Tom's Hardware Verdict

A small-format resin 3D printer with a bargain-basement price, the Longer Orange 10’s weak output and wobbly build quality make it a poor bargain.

Pros

- +

+ Inexpensive price

- +

+ Small footprint

Cons

- -

Laser-cut UV lid feels wobbly

- -

Low XY resolution

- -

Small build volume

Why you can trust Tom's Hardware

The Longer Orange 10 is the entry-level 3D printer in the Orange lineup and sits below the Orange 30 and Orange 4K in both price and features. It’s available from the Longer site for $139, a surprisingly-low price that is around the cheapest I’ve seen a 3D printer of any kind for sale.

After testing the Orange 10, I’m left with more questions than answers as to who this printer is marketed towards. It uses an RGB masking LCD that defaults to a slow per-layer cure time as well as a small build volume. Importantly, it also has a pixel resolution that is over 50% larger than the Creality LD-002R, a comparable printer in price and size, resulting in lower resolution prints and pronounced stepping on shallow curves that leave this unable to compete even with the best budget 3D printers.

Longer Orange 10 Specifications

| Machine Footprint | 6.7" x 6.7" x 14.2" (17.0cm x 17.0cm x 36.0cm) |

| Build Volume | 3.86" x 2.17" x 5.5" (98mm x 55mm x 140mm) |

| Resin | DLP Photopolymer Resin |

| UV Light | UV Matrix 405nm UV LED |

| Masking LCD Resolution | 854 x 480 |

| Masking LCD Size | 4.5" |

| Interface | 2.8" LCD Touchscreen |

| XY Axis Resolution | .115mm |

Included in the Box of Longer Orange 10

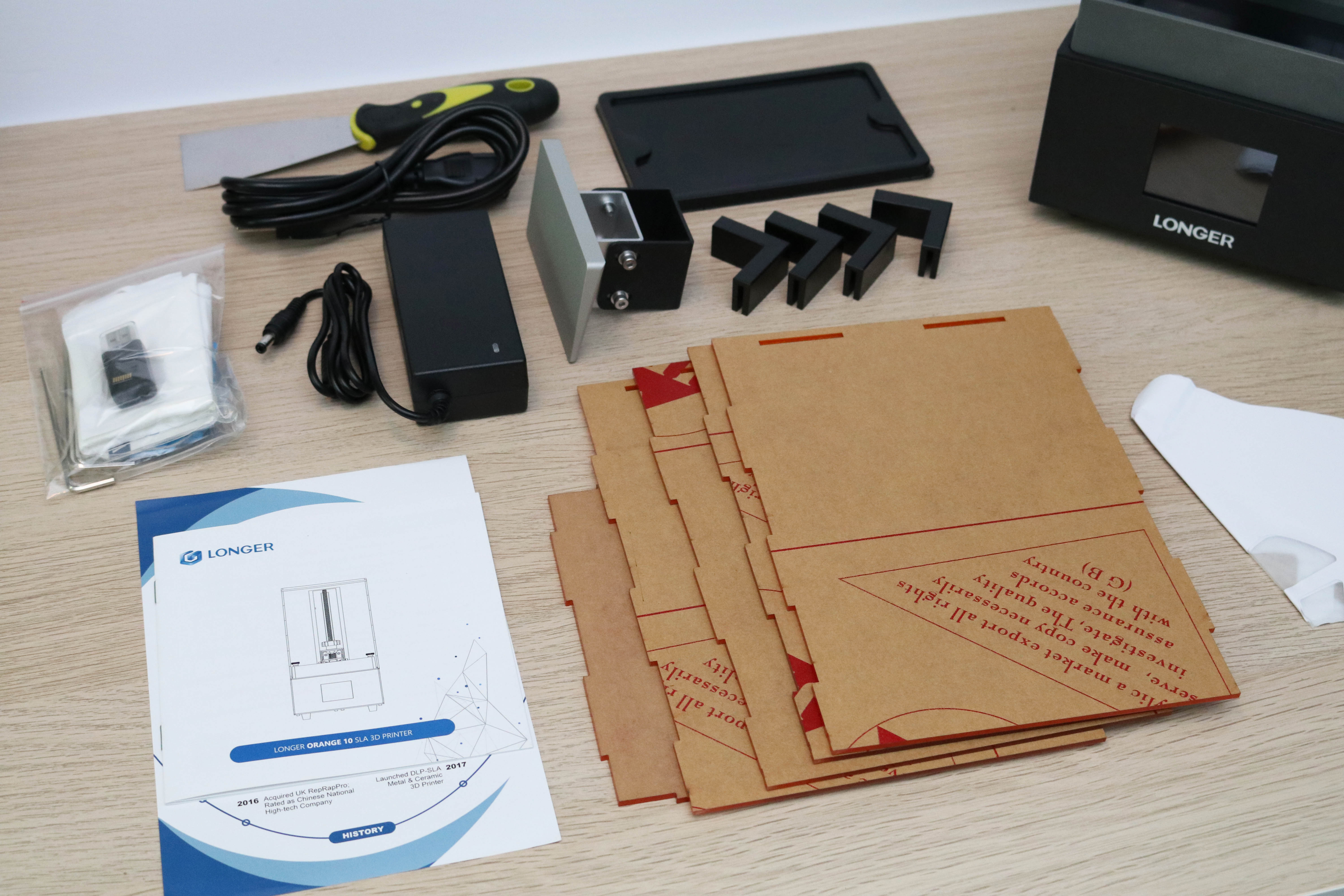

The Longer Orange 10 ships with all of the consumables you need to get up and printing including the power supply, a metal scraper for removing parts, gloves, a clean-up rag, a microSD card, a USB microSD card reader, and some resin filters for reusing resin. The UV-resistant lid ships disassembled (more on that later), and all the pieces required to assemble it are included in the box. The Orange 10 also includes a printed manual that covers all of the steps involved with getting the printer up and running.

