EVGA SuperNOVA 850 P2 Power Supply Review

EVGA recently enriched its P2 line with three new members, featuring 650W, 750W and 850W capacities. All three, like the other P2 models, are made by Super Flower and feature Platinum efficiency. Today we're testing the 850 P2.

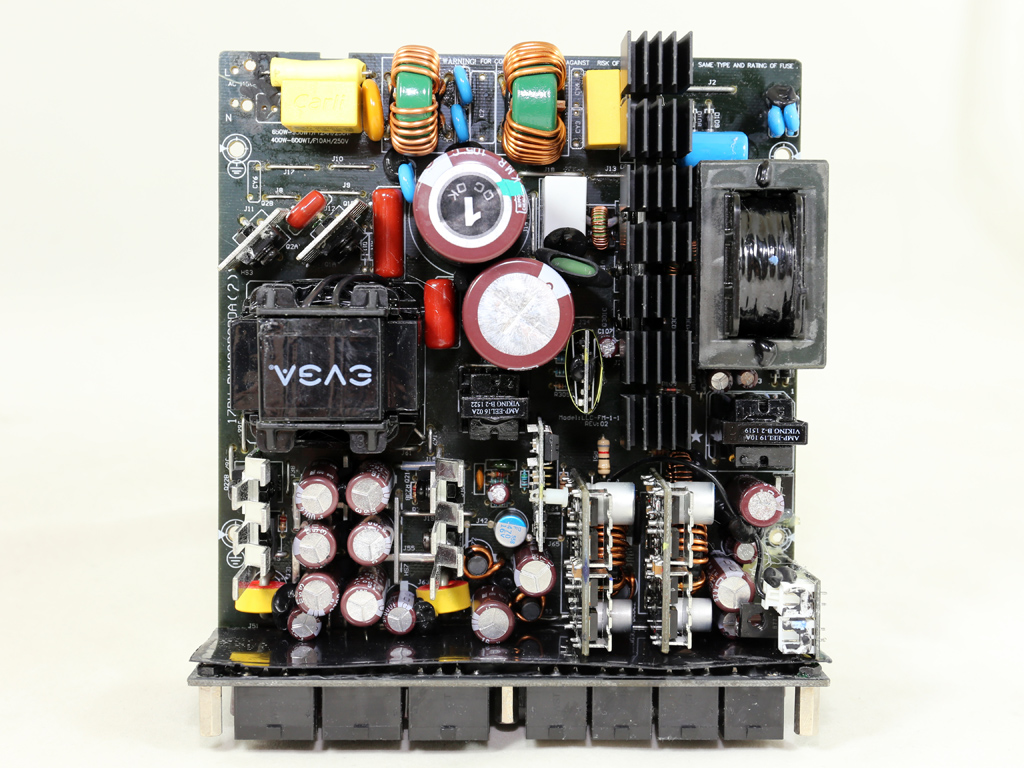

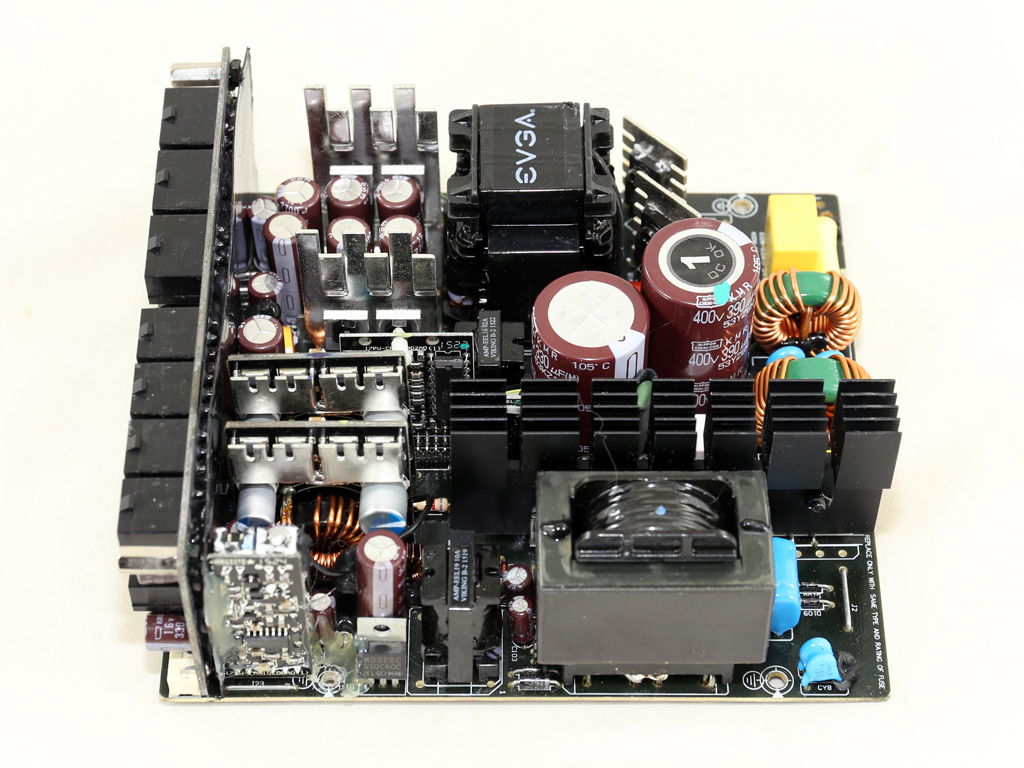

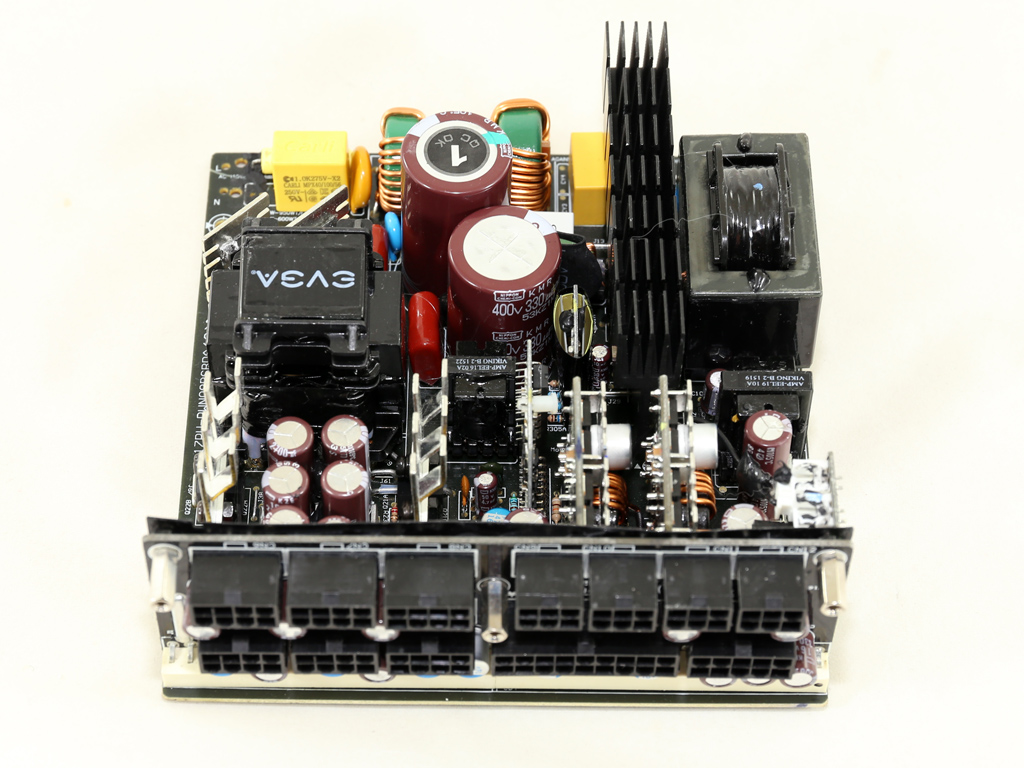

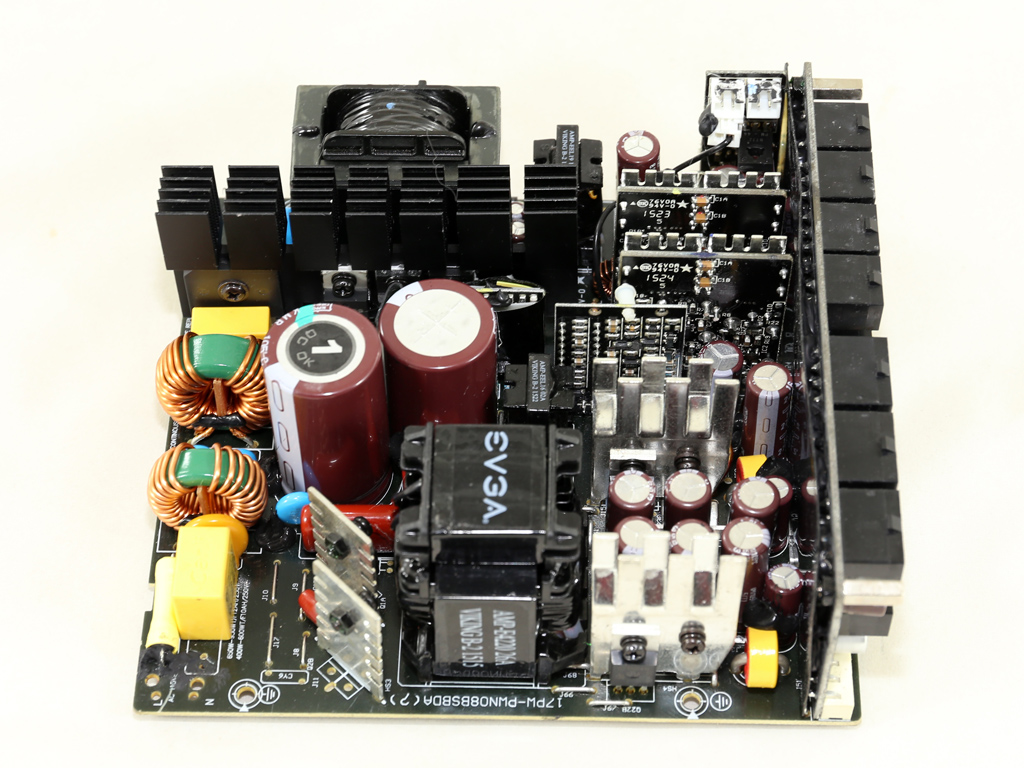

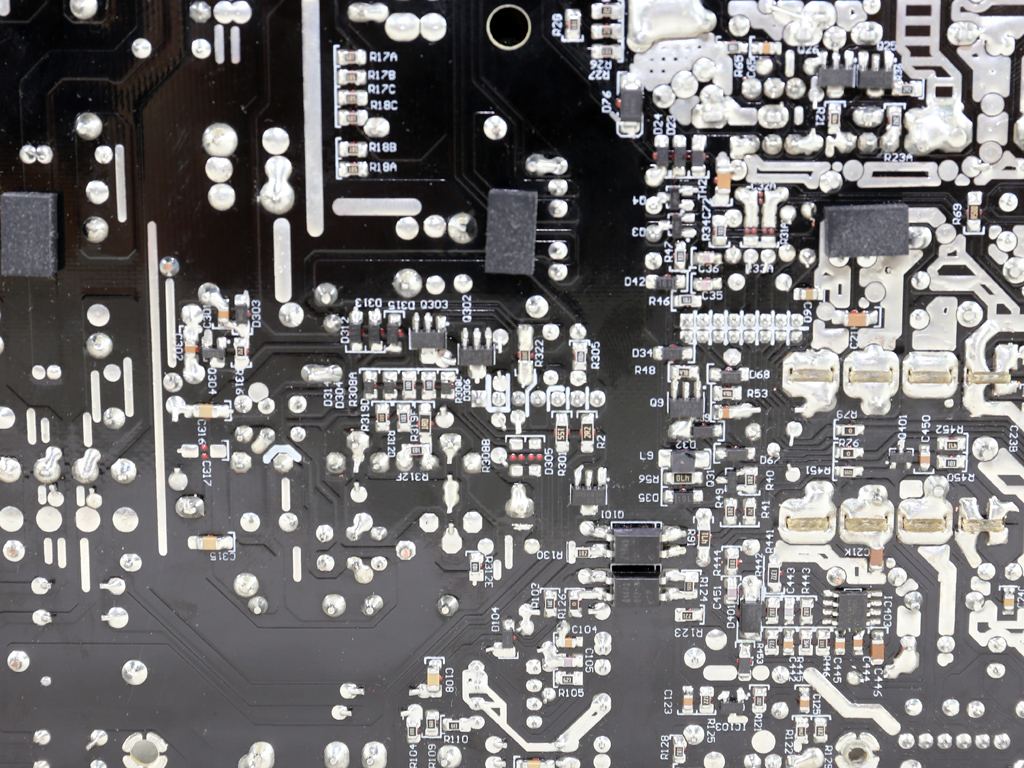

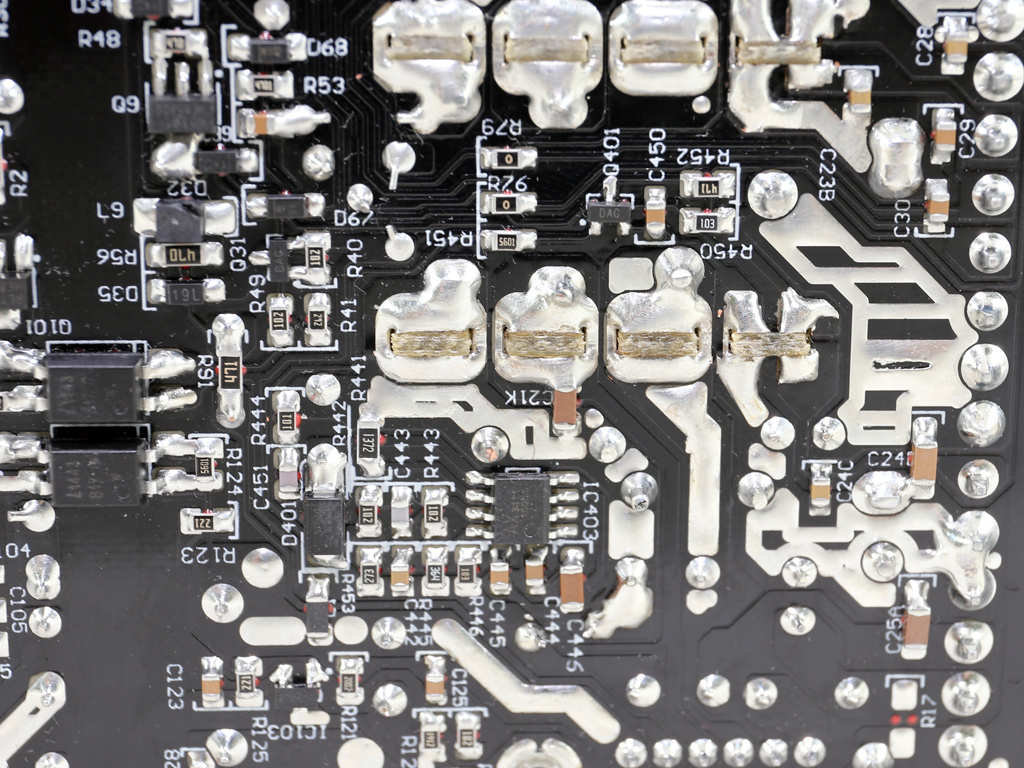

A Look Inside And Component Analysis

Parts Description

Before proceeding with this page, we strongly encourage you to a look at our PSUs 101 article, which provides valuable information about PSUs and their operation, allowing you to better understand the components we're about to discuss. Our main tools for disassembling PSUs are a Thermaltronics soldering and rework station, and a Hakko 808 desoldering gun.

