Crucial's m4 SSD Tested At 64, 128, 256, And 512 GB

Hard Drives And SSDs: Capacity Vs. Performance

Before we dive into SSD performance, you’re probably asking why performance improves as capacity goes up, right? After all, that’s certainly not the case with hard drives. In a mechanical drive, capacity is determined by the form-factor, number of platters, and areal density. Often, however, hard drives have a lower shipping capacity than what you would get if you added up the drive's relevant specs.

For example, a 160 GB Barracuda 7200.12 uses a single 500 GB platter. However, Seagate only uses the outer-most sectors, because this allows for higher performance. So whether you buy a dual-platter 1 TB drive or the 160 GB Barracuda 7200.12, you’re getting a maximum outside-diameter data rate of 125 MB/s.

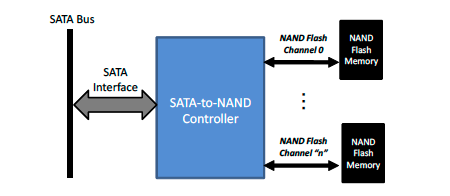

Of course, SSDs are different. Instead of a spinning magnetic media, you have solid-state memory packages attached to a piece of controller logic. Those NAND-based devices communicate over multiple channels, and it's up to the SSD vendor to populate them in a way that yields the desired capacity, performance level, and cost.

Intel's own proprietary controller is a 10-channel design, for instance. In our example on the previous page, the 80 GB X25-M achieves 70 MB/s because all 10 of its channels are populated. The 40 GB X25-V employs the same controller, but a shift down to five channels correspondingly cuts write speed to 35 MB/s.

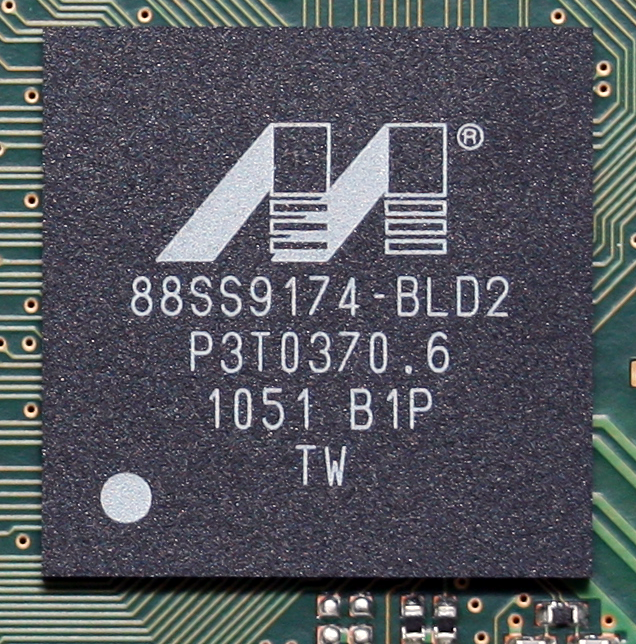

The Marvell 88SS9174 controller used by Crucial in its m4 SSDs is an eight-channel design. All of the m4s fully populate the controller's available channels, and yet there are still significant spec sheet-level differences between the four family members. This is because simply exploiting every channel isn't enough to saturate them. The number of packages residing on each channel matter. The number of memory dies in each package matter. The density of each die matters. And the firmware-level modifications a company like Crucial implements to help control performance scaling up and down the stack matter.