Assembly of Longer Orange 10

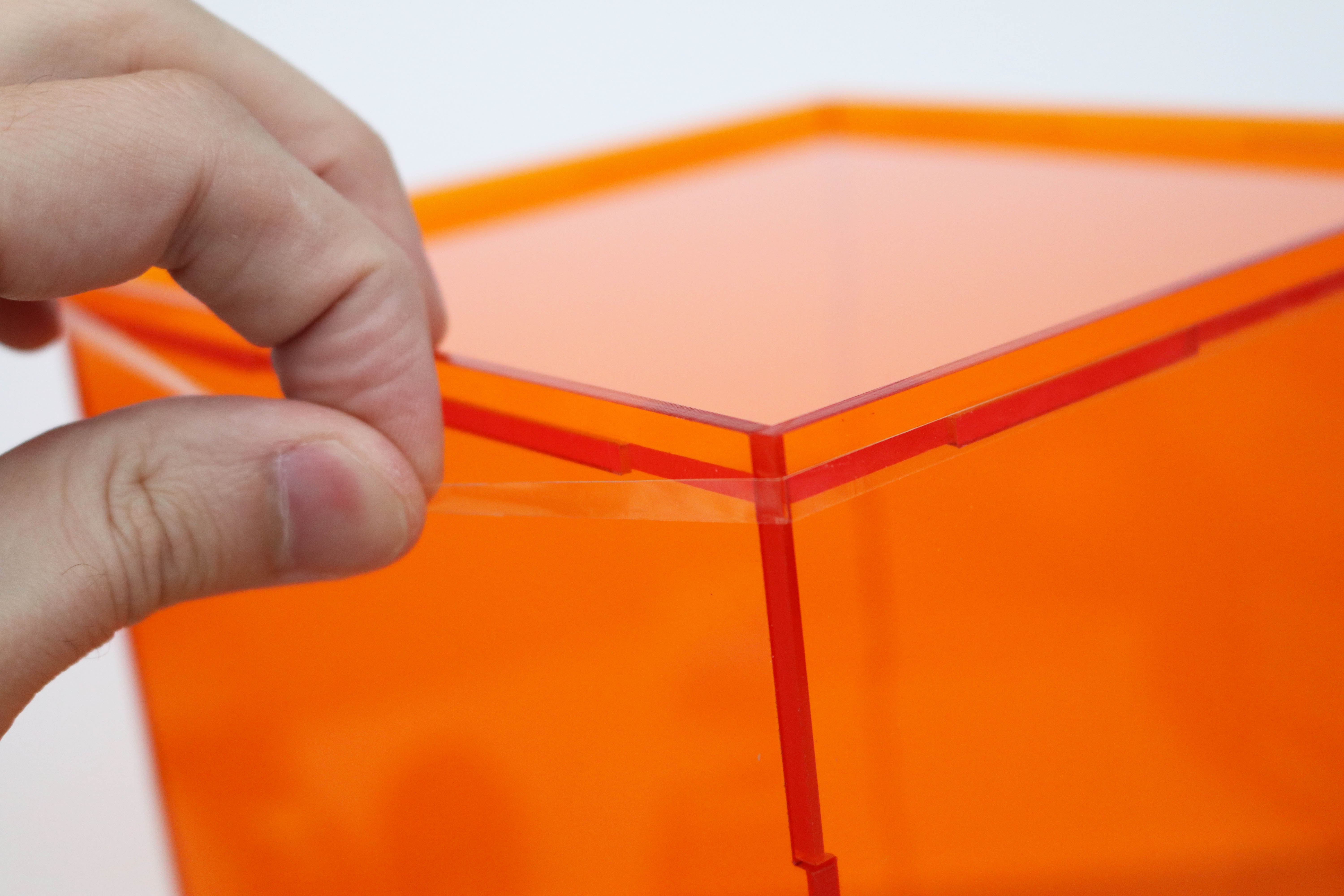

The Longer Orange 10 includes a UV-resistant lid that requires assembly before it can be mounted onto the printer. This is a little unusual; most MSLA resin printers like the Anycubic Photon Mono, Creality LD-002R, and the Elegoo Mars Pro use a single-piece acrylic lid that ships mounted to the printer. The lid for the Longer Orange 10 ships in five pieces that all have a protective film applied to both sides. This film tends to tear and delaminate when peeled and was very time-consuming to remove; it took me almost fifteen minutes to remove it fully.

Once the protective film has been removed, the lid can be assembled. The jigsaw pattern on the sides of the panels allows them to snap into place, and the included black brackets hold the side panels together before the top panel is added. Assembling the lid felt a bit like a juggling act; the brackets and top hold the sides together, but the sides can’t be assembled without the top to hold them in place. It took a few tries to get it right but the lid eventually snapped together.

The lid is held together with a pair of rubber bands; one at the top and one at the bottom. While this solution is relatively inexpensive and allows the printer to ship in a slightly smaller box, the general shakiness and lack of a sturdy lid did not inspire much confidence in me after it was put together. The rubber bands pulled tight around the acrylic corners, and I’m concerned that picking up the lid will cause the rubber band to tear over time from rubbing against the sharp corners of the acrylic panels.

Design of Longer Orange 10

The user interface of the Longer Orange 10 is a 2.8-inch color touchscreen LCD that offers basic functionality controls as well as real-time information during printing. The LCD is bright and responsive, but the overall UI is a little bare and the controls used to calibrate the build platform aren’t labeled intuitively.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The Orange 10 uses a custom controller board with an STM32F103 microcontroller and an A4988 stepper driver. The controller board cooling fan is the loudest component on the printer, and it operates at a very reasonable volume during printing. The case of the Orange 10 is made from bent sheet metal, and I liked the solid and stable feel that it provided.

The masking LCD on the Longer Orange 10 is a 4.5-inch screen with a resolution of 854 x 480. This combination results in a relatively low .115mm XY resolution, a much coarser resolution than the .035mm achieved by the 4K resolution masking LCDs like the one on the Phrozen Sonic Mini 4K. Even non-4K masking LCD screens like the one on the Creality LD-002R are capable of sub-.1mm resolution (the LD-002R is .075mm), so this slightly-thick XY resolution can result in parts with visible stepping on shallow curves.

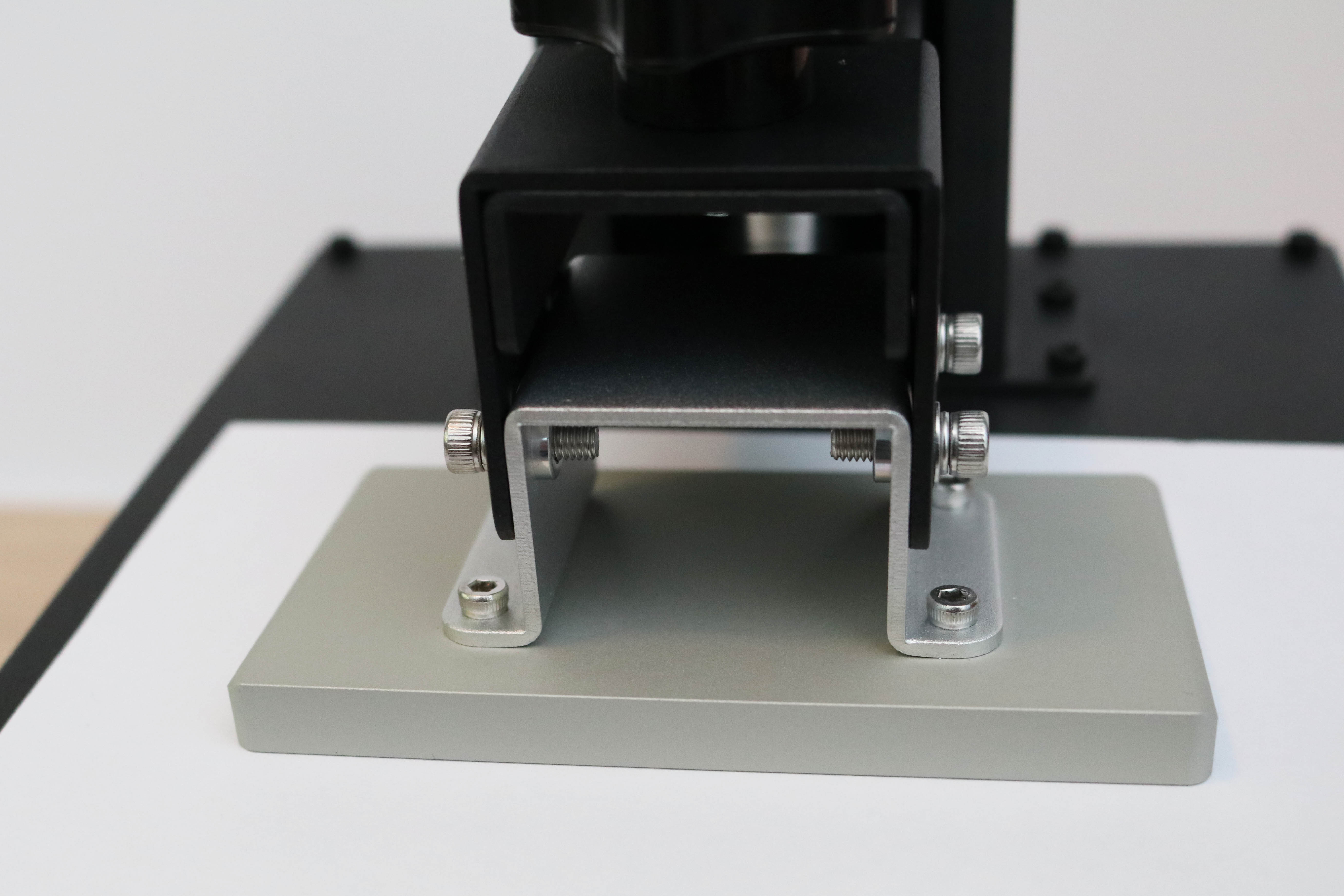

The build platform has a rear-facing slant, which allows resin to drip back into the vat during printing. The gantry to which it attaches is made from a bent piece of metal and the Z threaded rod has an anti-backlash nut installed to prevent banding during rapid movements. The motion components on the machine generally feel solid, and the gantry doesn’t seem to have any play during printing.