| Primary Side | |

|---|---|

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Inrush Protection | NTC Thermistor & Relay |

| Bridge Rectifier(s) | 1x |

| APFC MOSFETs | 2x Infineon IPI50R140CP (550V, 15A @ 100 °C, 0.14 ohm) |

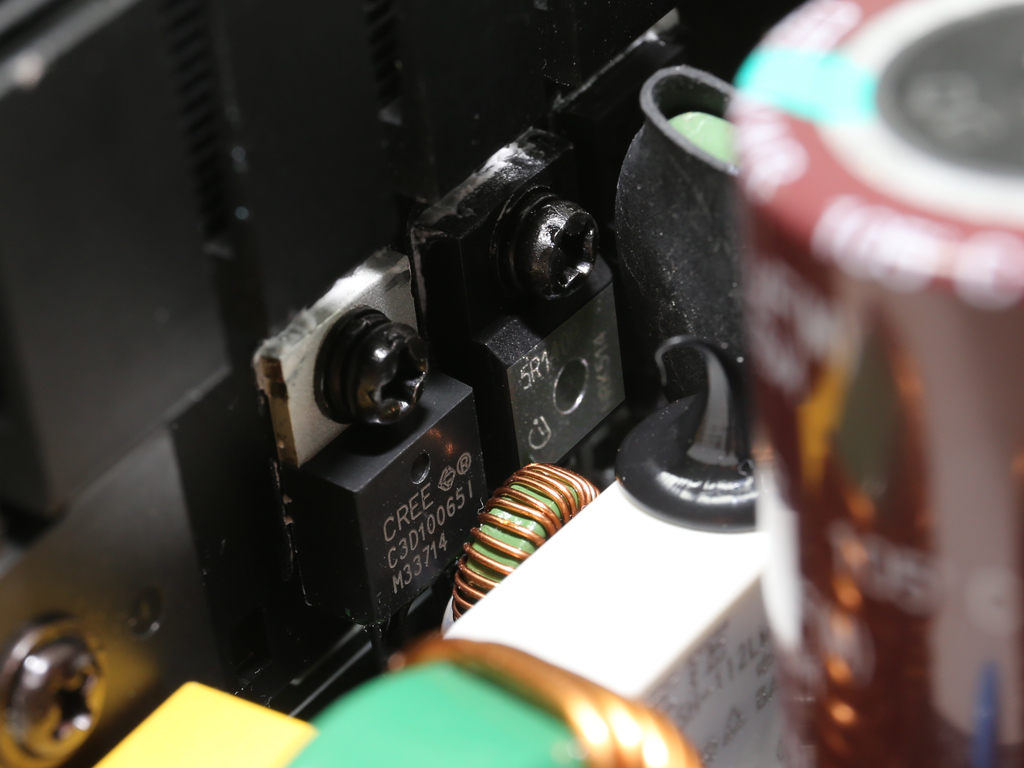

| APFC Boost Diode | 1x Cree C3D10065A (650V, 10A @ 153 °C) |

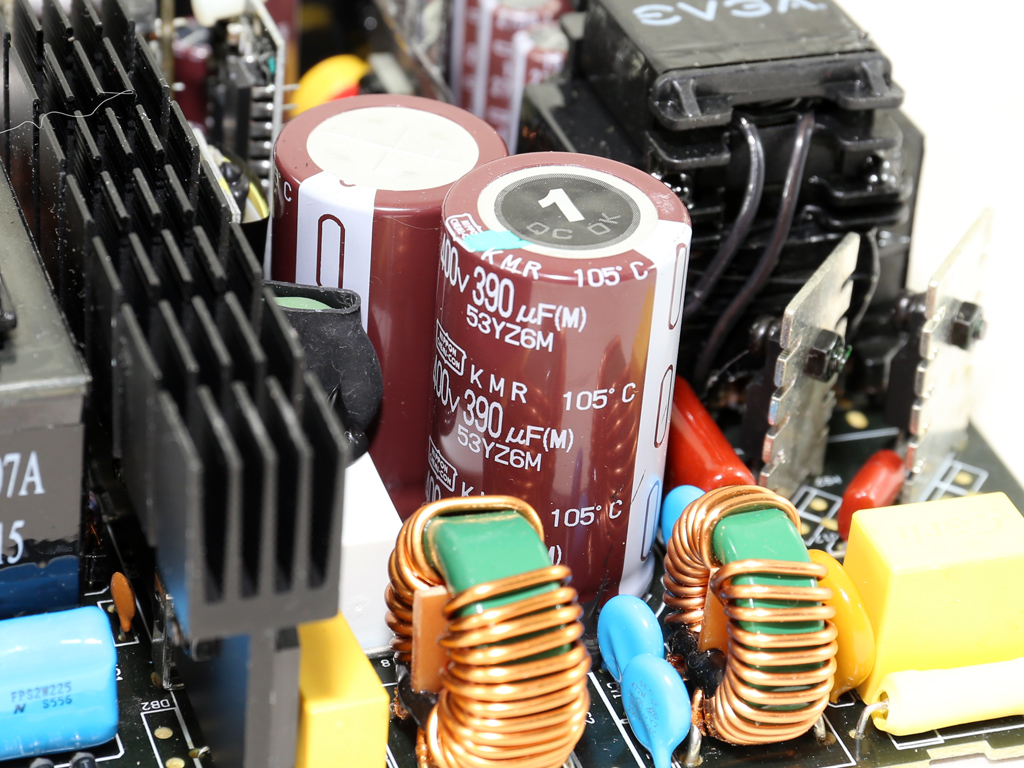

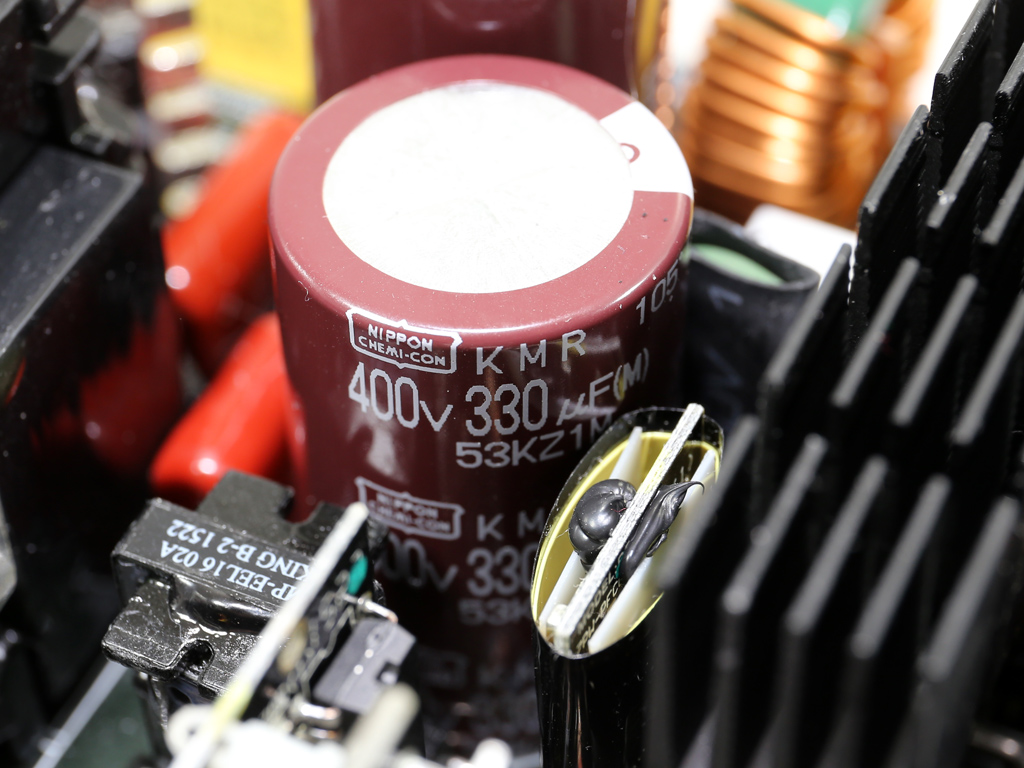

| Hold-up Cap(s) | 2x Nippon Chemi-Con (400V, 390uF & 330uF or 720uF combined, 2000h @ 105 °C, KMR) |

| Main Switchers | 2x Infineon IPI50R140CP (550V, 15A @ 100 °C, 0.14 ohm) |

| APFC Controller | Infineon NCP1653A |

| Switching Controller | AA9013 |

| Topology | Primary side: Half-Bridge & LLC Resonant Converter Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETs | 6x Infineon IPP023N04N G (40V, 90A @ 100 °C, 2.3 mohm) |

| 5V & 3.3V | DC-DC Converters: 8x Infineon IPD060N03L G PWM Controller: 2x NCP1587A |

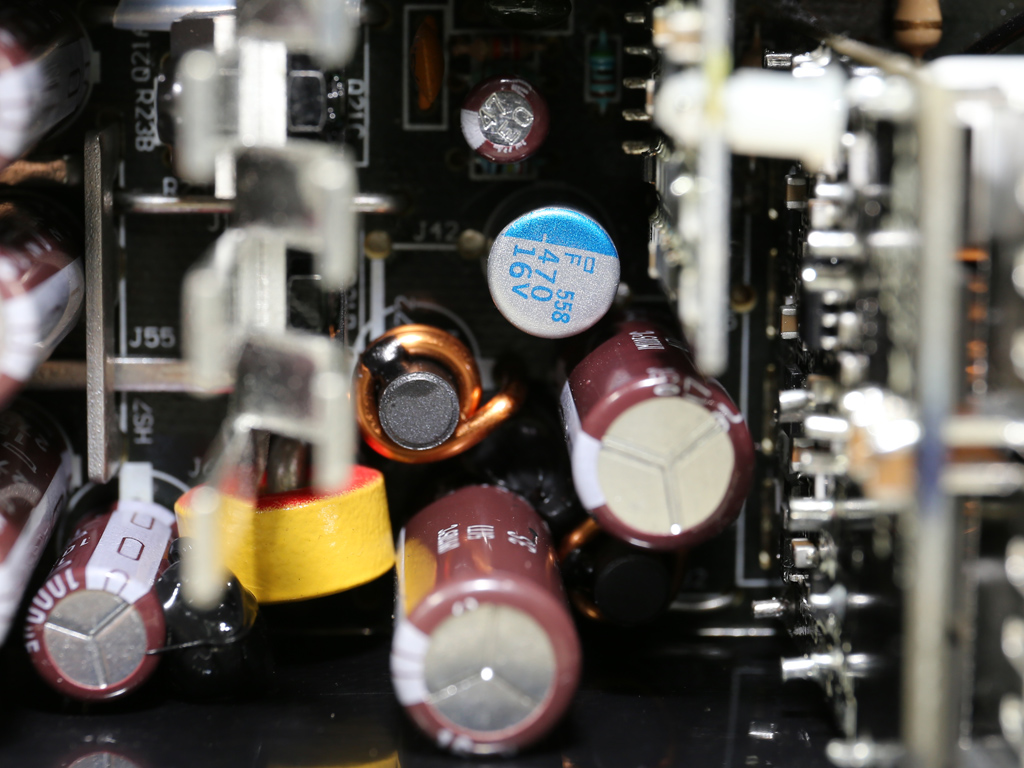

| Filtering Capacitors | Electrolytics: Nippon Chemi-Con (105 °C, KY, KZE, KRG) Polymers: Nippon Chemi-Con |