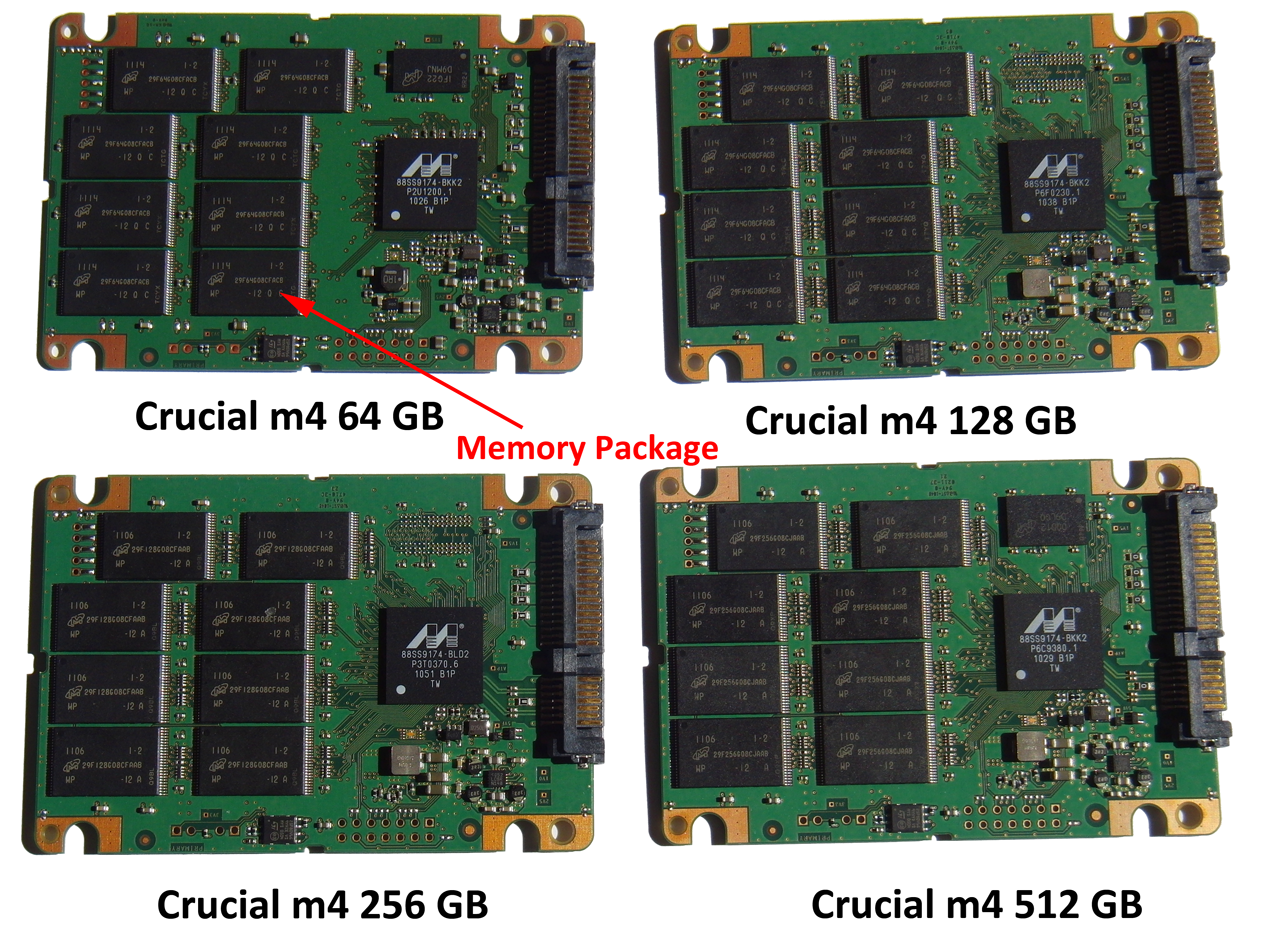

| Crucial m4 | 64 GB | 128 GB | 256 GB | 512 GB |

|---|---|---|---|---|

| Channels Used | 8 | 8 | 8 | 8 |

| Memory Packages | 8 | 16 | 16 | 16 |

| Memory Packages Per Channel | 1 | 2 | 2 | 2 |

| Die Density | 32 Gb | 32 Gb | 64 Gb | 64 Gb |

