Upgrading And Repairing PCs 21st Edition: PC Diagnostics

PC Maintenance Tools

PC Maintenance Tools

To troubleshoot and repair PC systems properly, you need a few basic tools. If you intend to troubleshoot and repair PCs professionally, there are many more specialized tools you will want to purchase. These advanced tools enable you to more accurately diagnose problems and make jobs easier and faster. Here are the basic tools that should be in every troubleshooter’s toolbox:

- Simple hand tools for basic disassembly and reassembly procedures

- Diagnostics software

- A multimeter

- Chemicals (such as contact cleaners), component freeze sprays, and compressed air for cleaning the system

- Foam swabs, or lint-free cotton swabs if foam isn’t available

- Small nylon wire ties for “dressing” or organizing wires

Some environments also might have the resources to purchase the following devices, although they’re not required for most work:

- Memory module tester

- Serial and parallel loopback (or wrap) plugs to test serial and parallel ports

- A USB testing plug to test USB ports

- A network cable scanner (if you work with networked PCs)

- A POST card

These tools are discussed in more detail in the following sections.

Hand Tools

Tip

For a comprehensive selection of electronics parts, tools, and other supplies, I recommend the following sources:

For tools only, I also recommend Stanley Supply & Services (formerly Jensen Tools and Contact East).

Most of these companies also have comprehensive paper catalogs, which can often make it easier to do general browsing and find what you need.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

When you work with PC systems, the tools required for nearly all service operations are simple and inexpensive. You can carry most of the required tools in a small pouch. Even a top-of-the-line “master mechanics” set fits inside a briefcase-sized container. The cost of these toolkits ranges from about $20 for a small service kit to $500 for one of the briefcase-sized deluxe kits. Compare these costs with what might be necessary for an automotive technician. An automotive service technician would have to spend $5,000–$10,000 or more for a complete set of tools. Not only are PC tools much less expensive, but I can tell you from experience that you don’t get nearly as dirty working on computers as you do working on cars.

In this section, you learn about the tools required to assemble a kit that is capable of performing basic, board-level service on PC systems. One of the best ways to start such a set of tools is to purchase a small kit sold especially for servicing PCs.

Because they work better than conventional screwdrivers, use nut drivers to remove the hexagonal-headed screws that secure the system-unit covers, adapter boards, disk drives, and power supplies in most systems. You will, however, still need standard screwdrivers for systems that have substituted Phillips-head screws for the more standard hexagonal-head screws. If slotted screws are used, they should be removed and replaced with Torx (preferred), hex, or Phillips-head screws that capture the driver tool and prevent it from slipping off the head of the screw and potentially damaging the system.

Caution: When you are working in a cramped environment such as the inside of a computer case, screwdrivers with magnetic tips can be a real convenience, especially for retrieving that screw you dropped into the case. However, although I have used these types of screwdrivers many times with no problems, you should be aware of the damage a magnetic field can cause to magnetic storage devices such as floppy disks. Laying the screwdriver down on or near a floppy can damage the data on the disk. Fortunately, floppy disks aren’t used that much anymore. Hard drives are shielded by a metal case; optical drives are not affected because they’re not magnetic; and memory and other chips are not affected by magnetic fields (unless they are magnitudes stronger than what you’ll see in a hand tool).

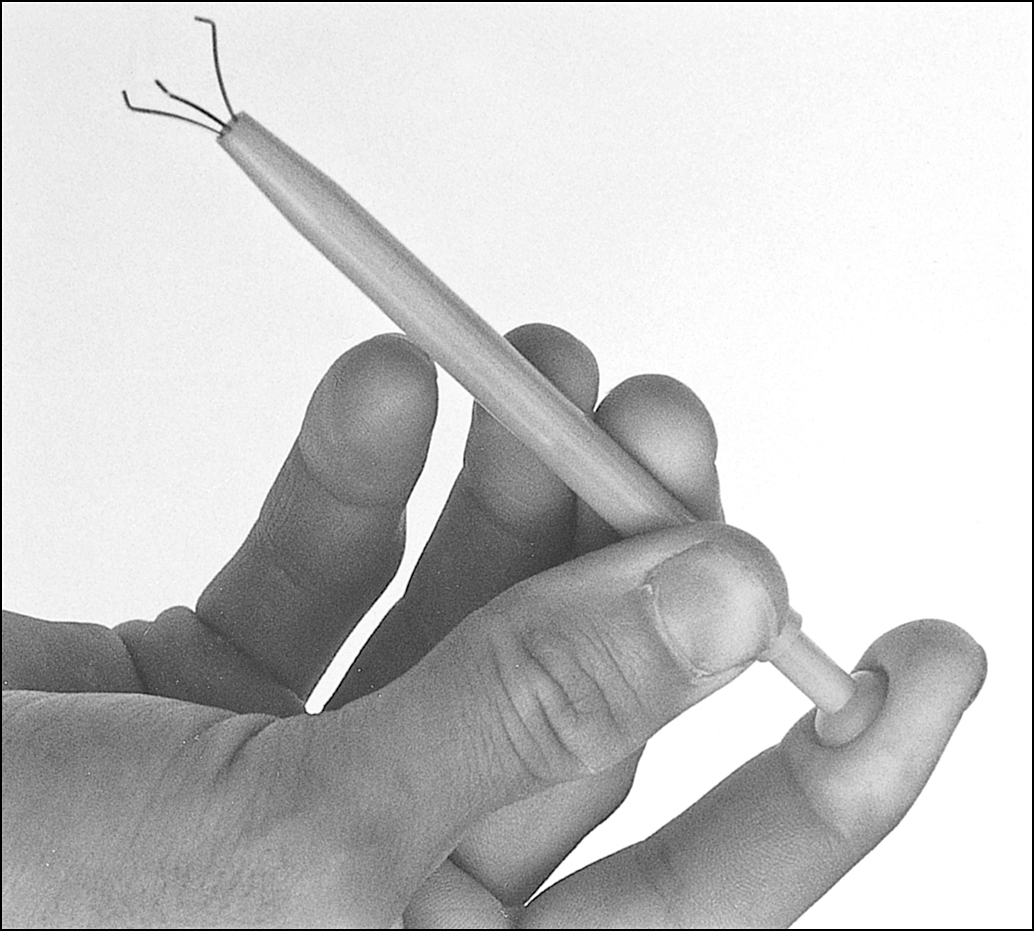

Tweezers or a parts grabber like the one shown in the image below can be used to hold any small screws or jumper blocks that are difficult to hold in your hand. The parts grabber is especially useful when you drop a small part into the interior of a system; usually, you can remove the part without completely disassembling the system.

Current page: PC Maintenance Tools

Prev Page Windows 7/Vista And Windows 8 Startup Next Page Hand Tools ContinuedTom's Hardware is the leading destination for hardcore computer enthusiasts. We cover everything from processors to 3D printers, single-board computers, SSDs and high-end gaming rigs, empowering readers to make the most of the tech they love, keep up on the latest developments and buy the right gear. Our staff has more than 100 years of combined experience covering news, solving tech problems and reviewing components and systems.