Leveling the Build Platform on Longer Orange 10

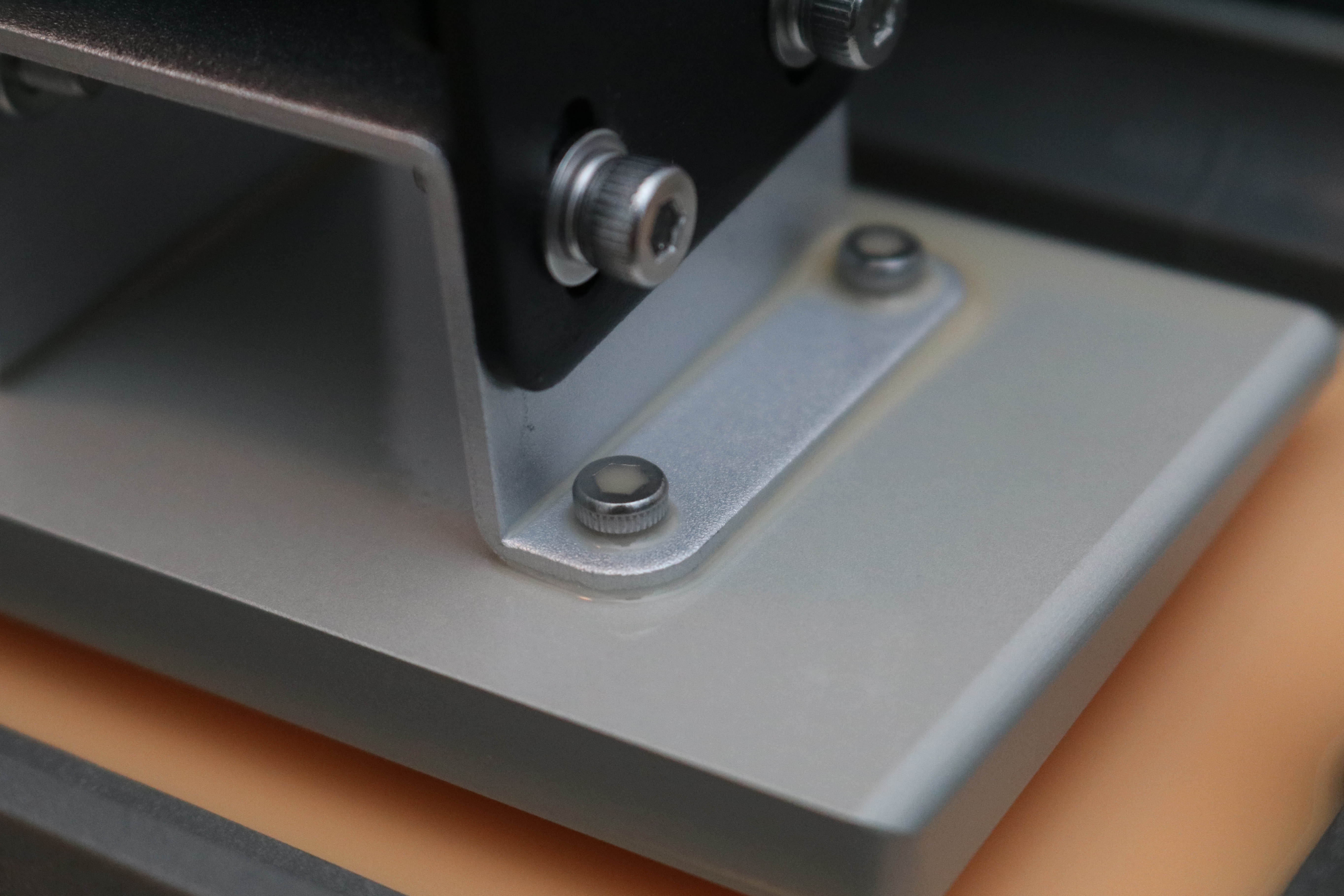

The build platform on the Longer Orange 10 is secured to the gantry with four bolts that are also used for leveling. After loosening the bolts on the gantry and placing a piece of paper over the masking LCD screen, I dropped the build platform to the home position and tightened the bolts on the gantry.

The bolts have split ring lock washers as opposed to regular washers, which make leveling the bed a tedious and difficult task. As I tightened the bolts, the split ring washer moved just slightly and caused the build platform to raise or lower. Leveling this printer was a challenge that required me to work very slowly to make sure the build platform didn’t shift while tightening.

After I leveled the build platform, I installed the resin vat in the printer and secured it with the two attached thumbscrews. The vat has a polymer frame with fill indicators graduated to the max fill line of 200ml embossed on the side. The FEP film at the bottom of the vat has been installed, pretensioned and is ready to use right out of the box.

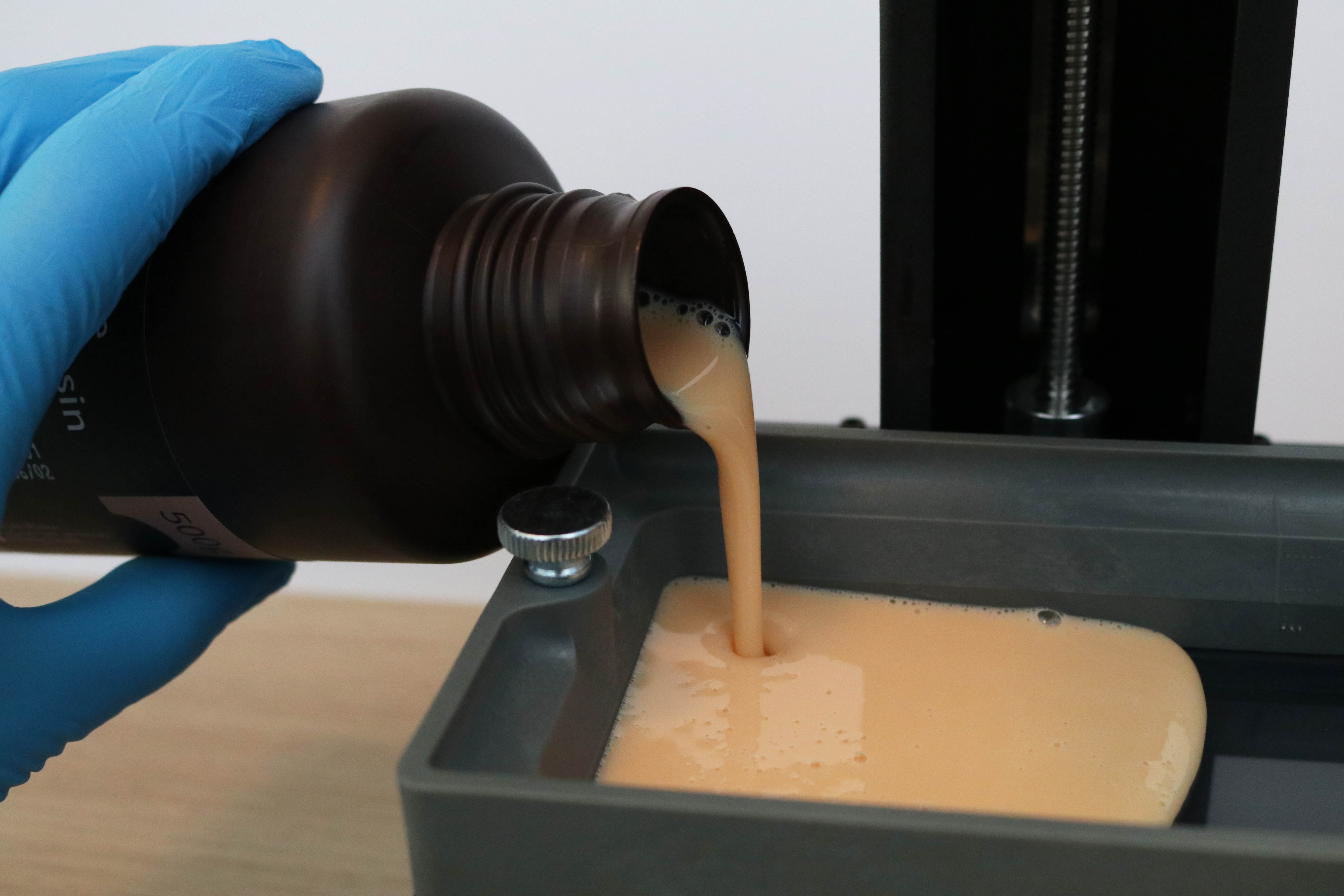

Printing Safety with Longer Orange 10

The Longer Orange 10 uses 405nm UV resin, a material that you need to handle safely when in an uncured state to avoid injury. The resin can be harmful when making contact with skin, so make sure to wear gloves when pouring, cleaning up, or handling uncured resin. I also make sure I’m wearing gloves when removing the build platform after a print, as the resin tends to pool on top of the platform and can drip off while the platform is being removed.