| Dies Per Package | 2 | 2 | 2 | 4 |

| Dies Per Channel | 1 | 4 | 4 | 8 |

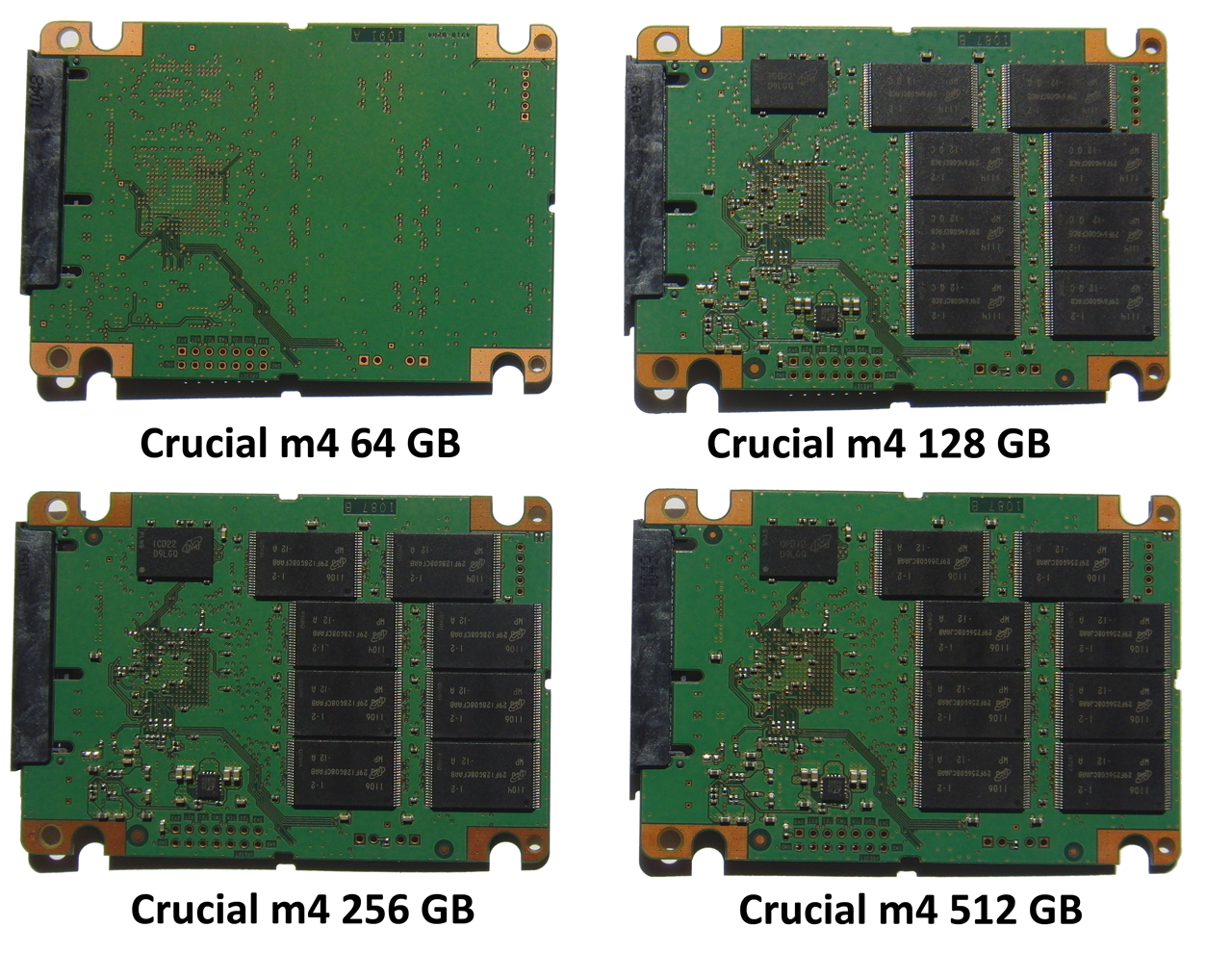

As you can see, all four SSDs look quite similar from the top. We've clearly labeled a memory package on the 64 GB model, in case you're not familiar with the terminology in the chart above.

