Gigabyte's new motherboard supports massive 128-pound GPUs — Reinforced slots still can't fix GPU PCB cracking

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

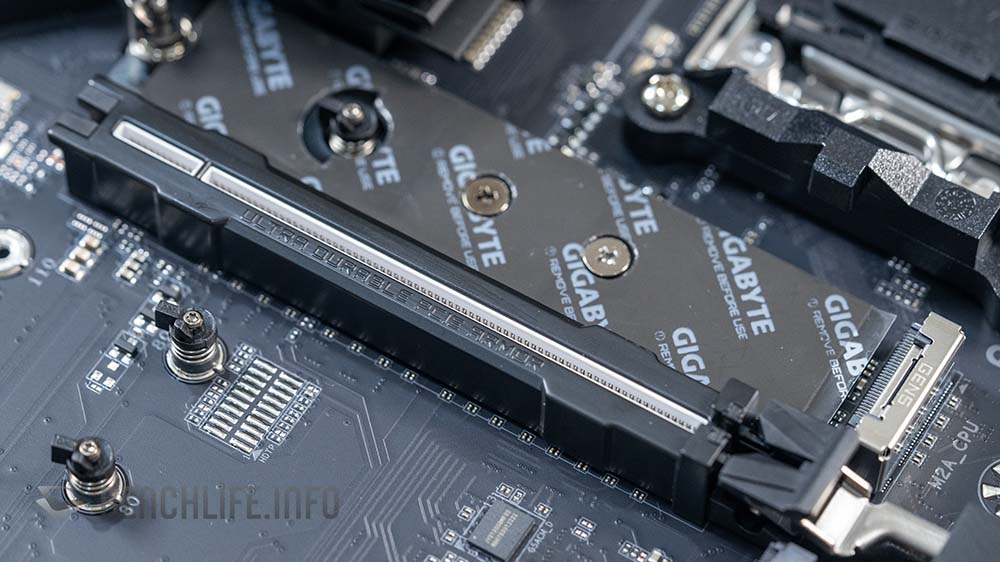

Chinese publication Benchlife has shared a preview of the Gigabyte B650E Aorus Pro X USB4, which supports AMD's next-generation Ryzen Zen 5 processors. One of the motherboard's key selling points is the primary expansion slot, which can support graphics cards up to 128 pounds.

