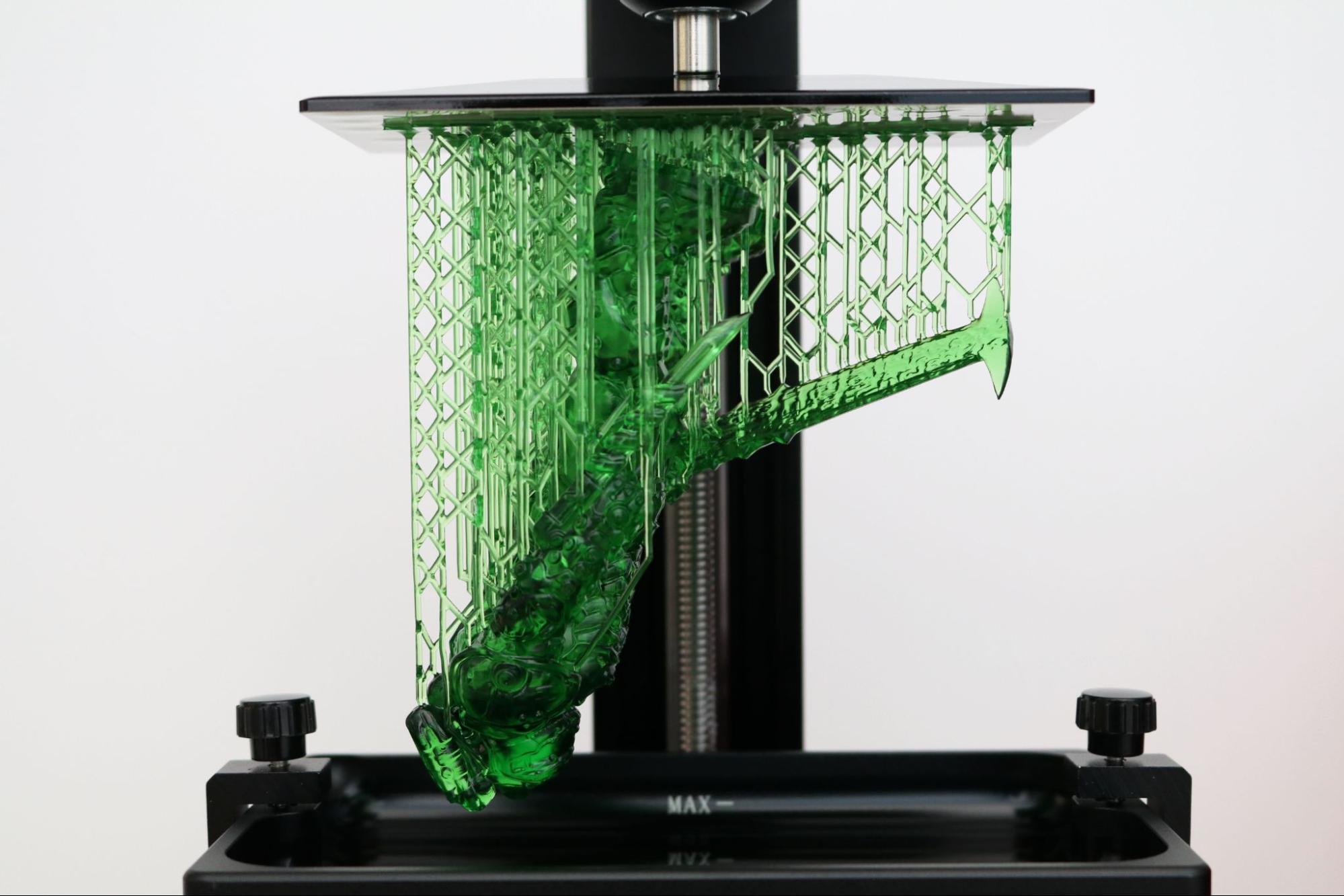

I used Elegoo Standard Photopolymer Clear Green resin for this model, and it printed perfectly on the first try. The support structure generated by Chitubox held the model to the build platform without any problems, and the 2K-resolution masking LCD captured all of the detail present in the 3D model. After a quick rinse in 99% isopropyl alcohol, I was able to easily detach the support structure from the model and wash the excess resin off the inside and outside of the model. The print time for this model was just over 8 and a half hours, so this definitely qualifies as an ambitious print to test out a machine.