Make sure you use the Orange 10 in a well-ventilated room to minimize the danger from inhaling fumes. Any spills or uncured resin stuck to a surface should be cleaned using 99% Isopropyl Alcohol and the container for the resin should be kept closed and secured when not actively pouring material.

The build platform on the Orange 10 has four upward-facing bolts that are used to secure it to the bracket. This is a poor design element, as the location of the bolts means it is very difficult to clean uncured resin off inside the bolt caps or clean the space between the bolt heads and the bracket. While the slanted build platform does allow the majority of the resin to slide back into the vat, it still pools around where the bracket meets the build platform and it can be difficult to clean completely. While this isn’t a problem unique to the Longer Orange 10, it is certainly something I find to be unnecessarily time-consuming and could be easily solved with a one-piece build platform.

Printing the Included Test Prints on the Longer Orange 10

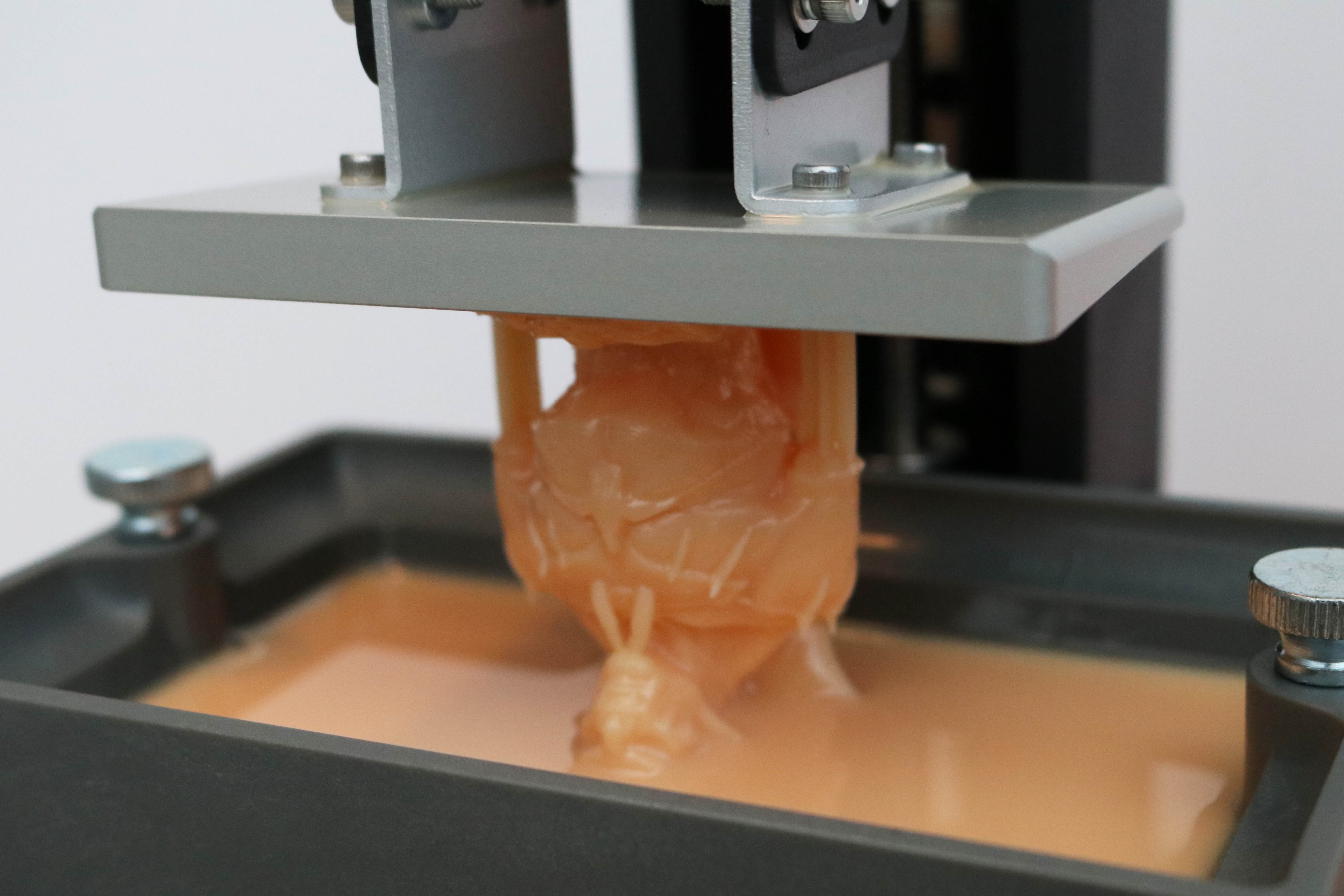

The Longer Orange 10 includes four pre-sliced models that are ready for printing, as well as the .STL files used to make them. The first one I tested was VampireLordBust.lgs, a 75.26mm model that prints in five hours and nine minutes. The model (which I found uploaded on MyMiniFactory by searching for the file name) has supports designed into the model as opposed to being generated by the slicer software.

I try to avoid models with supports designed into them, as every printer will handle them differently and the slicer software is usually better at generating them. This is more of a problem with MSLA resin printers, as larger supports need to be broken off which can shatter or crack the brittle cured resin.

The part printed without any issues and, as expected, removing the support material left some defects. The two large bars underneath the arms were difficult to remove fully, and the thin beams under the chin left material behind after they were cracked off. The overall level of detail on the model was muted, and the resolution didn’t look as sharp as I would have expected from an MSLA resin printer. The teeth on this vampire bust have been individually modeled, but I noticed that they were difficult to differentiate on the printed model.

The built-in model The_Three_Wise_Skulls_20mb.lgs is a taller print (107.25mm) that let me get a better feel for the level of detail the Orange 10 was capable of. This sliced model was interesting for two reasons; it prints out completely support-free, and it also prints completely solid. This means that it uses more resin in the printing process and has a heavier, denser feel than the Vampire Lord bust (78 grams as opposed to 27).

I was a little more impressed with the detail shown on this model, and the nine hour and 17 minute print time was a pleasant surprise considering the height of the model. The low XY resolution (.115mm) leads to visible stepping on the shallow curves of the model, most notably the back and sides of the skulls.