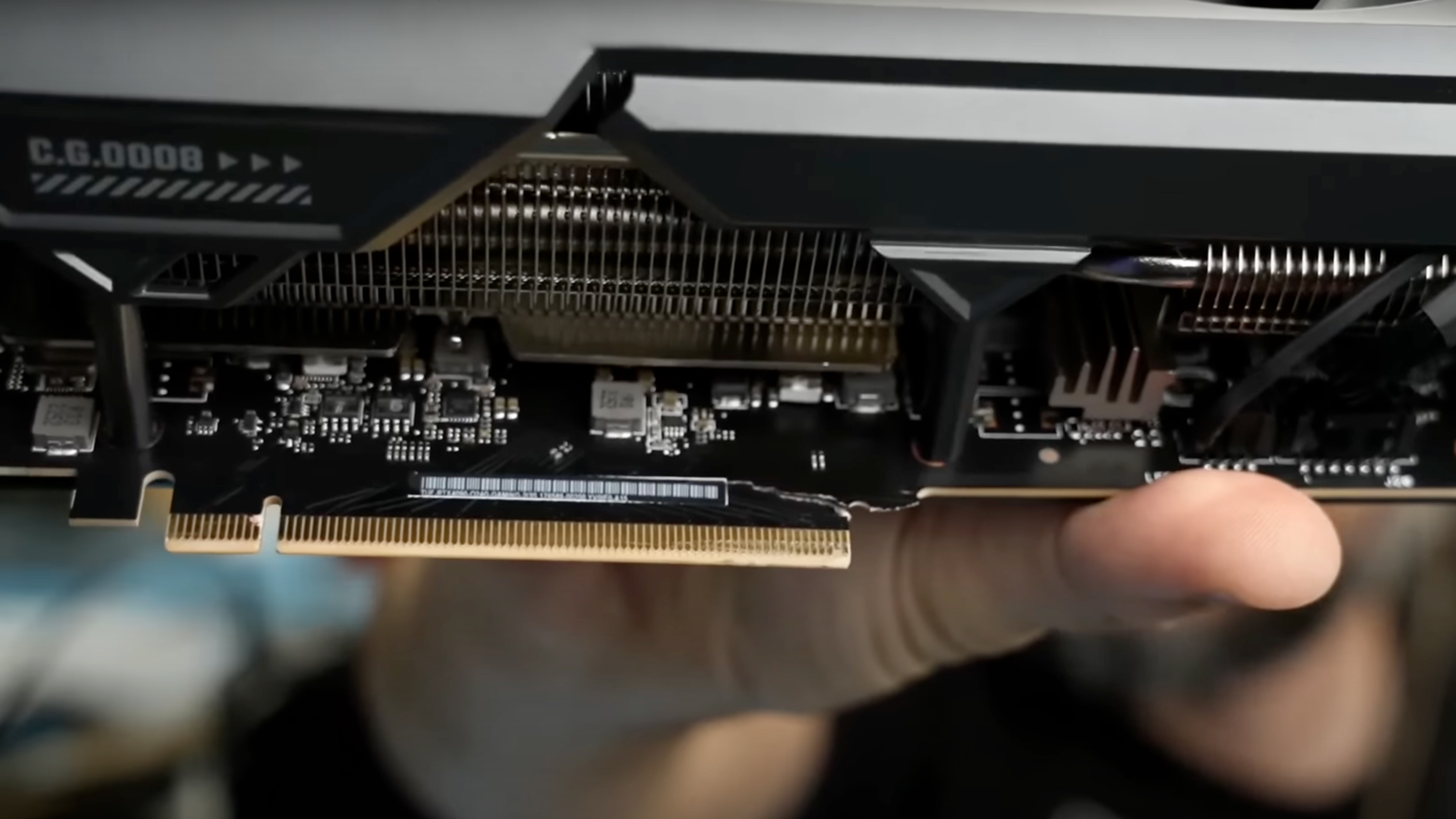

Despite being among the best graphics cards, the GeForce RTX 4090 has endured much controversy. First, there were reports of the 16-pin power connector suffering meltdowns. Later, accounts surfaced of the PCB cracking near the PCIe locking tab due to how bulky modern graphics cards have become. Gigabyte eventually revised the design of the brand's GeForce RTX 4080 and GeForce RTX 4090 graphics cards. For extra measure, Gigabyte has implemented what the brand calls the "PCIe UD Slot X" in some of its high-end Intel and AMD motherboards.

If you're new to Gigabyte motherboards, the PCIe UD Slot X is a reinforced expansion slot. The manufacturer claims the unique design provides 10X more strength to house even the heaviest graphics cards. The slot conforms to a one-piece design that's fixed to the motherboard and screwed into place with a dedicated backplate. The PCIe UD Slot X also has an interior rubber strip to prevent nasty scratches on the graphics card's PCB and features a zinc alloy material that serves as an electromagnetic shield for high-speed signals.

While the PCIe UD Slot X feature isn't novel, this is the first time we've been given a specific metric of the maximum weight it can withstand. One trend we've seen is that graphics cards are becoming larger and more power-hungry. The transition from the GeForce RTX 30 series (Ampere) to the GeForce RTX 40 series (Ada Lovelace) is a perfect example. Although there are early whispers that the forthcoming GeForce RTX 50 series (Blackwell) likely won't be any slimmer, 128 pounds is overkill.

Moreover, the initial PCB cracking was caused by the design of the cutout, which didn't mitigate the weight of the graphics card. So, while Gigabyte's PCIe UD Slot X supports up to 128 pounds, it still won't impede PCB cracking because the problem lies in the graphics card and not the expansion slot. There weren't any reports of the expansion slot breaking. It was always about the graphics card's warping or the PCB cracking.

Perhaps the 128 pounds refers to impact load, which would make sense. A more sturdy expansion slot will help with shipping and transportation, especially in the case of pre-built machines. But then again, if the fall is high enough, it won't matter if the expansion slot can accommodate up to 500 pounds because the graphics card would probably break. In a situation like this, many would prefer that the expansion slot come off the motherboard rather than fracturing the graphics card, which, in most cases, is the more expensive hardware.

As Computex 2024 approaches, we'll likely have more information on Gigabyte's upcoming motherboards for Zen 5 processors. Maybe the vendor will provide more details on the expansion slot. Who knows, we might even get a live demonstration, and Gigabyte can prove us wrong that it's not just a marketing gimmick.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Zhiye Liu is a news editor, memory reviewer, and SSD tester at Tom’s Hardware. Although he loves everything that’s hardware, he has a soft spot for CPUs, GPUs, and RAM.

-

This isn't an entirely new feature actually. "Jeff Butts" also brought up this issue in his recent article:Reply

https://www.tomshardware.com/pc-components/chipsets/amd-expected-to-release-800-series-motherboard-chipsets-for-ryzen-9000-cpus-chipset-series-numbers-to-run-in-parallel-to-intel

In fact, Benchlife notes that the “B650E Aorus Pro X USB4 motherboard matches the specifications of most AMD X870 motherboards.” It also features a reinforced PCIe slot supporting up to a maximum weight of 58 kg. I can’t for the life of me figure out why you’d need your PCIe slot to withstand so much weight, but there you have it.