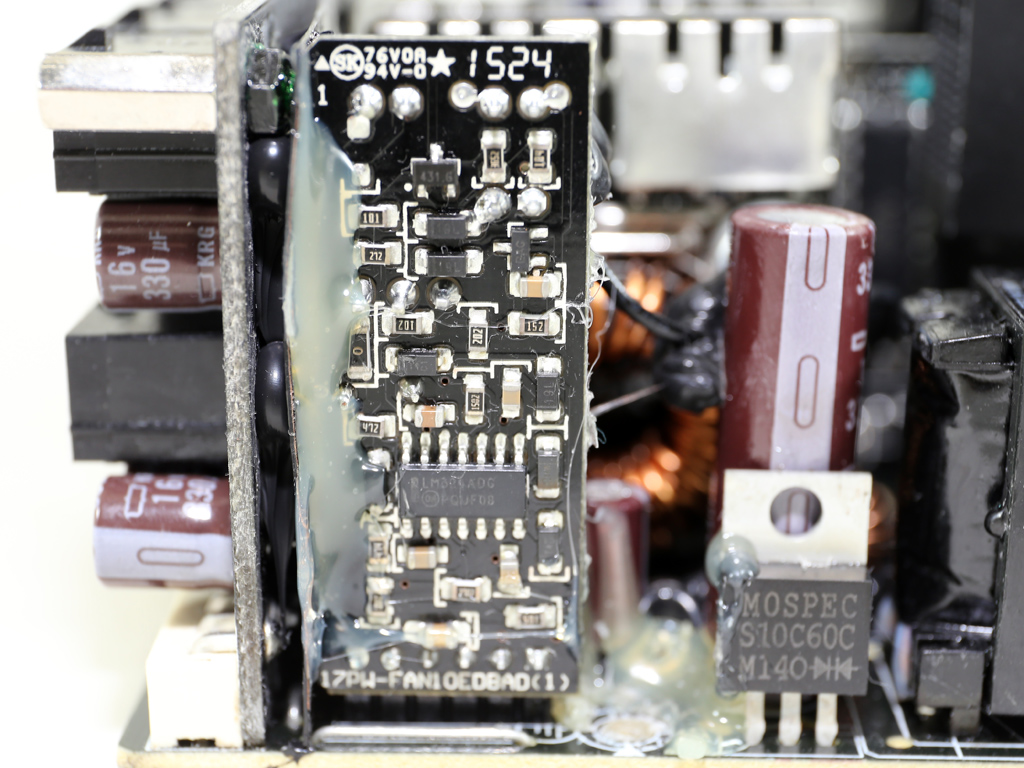

| Supervisor IC | AA9013 & LM324ADG |

| Fan Model | Globe Fan RL4Z B1402512HH (140mm, 12V, 0.5A, 1800 RPM, 135.74 CFM, 36.7 dB[A], DBB) |

| 5VSB Circuit | |

| Rectifier | 1x Mospec S10C60C SBR |

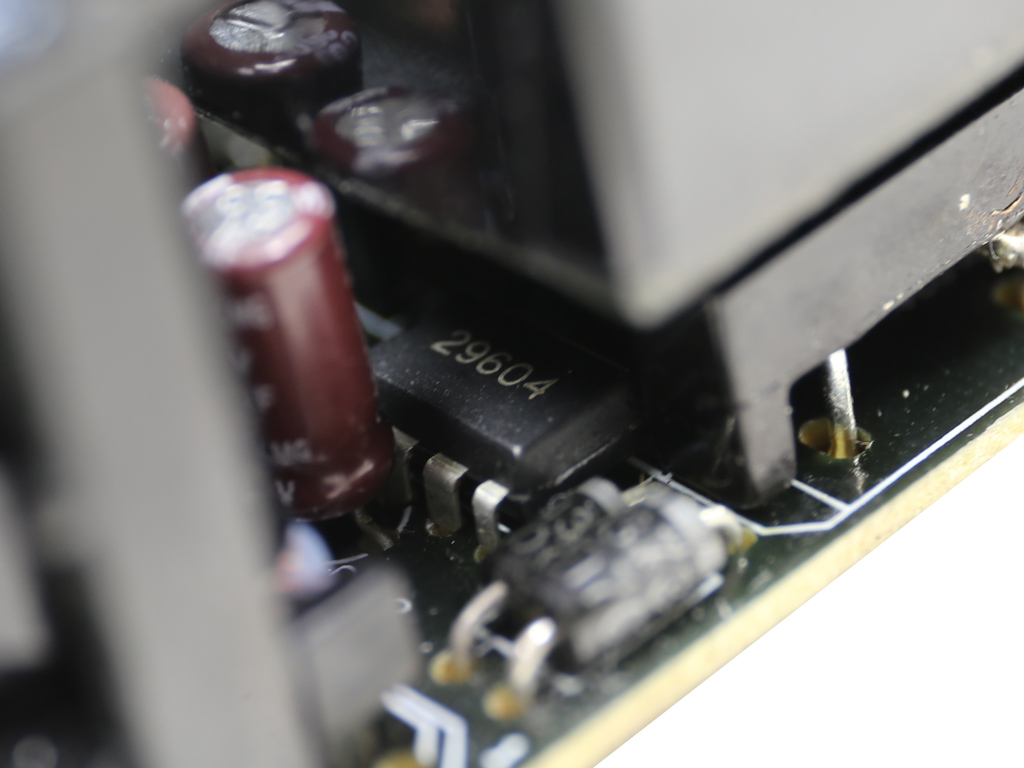

| Standby PWM Controller | 29604 |

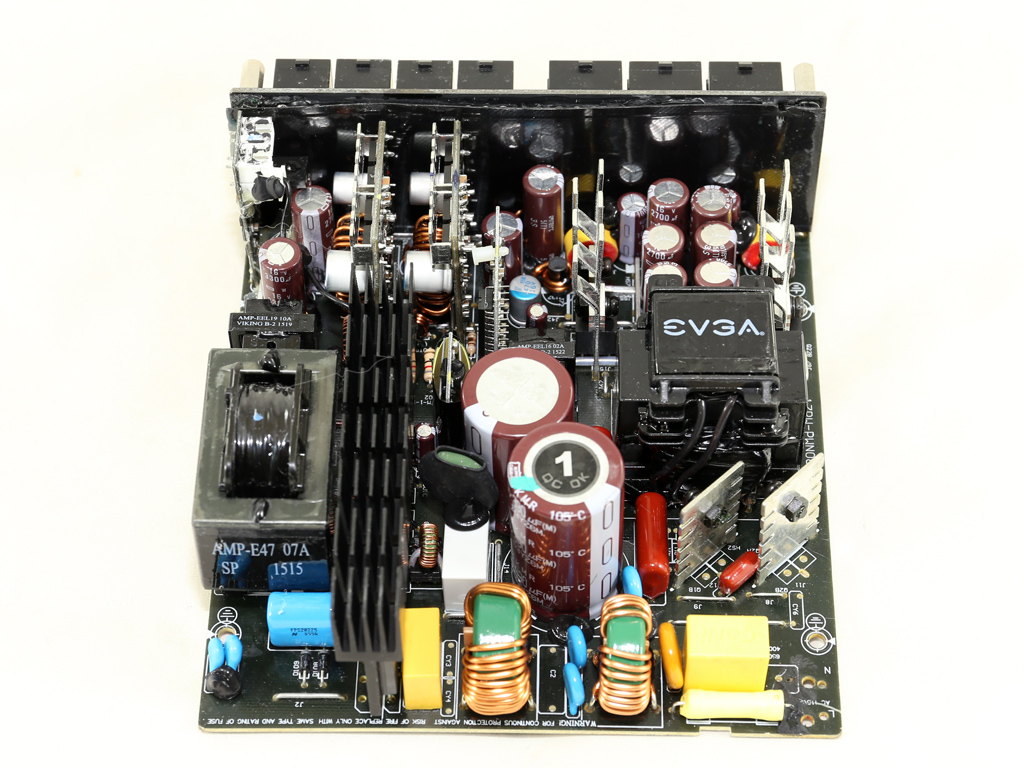

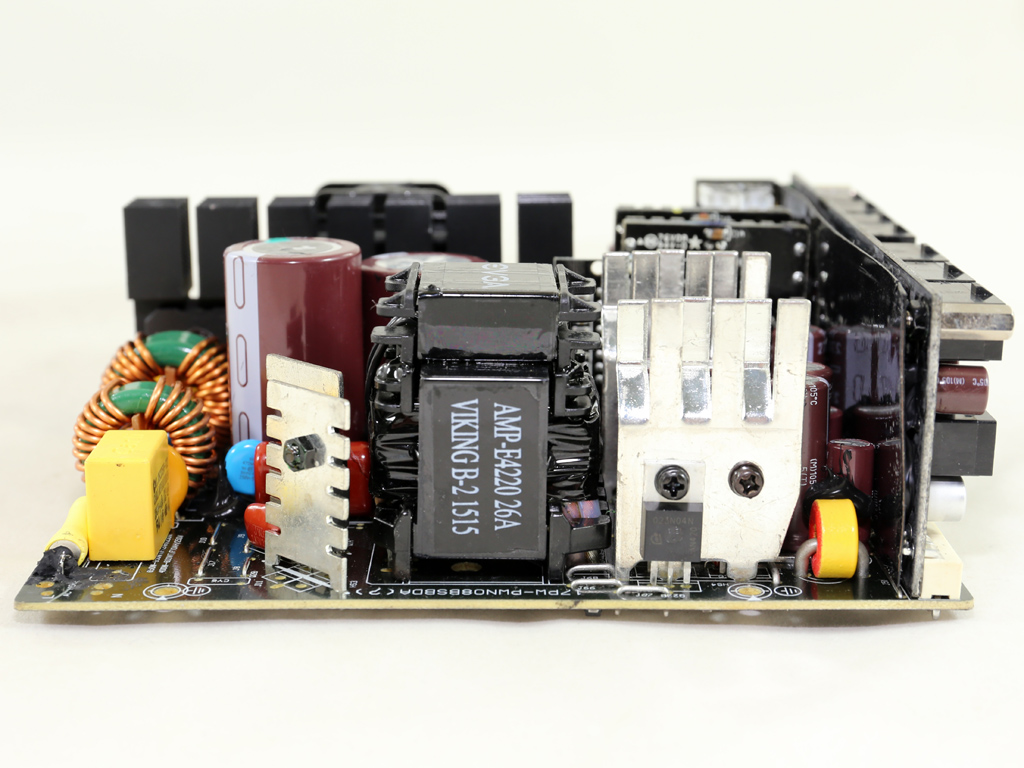

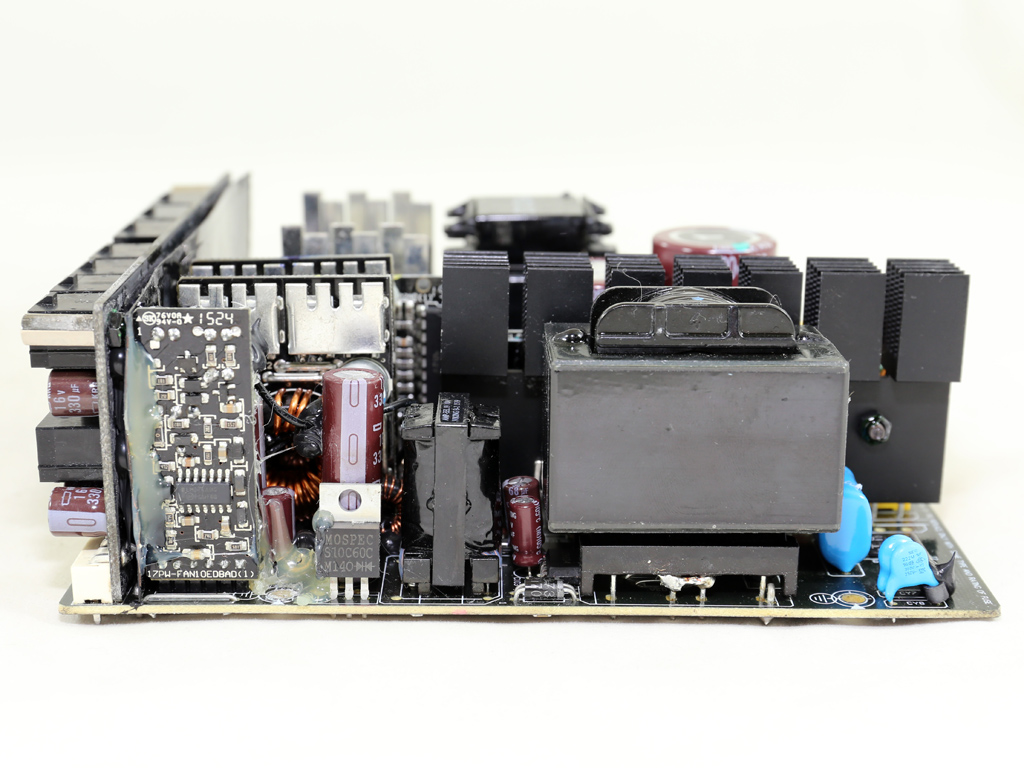

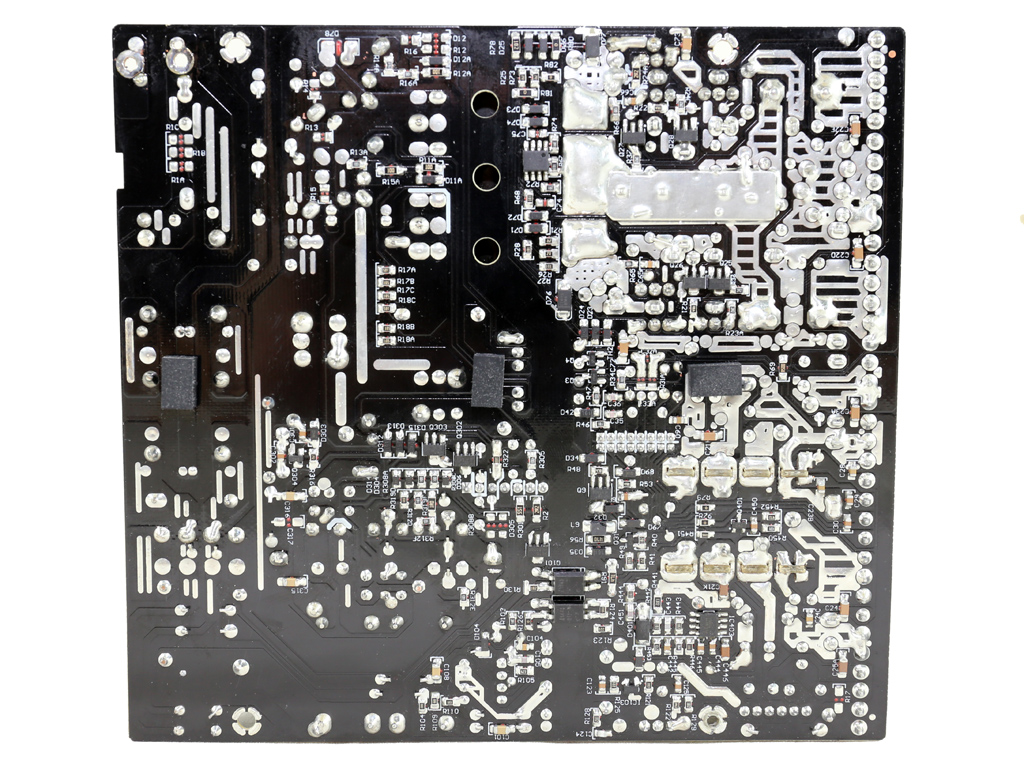

This unit's Super Flower Leadex platform is among the best available. It offers good reliability along with high performance. And thanks to its minimal energy losses, it can be cooled efficiently with a low-speed fan. On the primary side, a half-bridge topology is used along with an LLC resonant converter that provides almost lossless switching. On the secondary side, a pair of VRMs generate the minor rails, while the +12V rail is rectified by a number of FETs. All capacitors, both polymer and electrolytic, are provided by Nippon Chemi-Con. This helps the unit's reliability and allows EVGA to offer a 10-year warranty without worrying too much about an increased number of RMAs after several years.

