Aqua Computer Makes 3D-Printable Skylake CPU Delidding Tool

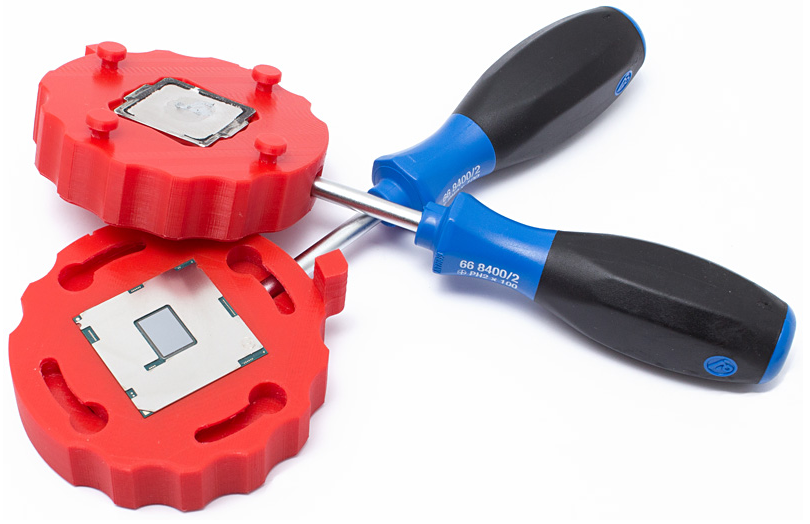

Aqua Computer designed a CPU delidding tool that you can 3D print at home, if you have a 3D printer.

In order to delid a CPU, many users prefer using dedicated tools to do the job for one very simple reason: Although you can use nothing more than a vice, flat-head screwdriver, and a hammer, you can imagine what may happen if you opt to take that route. For that reason, various manufacturers have built their own CPU delidding tools, the most recent of which is Aqua Computer from Germany. Its tool is a little different from its competitors, however, as rather than buying one from Aqua Computer, you can 3D print it at home.

Among the handful of changes that Intel made to its design in the transition to Skylake CPUs, one of the things it did not change is that it still uses thermal paste between the CPU die and the HIS (integrated heatspreader) instead of soldering them. Heat is therefore transported to the CPU cooler less efficiently, raising operating temperatures and reducing overclocking headroom. To reduce temperatures, users delid their CPUs to have the CPU die make direct contact with the cooler.

Aqua Computer’s tool works quite simply. You first insert the Skylake CPU in the bottom pocket, place the top over it, and rotate it 15 degrees until locked. Then, you grab two screwdrivers, stick them in the holes, and twist a little further until you hear a crack. That crack is the glue bond breaking between the CPU’s IHS and the substrate.

You can download the files to 3D print the Skylake Twister at Thingiverse.

Follow Niels Broekhuijsen @NBroekhuijsen. Follow us @tomshardware, on Facebook and on Google+.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Niels Broekhuijsen is a Contributing Writer for Tom's Hardware US. He reviews cases, water cooling and pc builds.

-

Saberus Twist until you hear a crack. That phrase makes my hair stand on end. I can understand the benefits of de-lidding for performance enthusiasts, but as a tech I shudder.Reply

So my thought is, is this foolproof? Or are you just as likely to damage the die? -

beckerp86 To the author:Reply

I don't believe the 1151 socket design allows you to leave the Integrated Heat Spreader (IHS) off of the CPU. The CPU would sit too low in the socket for any cooler to touch. For anyone thinking about de-lidding, please confirm before proceeding with the instructions in this post. -

InvalidError Reply

It depends on the cooler's tolerances and their retention clip designs. Some HSF use spring tensioning (ex.: 212+/EVO) and can accommodate much wider tolerances than other HSFs, like Inte'ls stock design, which are designed with exact physical dimensions in mind. HSFs that use long threaded screws with no stops can accommodate any CPU height but you need to be careful about fastening the HSF evenly and not apply excessive force.17174152 said:I don't believe the 1151 socket design allows you to leave the Integrated Heat Spreader (IHS) off of the CPU. The CPU would sit too low in the socket for any cooler to touch. -