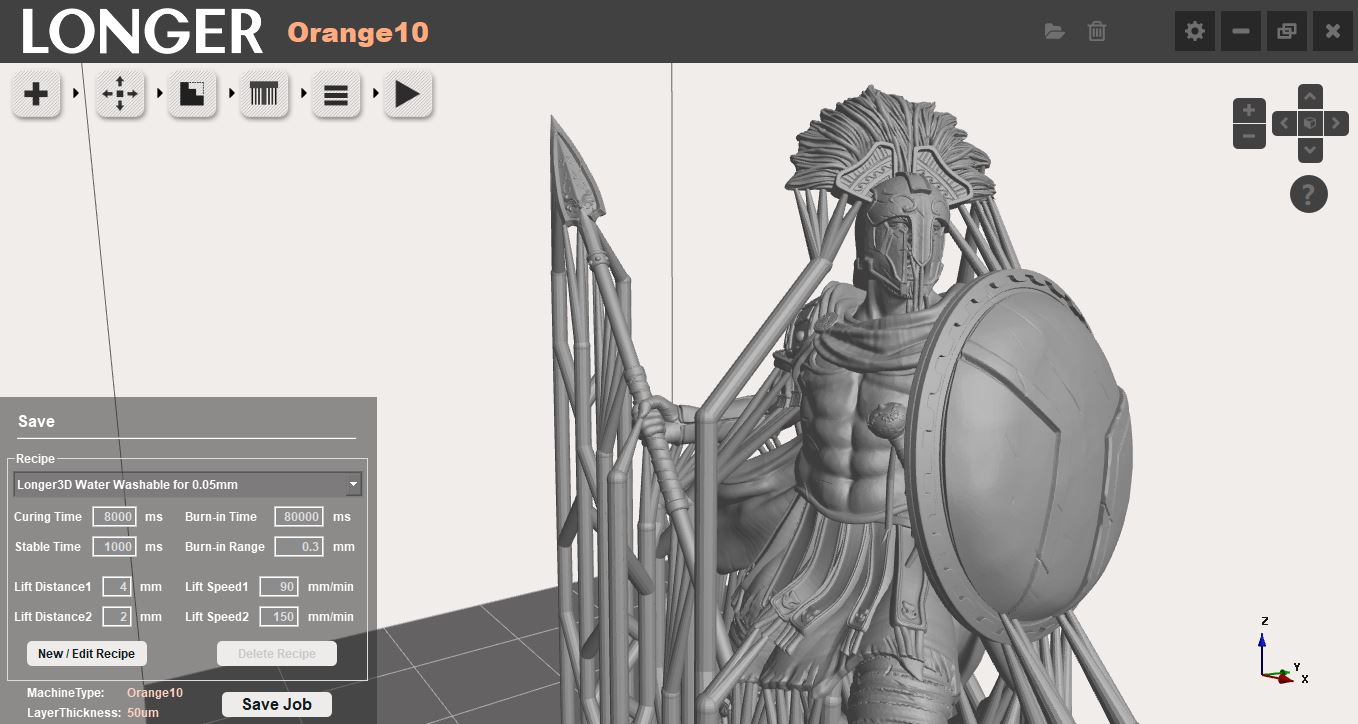

Preparing Files for Printing with LongerWare

Longer includes two apps with the Orange 10; LongerWare and Chitubox. LongerWare is an app that is designed for the Orange 10, Orange 30, and Orange 120 MSLA resin 3D printers. LongerWare includes profiles for the various resin types including water-washable, standard, and castable at multiple resolutions. LongerWare offers the functionality you would expect from a slicing software, such as the ability to scale, rotate, and move models before preparing them for printing.

I was disappointed in the overall experience while using LongerWare, though, as

thesoftware feels a little unfinished. There’s no ability to preview print times or material usage in the software, and once exported as an .lgs file for the Orange 10, the object can’t be opened to examine the settings. This feels like a major oversight, and it made planning my print schedule a little difficult. The only way to see the estimated print time is to save a project as a .lgs file, export it to the microSD card, insert the card into the printer, click print, and then see the time on the printer touchscreen interface.

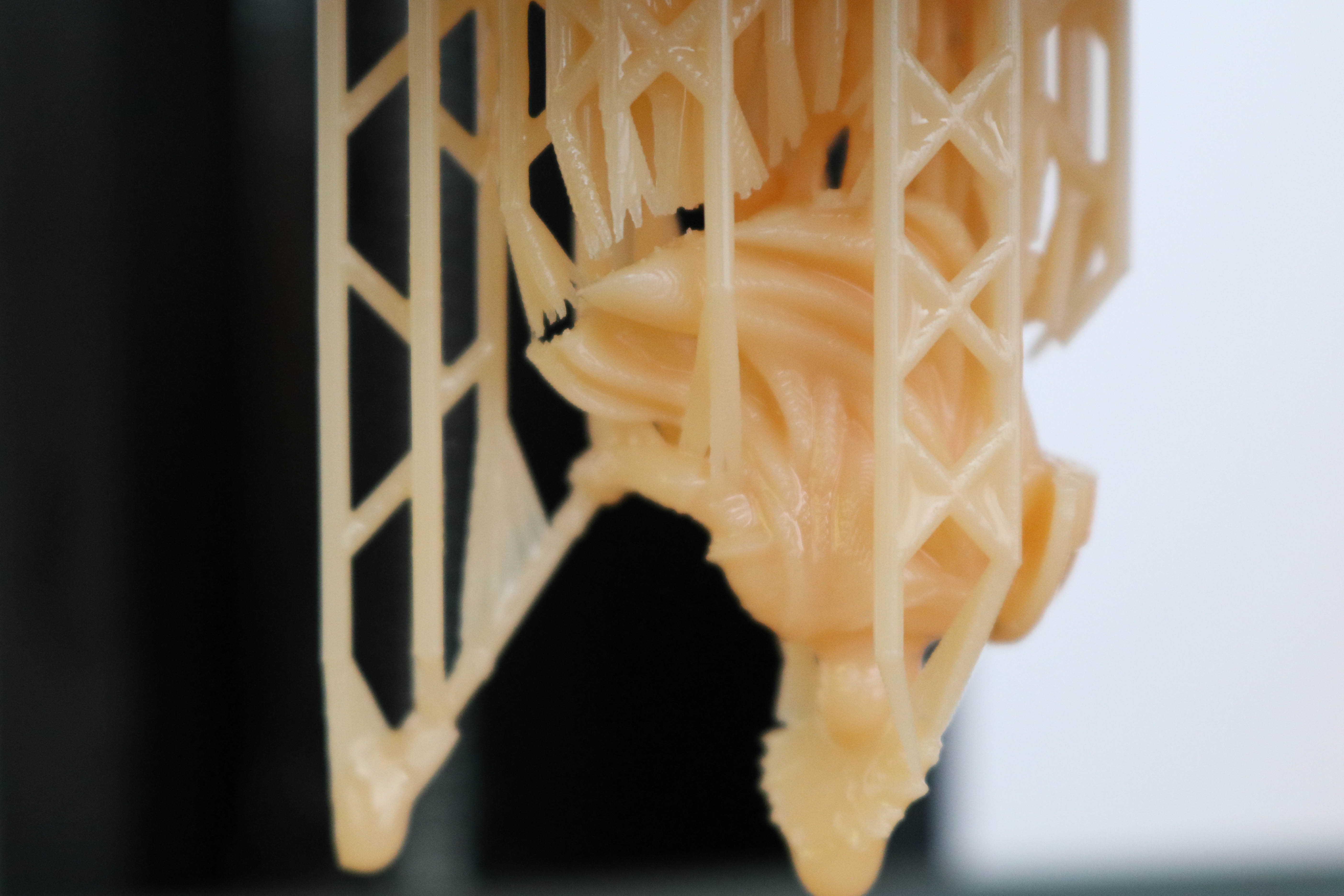

To test out LongerWare, I printed out a 32mm mini from Loot Studios sliced using the .05mm Water Washable resin profile. The mini (32mm_Georgios_HelmetVersion) printed in just over four hours, and it wasn’t until the mini was above the vat of resin that I noticed the supports had not attached to the model at various points. After removing the model and cleaning it, I saw that the shield was missing a large section. The supports for the shield printed all the way up to the contact point then stopped abruptly, leaving me to believe that the connection between model and support wasn’t strong enough to hold the model in place.

Despite the lack of support material on the shield, the spear printed without issue and successfully completed. The quality of the support material on the spear is hit or miss, with some of the individual structures fused with those adjacent to them.The various defects in this model are frustrating, but the bigger takeaway for me was the difficulty in using the LongerWare software. When compared with the alternative offered by Longer (Chitubox), it’s hard to imagine a situation where it would be advantageous to use LongerWare.