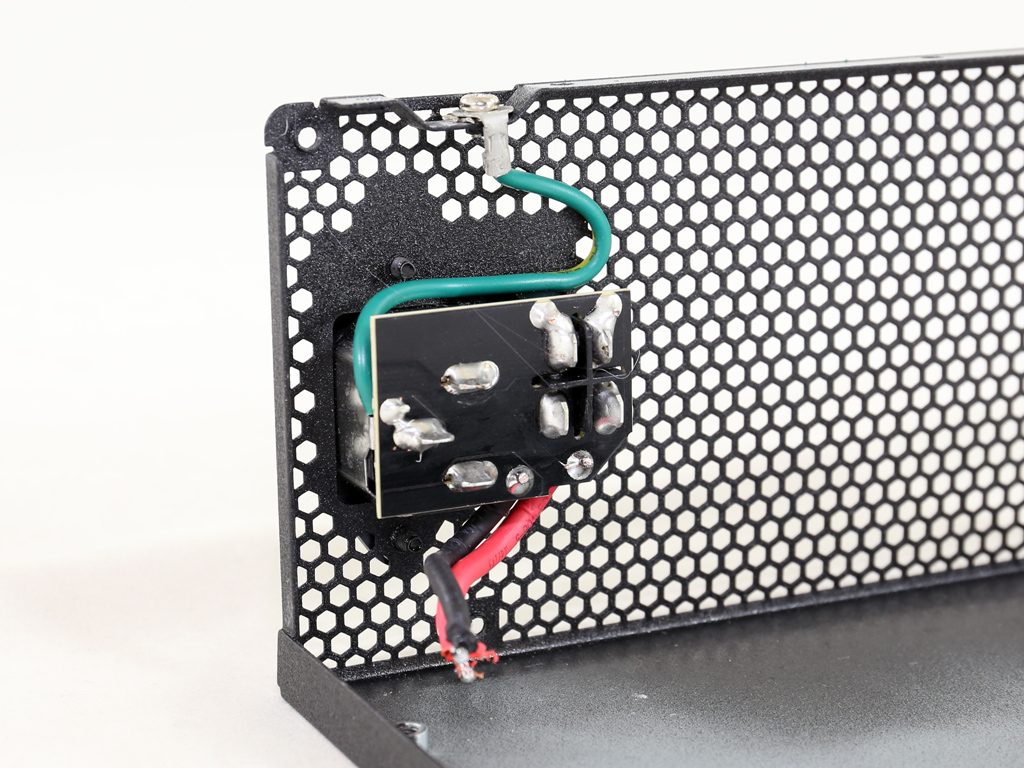

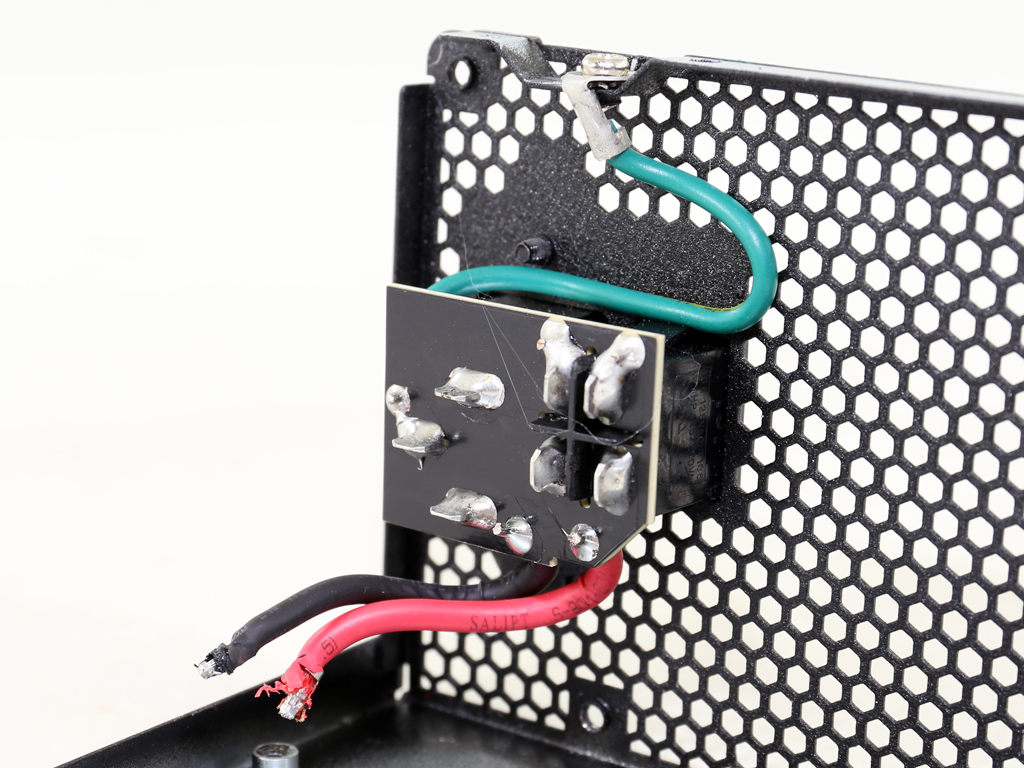

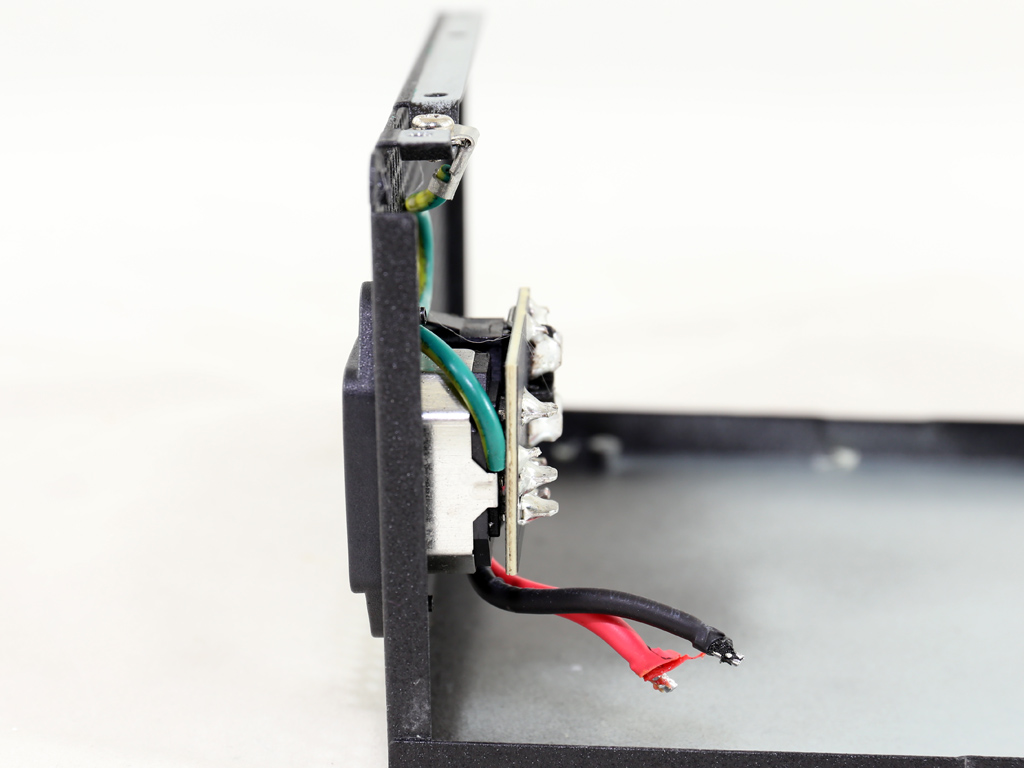

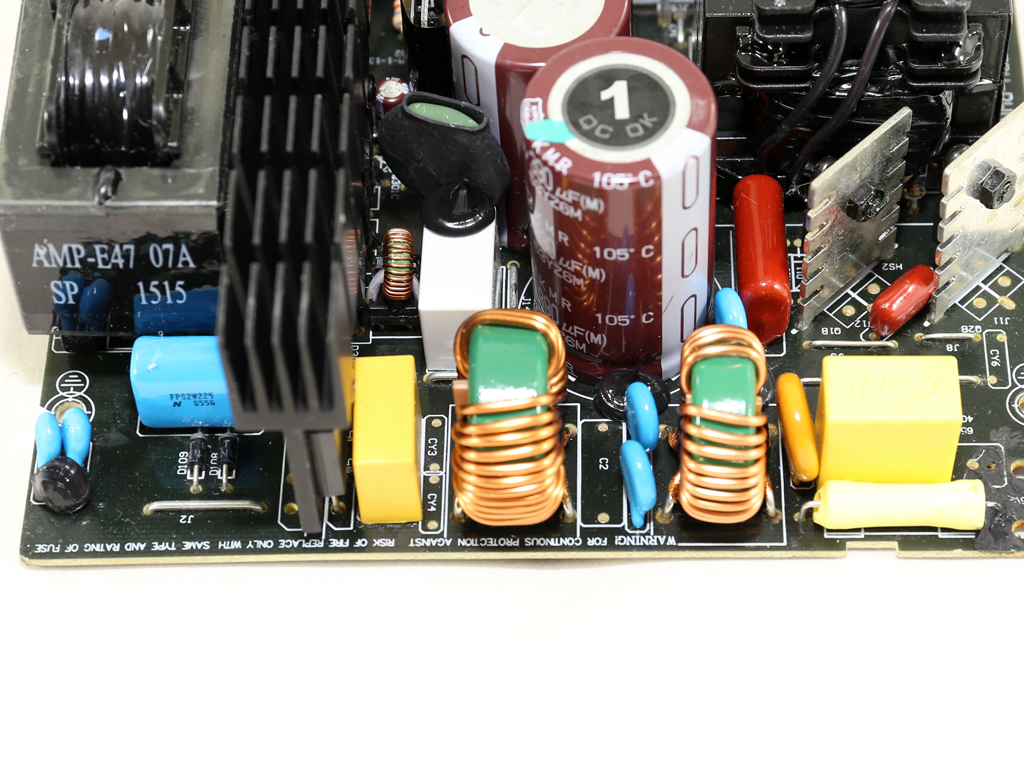

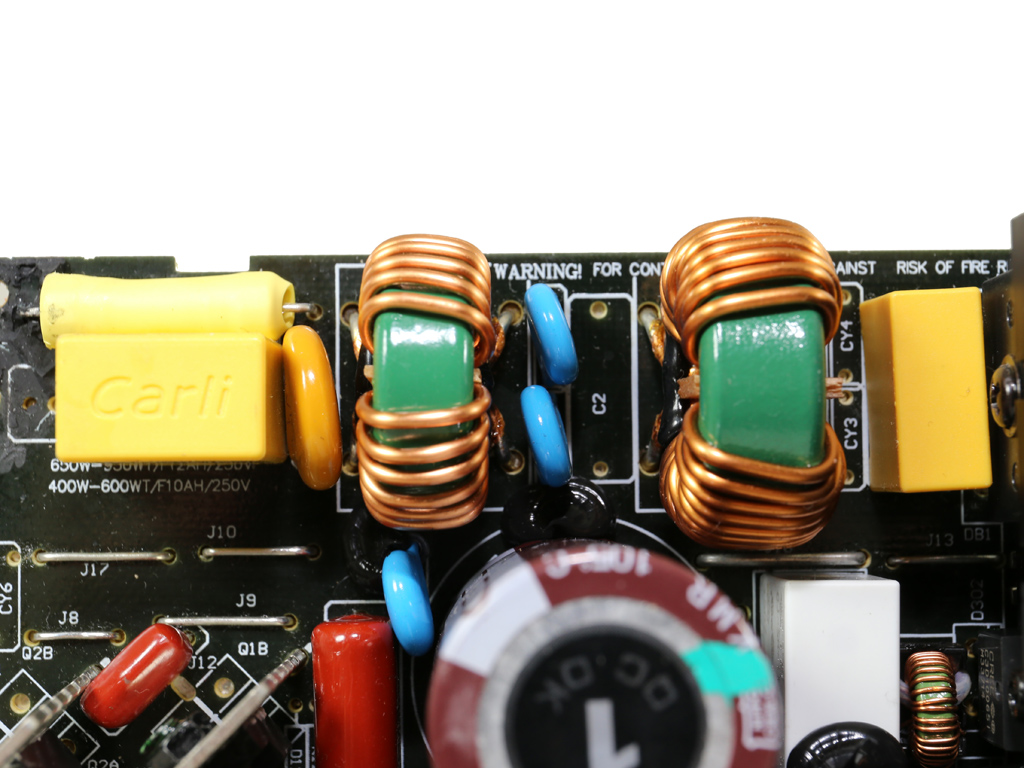

The small PCB behind the AC receptacle doesn't host any EMI filtering components. Those are all installed on the main PCB and include four Y caps, a pair of X caps, two CM chokes and an MOV. There is, of course, an NTC thermistor for protection against large inrush currents, along with an electromagnetic relay responsible for bypassing it once the start-up phase finishes.