After curing the model in a UV-curing chamber, the finished product looks like a piece of cut emerald. The marks from the support structure are virtually non-existent, and the .05mm Z layer height created a model with barely visible stepping. Without using any magnification, I could only see the stepping on the very top of the helmet and shoulder pauldrons. While the 2K screen doesn’t provide the same ultra-high XY resolution as the 4K screen on the Phrozen Sonic Mini 4K, you’d be hard-pressed to see the difference with your naked eye.

For reference, the Sonic Mini 4K has a .035mm XY resolution, as opposed to the .05mm XY resolution of the Mars 2 Pro. The difference, .015mm, is about the size of a white blood cell and less than a quarter of the average width of a human hair (about .01mm).

Comparison of the Elegoo Mars Pro vs. Elegoo Mars 2 Pro

The Elegoo Mars 2 Pro shares many visual and functional similarities to its predecessor, the Mars Pro. Despite a nearly identical outward appearance, the Mars 2 Pro offers a larger build volume, a higher resolution screen, and a higher build / footprint ratio. The Mars Pro has a Y axis size of 2.56 inches, which can be limiting when making anything other than small miniature models.

| Header Cell - Column 0 | Elegoo Mars Pro | Elegoo Mars 2 Pro |

|---|---|---|

| Masking LCD Resolution | 1440 x 2560 | 1620 x 2560 |

| XY Resolution | .047mm | .05mm |

| Build Dimensions | 4.53 x 2.56 x 5.9 inches | 5.08 x 3.15 x 6.3 inches |

| Build Volume | 68.42 cubic inches | 100.81 cubic inches |

| Printer Dimensions | 7.87 x 7.87 x 16.14 inches | 7.87 x 7.87 x 16.14 inches |

| Printer Volume | 999.66 cubic inches | 999.66 cubic inches |

| Build / Footprint Ratio (higher is better) | 6.80% | 10.10% |

The XY accuracy of the Mars Pro is slightly higher (by 3 microns, a measurement that would be difficult to measure, and impossible to see) due to the smaller LCD size, but the overall print volume is roughly 60% of the volume of the Mars 2 Pro. The slightly larger Z height of the Mars 2 Pro is a benefit, but the real benefit is in the increased XY plane which will enable you to print multiple small parts simultaneously.