This Article: "While the PCIe UD Slot X feature isn't novel, this is the first time we've been given a specific metric of the maximum weight it can withstand"

FWIW, some of the Gigabyte's previous INTEL motherboard also had this feature, the "PCIe UD Slot X" PCIe 5.0 x16 slot, with 10X strength for the graphics card.

Z790 AORUS XTREME X, and also the PRO X model. Few more boards are there, but those are Chinese/APAC-exclusive models though, with some previous Intel chipsets as well.

https://www.gigabyte.com/Motherboard/Z790-AORUS-XTREME-X#kf

https://i.imgur.com/j3hTu6O.png -

Notton The slot isn't the problem. Reinforcing it doesn't solve anything.Reply

The problem is the GPU is too heavy.

Ideally, the back plate or heatsink should have holes so it can be bolted directly on the case.

Similar to how an engine block is mounted to a frame/chasis.

Or, how a mobo gets mounted to the case. -

bit_user My hunch is that people are misinterpreting their claim (perhaps partly their fault, for misrepresenting).Reply

If you consider the problem of an OEM like Alienware shipping a PC with a dGPU, they ship it fully-assembled and need to be sure that even if the delivery driver drops the box or it falls off of a tall stack, that the shock won't damage the motherboard. So, you build in some assumptions about what kind of shock it can handle, like 20 G with a GPU of up to 6.4 pounds. Then, by the magic of Newtonian physics, a cool trick you can play is to say that it can support a static GPU weight of 128 pounds. The two forces are equivalent.

Anyway, this information tells OEMs like Alienware that they must either use better packaging or lighter GPUs, so they don't exceed that force for packages dropped from less than whatever height the shipper will guarantee. Further, they can theoretically use packaging making it evident if the package was subject to excessive force, during shipment, or maybe just embed a little IoT accelerometer. -

bit_user Reply

This used to be a solved problem... I'm having trouble finding a good link, but anyone who built PCs in the 90's should remember how there used to be slots on the front side of the card cage to hold the front edge of full-length add-in cards.Notton said:Ideally, the back plate or heatsink should have holes so it can be bolted directly on the case.

I've also seen cases with an over-the-top brace, to support the cards. This obviously places limits on the height of the card and requires the PCB be exposed at that point. -

TechLurker Given that GPU weight isn't likely to go down on the high-end, esp. if the rumors that the brick-sized, 4.5 slot reference cooler prototype will be reused on NVIDIA's next top-end GPU, and the continuing push for more power/performance, there's merit to adopting some new design elements mainly to spread the weight across more, besides GPU brackets or braces.Reply

To list off some ideas I've read in the past:

A new "AGP 2.0" style slot exclusively dedicated to GPUs (at first), except it's still wired as PCIe but designed to handle thicker PCBs and also provide pass-through power to GPUs to cut the dangling weight of external power plugs. This was pushed around a bit back when GPUs were already hitting 2.5 slots and 3 x8 power pins, but never left the conceptual stages. I do remember a number of articles suggesting GPUs should have their own special slot as power draw and cooling requirements increased, and this seemed the most practical. It's also future proof if it can be expanded to become a new PCIe slot standard, being only slightly thicker than a regular reinforced PCIe slot.

The next idea was redesigning the shroud +heatsink (+backplate if included) to be load-bearing. Have it and the backplate functionally become 1 piece (when assembled) that relieves the weight off the PCB some and would have the I/O shield/PCI screw in points connected to the shroud instead of the PCB. It would effectively be its own built-in GPU bracket, esp. if the long and narrow ends of the shroud were made of metal. And given that the heatsink is also designed to connect to the shroud, the weight on the PCB is further reduced.

The last idea was tweaking GPU plastic shroud designs to include 4+ integrated, adjustable stabilizers along the slot-side that would let it raise/lower some rubber feet to level the GPU to the motherboard, whether it has a plastic shroud or not over the face. The idea being to at least redistribute some of the weight to other points of contact with the mobo. It would increase the thickness of the GPU shroud though, unless some cooling finstack is cut away to allow nestling of the stabilizers while keeping a thinner shroud. -

bit_user Reply

Nope. Given what I said about shipping-related concerns being the real issue, that won't help at all if the box is dropped so the front or back of the PC is facing down.Alvar Miles Udell said:Give me a new form factor with a vertical GPU slot, problem solved. -

Alvar "Miles" Udell Reply

Remove the GPU before shipping?bit_user said:Nope. Given what I said about shipping-related concerns being the real issue, that won't help at all if the box is dropped so the front or back of the PC is facing down. -

USAFRet Reply

Requiring the purchaser to "assemble"?Alvar Miles Udell said:Remove the GPU before shipping?

Not!

Thats why people buy prebuilts.