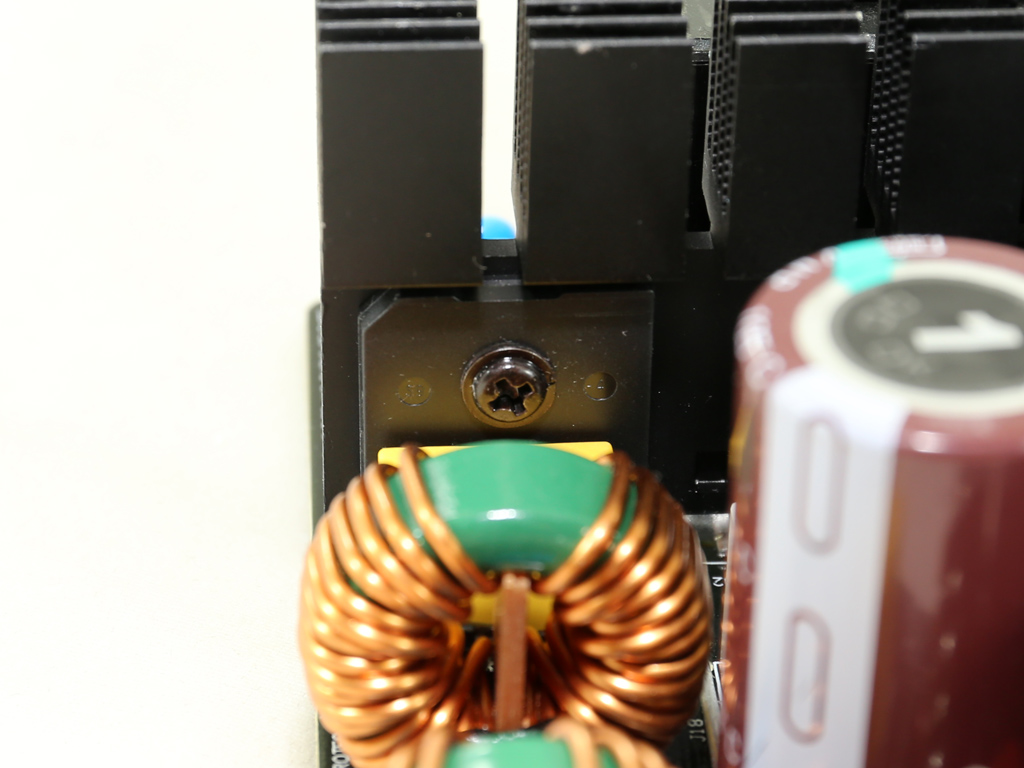

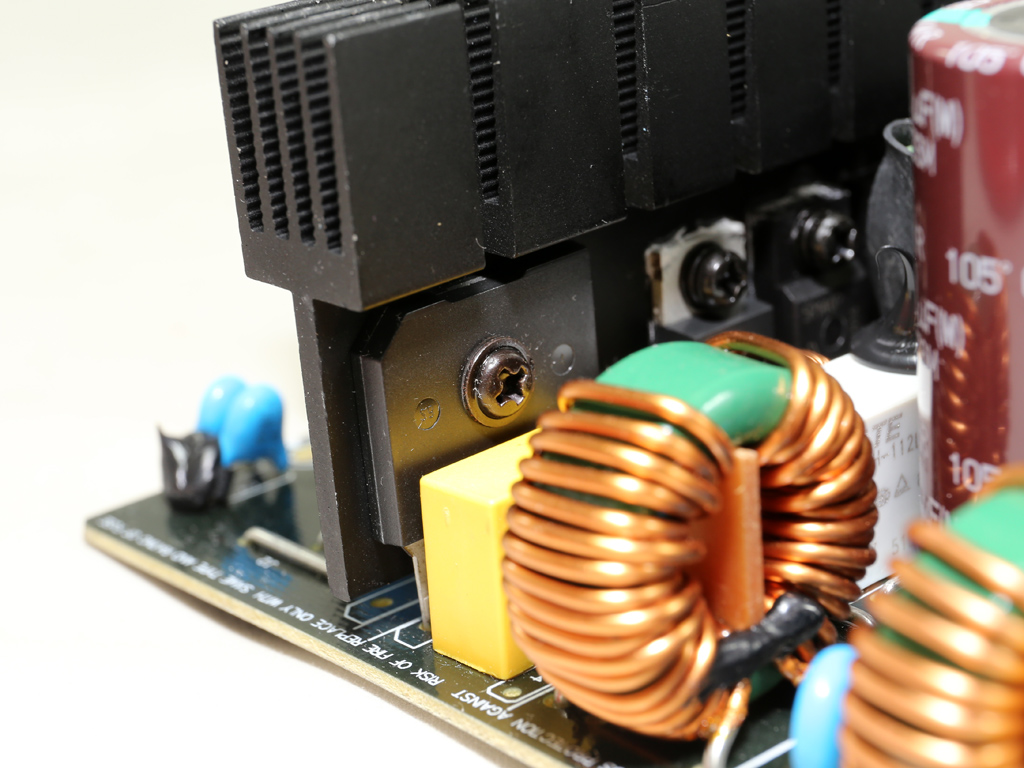

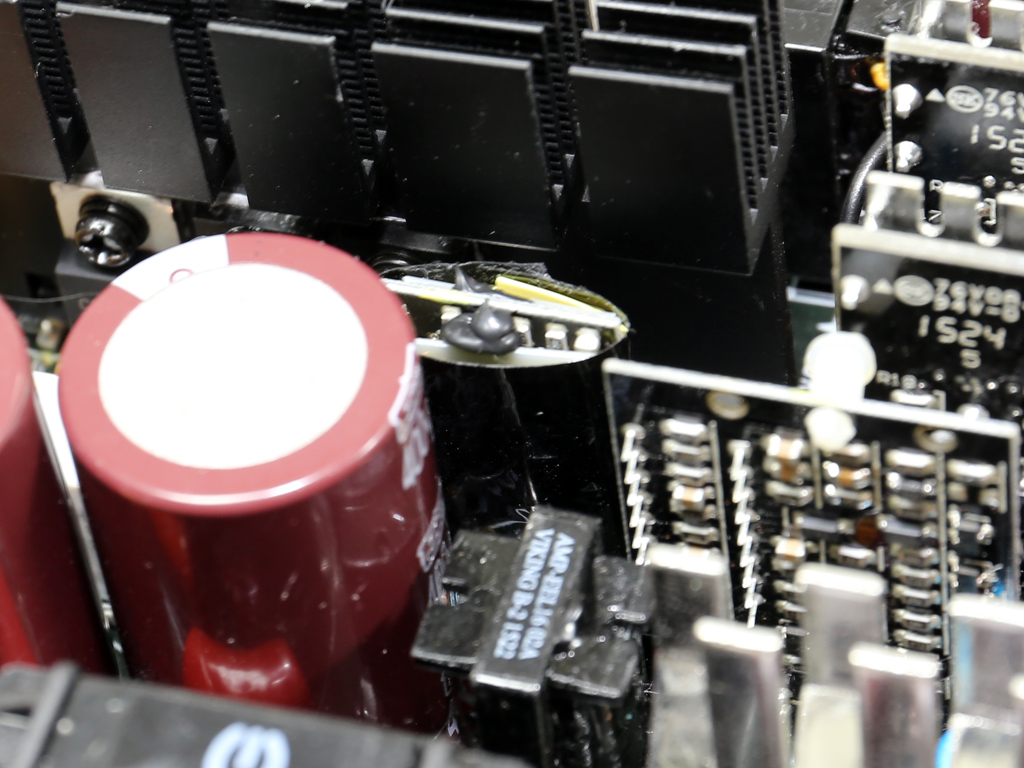

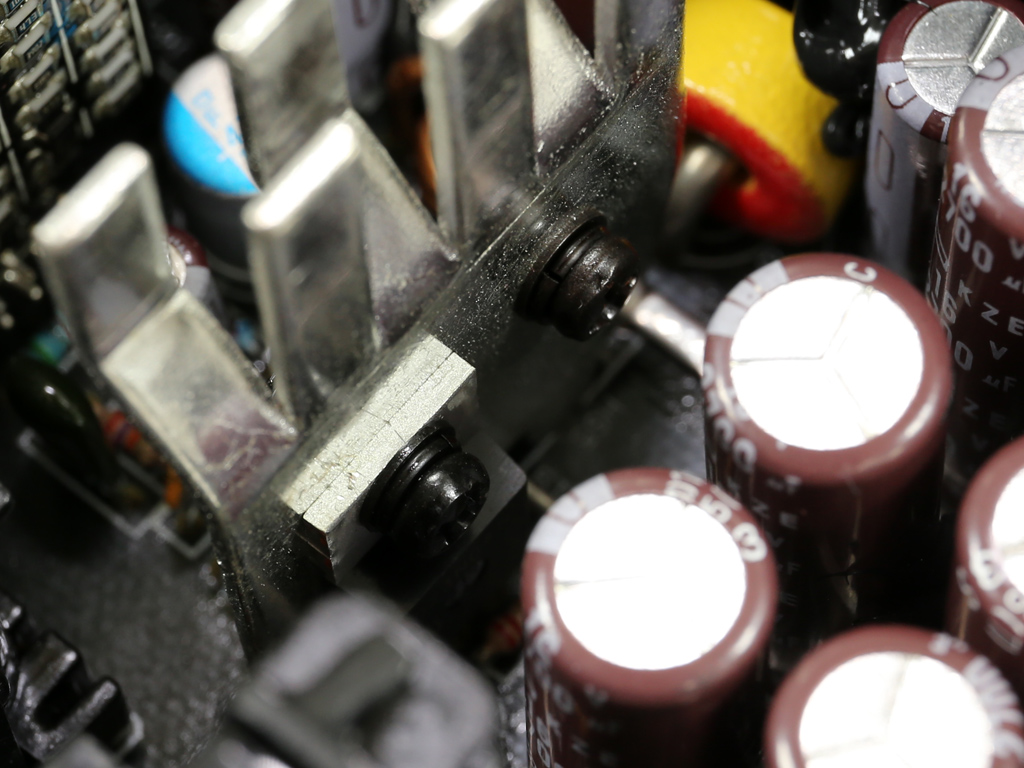

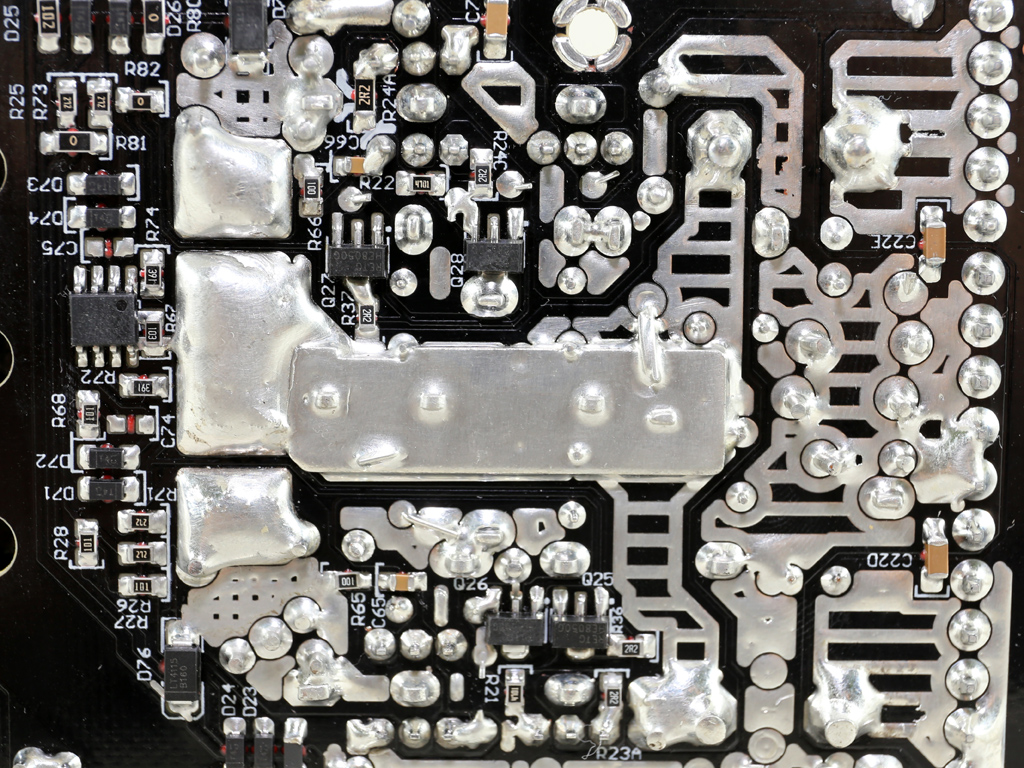

The single bridge rectifier is installed on the APFC heat sink; its markings are on the hidden side, so we couldn't identify it. In the APFC converter, two Infineon IPI50R140CP FETs are used, along with a single Cree C3D10065A boost diode. The bulk caps are a pair of Chemi-Cons with 390uF and 330uF capacities, so their combined capacity is 720uF. Normally, the capacity of the bulk caps should exceed 800uF to allow for a higher hold-up time, but this would have a negative impact on efficiency since larger APFC caps need larger pulses of current in order to keep their charge and naturally this results in greater energy losses. We would also like to see bulk caps rated for higher voltages, since 400V comes close to the APFC's 380V DC bus voltage.