Printing a Bust on the Elegoo Mars 2 Pro

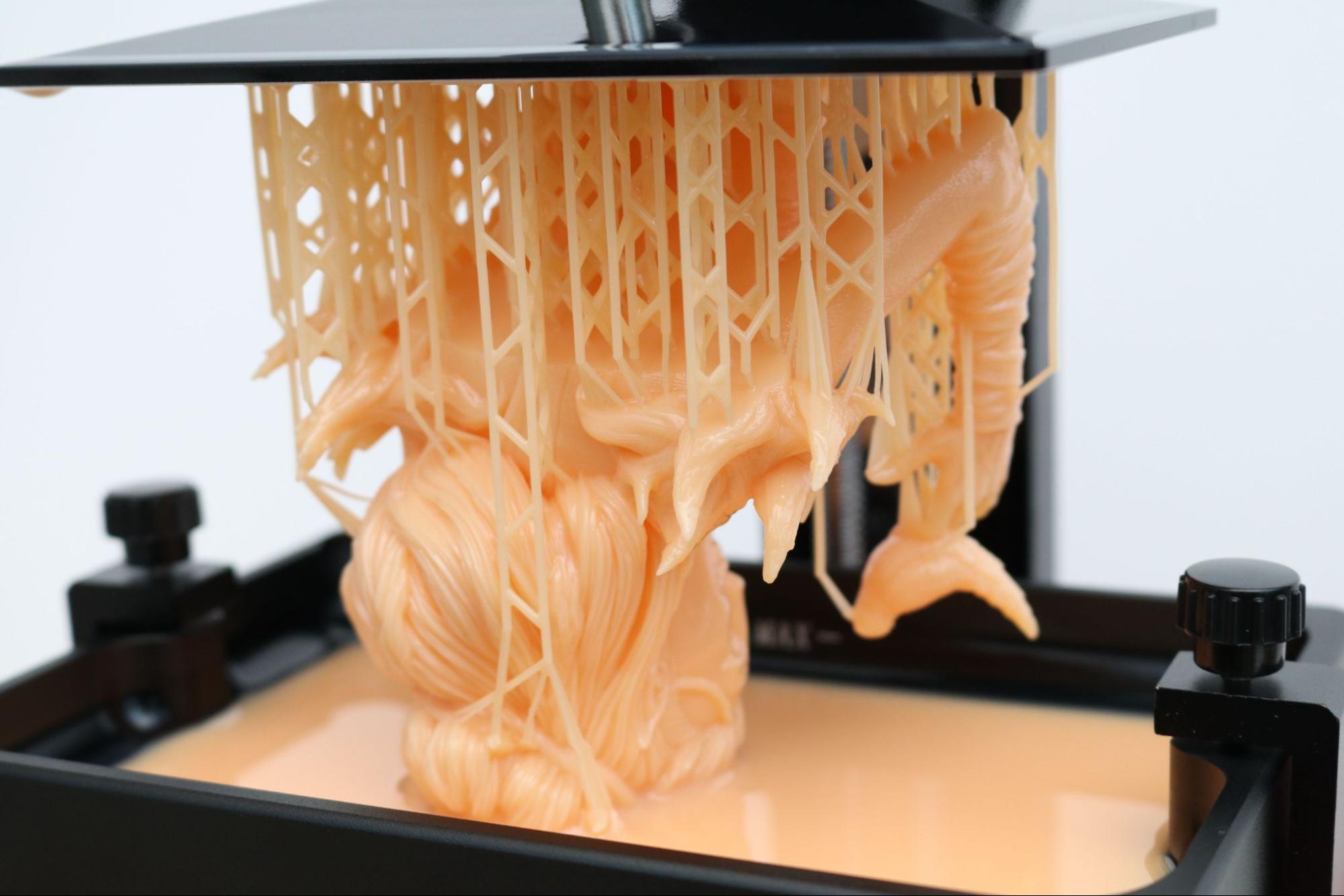

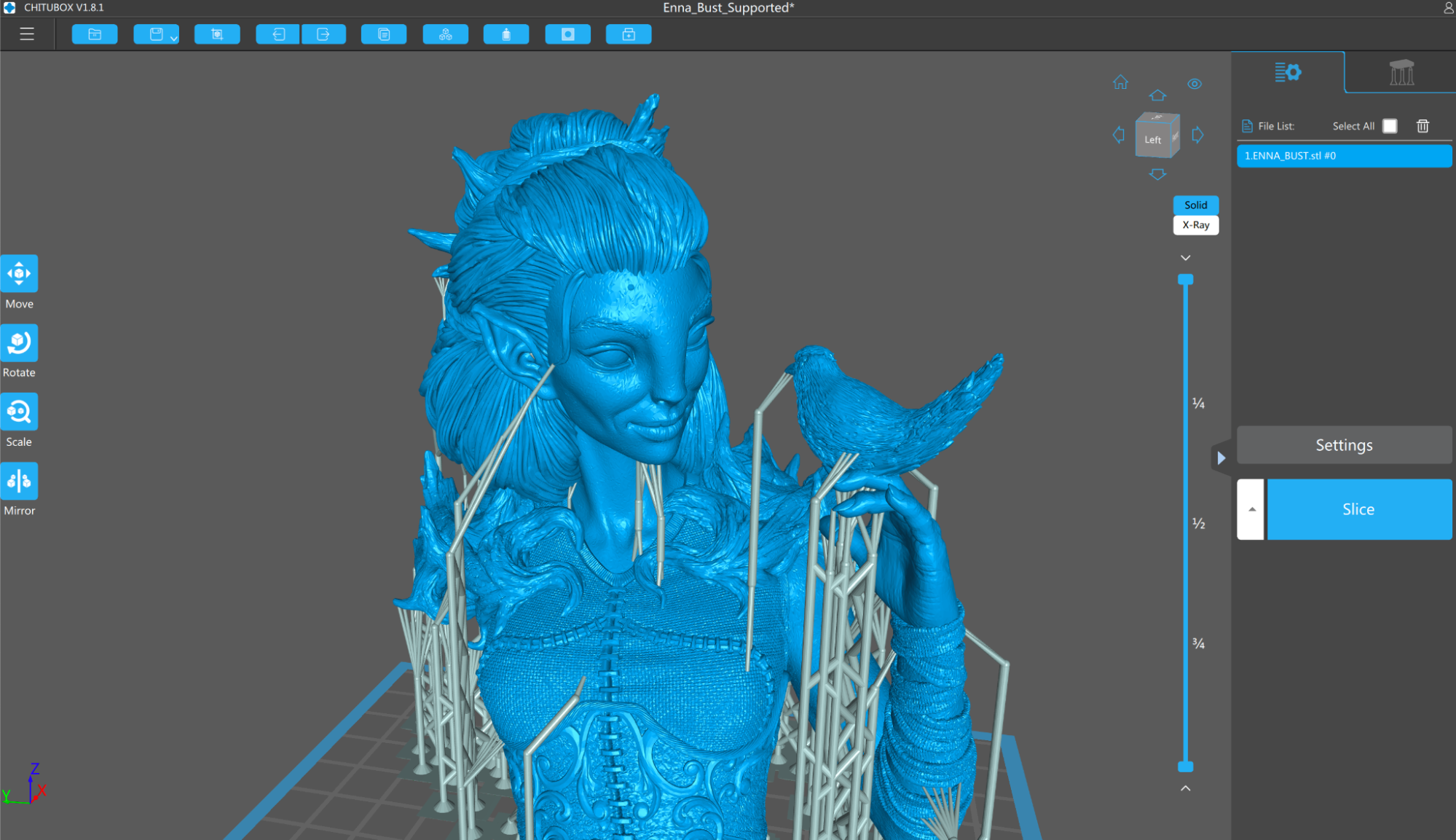

Unlike FDM 3D printers like the Creality Ender 3 Pro, the print time on resin printers like the Elegoo Mars 2 Pro is solely determined by the number of layers, or height of the model. This means that printing wide models takes just as much time as narrow ones provided they’re the same height. To demonstrate this, I printed the Enna bust from Loot Studios, which features a wide cross-section that utilizes most of the available build area of the Mars 2 Pro.

This model had support material already generated and was hollowed by the artist, so I didn’t need to make any alterations or adjustments for resin printing on the Mars 2 Pro. Something to note here is the bird on the hand of the woman; this is a feature that would be very difficult to make on an FDM 3D printer due to the amount of support material required for scaffolding. Chitubox estimated 6 hours and 7 minutes for printing which I found to be an accurate estimate.

I used Elegoo Water Washable Beige resin for this print and used the same default settings in Chitubox I used for the clear green resin. Just like the first print, the support structure on the model printed perfectly and held the model to the build platform without warping or curling. The beak on the bird really impressed me; the single support column of support originated from the model and still cured perfectly, holding up the beak without deforming. After rinsing the model in warm water and scrubbing off the excess resin, I detached the support material with minimal effort and virtually no scarring on the model.

