Micron P420m SSD Review: 1.4 TB Of PCI Express-Attached Storage

After the success of its P320h, Micron is following up with the P420m, an MLC-based PCI Express x8 add-in card aimed at more read-oriented enterprise customers. How does it compare to the company's SLC-based flagship? We benchmark ours thoroughly.

Going Piece By Piece Through The Micron P420m

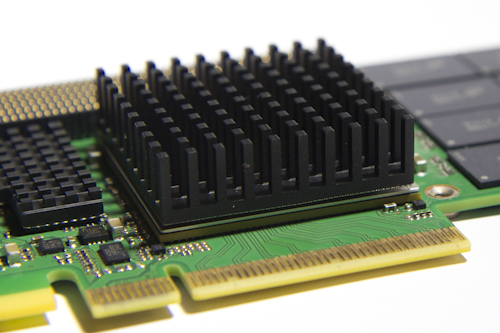

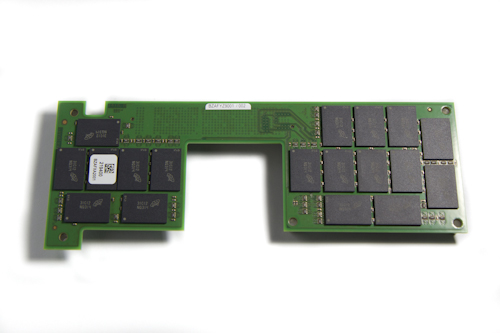

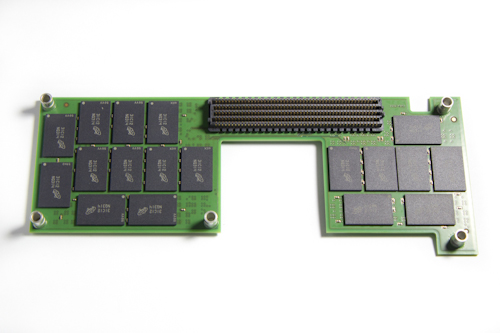

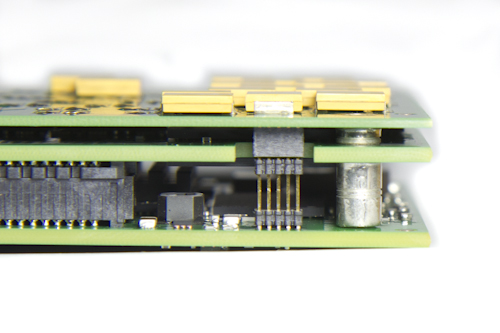

Visually, the P420m is quite a bit different looking than the P320h. Micron choose to cover the entire power loss protection board with black plastic. With it removed, you clearly see that the complete drive is made up of three PCBs with a large heat sink sticking through two of them.

The first PCB has a little bit of everything, but we are going to focus on its flash controller. Micron is using the exact same processor as the one on its P320h. As we noted in Micron RealSSD P320h Review: A PCIe Drive Capable Of 3.2 GB/s, this controller was jointly produced with IDT and is customized to work specifically with Micron's NAND and firmware algorithms. Unlike most SATA/SAS controllers, which only support eight channels and 16 NAND placements, the P420m's controller has 32 channels and supports 64 placements. This extended parallelism facilitates the high read performance noted in the specifications. It's also one of the reasons why the P420m, like the P320h, doesn't hit its peak performance until a queue depth of 256.

We didn't have it in us to remove the heat sink. It's attached with a thin wire mesh covered by adhesive. Popping it off would almost certainly damage the mesh.

Next to the controller is a low-profile heat sink covering five DRAM packages, each of which adds 256 MB of DDR3-1600. There are four more on the back of the PCB, giving you a total of 2.25 GB on the P420m.