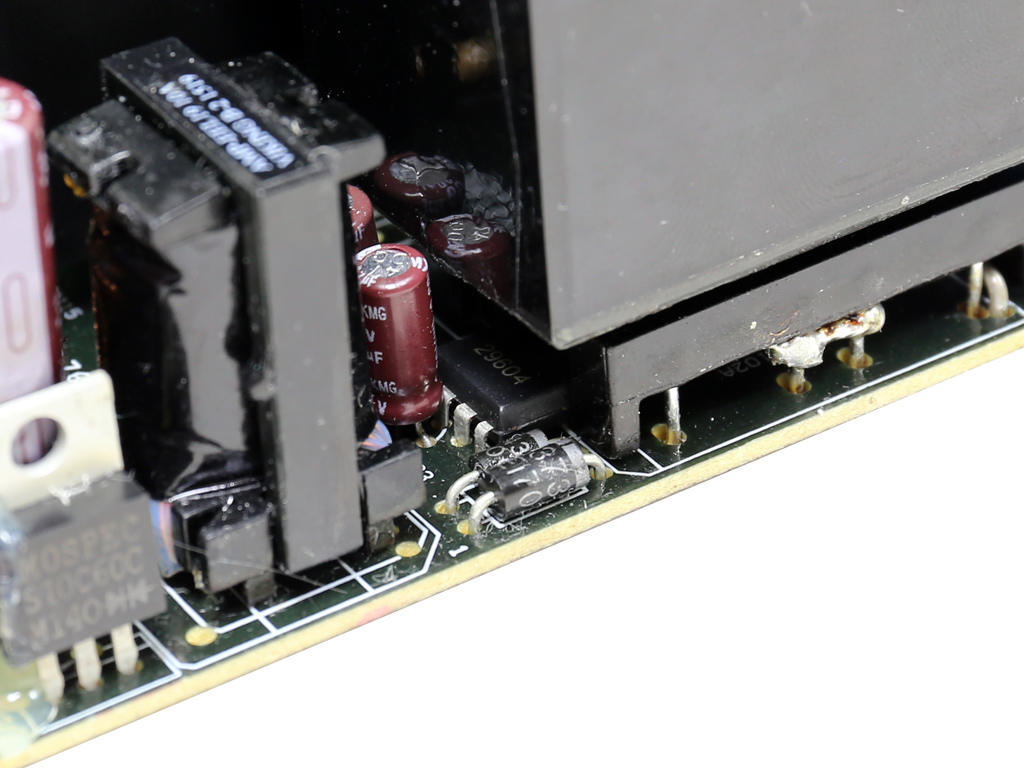

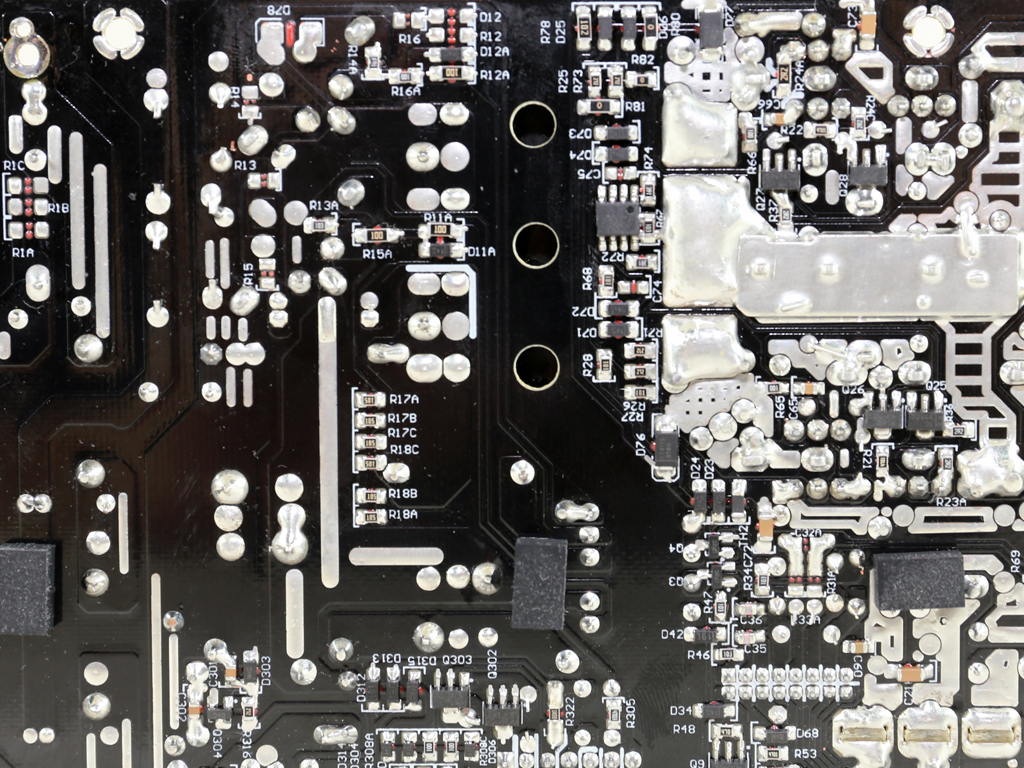

A vertical daughterboard surrounded by black insulating tape hosts the APFC controller, an NCP1653A IC provided by On Semiconductor.

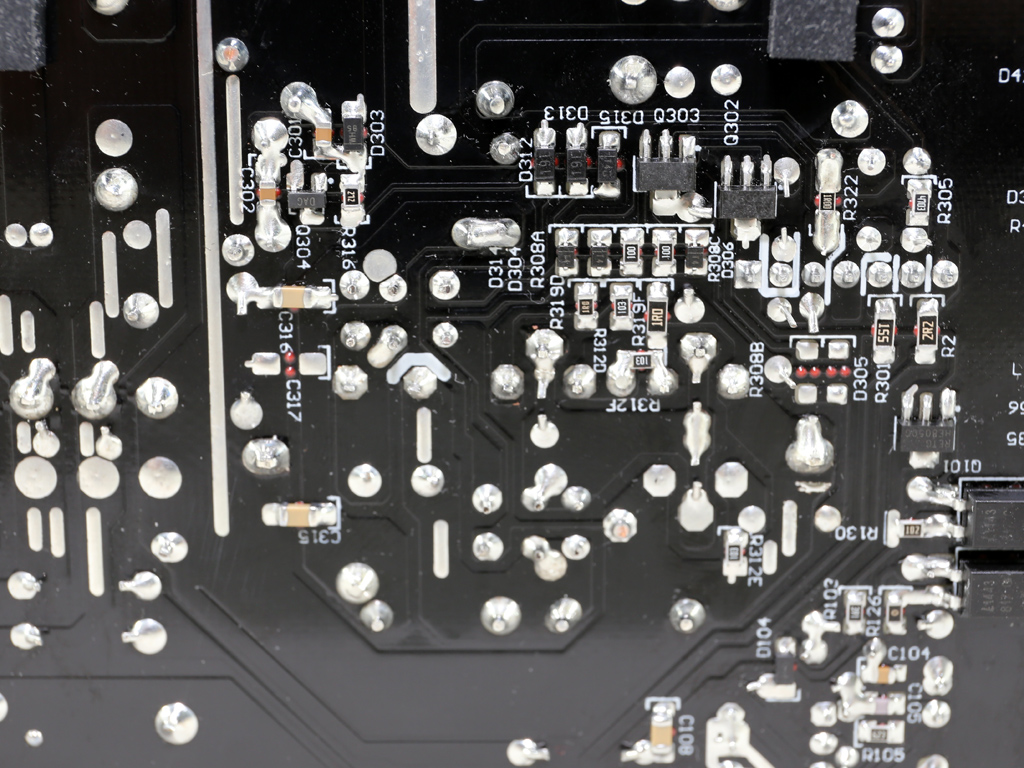

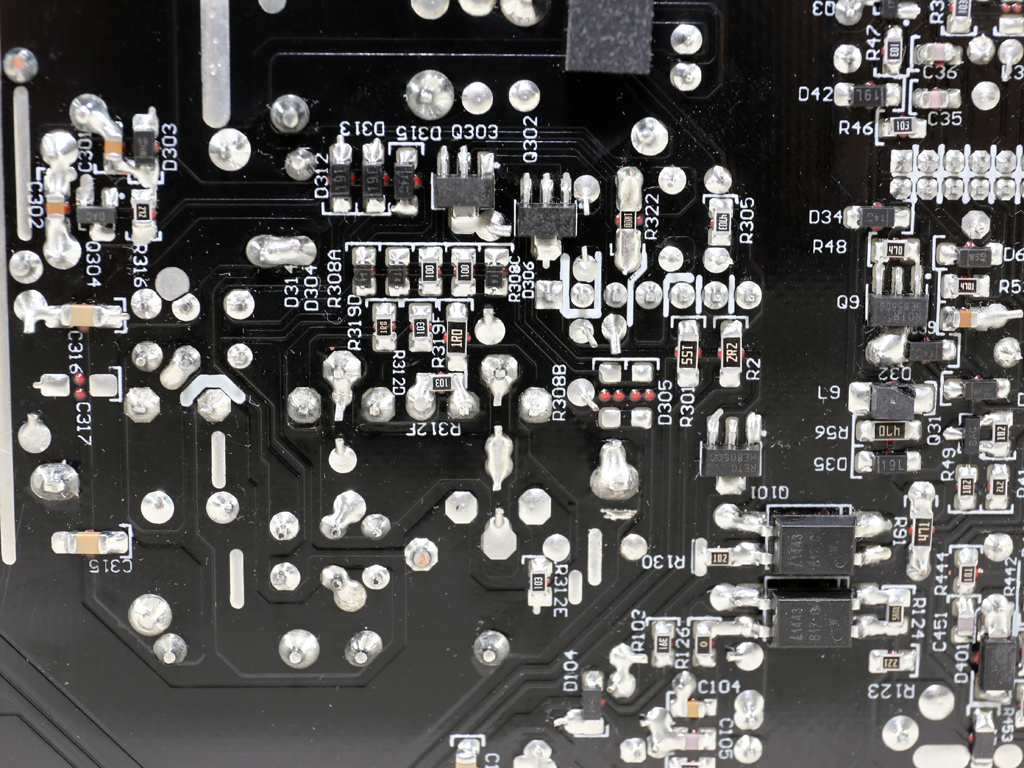

The main switchers, two Infineon IPI50R140CP FETs, are arranged into a half-bridge topology. An LLC resonant converter helps minimize the switching energy losses, providing a significant efficiency boost. The LLC resonant controller is a proprietary Super Flower IC with model number AA9013. The same IC most likely handles the PSU's protection features, and on the same PCB, we also find an LM324ADG quad op-amp.