The detail on the model is top-notch, and even at the standard layer resolution of .05mm, the hair on the model looks like an injection-molded model. The layers aren’t visible to the naked eye and the cloth texture is hyper-realistic. The Mars 2 Pro didn’t require any calibration before or after this print, and I feel confident that I could print this part over and over without any variance in the quality of the model.

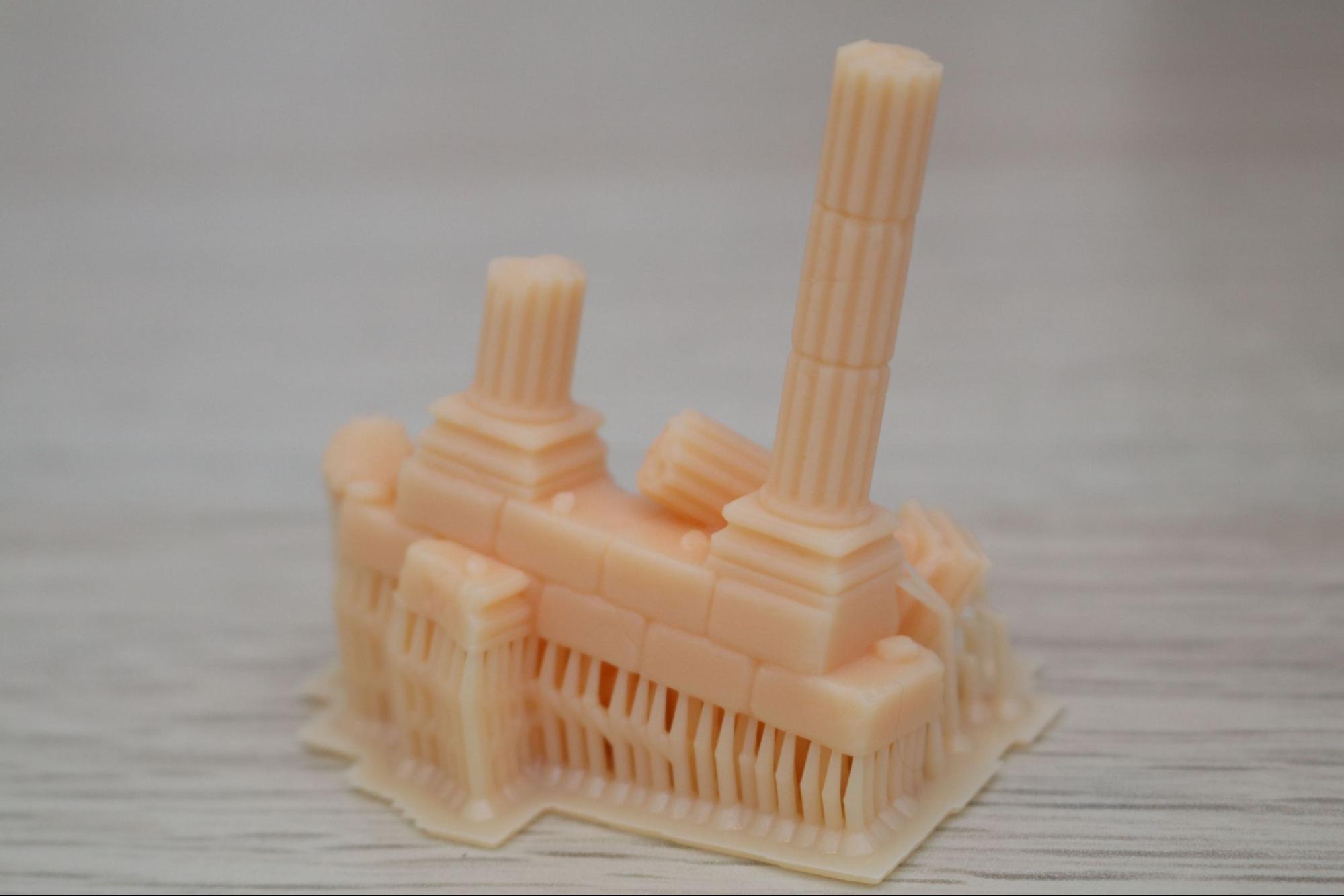

Printing Miniature Models on the Elegoo Mars 2 Pro

Resin 3D printers like the Elegoo Mars 2 Pro are popular in the tabletop-gaming community, and with good reason. Making highly-detailed miniature models is a challenge for most FDM 3D printers due to the small feature size, but the Mars 2 Pro handles these prints almost effortlessly. Printing out the ‘Ruins’ model by Loot Studio demonstrates this perfectly; this tabletop terrain model has texture modeled into the columns, each measuring just under 7mm in diameter.

Despite the small size of the model, the ruins take about 3 hours to print due to the 53mm height of the model. Running through a preview of the ruins, the texture is clearly visible in Chitubox and the .05mm XY resolution makes it possible for the Mars 2 Pro to resolve this detail in the printed model.

I centered this model in the center of the build platform, but Chitubox confirmed that up to four of these models could be printed simultaneously in the same amount of time. Printing multiple parts in parallel like this is ideal for small-batch production, and the reliability of the build platform leveling makes this possible on the Mars 2 Pro.

The water washable resin makes the post-processing of a model like this a minimally messy process. I soaked the model in warm water, which has the dual benefits of both removing excess resin as well as softening the support structure for removal. Once soaked, the supports peeled off and left small pockmarks where they had once been attached to the model.

Printing other miniature models from Loot Studio gave similar results. The details on the miniatures are crisply defined, and the overall quality of the models feels very similar to the injection molded quality of an off-the-shelf miniature. I used to say that 3D printing had a hard time making models that looked cleaner than what you could find at a dollar store toy aisle, but the smooth surface of these models indicates it might be time to retire that comparison.