Johnpombrio AT YOUR PERIL! I ruined a $300 Haswell, Broadwell? CPU by delidding it and then trying to get it to work afterwards. No one says that the delidded chip's top metal heat spreader will fit onto the chip after you are done removing it and repasting it. I got it to barely work by playing with the screws to the CPU cooler (just 3 were allowed to be screwed in). Eventually, it failed completely. did it help? I got all of 2% cooler results. NO, NOT WORTH IT! Do NOT listen to all of the glowing results that some people got (or at least pretended they got). they were the lucky ones.Reply -

Johnpombrio Reply17173938 said:Twist until you hear a crack. That phrase makes my hair stand on end. I can understand the benefits of de-lidding for performance enthusiasts, but as a tech I shudder.

So my thought is, is this foolproof? Or are you just as likely to damage the die?

Delidding it relatively straightforward and I doubt that many will break it during the delidding process. It is a BEAR to get it to work once the lid is off tho and I lost my $300 chip during that harrowing process. -

firefoxx04 John, sounds like you were in over your head. De lidding is easy. Nobody told you to only have 3 of the 4 screws fastened on your heatssink. You made that terrible decision.Reply -

outlw6669 Yeah, you generally don't want to install the CPU delidded unless you are 100% sure your equipment is compatible with the shorter, and more fragile, stack.Reply

The better option for most is to delid, clean off the old TIM and adhesive then replace the lid with a lesser amount of higher quality TIM installed.

No need to use any additional adhesives when reassembling, the socket cover and cooler will keep everything in place with full original cooler compatibility. -

Darkk All of this reminds me back in the day when the CPU didn't have heat spreaders installed at all. You actually saw the back of the silicone wafer (CPU). Heat sinks were carefully designed to have direct contact without crushing it unless you totally installed it wrong.Reply

This was the most efficient way to transfer heat directly to the cooler. Problem was too many folks screwing up their CPUs so AMD and Intel decided to install heat spreaders on the later versions of the processors.

Intel and AMD could crank out special editions of their CPUs without the head spreader long as the cooler is designed for it. This is a very small market for it so doubt they'll even do it.

-

InvalidError Reply

You don't need to install it "totally wrong" to get horrible sounds like crushing sand during the install process and chipping the edges/corners. You just need a slight angle while starting to apply pressure to hook the retention clip. This got better when AMD put rubber spacers around the die to stabilize heatsinks. Vibrations during shipping could also cause the HSF to lift up from the die and slam back down on it.17177319 said:Heat sinks were carefully designed to have direct contact without crushing it unless you totally installed it wrong.

With the LGA sockets, the IHS also has the additional role of spreading out the socket and HSF clamp force to provide reasonably even pressure across all 1150-2011 contact points.

Yet another reason for the IHS is to provide enough thermal mass for the CPU to throttle itself or shut down without self-destructing if the HSF came off during shipping or is not installed properly.

Protecting the die from mechanical abuse is only one of many reasons to bother with the extra cost and complexity of putting IHS on desktop CPUs. -

PigmonkeY I just want to point out here that when people talk about delidding with skylake, what we're talking about is pulling the IHS off, clearing out the paste that's inside, and replacing with either a higher performance paste (Tgrizz?), or a liquid metal compound (CoolLaboratory Liquid Ultra is the most common here).Reply

You then reinstall the cpu into the socket and PUT THE HEATSPREADER BACK ON.

You can hold the heatspreader on simply with retention clip force, or you can add some silicone RTV sealant in a very thin bead on the bottom of the spreader and then place it on the cpu, and close the retention clip.

Skylake CPUs are indeed too short to be used without the IHS in most configurations, but the difference is very very minimal from using the IHS with a proper liquid metal thermal compound. People report 7-15C drops under full load, which is nothing to shake a stick at at all.