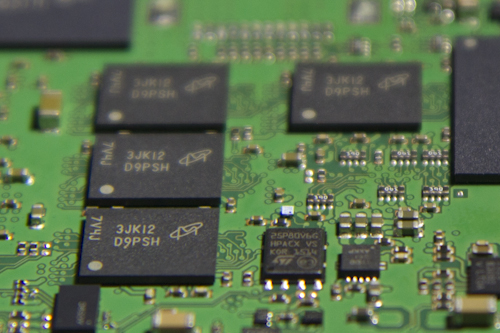

It'd be impossible to miss the 25 nm MLC flash, which is a major departure from the 34 nm SLC used on Micron's P320h. There are 28 NAND packages on the main PCB.

The next PCB's job is purely to host NAND and a handful of discrete components. This is where you'll find the remaining 36 packages (adding up to 64 in all). Do the math and we figure out that each package hosts eight 32 Gb dies. In contrast, the 700 GB model's packages each host four dies. This means the 1400 GB version has 2048 GB of raw flash on-board.

Micron's redundancy technology takes up roughly one-eighth of that number, or 256 GB. The rest, about 22%, is used for over-provisioning.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

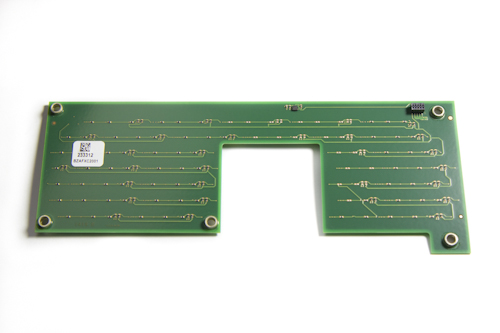

The third PCB handles power loss protection.

Our sample has 48 tantalum capacitors, with pads for many more. Unlike the substantial connector between the first and second boards, this power loss PCB is connected to the main one through a tiny eight-pin header.

The PCB is also extremely thin, presumably only a few layers thick. You could almost say it's fragile, which is why Micron secures it at five points to the rest of the drive. Power loss protection is one key feature that was missing from the P320h, and is a welcomed addition on the P420m.

Micron tends to make data protection a priority on its enterprise-oriented SSD products, and the P420m is no different. The company leverages its RAIN (Redundant Array of Independent NAND) technology, seen on the P320h and P400m, to enable RAID 5 redundancy across all flash channels. RAIN recovers lost data beyond just page-, block-, and die-level failures. The P420m also checks data using CRC (Cyclic Redundancy Checksums) and ECC (Error Checking and Correcting) algorithms prior to and upon exit from each element in the transfer chain.

Although the P420m and P320h don't look like each other physically, architecturally speaking, they might as well be twins.

Current page: Going Piece By Piece Through The Micron P420m

Prev Page Micron P420m: A Read Focused, PCIe-Attached SSD Next Page Test Setup, Benchmarks, And Methodology-

merikafyeah Seems like enterprise non-volatile storage is finally starting to approach the speeds of comsumer ram drives:Reply

http://www.thessdreview.com/our-reviews/romex-fancycache-review-ssd-performance-at-13gbs-and-765000-iops-in-60-seconds-flat/

Considering that the cost/GB of RAM is about $7/GB, it may not be such a bad idea to use RAM storage + backup generators instead of traditional non-volatile flash nand. -

rezzahd Maybe once the price drops I would pick one of these up, but I think we all know it will be a while before that happens.Reply -

BasslineJunkie Reply

Same here. I love the concept but price/gb isn't where it should be. But i do have some extra pci express slots that need filled!11507252 said:Maybe once the price drops I would pick one of these up, but I think we all know it will be a while before that happens.

-

utomo It is good to see good competition like now. keep comparing like this and hope soon we will get the good mature technology. now the SSD still have many improvement ideas. manufacturer need to work harder to win the market which is big.Reply -

ACTechy Awesome. Later down the road, when the price falls, these are going to be the thing to have. Really like PCI based SSD.Reply -

urbanman2004 TL;DR. I could benefit from something like this saving space on my system. It must have a hefty priceReply