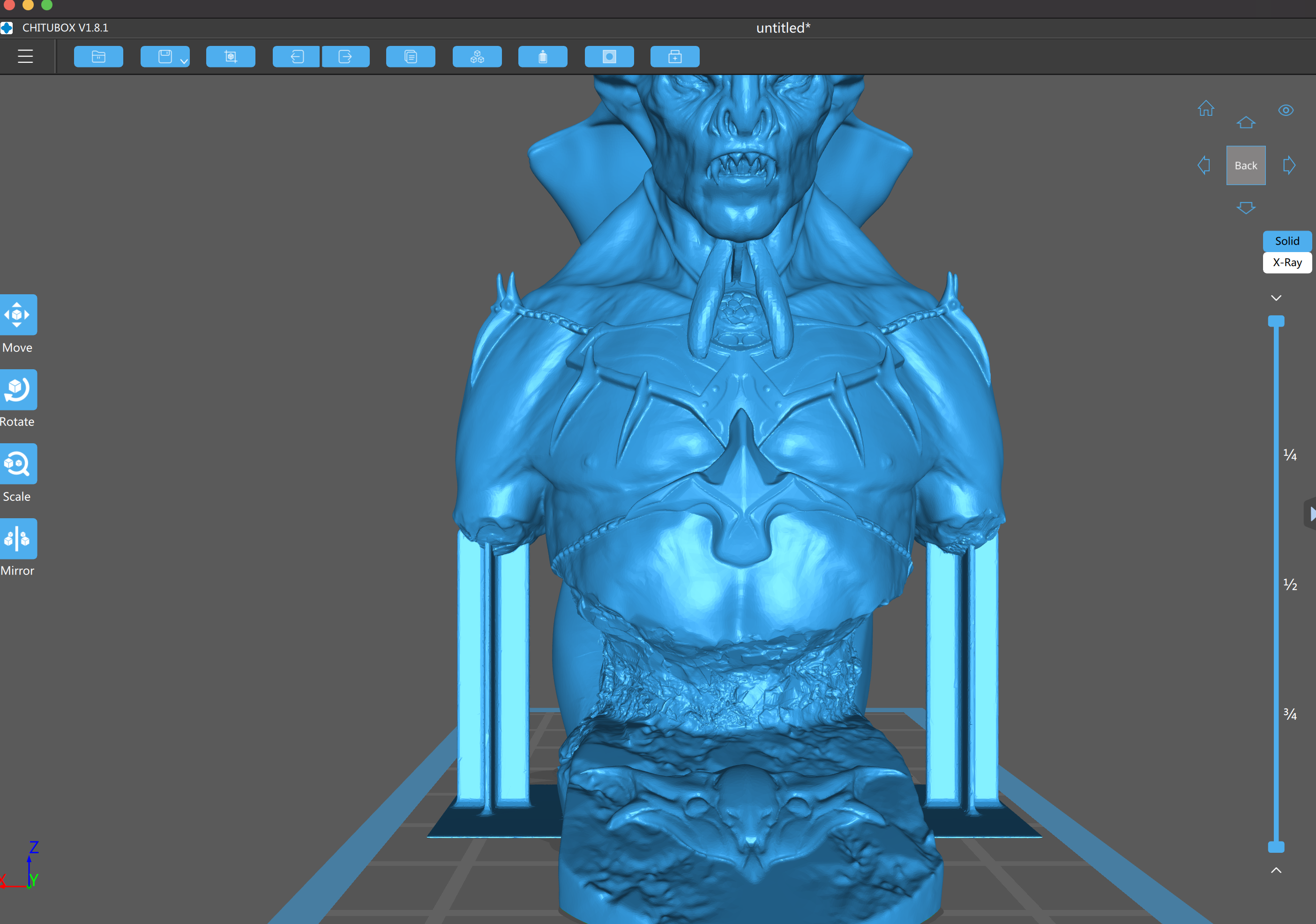

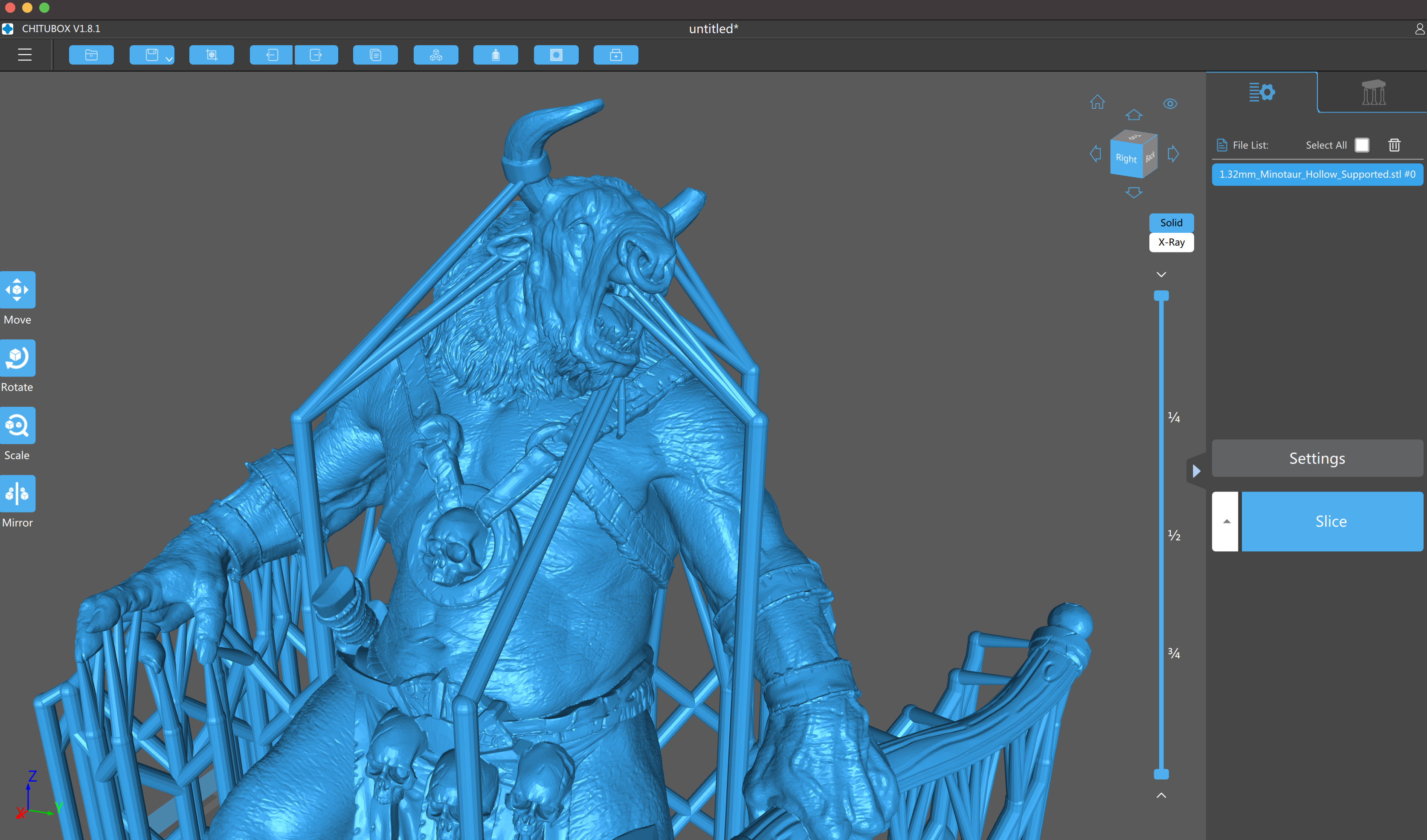

Preparing Files for Printing with Chitubox

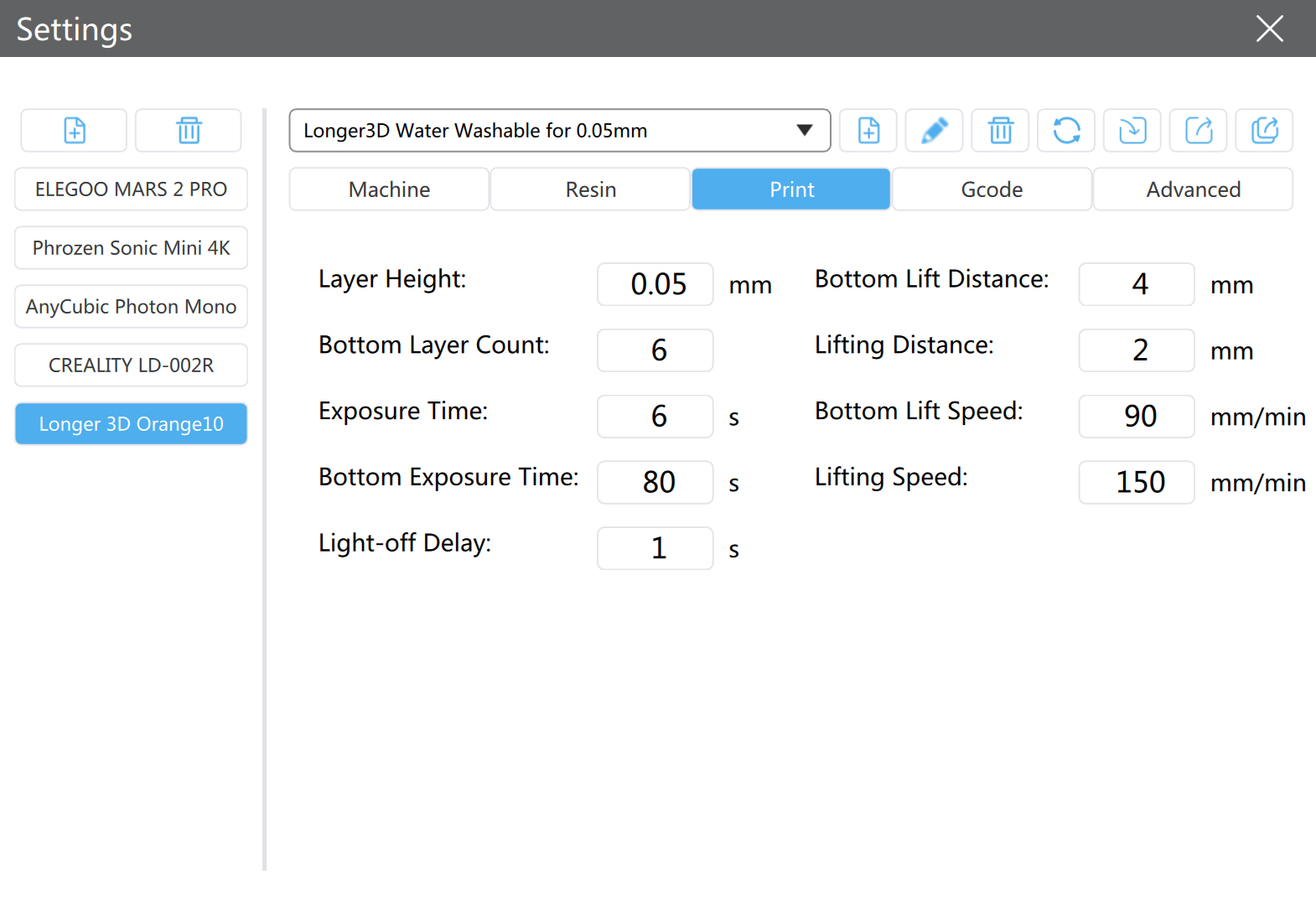

Chitubox includes the Orange Longer 10 on its list of supported printers, but you’ll need to import a plugin to export the .lgs extension used by the printer. Longer includes both the Chitubox app as well as the required plugin on the microSD card included with the machine. Chitubox offers all of the functionality of LongerWare as well as additional features such as print time estimates, material usage estimates, and the ability to fix any potential issues with a sliced file by deleting islands (individual pixels that are not connected to the main body and can float around in the vat or stick to the FEP film).

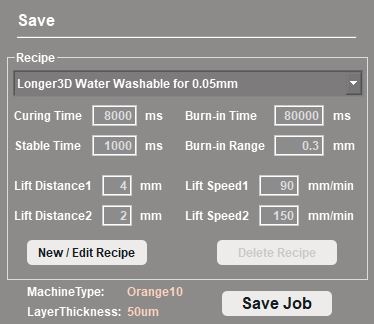

I used the same profile on Chitubox that I used on LongerWare (Water Washable for 0.05mm), but I noticed that the exposure time was set to six seconds as opposed to eight. This is a minor difference, but it did make me wonder about what other changes may exist in the various profiles between the slicers. The Z speeds all seemed to be the same, and the bottom layers had the same exposure and height settings as well.

Sliced in Chitubox, the 32mm miniature Minotaur model by Loot Studios printed out in 3 hours and 2 minutes and didn’t seem to have the support delamination issue that the model sliced in LongerWare had. The detail was similar to the other models printed, although some of the smaller features looked a little soft. The support material was attached to the model throughout, and the removal was quick and easy.