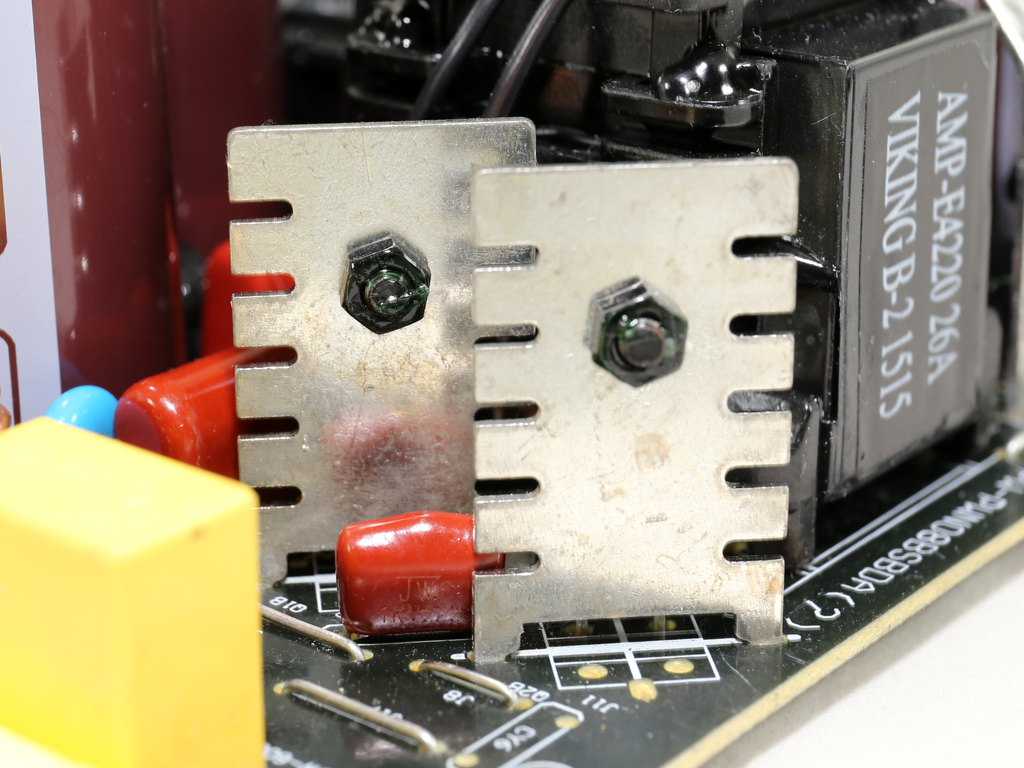

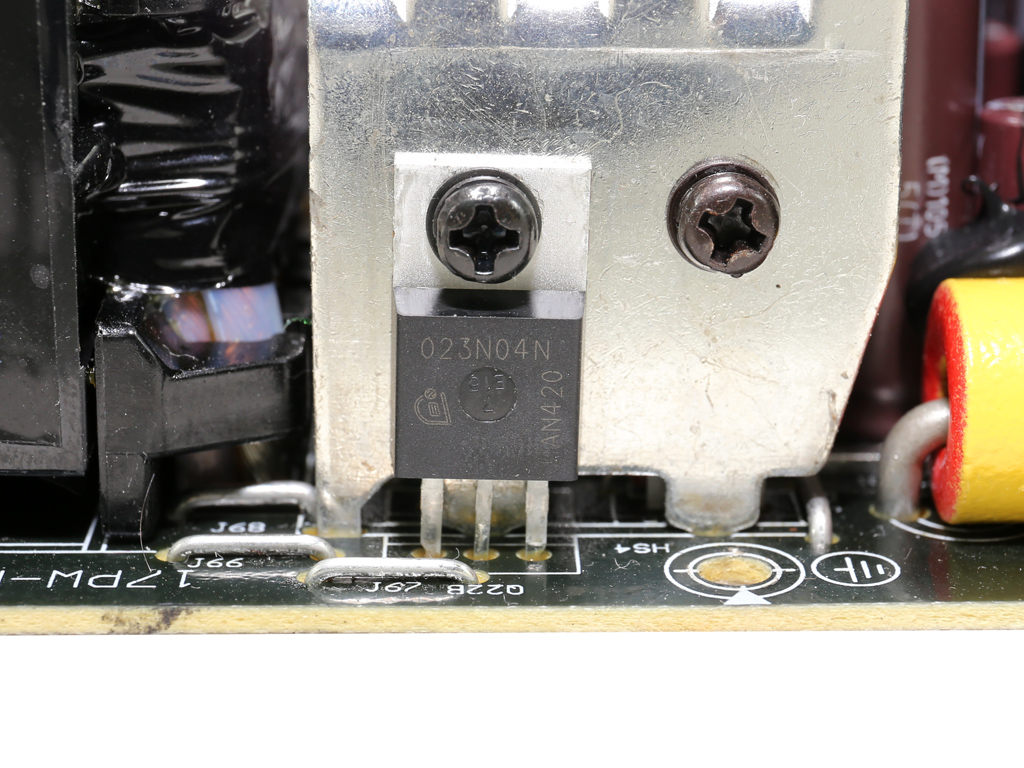

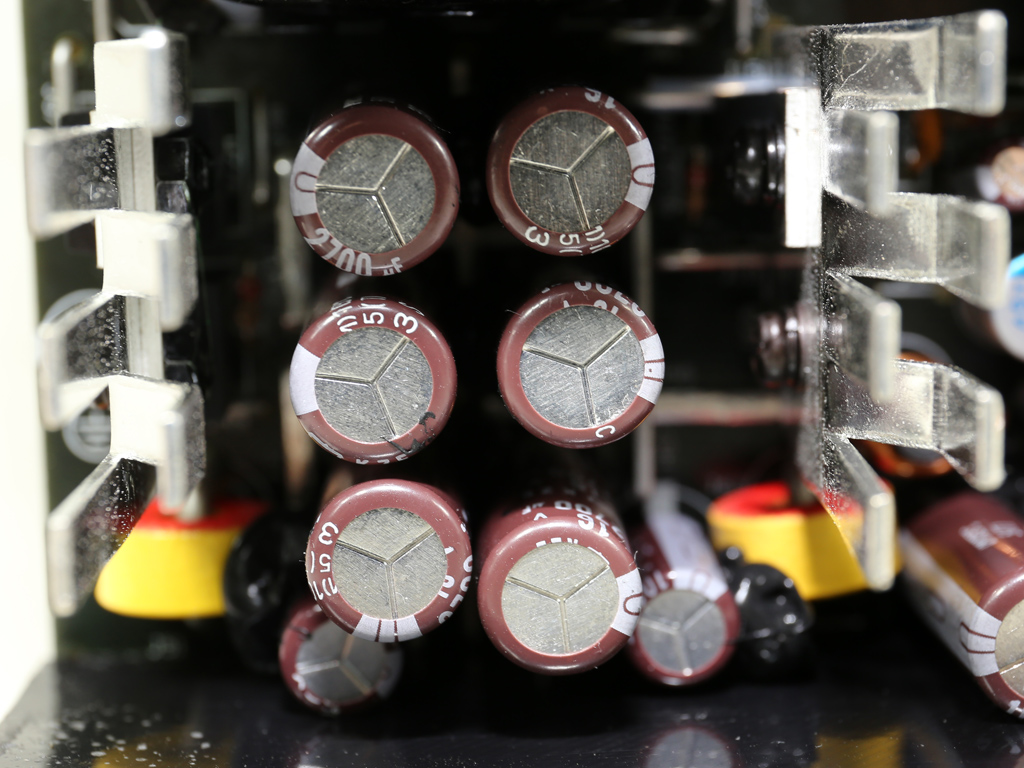

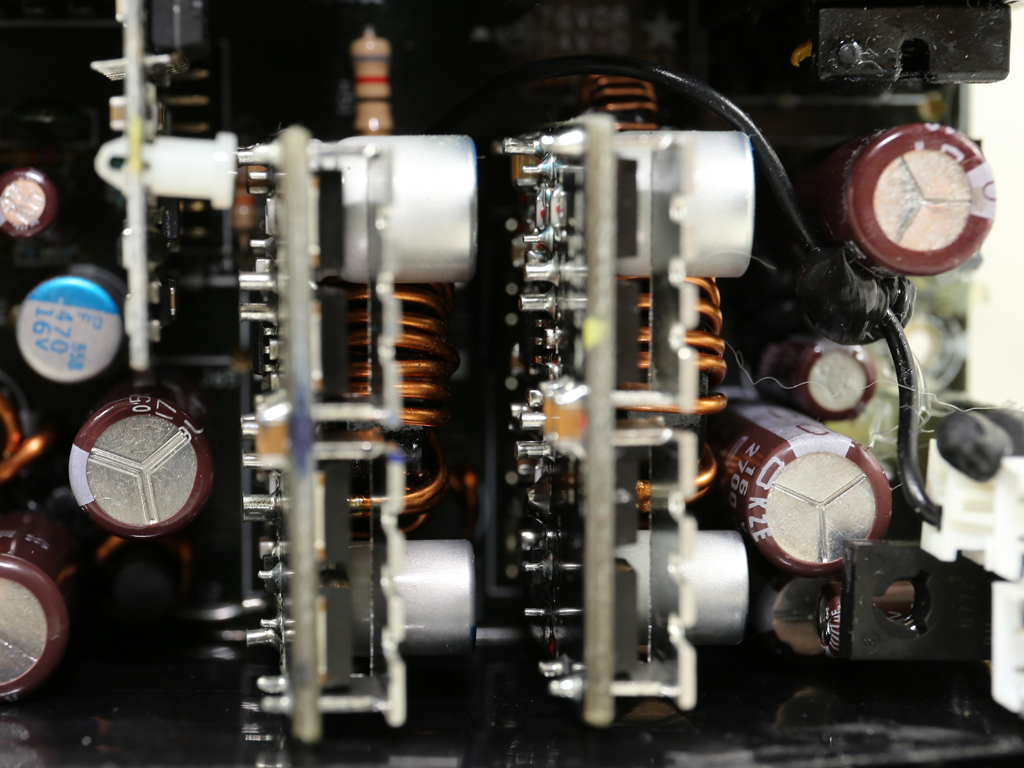

A synchronous design is used on the secondary side, so the +12V rail's generation is handled by six Infineon IPP023N04N G FETs. Two small heat sinks cool the +12V FETs. Among them, several electrolytic Chemi-Con caps (all rated at 105 °C and mostly KZE-series caps) are used for ripple filtering. There's also a single polymer Chemi-Con cap in the same area.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

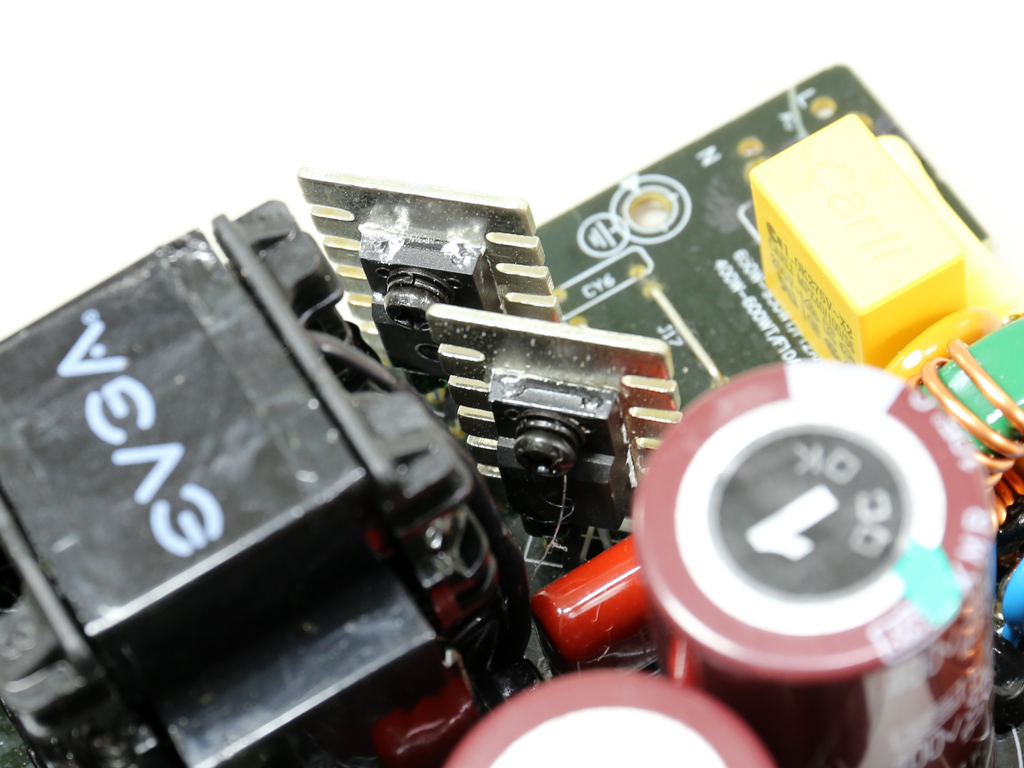

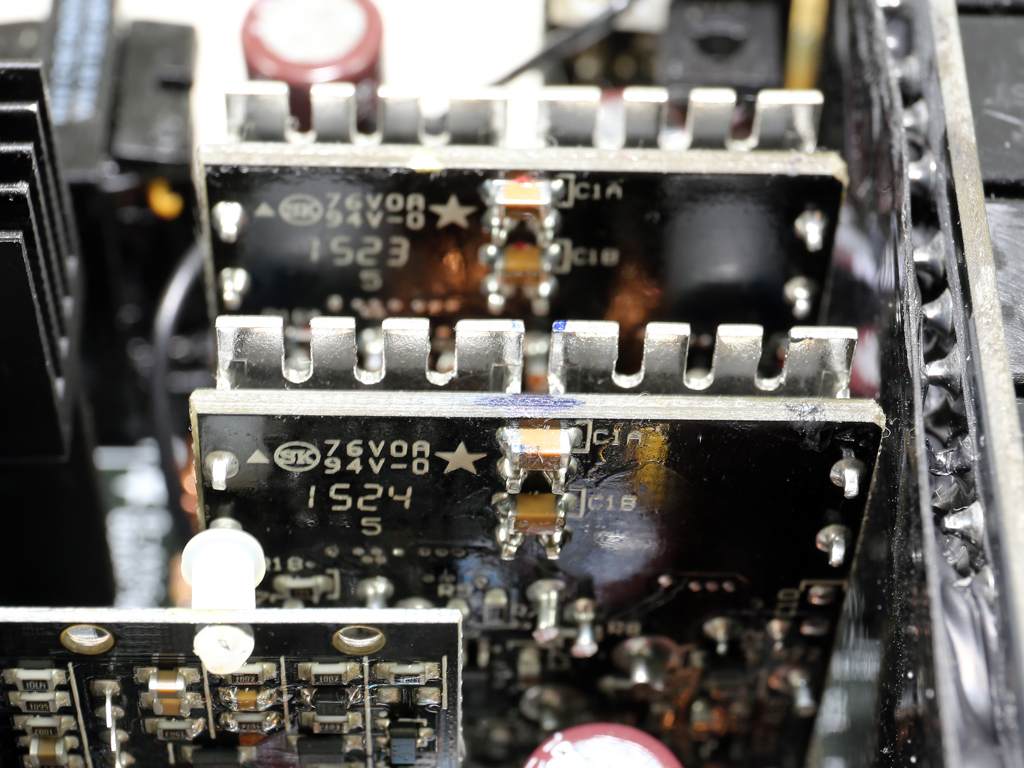

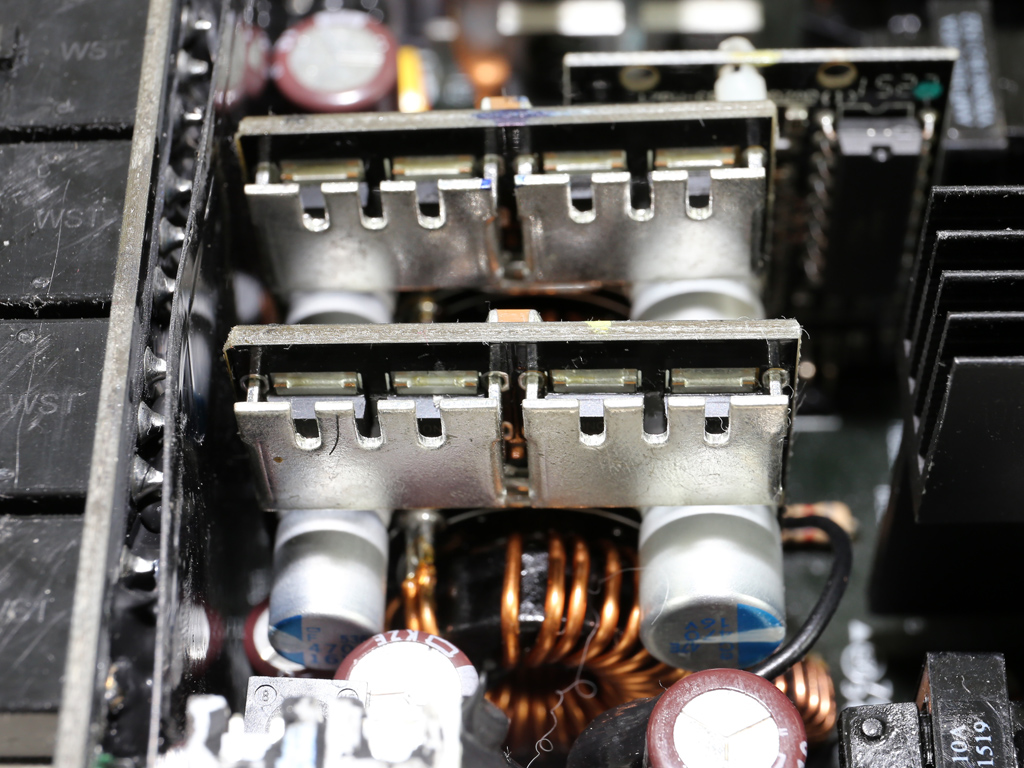

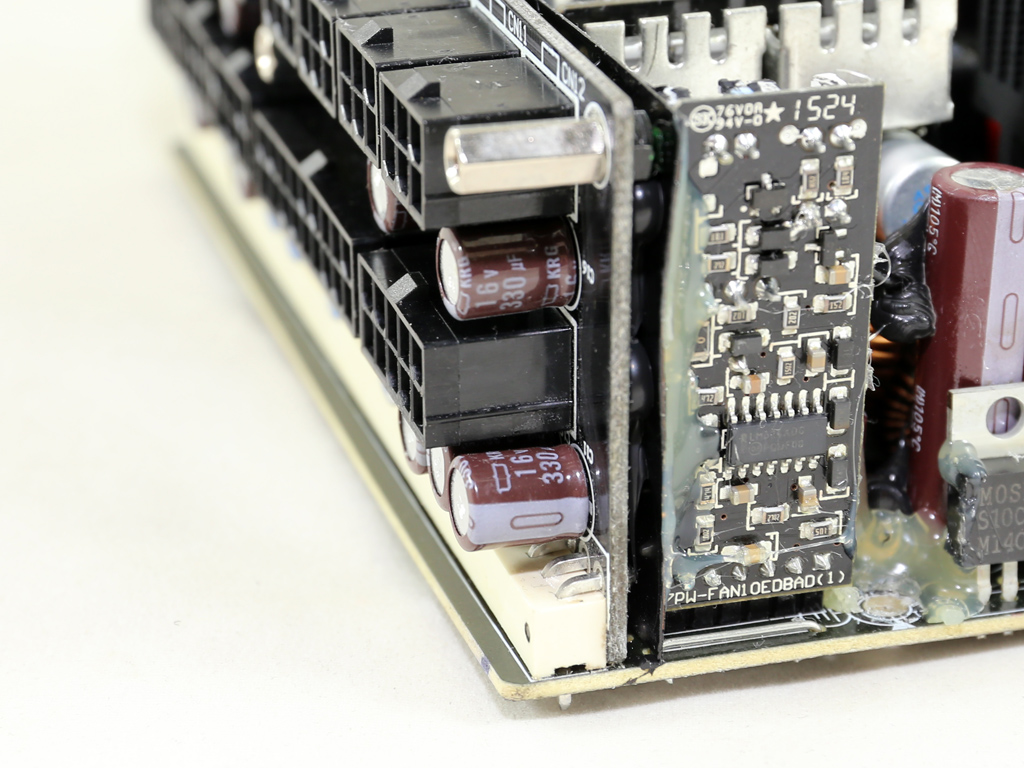

A couple of voltage regulation modules (VRMs) generate the minor rails. Each VRM uses four of Infineon IPD060N03L G FETs, along with a NCP1587A PWM controller. Metal shields above the FETs provide EMI protection.

The fan controller's PCB uses an LM324ADG op-amp. We applied lots of glue to the PCB's base since it can easily break once you try to detach the fan and ECO switch headers. Next to the fan control PCB is the usual Mospec S10C60C SBR, used on most Leadex platforms, responsible for regulating the 5VSB rail. The standby PWM controller is a small IC with a "29604" marking. There is no info available on this IC.