Bottom Line

There are a lot of MSLA resin 3D printers available right now, so it can be hard for manufacturers to release a machine that stands out. Elegoo has had a long string of successful machines with their original Mars, Mars Pro, and Saturn 3D printers, and the Mars 2 Pro easily takes its place with these printers. The ease-of-use, solid construction, and high quality components make the Elegoo Mars 2 Pro a fantastic value for anyone with a budget of $300 or less.

If you’re looking for a printer that’s less expensive than the $260 Mars 2 Pro, you can get similar results from the original Mars Pro which is currently $189.99 on Amazon and $179.99 direct from Elegoo. If you’re looking for 4K resolution from a machine that you can purchase today, the Phrozen Sonic Mini 4K is available on Amazon for $369.99.

Elegoo has recently announced the Mars 3 Ultra 4K, which will replace the Mars 2 Pro as the flagship of the Mars line. With a ship date of August 30th and a price point of $300, the Mars 3 Ultra 4K is a logical successor to the Mars 2 Pro, but you’ll have to wait if you want to take advantage of the 4K resolution screen.

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.

-

Guenni187 I read your review of the Anycubic Photon Mono. You rated the Elegoo Mars 2 Pro slightly better than the Anycubic Photon Mono.Reply

Now there is the Anycubic Photon Mono 4K how about this one. Is the Anycubic Photon Mono 4K now better than the Elegoo Mars 2 Pro.

Or would you still recommend the Elegoo Mars 2 Pro.

Thanks in advance :) -

USAFRet Reply

What was best 3 years ago is not necessarily best today.Guenni187 said:I read your review of the Anycubic Photon Mono. You rated the Elegoo Mars 2 Pro slightly better than the Anycubic Photon Mono.

Now there is the Anycubic Photon Mono 4K how about this one. Is the Anycubic Photon Mono 4K now better than the Elegoo Mars 2 Pro.

Or would you still recommend the Elegoo Mars 2 Pro.

Thanks in advance :)

This is an old review.