Print Size Comparison of the Longer Orange 10 vs. Creality LD-002R

The Longer Orange 10 is a compact 3D printer with a noticeably smaller footprint than other MSLA resin 3D printers. The $199 Creality LD-002R MSLA resin 3D printer offers similar specifications at a slightly-higher price point, so it makes sense to compare the overall build volume and printer volume to get a feel for how much smaller the Longer Orange 10 really is.

| Header Cell - Column 0 | Longer Orange 10 | Creality LD-002R |

|---|---|---|

| Masking LCD Resolution | 854 x 480 | 2560 x 1140 |

| XY Resolution | .115mm | .075mm |

| Build Dimensions | 3.86 x 2.17 x 5.5 inches | 4.69 x 2.56 x 6.3 inches |

| Build Volume | 46.07 cubic inches | 75.64 cubic inches |

| Printer Dimensions | 6.7 x 6.7 x 14.2 inches | 8.7 x 8.7 x 15.9 inches |

| Printer Volume | 637.44 cubic inches | 1203.471 cubic inches |

| Build / Footprint Ratio (higher is better) | 7.20% | 6.20% |

The significantly reduced length in the X and Z axes on the Orange 10 directly translates to a significantly impacted build volume when compared with the LD-002R. The lower resolution masking LCD on the Orange 10 means that the XY resolution is also lower than the LD-002R. However, the compact form factor of the Orange 10 gives it a slight advantage when comparing the overall build volume to footprint ratio.