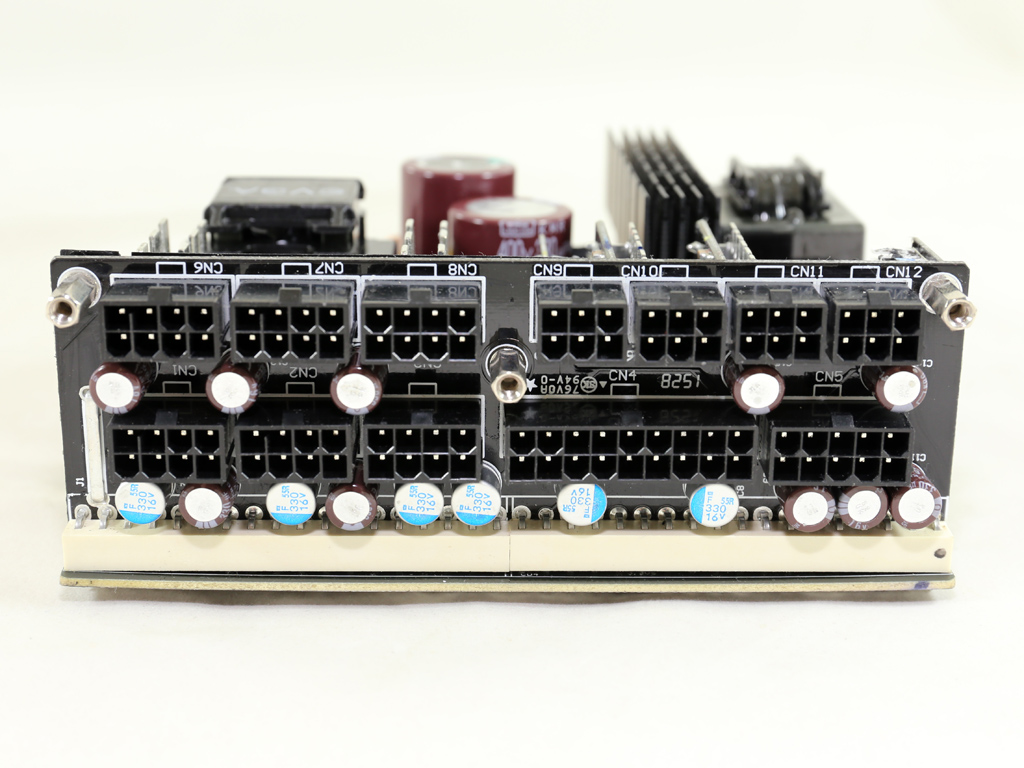

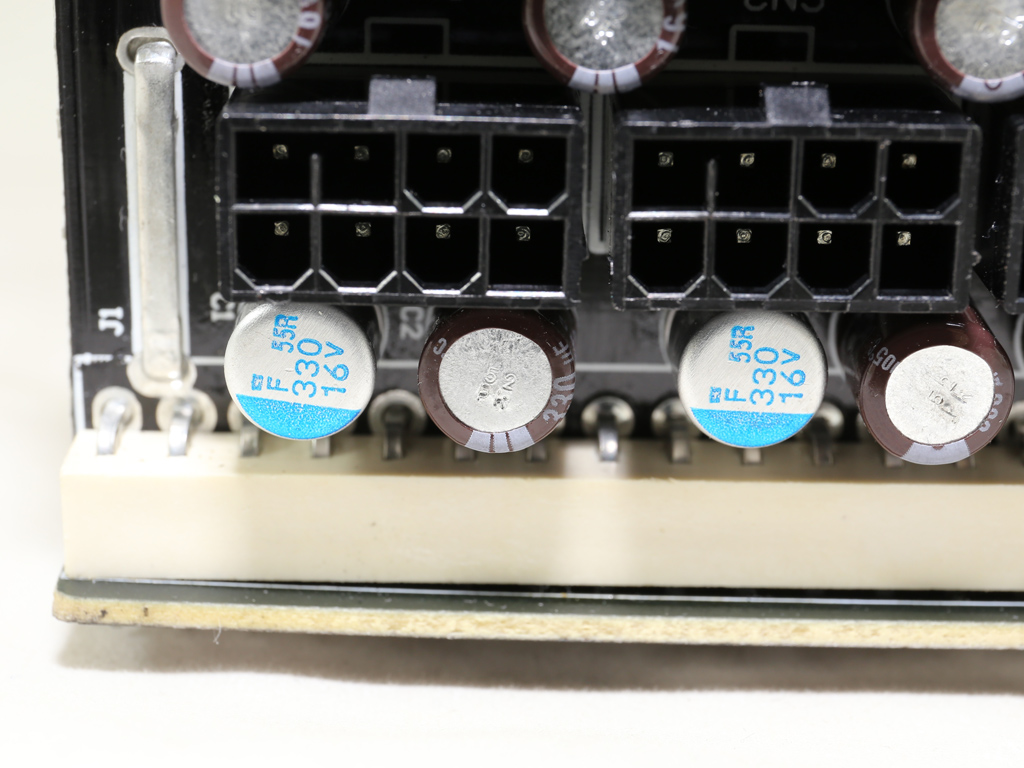

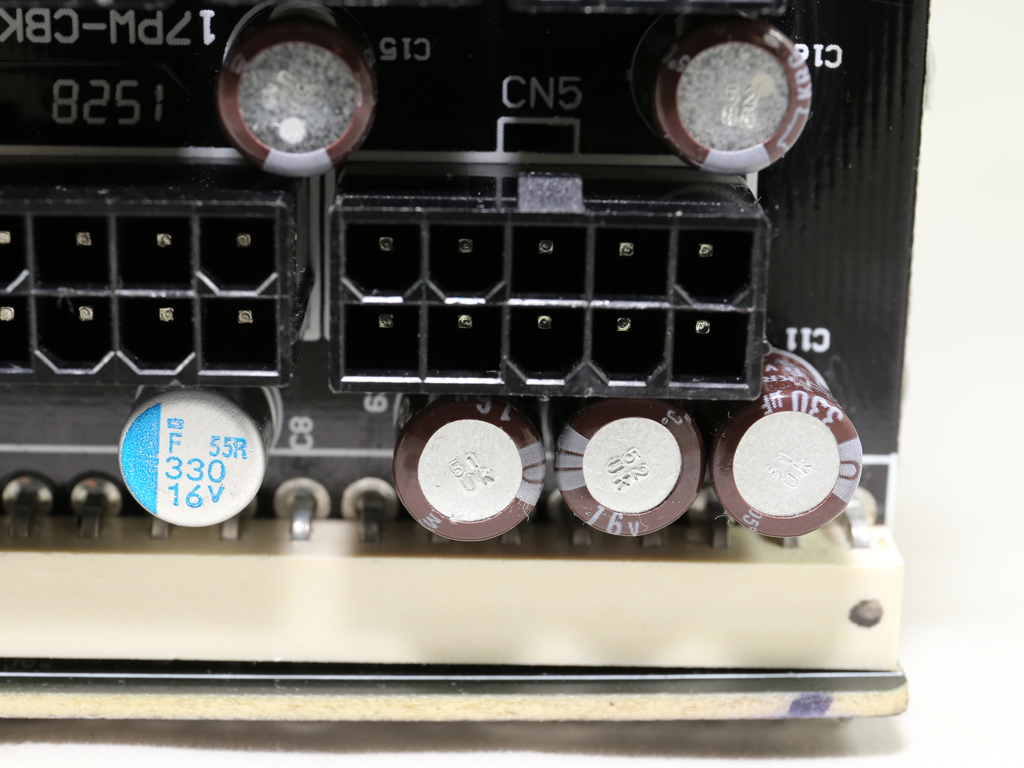

On the front of the modular PCB, several Chemi-Con polymer and electrolytic caps provide extra ripple filtering to the rails. The electrolytic caps belong to Chemi-Con's KRG line limited to 1000-hour lifespans at 105 °C. However, because this is a low-stress area, you shouldn't run into any problems with them. Still, it'd be nice if the company used higher-quality electrolytic caps here.

Soldering quality is quite good. We did spot some component leads that should be shorter, though.

Super Flower isn't a fan of Fluid Dynamic Bearing (FDB) fans, even though the competition uses them in their high-end solutions. Double ball-bearing fans are still good though, and given the Leadex platform's aggressive semi-passive mode, they'll undoubtedly last a long time.

The fan used in this PSU comes from Globe Fan and its model number is RL4Z B1402512HH (140mm, 12V, 0.5A, 1800 RPM, 135.74 CFM, 36.7 dB[A]). It typically spins slowly due to a relaxed profile. We had to push the 850 P2 very hard at close to 49 °C ambient in order to make the fan spin at full speed.

Current page: A Look Inside And Component Analysis

Prev Page Packaging, Contents, Exterior And Cabling Next Page Load Regulation, Hold-Up Time And Inrush Current

Aris Mpitziopoulos is a contributing editor at Tom's Hardware, covering PSUs.

-

JQB45 ReplyWhy can't US use 220v, man so much more efficient.

Tradition... There is nothing (I believe) stopping you from running a 220v circuit. I know we have one 20amp NEMA circuit in this house specificity for the computer room. Its not common to see those in house holds either. -

cliffro Reply17550218 said:Tier-1 but on the low end of Tier-1 due to its hold up time.

Scores a 9.7 on Jonnyguru, but is low end of tier 1 got it.

I like Tom's in general, been coming here since Tom was actually doing reviews, but I'll take JonnyGuru's(or Oklahoma Wolf) word that this is an awesome PSU, it scored 10 of 10's in all but Value, where a couple of similar quality PSU were a tad cheaper.

I've got the G2 model(thanks to their review of it) and couldn't be happier with it. Well other than they now have Platinum and Titanium versions and would prefer one of those. But 80+ Gold is still good enough for me. -

powernod Reply17550218 said:Tier-1 but on the low end of Tier-1 due to its hold up time.

Scores a 9.7 on Jonnyguru, but is low end of tier 1 got it.

I like Tom's in general, been coming here since Tom was actually doing reviews, but I'll take JonnyGuru's(or Oklahoma Wolf) word that this is an awesome PSU, it scored 10 of 10's in all but Value, where a couple of similar quality PSU were a tad cheaper.

I've got the G2 model(thanks to their review of it) and couldn't be happier with it. Well other than they now have Platinum and Titanium versions and would prefer one of those. But 80+ Gold is still good enough for me.

Well, i think that you don't pay that much attention to Jonnyguru.com, as much as you claim.

Look here, at Jonny's tier list, and notice what tier is the EVGA's P2 line :

http://www.jonnyguru.com/forums/showthread.php?t=12947

-

dstarr3 ReplyWhy can't US use 220v, man so much more efficient.

The same reason so many regions have different plug types. They all designed these things before anyone had the idea to standardize these things across regions, and by now it's an incredible amount of work to have to redesign the infrastructure of entire countries. -

Adhmuz ReplyWhy can't US use 220v, man so much more efficient.

"Technology, current at the time of US electrification, locked the US into 110, then 120 volt outlets. Europe's electrification came later, and proceeded in response to advanced technology. The US was too deep into the 110/120 volt infrastructure to upgrade."

Gotta hand it to the Americans for inventing the concept of the grid and power distribution to the masses, they did it first, and Edison's equipment at the time ran best on 110v so it was the obvious choice. Currently it's at 120v, this was changed in the 50s. Don't forget houses are supplied with 240v, this is what runs our hot water heaters, ovens and air conditioners. Just the old way is still too set in stone to be changed, not to mention 120v is safer for human exposure (a shock from a 120v outlet is much less dangerous than that of a 240v outlet, having experienced the 120v shock I can't imagine how painful a 240v would be) -

10tacle Reply17552491 said:Just the old way is still too set in stone to be changed, not to mention 120v is safer for human exposure (a shock from a 120v outlet is much less dangerous than that of a 240v outlet, having experienced the 120v shock I can't imagine how painful a 240v would be)

Yep...I was popped by a 220v 3-prong washing machine plug wire that arced some two decades ago (when it was still known as a 220v power connection) and it knocked me on my butt. It makes getting hit by 120v (used to be 110v), which I've also experienced more recently, seem like carpet static electricity.

-

cliffro Reply17552081 said:17550218 said:Tier-1 but on the low end of Tier-1 due to its hold up time.

Scores a 9.7 on Jonnyguru, but is low end of tier 1 got it.

I like Tom's in general, been coming here since Tom was actually doing reviews, but I'll take JonnyGuru's(or Oklahoma Wolf) word that this is an awesome PSU, it scored 10 of 10's in all but Value, where a couple of similar quality PSU were a tad cheaper.

I've got the G2 model(thanks to their review of it) and couldn't be happier with it. Well other than they now have Platinum and Titanium versions and would prefer one of those. But 80+ Gold is still good enough for me.

Well, i think that you don't pay that much attention to Jonnyguru.com, as much as you claim.

Look here, at Jonny's tier list, and notice what tier is the EVGA's P2 line :

http://www.jonnyguru.com/forums/showthread.php?t=12947

This is the summary for my EVGA 850 G2 (Tier 2 according to his list, a WIP according to the post)

Performance

It scores a 9.9 of 10, and is somehow a Tier 2 according to that list. I have no clue as to what he is doing with his list on the forums. I cannot explain HOW a unit that scores 9.9 of 10 is anything less than Tier 1. There are some Corsair units that scored perfect 10's that are also listed as Tier 2 on it as well.

10

Functionality

10

Value

10

Build Quality

9.5

Total Score

9.9

Summary

Buy one. Do I really need to say anything else at this point? Once again, EVGA has something awesome here the competition can't seem to touch price wise. Performance? There are better units, yes. Not very many, but they exist. The real story here is how EVGA keeps managing to offer this kind of performance and still be more affordable than nearly everything else out there, and they have pretty much found perhaps the only OEM on Earth capable of doing it for them. It's got to be real nice being EVGA right now.

The Good:

outstanding ripple suppression

excellent voltage regulation

fully modular

semi-fanless mode

nice blacked out cablingThe Bad:

nothing at all

The Mediocre:

reviewing awesome units is getting dull... where's that gutless wonder in my pile? Second in line? Well, at least I'm guaranteed something interesting in all the wrong ways in a couple weeks...

If it's scoring that close to 10, or an actual 10 (his highest score), it's a Tier 1 to me. And I'd never second guess buying one regardless of brand. -

Amdlova you guys cry like a baby. i use 227v on the computer no ground. with a multimeter can see about 45v on chassis its nice to touch it. i use a ps3 power supply to drive a 400w car amplifier and the psu barely get warm, no fan only passive cooler. 127v as no good use anymore on non days.Reply