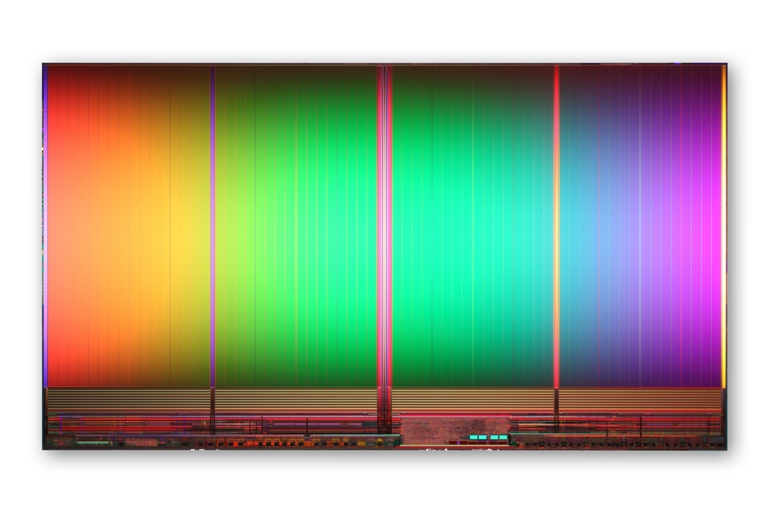

Within each one of those packages, you can have one, two, or four physical NAND flash dies. The shot above is an 8 GB (64 Gb) die manufactured on IMFT's 25 nm process. It measures about 167 square millimeters on its own.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Standardized interfaces like ONFi ensure that any compatible NAND device employs the same pin-out, a unified command set, improved data integrity, and a host of other benefits. When a controller vendor like Marvell or SandForce incorporates support for those interface standards, it allows drive partners to switch between NAND chips manufactured by several possible suppliers without worrying about some sort of compatibility issue. It just so happens that all four Crucial m4 drives employ 25 nm ONFi 2.2-compliant NAND manufactured by Micron (hardly a surprise there, right?).

See how the 128, 256, and 512 all have 16 NAND packages (eight up front and eight around back)? Similar though they look, they're not all the same. The 128 GB model has two 4 GB die per package, the 256 GB has two 8 GB dies per package, and the 512 GB has four 8 GB dies per package. That’s how SSD manufacturers end up with higher-capacity SSDs, even though the number of chips you see stays the same.

Current page: Hard Drives And SSDs: Capacity Vs. Performance

Prev Page Performance Across Capacities Next Page Test Setup And Benchmarks-

wintermint I've been recommending the Crucial m4 128gb to people, and after seeing this.. I'm glad I did :]Reply -

sceen311 it'd be nice if they threw a 7200 rpm hardrive on the bench... We don't all have laptops ya know.Reply -

compton I'm glad this was done. It's rare that you get the chance to stack all the capacity points up (as in never). I bought an Intel 510 120GB and a M4 64GB and my own testing showed that you'd never know the difference besides the capacity (in day to day use, besides lower max write MB/S). I kinda like keeping my system drive to a bare minimum -- just Win7 no swap or hibernate, Office, a few other apps, and then I keep my Steam folder on a separate drive. Simple. I will say that if you are building a new system, cut whatever you have to in order to fit at least a 64GB SSD -- the M4 is excellent at any capacity. I'd rather have to go down to an i3 from a 2500k than from a SSD to a HDD. I get tired of people saying "it's not worth it" and "they're not much faster than a 7200rpm". Those people must be doing it wrong.Reply -

beenthere Now if they could only make these SSDs reliable, we could all enjoy some performance improvement. Intel, Micron, OCZ and Corsair to name a few have all had reliability/compatibility/firmware issues of some sort resulting in loss of data, which for me is simply unacceptable.Reply -

Last month I got a 64GB for my laptop and a 128GB m4 for my desktop. So far no issues, and the speed is great. Glad I got the 128GB and not the 256GB.Reply

-

PCMark 7 Storage tests are just pathetic, they have messed some of them up on purpose it seems just to shrink the difference between systems containing SSD and the ones containing HDD only, useless bench from start to "finish"...Reply

-

mroanhaus I picked up the 64 GB M4 two weeks ago on Newegg for under $90. I am so glad I bought it, the thing makes boot times lightning fast. I have Win7 64-bit, Photoshop, 3DS Max, Google Chrome, and a few little monitoring and Bitcoin mining apps on there and I STILL have 21 GB to spare. Don't buy the 128 GB unless you really need it, throwing Steam and other massive apps will be much better suited on a secondary HDD. SSDs are simply amazing and well worth the money spent, even if you're a cheapass like me they're still affordable. The time saved from having to wait around while booting your computer makes SSDs worth the money imoReply -

burnley14 ReplySee how they all hover pretty close to the same price per gigabyte, while sequential write and random write performance trend upward? Those are the spoils available to folks willing to spend more on higher capacities.

This is true, but in 6 months when the whole lineup is outdated and the next generation of drives blows these ones away, those that spent more are going to have spent the extra money without much purpose. -

cknobman burnley14This is true, but in 6 months when the whole lineup is outdated and the next generation of drives blows these ones away, those that spent more are going to have spent the extra money without much purpose.Reply

Well going by your logic why should anyone ever spend money on anything in technology??? Guess its always a waste huh?

Failed logic.