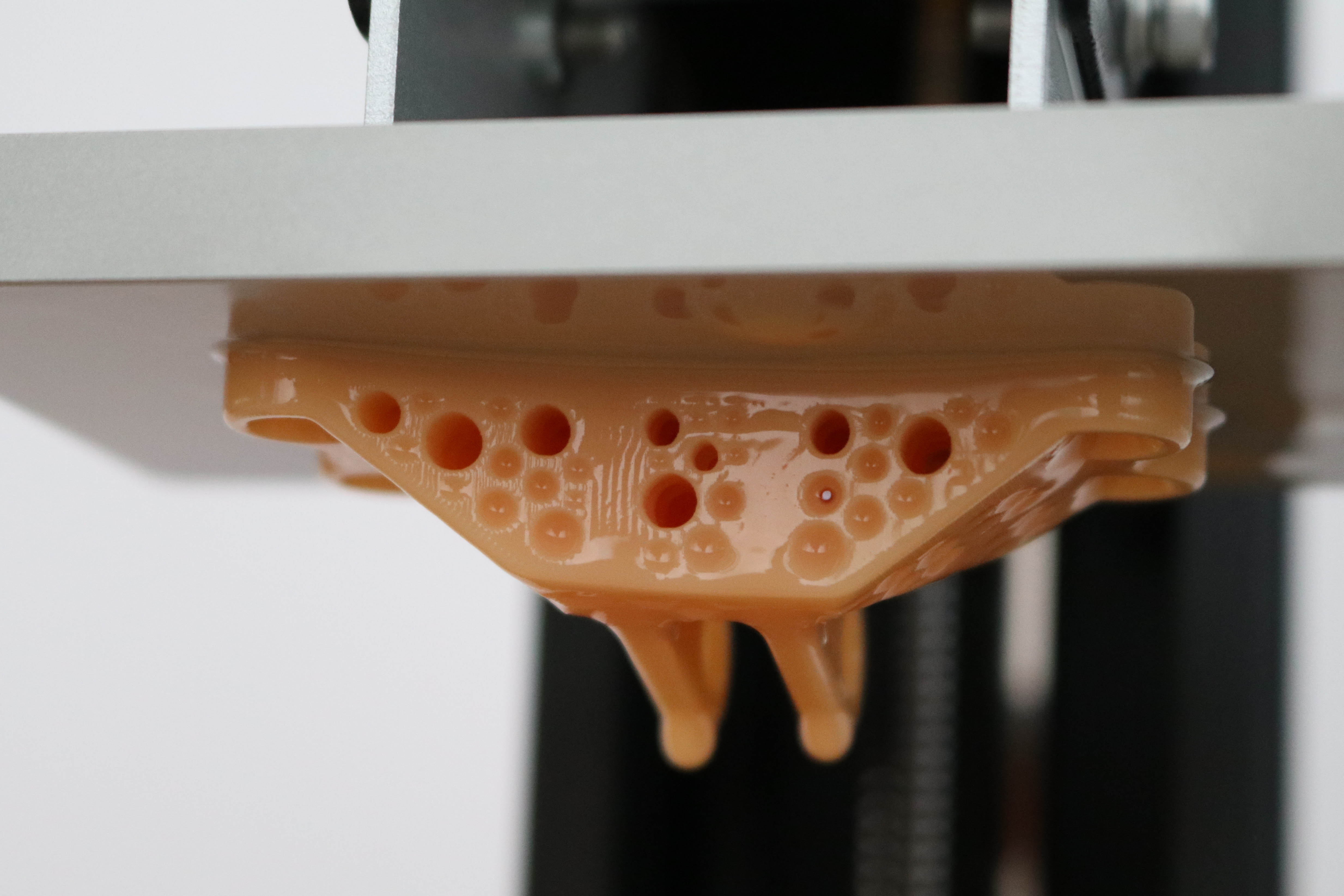

Printing the Included Bracket Print on the Longer Orange 10

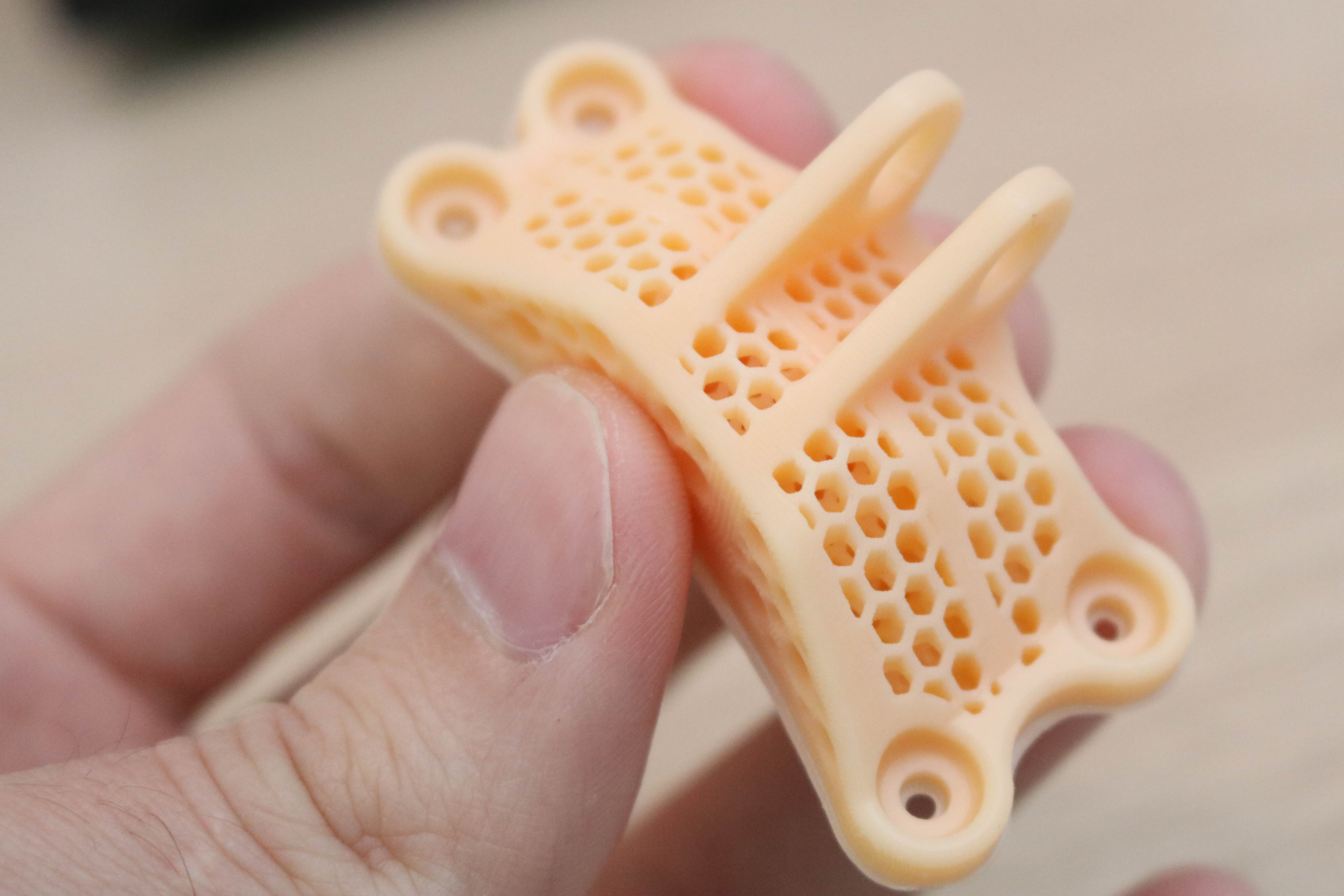

After printing a few miniatures, I wanted to see how the Longer Orange 10 performed when making parts that were intended for real-life use. The Orange 10 includes a file on the microSD called ‘BRACKET.lgs’ which prints out in a speedy hour and a half. The bracket has been filled with hexagonal lightweighting holes that perforate the model vertically and circular lightweighting holes that run through horizontally.

The printed bracket felt stiff and lightweight, and the inclusion of this model gave me something to think about while it was curing. While the overall resolution of the Orange 10 doesn’t seem up to the task of printing highly-detailed miniatures, larger or blockier models that don’t require sharp detail may be a good fit for this printer.

The bracket had a minor amount of stepping in the XY plane, but that’s less of a consideration when printing functional parts like this. Seeing this model made me think that this printer may have a home with any user who is looking to print functional parts where accuracy is less of a concern.

Bottom Line

The Longer Orange 10 is currently available directly from Longer for $139. In addition, the Orange 10 is $179.99 on Amazon, and Amazon Prime members can currently pick it up for a very reasonable $143.99 with free shipping. At that price, it can certainly appear that the Orange 10 is a good value for someone interested in getting involved with 3D printing.

Unfortunately, I have a hard time finding a compelling reason to go with the Longer Orange 10 as one of the best budget 3D printers when other budget MSLA resin 3D printers like the Creality LD-002R exist in the same price range. The relatively low resolution on the XY plane and non-Mono LCD means that the Orange 10 will take longer to print lower resolution parts than other budget MSLA resin machines. The Orange 10 strikes me as an application-specific machine, but you will need to have that application ready and in mind before purchasing this printer.

Generally speaking, a lot of the appeal of the Orange 10 will likely come from the rock-bottom pricing of the machine. For users unconcerned with speed or accuracy who want a hands-on assembly like they would get from the Creality Ender 3 Pro FDM 3D printer, the Orange 10 offers a complete MSLA resin 3D printing experience for less money than a date night for two.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.